To transform our customer products and markets by challenging traditional perceptions of a ‘bearing’ through collaborative innovation and integrated, added-value engineering solutions.

Customer Satisfaction, Technology Leadership, Innovation, People and Processes are at the heart of our vision.

BNL has three manufacturing sites worldwide, in the UK, Thailand and China. We also have sales and engineering offices in Knaresborough (UK), Tokyo (Japan), Shanghai (China) and Foxboro (USA).

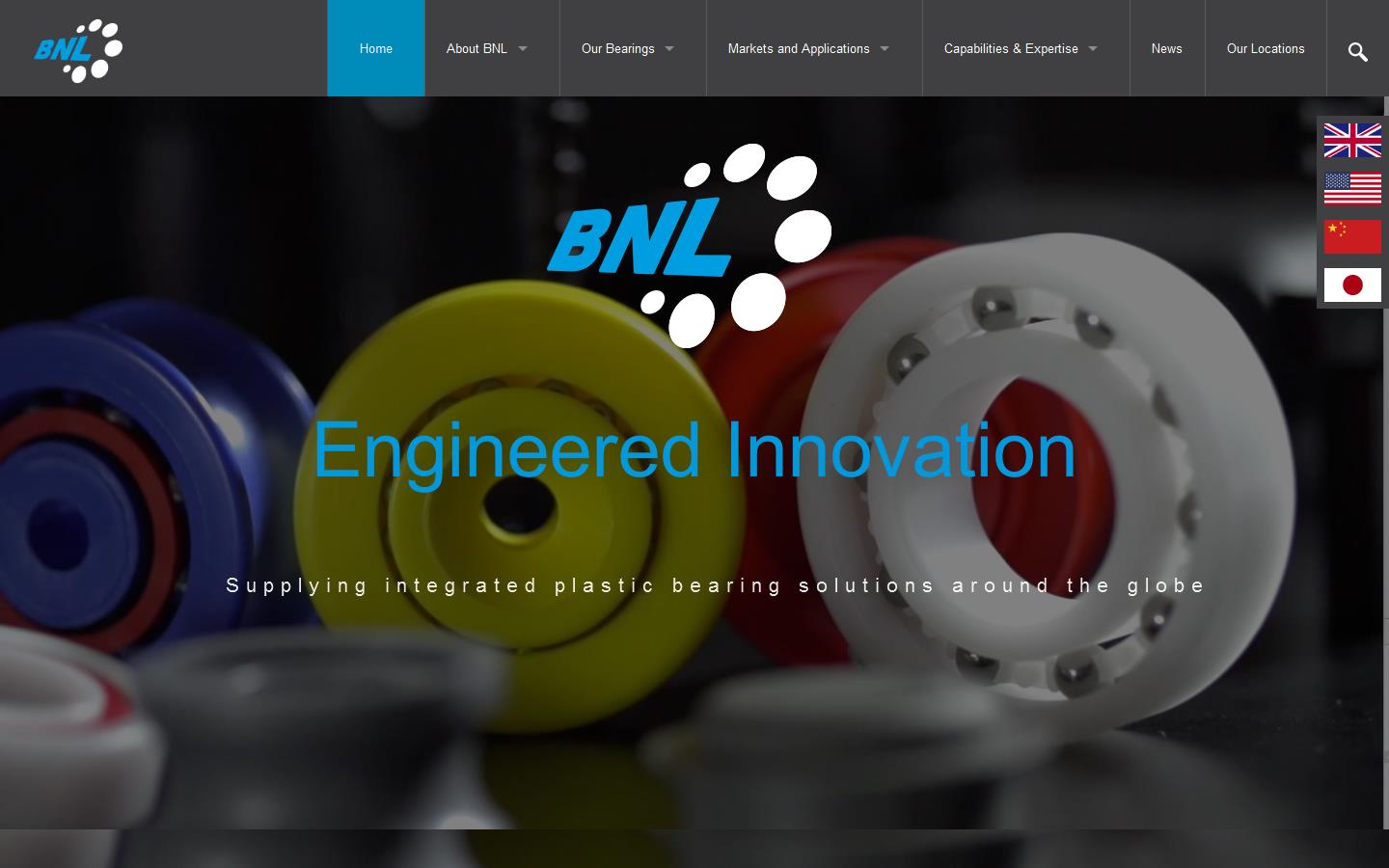

We focus on providing our customers with bearing designs that will achieve their desired objectives. More than just a bearing, our engineered solutions can provide operational savings, improved performance and longer product life.

Value Added Design: Our integrated designs add value whilst reducing component count, assembly operations and product weight, by combining multiple components and functions into a single moulded part.

Quality and Consistency: We are ISO 9001, ISO 14001 and IATF 16949 accredited at all moulding production sites, reflecting our commitment to stringent quality standards and ensuring we deliver quality and value from concept to production.

ISO 9001 ISO 14001 ISO 45001 IATF 16949 Environmental Policy Statement

High Performance Products: Our bearings are fully moulded to maintain the fine crystalline layer on the surface area of the bearing race-way, which significantly improves wear resistance, increasing the efficiency and life of our products.

Global Partnership: Partnership with and understanding of our customers is important to ensure we can meet their expectations and requirements. Our global team offers support to all our customers worldwide throughout our relationship with them.

approvedbusiness.co.ukBNL Tel: +44 1423799200

approvedbusiness.co.ukBNL Tel: +44 1423799200