Industry 4.0 Standard Barwell Gear Pump Continuous Rubber Preformers

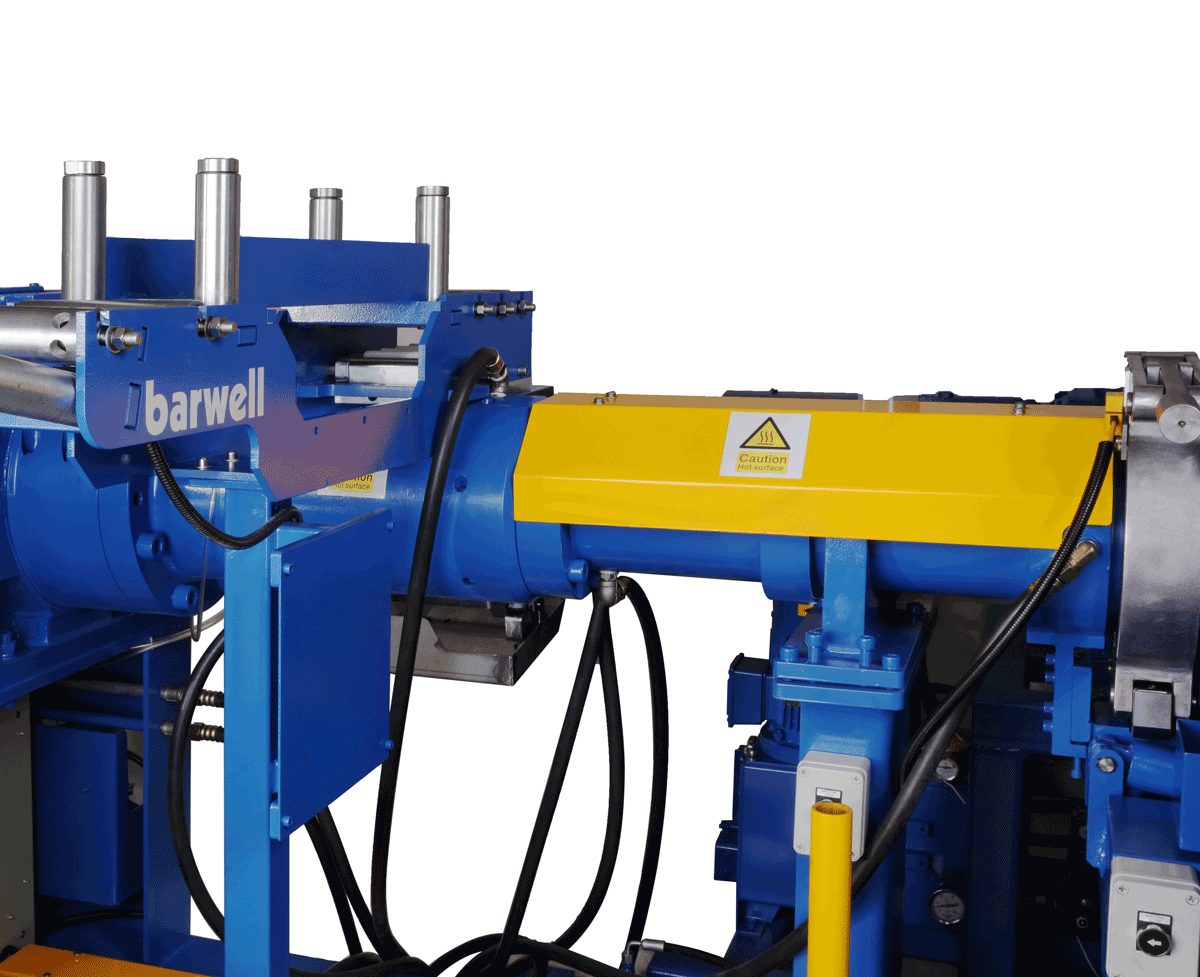

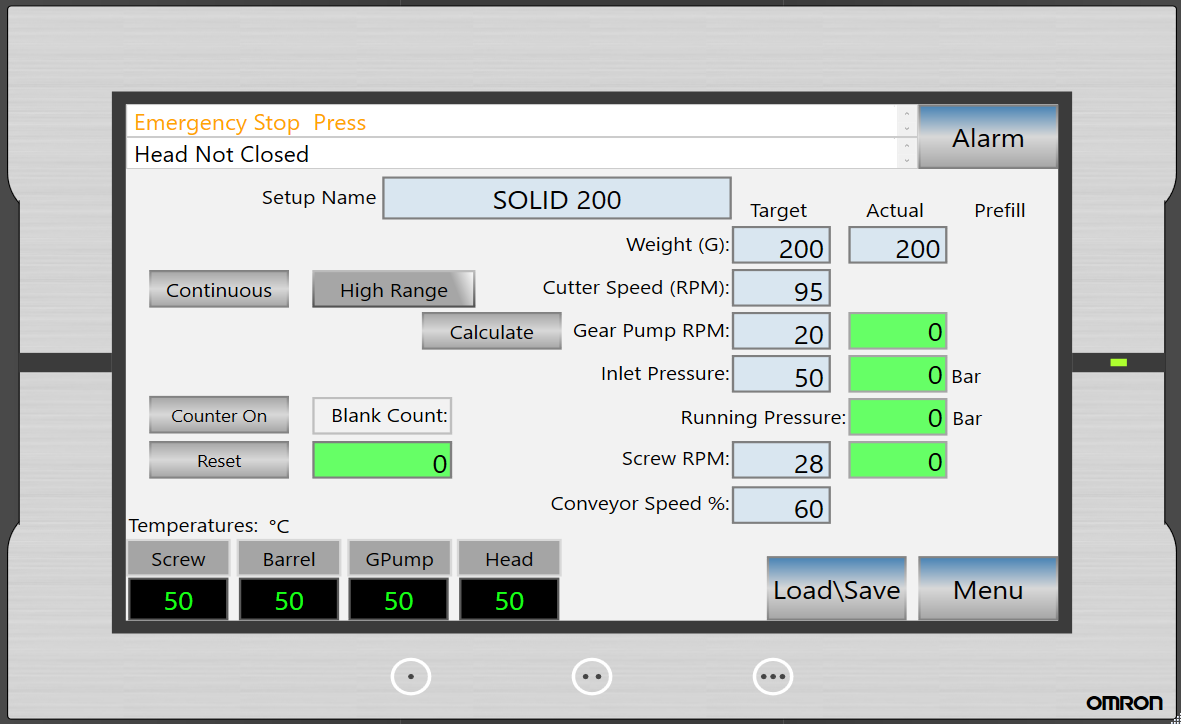

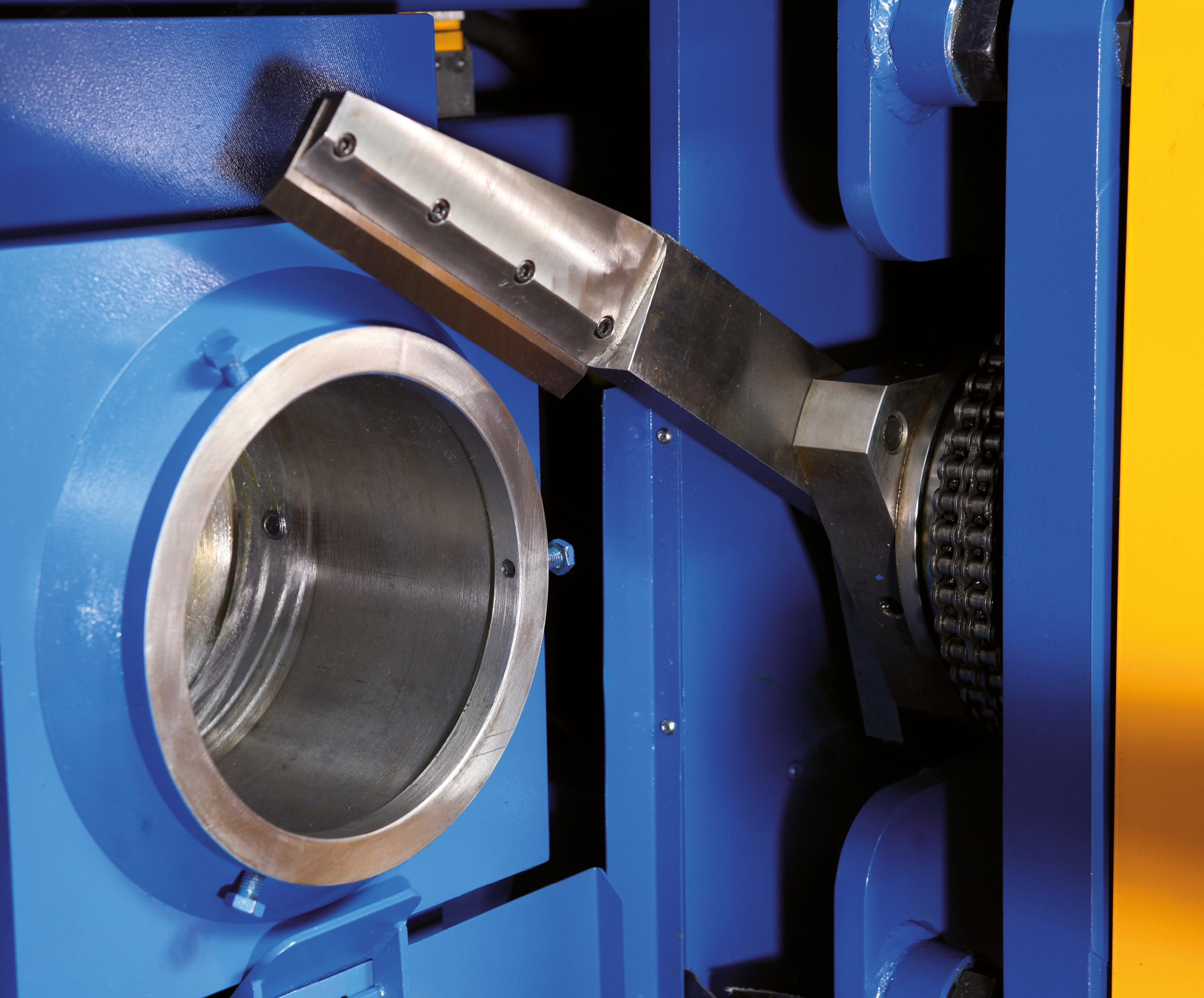

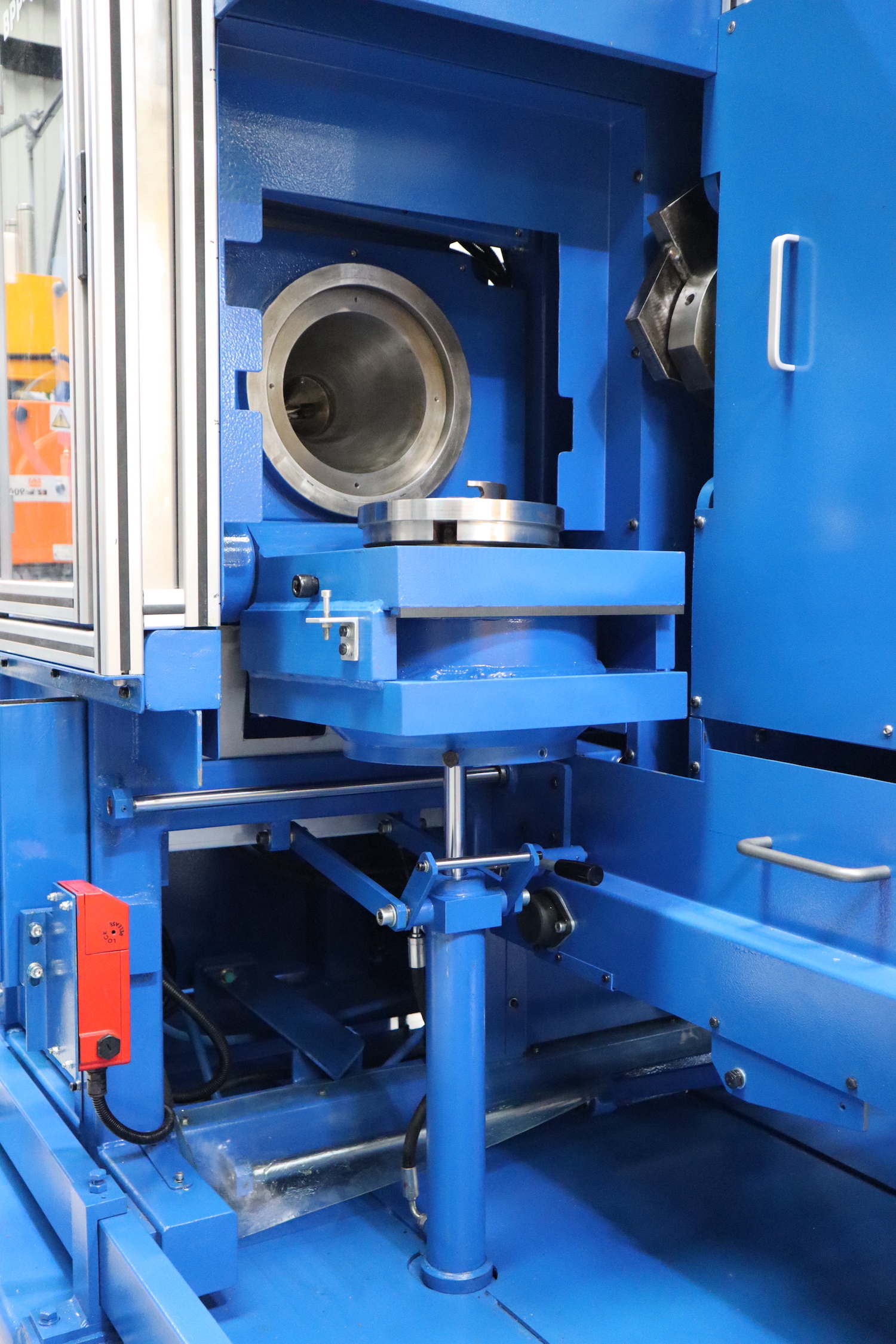

The Barwell Gear Pump-NX Preformer is a fully automated and highly advanced screw extruder with gear pump technology, specifically designed to provide high levels of control and processing flexibility. The range is ideal for the preforming or extrusion of almost any form of rubber compound.

This is the new generation Barwell that will transform your rubber preforming and extrusion by using a safe Internet Gateway and advanced technology allowing machines, devices, sensors, and people to connect and communicate with each other.

- Excellent for long continuous production runs or for profile extrusion requiring greater dimensional stability.

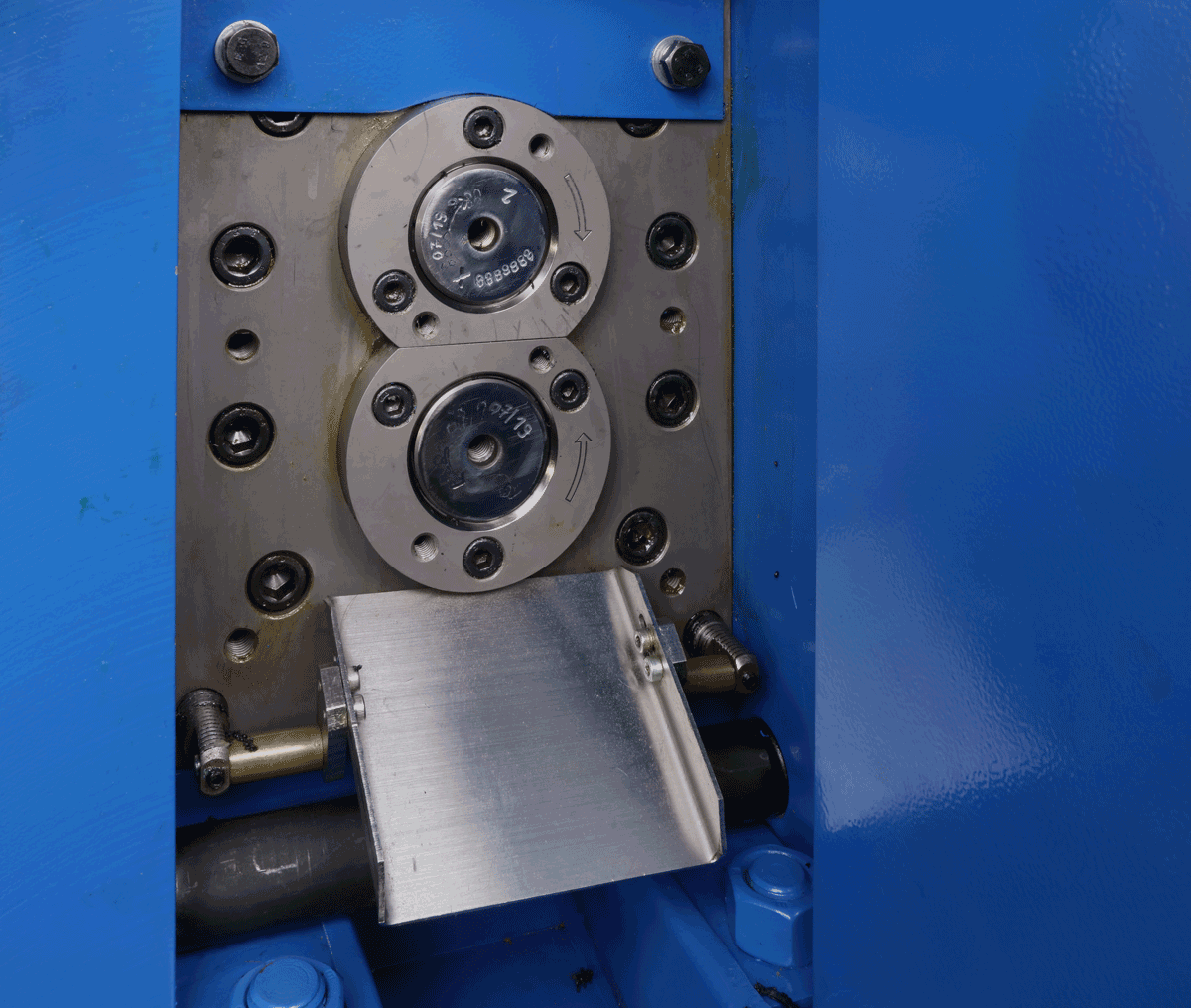

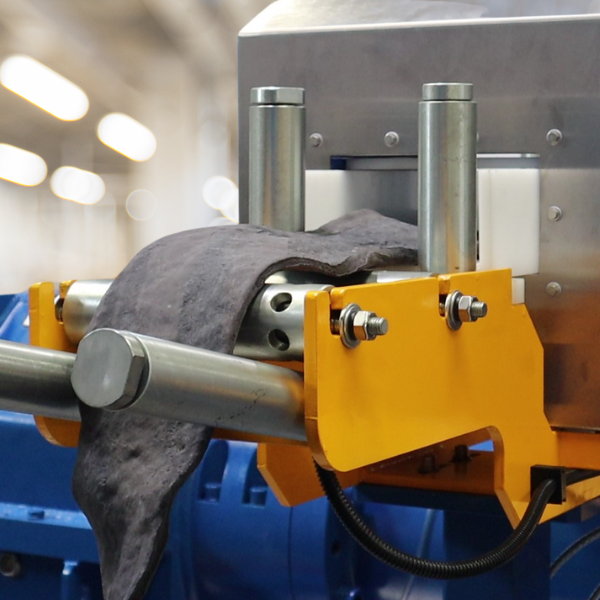

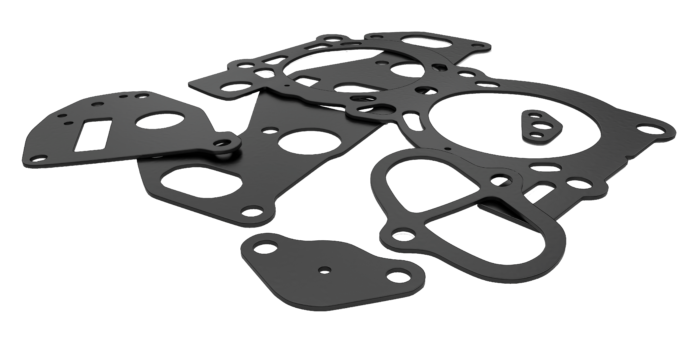

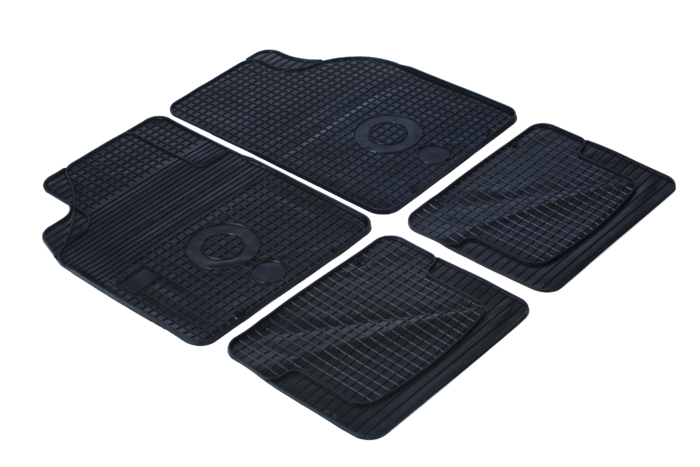

- Suitable for the production of rubber preforms/blanks, pellets, and also strips and cord extrusions

- A fully automated processing method which reduces user dependence and increases productivity

- Technologically advanced processing provides optimum levels of dimensional stability, product consistency, accuracy and superior quality

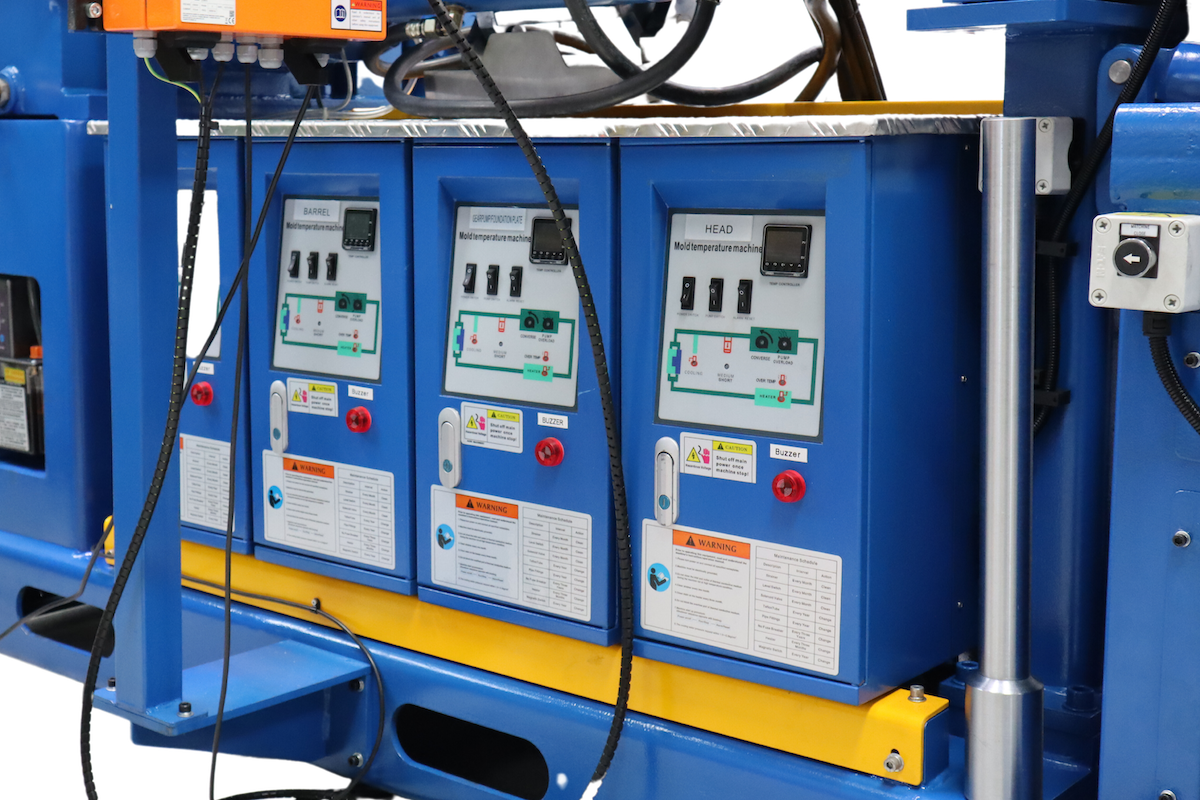

- An intelligent process that ensures very high-temperature control providing versatility at low temperatures

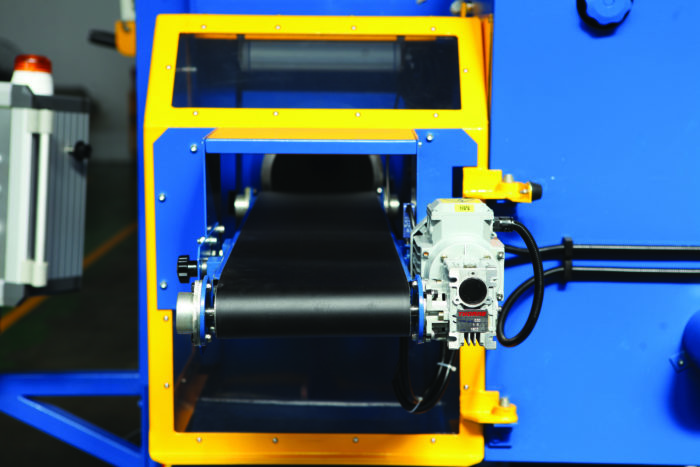

- Enables extrusion, cutting and check-weighing in one precise and efficient process

- A cost-cutting solution reducing material wastage and labour costs as well as negating the need to pre-heat your rubber on a two-roll mill

- A safe, reliable and user-friendly system

- Non ‘NX’ Industry 4.0 versions are also currently available