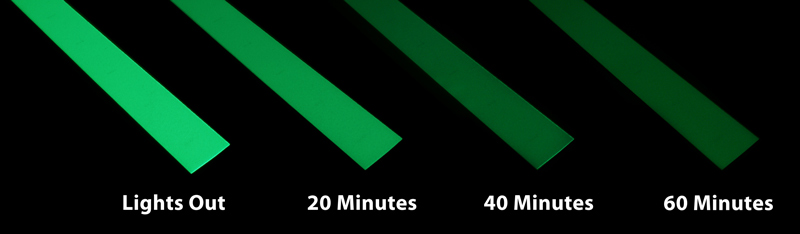

In layman terms, a photoluminescent material is something that absorbs energy when lights are present (incandescent or candescent) and when there is a lights out situation it then emits it. Glow in the dark in its synthetic format has not been around for that long, watch faces being an early adopter. The early watch faces were radioactive and indeed was a killer to the workers who were encouraged to dab their brushes on their lips with the radioactive radium on prior to painting to achieve a fine tip. Things have changed greatly since then, Heskins and all the other manufacturers of photoluminescent products use the safe strontium aluminate compounds. So getting back to the question. A glow in the dark tape, when exposed to light, will absorb photons, the photons excite the electrons to a higher energy state. The excited electrons are stored in a metastable energy state, I did not understand what this was but someone once described it as like a ball balanced at the top of a hill, the ball is stable but is not at its lowest energy state, that would be when it eventually rolls to the bottom of the hill. The electrons will eventually return to their state as if they rolled to the ground thus releasing the stored photons, this creates the characteristic glow that we are familiar with. The intensity of the glow is determined by the quality and quantity of the photoluminescent compound added used to produce the glow in the dark tape.

How photoluminescence is measured

There needs to be some value, be wary of values that are listed only in hours, this is meaningless without data, anyone can claim 10 hours, 12 hours etc, what is the value at a given time point?

Photoluminescent values are tested by a spectrometer, this then quantifies it using MCD. For companies that are serious about photoluminescent tape values you should receive an MCD value. MCD is a Minimum Contrast of Detection; a calibrated light provides the initial energy then at set time points a quantifiable value is generated, this allows for comparisons to be performed.

The certifications for glow in the dark tape

The certifications are numerous that depend on the industry and/or geographical location but the two major ones that Heskins are requested for are DIN 67510 and ASTM 2072. As stated before, there are so many standards outside of these for different applications including the common ISO 17357.

Certification grades

This is the bit that gets interesting. DIN 67510 is a scale, it would sound logical that A is the best but is the reverse, A is the first level that needs achieving on DIN 67510, the quality increases with each letter. We have glow in the dark tape that is a C (H8152) and have also previously produced D for custom orders. ASTM 2072 is different, this requires a minimum obtainable value, again, we achieve that.

Colours

Almost all colours of glow in the dark tape you will ever see are the usual green type, the colour is omnipresent in the market. Heskins uniquely manufactures numerous other colours, these include red, orange, yellow and blue.

As always, we are happy to help and provide samples!