Pendle Polymer Engineering Ltd specialises in the design and production of custom rubber mouldings and anti-vibration solutions for the automotive, off-highway vehicle, and industrial sectors.

Pendle Polymer has extensive expertise in rubber-to-metal bonding, with its products used in a wide range of applications, including engine and cab anti-vibration mounts for trucks and excavators, suspension bushes for passenger and commercial vehicles, precision rubber mouldings for tractors, helicopters, submarines, trains, and various industrial uses.

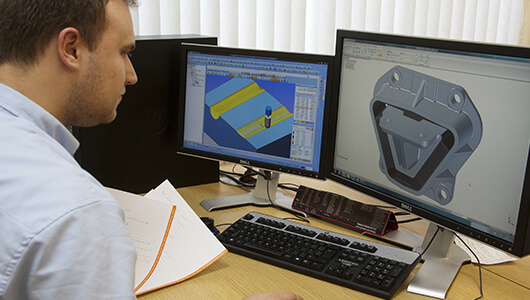

Pendle is equipped to collaborate closely with customers, offering moulded rubber solutions that cover every stage from concept design and toolmaking to product testing and final production.

Our Products Include:

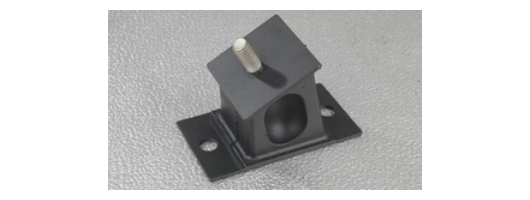

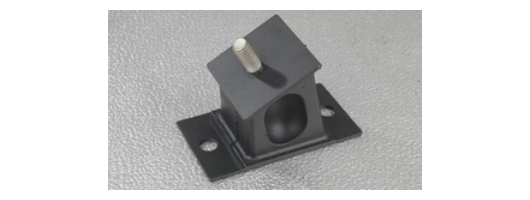

Anti Vibration Mounts

Our anti vibration mounts are produced with strict specifications to guarantee reliable, long-term performance.

Bespoke Components

We have established a solid reputation for collaborating with customers to design and produce custom components tailored to their specific applications. We strive to provide solutions that are both cost-effective and engineered to meet customer requirements.

Bonded Bushes

With many years of experience as a Tier 1 supplier, we collaborate closely with our customers' engineering teams, offering prototype development and durability testing to ensure optimal ride, handling, and long service life. Having produced over 1 million bonded bushes for vehicle suspension systems and cab pivot bushes, Pendle Polymer continuously seeks process improvements to provide a competitive advantage for our customers.

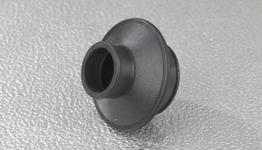

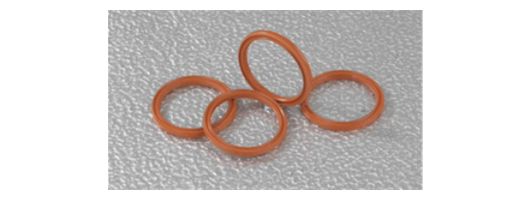

Fluid Seals

We produce a wide range of fluid seals for diverse markets, including industrial, rail, aerospace, and automotive applications.

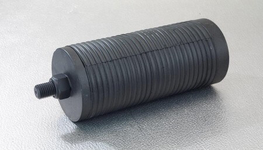

Precision Rubber Mouldings

Pendle Polymer produces precision rubber mouldings tailored to customer specifications in a range of compounds, from food-grade materials to high-temperature resistant polymers. We are happy to provide support and guidance in product development to meet your specific application needs.

Modern high-performance requirements place growing demands on rubber technologists and engineers. While standard "off-the-shelf" solutions remain part of our offerings, the majority of customer inquiries tend to require custom, tailored solutions.

Our anti vibration products are used in a variety of applications, from mountain bikes and motorcycles to sports cars, commercial vehicles, machinery mounts, earth movers, trains, and helicopters. We also supply precision mouldings and seals for diverse uses, including compressed air, natural gas, petroleum, nuclear waste, yogurt, beer, and drinking water. Pendle Polymer serves a global customer base, regularly supplying products to North and South America, Europe and Scandinavia, the Middle East, and China.

The company has long understood the significance of well-established quality assurance procedures, achieving ISO 9000 accreditation in 1990. In line with our commitment to continuous improvement, we are upgrading our system to meet the automotive standard TS16949, with a goal of obtaining certification by 2017.

-

-

-

-

-

-

-

Anti Vibration Mounts

Rubber to Metal Bonding

Bonded Bushes

Shock Isolation Mounts

Precision Rubber Mouldings

Fluid Seals

Bespoke Components

Previous

Next

approvedbusiness.co.ukPendle Polymer Engineering Ltd Tel: 01282 868916

approvedbusiness.co.ukPendle Polymer Engineering Ltd Tel: 01282 868916