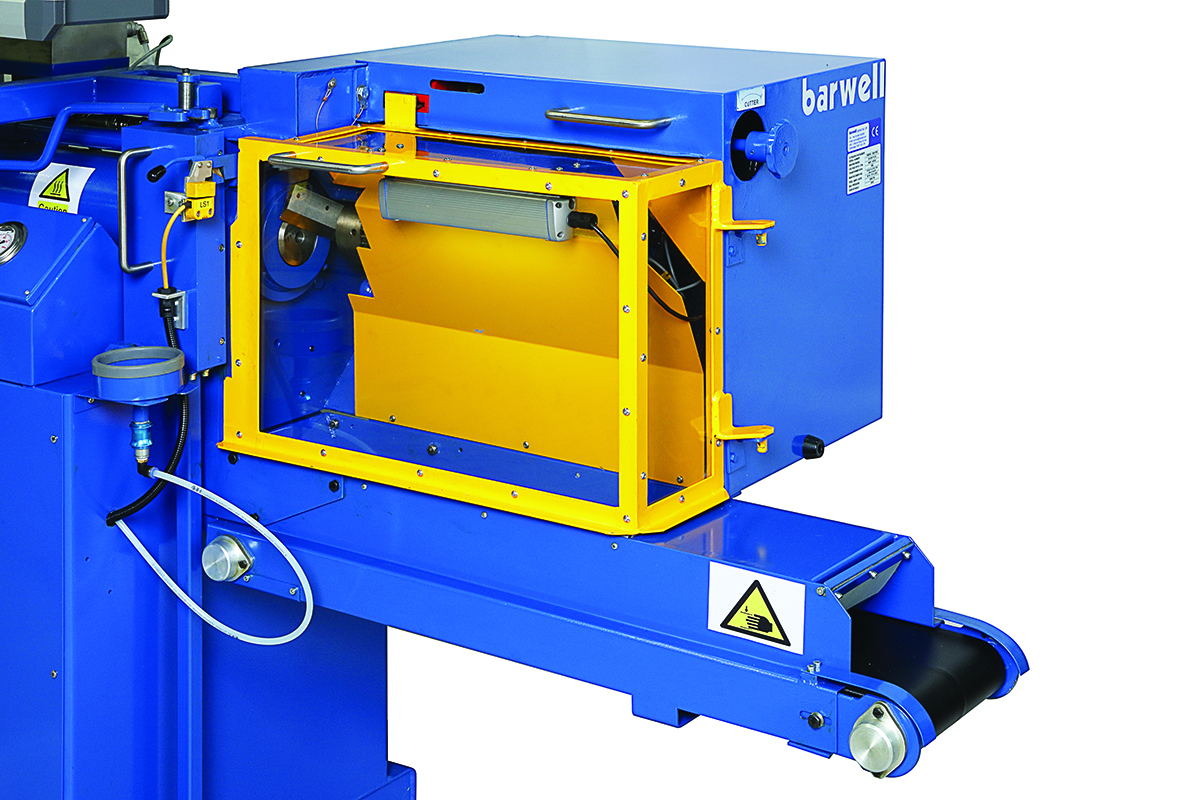

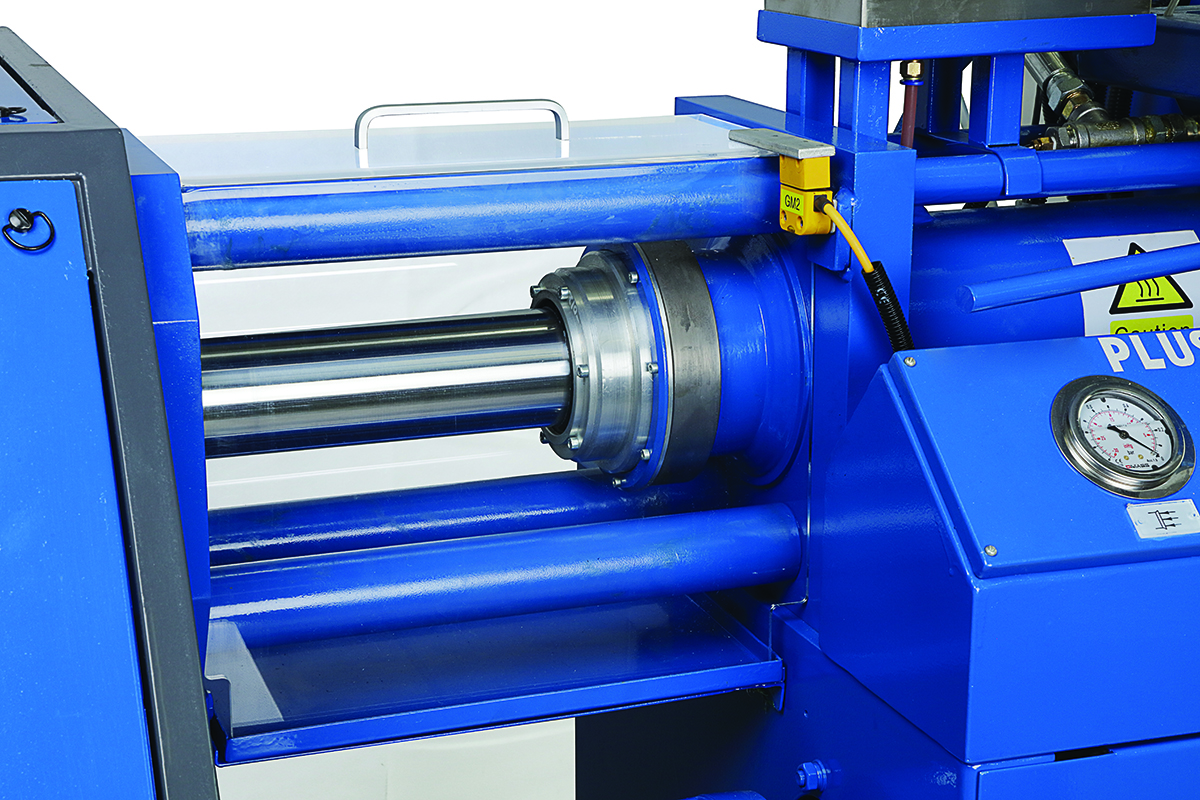

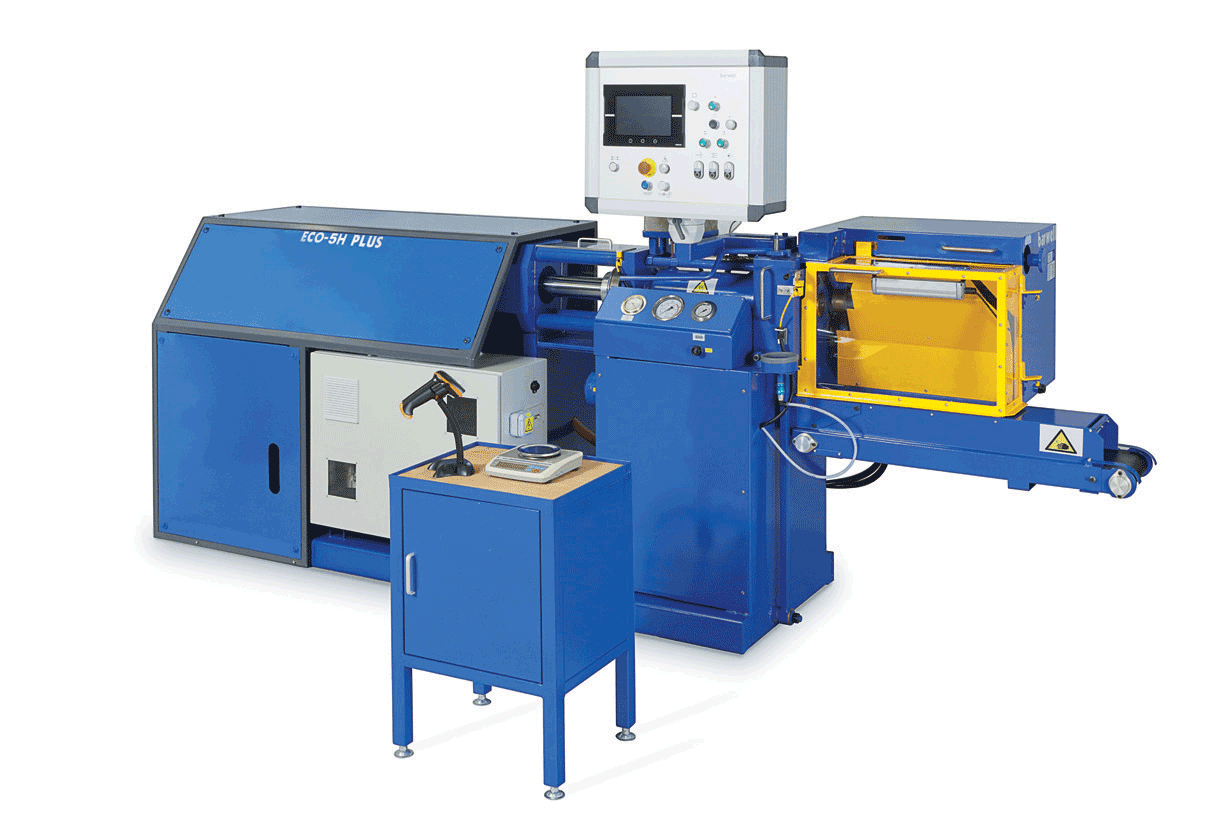

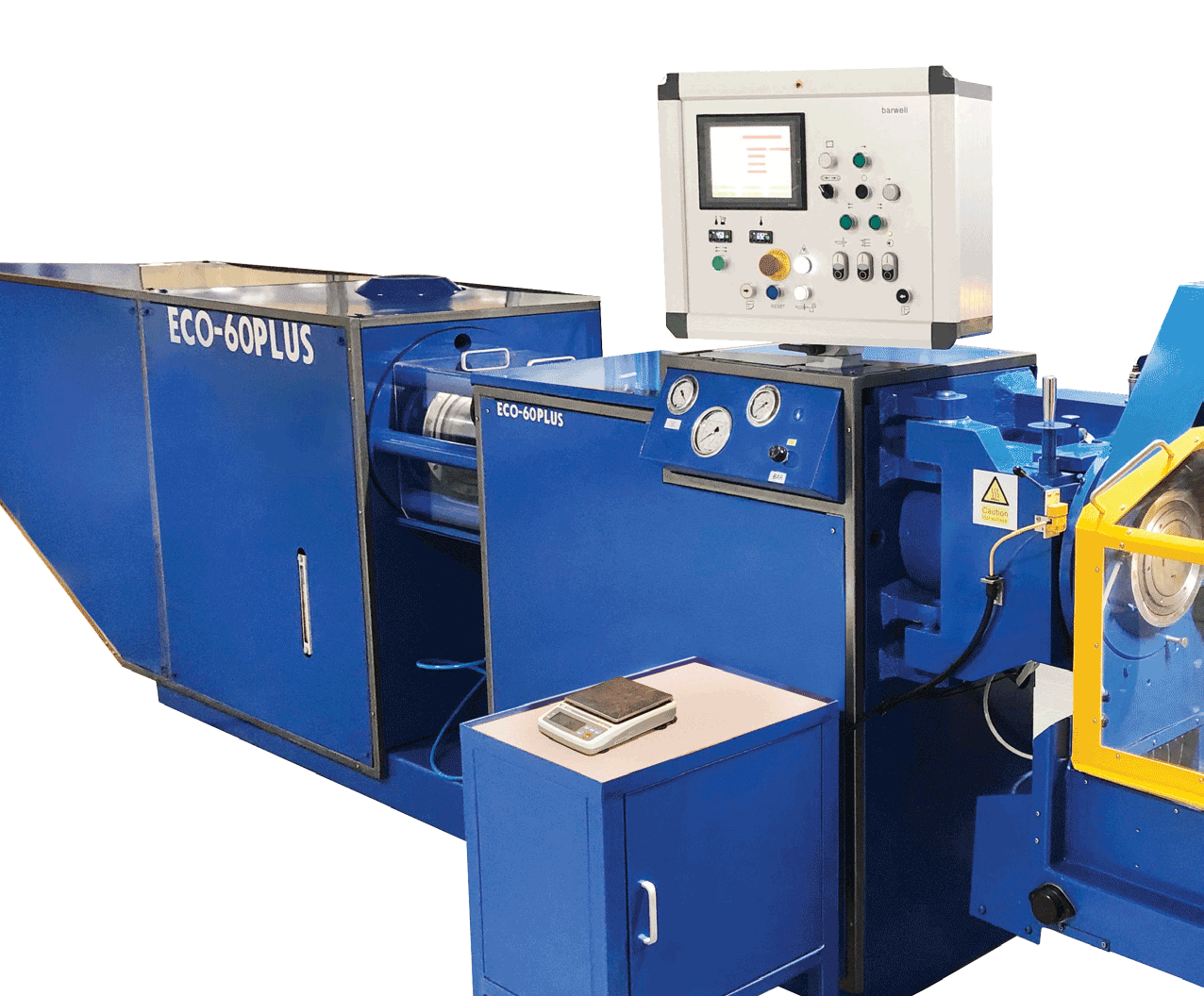

ECO Ram Preformers and Extruders

The Barwell ECO range of high-performance machines, low investment, energy and cost-saving Ram Rubber Extruders and Preformers are specifically designed for the accurate and efficient processing of rubber and synthetic polymer compounds across multiple industries.

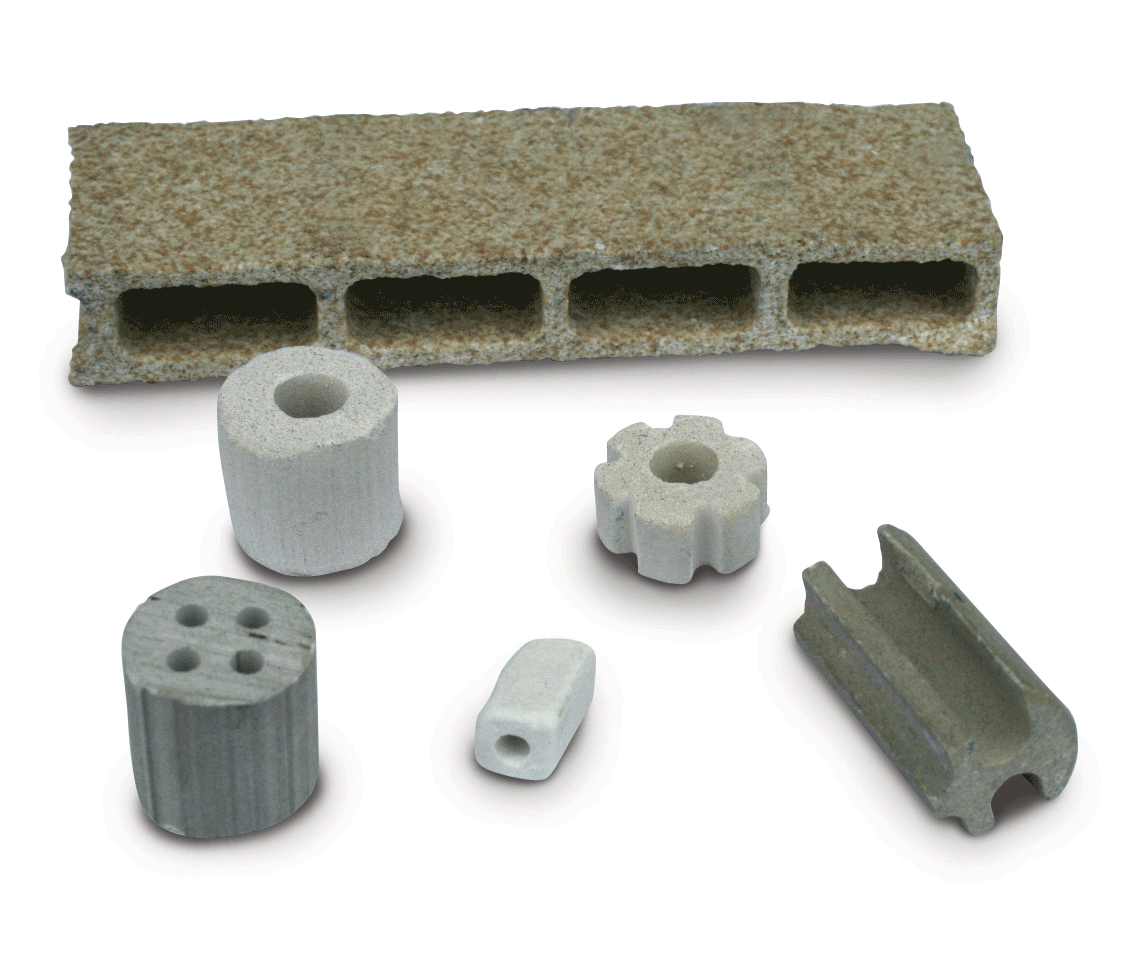

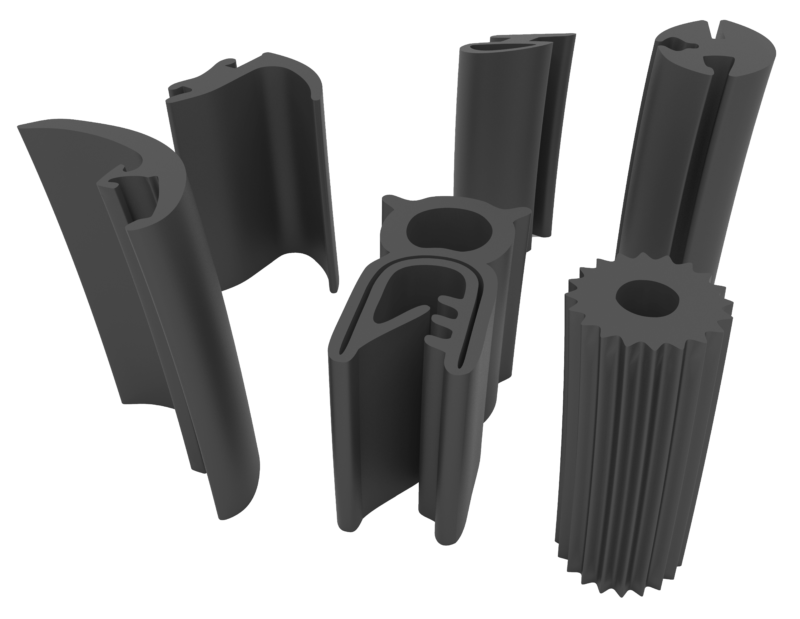

- Suitable for the batch-fed production of rubber preforms/blanks, pellets, and also strips and cord extrusions

- A versatile and high-quality processing system ensuring most types of compound can be processed to produce consistent and accurate product

- Enables quick colour and material changes to be made from FKM to Silicones

- Operator-friendly, requiring minimal user training, increasing production capability

- An energy-saving method of production, significantly reducing power consumption

- A cost-cutting solution which reduces factory space usage, material wastage and labour costs, providing a quick return on investment

- Enables extrusion, cutting and check-weighing in one precise and efficient process

- Robust, safe, reliable and easy to maintain