Precision Waterjet Ltd is located on the scenic Jurassic Coast in Lyme Regis, Dorset.

Our Managing Director has been involved in the waterjet cutting industry since 1998. As one of the first operators in the UK to use an Omax machine, he later traveled across Europe to assist with overseas installations and technical support before founding Precision Waterjet.

We were among the first waterjet companies in the UK to achieve ISO 9001:2015 certification. We take pride in being an industry leader, ensuring that our processes and quality assurance checks deliver parts that are fully aligned with the specifications.

Our Services Include:

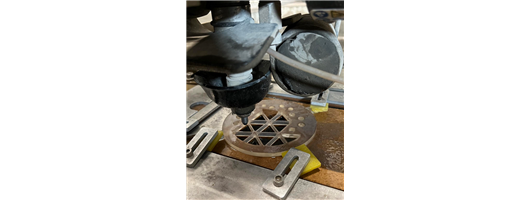

Precision Waterjet Cutting Process

Precision Waterjet uses both water-only and abrasive waterjet cutting technologies to shape nearly any material, including those up to 200mm thick. Advanced tools like Tilt-A-Jet®, optical locators, and pneumatic drills ensure precision, while Omax IntelliMAX software optimises material usage to reduce waste and cost. With an extensive stock of ferrous and non-ferrous materials in various grades and thicknesses, we can deliver parts within 24 hours. For non-stock materials, our suppliers provide next-day shipping for quick turnaround times.

Flat Bed Linishing & Brushing

Our linishing and brushing machine enables us to provide fully deburred, satin-grained finishes (DP1 or DP2) on components up to 300mm wide, streamlining production for metals like stainless steel, copper, and brass (excluding aluminum). This eliminates the need for costly pre-grained sheet purchases, offering a convenient, all-in-one solution for finished components.

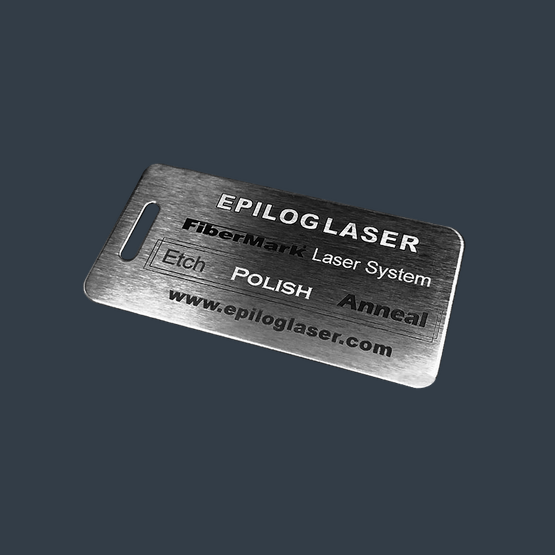

Laser Engraving & Etching

Using the Cermark process with our CO2 laser, we create high-contrast, permanent marks on metals like stainless steel and mild steel. Whether for full nameplates or simple ID numbers, we can accommodate parts up to 600mm x 450mm.

Precision Waterjet boasts the world’s largest fleet of OMAX machines, with eight state-of-the-art precision waterjets, including two new additions and six fully upgraded machines. Our two largest machines offer a cutting area of 2.54m x 1.39m, all achieving a cutting tolerance of ±0.075mm and positional accuracy of ±0.025mm. Equipped with advanced features like pre-loaded linear bearings, precision ball screws, and the MAXJET 5i nozzle delivering 54,000 psi, our machines provide 30% more cutting power than standard waterjets. Innovative tools such as the Tilt-A-Jet®, optical locators, and IntelliMAX Premium nesting software enable us to cut virtually any material up to 200mm thick with minimal waste. Rigorous maintenance ensures maximum reliability and minimal downtime.

We serve a diverse range of industries, including aerospace, automotive, marine, oil and gas, power generation, and precision engineering. Increasingly, architectural and composite companies recognize the advantages of waterjet profiling, which delivers high-precision, high-quality parts with reduced lead times and minimal post-processing. Waterjet's “cold cutting” method avoids heat, allowing precise profiling of ferrous, non-ferrous, nickel alloys, and other materials without structural changes. Capable of cutting intricate designs and holes as small as 1mm, it’s ideal for complex tasks like tapping-sized holes in thick materials. Environmentally friendly, waterjet cutting uses no harmful gases or liquids and produces no hazardous vapors.

Since 2006, Precision Waterjet has focused on reliable, precise cutting with exceptional quality, short lead times, and excellent customer service. We streamline manufacturing by managing material handling and ordering, helping customers save time. Additional services include linishing for satin finishes, CO2 laser part marking with durable Cermark, and finishing options like deburring and tapping, delivering ready-to-use components.

-

-

-

Precision Waterjet Cutting Process

Flat Bed Linishing & Brushing

Laser Engraving & Etching

Previous

Next

approvedbusiness.co.ukPrecision Waterjet Ltd Tel: 01297 444456

approvedbusiness.co.ukPrecision Waterjet Ltd Tel: 01297 444456