SI Protech (UK) Ltd strives to be recognised as an innovative leader in the industries it serves, especially within the beverage and brewing sector. Additionally, the company aims to be known as a top supplier of high-quality, technically advanced injection moulded components and assemblies.

We possess vast experience in product development, mould tooling, plastic injection moulding, and final production. Our company caters to various industries, including Beverage, Pharmaceutical, Personal Products, and Automotive.

As a technical injection moulding company, we specialise in producing high-specification products and solutions. We offer expert guidance on material selection, production feasibility, mould design, packaging, and more during the critical product development phase.

Our Services Include:

Research & Innovation

Research and innovation are key to SI Protech, driving creative and sustainable solutions for our customers. Through generating new knowledge, research plays a vital role in developing innovative products, processes, and services that enhance our customers' productivity, competitiveness, and overall success.

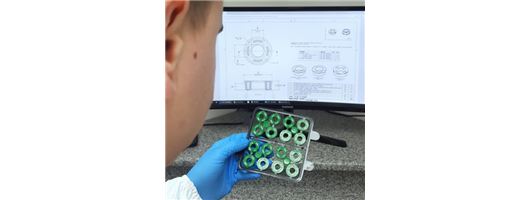

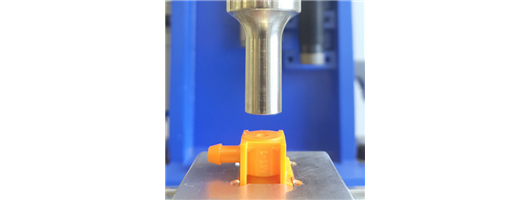

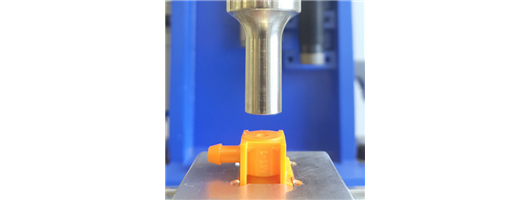

Product Development

We provide development support for those with limited experience in thermoplastics, offering services such as IP reviews, 3D component design and modelling, rapid prototyping, and material consultancy.

Design & Development

SI Protech (UK) Ltd is your trusted partner for material selection, production feasibility, product design, mould manufacturing, assembly systems, and technical packaging solutions. We assist customers with established products, those needing improvement or replacement, as well as new projects for companies and developers.

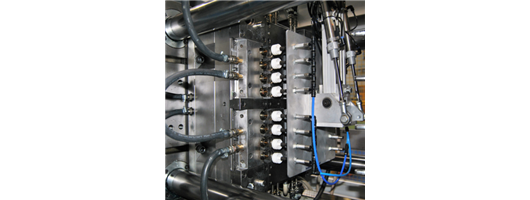

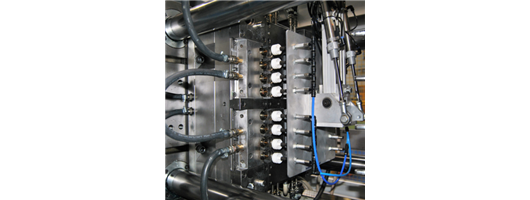

Manufacturing

We run a 28,000 square ft. facility, operating 24/7, 5-7 days a week. This includes 'white room assembly' for food and beverage products. Our manufacturing approach focuses on prevention rather than detection, emphasizing the development of a reliable process from the start, which is then maintained throughout batch production.

Injection Moulding

We specialise in working with a variety of polymers, including Polypropylene, Polycarbonate, Nylon, LDPE/HDPE, PBT, ABS, PC, SAN, GPPS, TPE, TPU, POM, and others.

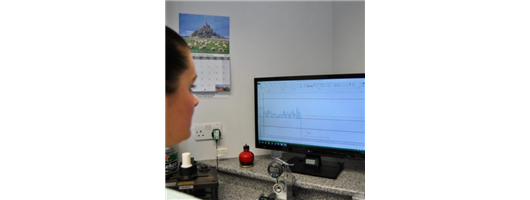

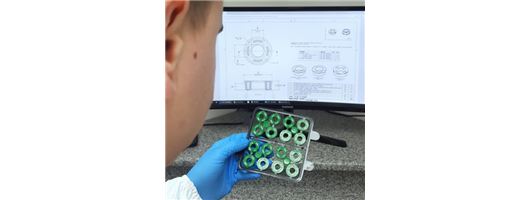

Quality Assurance & Control

Quality is fostered and enhanced internally through the use of Six Sigma and Lean methodologies. Additionally, all of our Quality Systems are externally certified by the BSI (British Standards Institute) to meet international standards, including ISO 9001 for Quality Management, ISO 14001 for Environmental Management, and ISO 22000 for Food and Drink Packaging Safety, Hygiene, and Security Management. SI Protech (UK) Ltd has established a strong reputation in the markets it serves.

SI Protech (UK) Ltd has built a great name within the markets it serves.

Widely recognised as an innovative and high-quality design, development, injection moulding, and assembly company in both multinational and UK market sectors.

Collaborating with numerous top companies, including Heineken, Anheuser-Busch InBev, Colep, Parker Hannifin, Honeywell, and others...

Got a project in mind? Reach out to us, and let's get started!

-

-

-

-

-

-

-

-

-

-

Manufacturing Services

Additional Manufacturing Facilities

Design & Development Services

Additional Design & Development services

Injection Moulding Specialists

IM Services

Knowledge Leaders in Plastics

Quality Control Services

Recycling & Waste Management

Sustainable Materials

Previous

Next

approvedbusiness.co.ukSI Protech (UK) Ltd Tel: 01903 733144

approvedbusiness.co.ukSI Protech (UK) Ltd Tel: 01903 733144