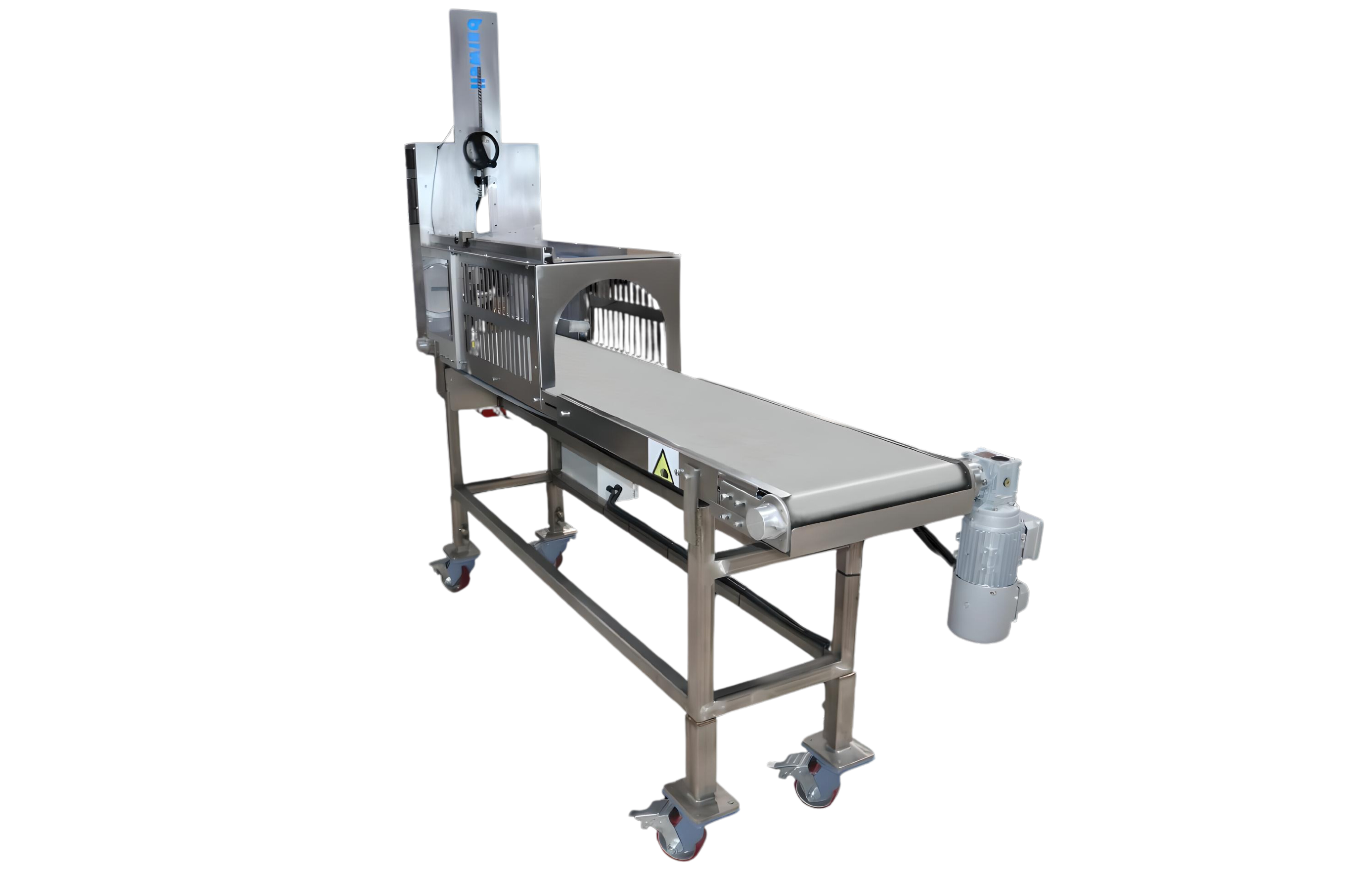

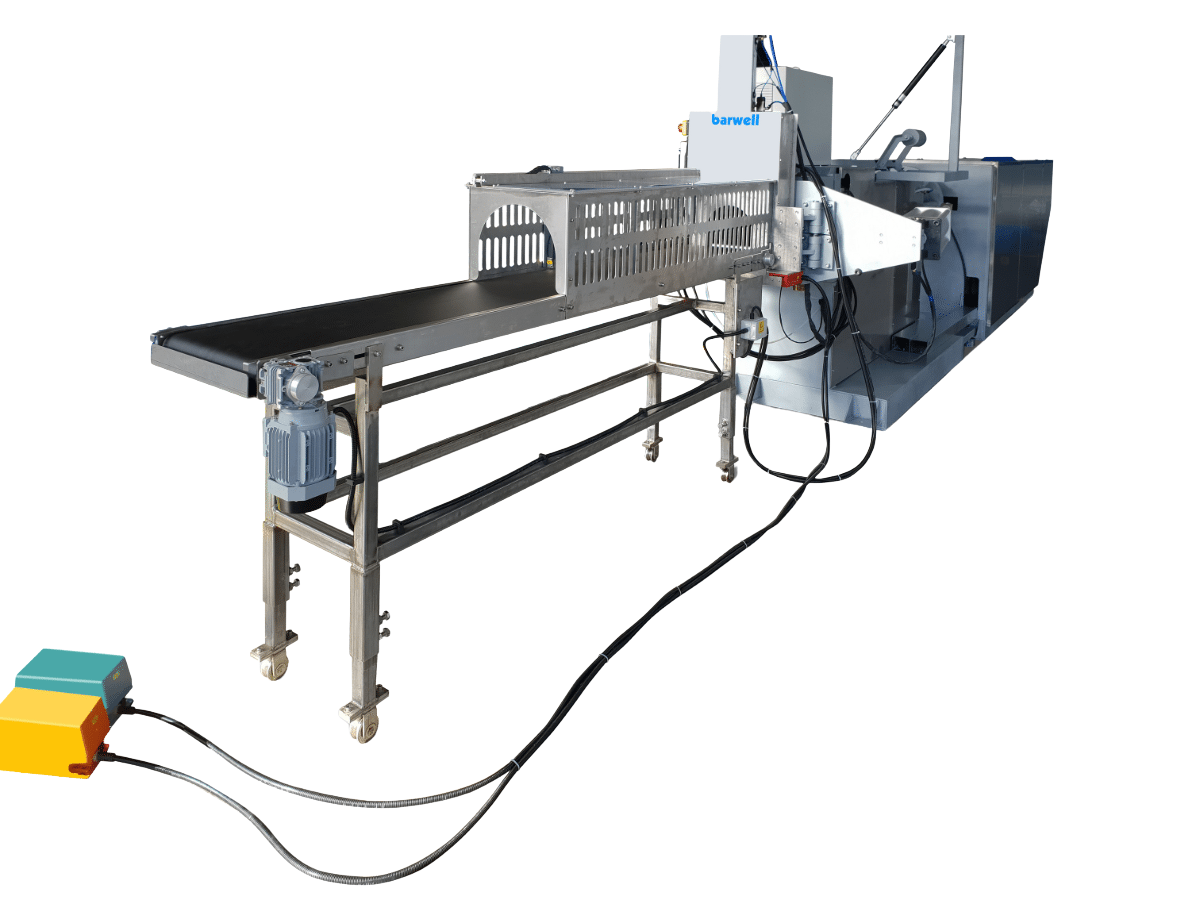

Barwell ECO Clean Room Rubber Ram Extruders

The Barwell ECO Clean Room is a range of high-quality and cost-saving ram extruders, designed for the efficient processing of rubber and synthetic polymer compounds in clean room environments.

- For contamination and air-free extrusion

- Ideal for silicone extrusion

- Direct areas of the machine which come in contact with rubber are either stainless steel, hard chromed, or hot galvanised painted to avoid material contamination

- Ideal for companies that operate with white, clear, or sensitive compounds and need to filter/strain or extrude

- Suitable for the batch-fed production of rubber strips, cord extrusions, tubes, and solid round sections

- Operator-friendly, requiring minimal user training, increasing production capability

- Robust, safe, reliable and easy to maintain