HydroBond 402-CCSM

- Total Waterproofing Strength: HydroBond 402-CCSM is a high-performance membrane for external waterproofing of below-ground structures. Its LDPE and geotextile fleece composite ensures excellent crack-bridging, forming a high-strength bond for unbeatable peel adhesion.

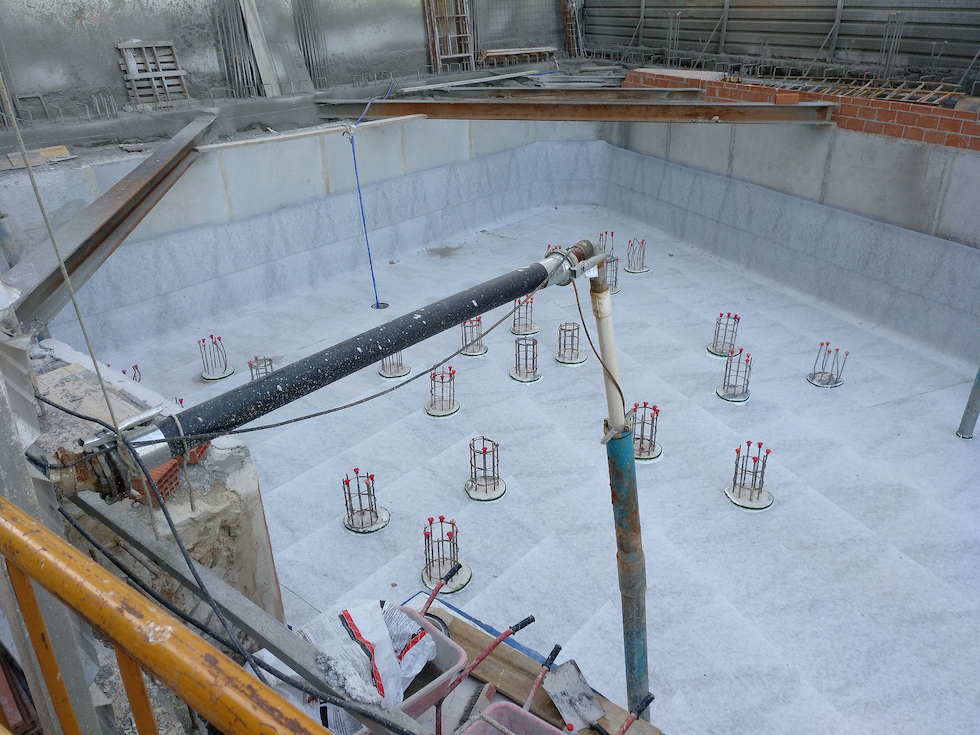

- Pre Applied: Laid above blinding or fixed to building line prior to the placement of the concrete. When used with other Newton HydroBond System products, it provides a coordinated approach to comprehensive structure waterproofing.

- No Compromise, No Leaks: HydroBond 402-CCSM guarantees a watertight seal for foundations, basements, tanks, culverts, and tunnel bases. Exceptional crack-bridging and peel adhesion qualities ensure protection even in challenging conditions.

HydroBond 402-CCSM is a high performance membrane for the external waterproofing of below-ground foundation structures, basements, water holding tanks, culverts and tunnel bases.

A composite of LDPE and a non-woven geotextile fleece, the membrane has excellent crack-bridging capabilities at places where cracks occur within the concrete. When pre-applied before the concrete, the wet concrete is absorbed into the fleece, integrally bonding it to the membrane. This results in a high-strength bond with exceptional peel adhesion qualities, preventing water migration between the concrete and the membrane, even when damaged.

HydroBond 402-CCSM can be used with other Newton HydroBond System products to provide a coordinated and combined approach to the waterproofing of the whole structure that includes protection against water penetrating through construction joints, through and around service entries and to movement joints.