Michael Smith Engineers expand plastic, leak free Pump range

18 March 2009

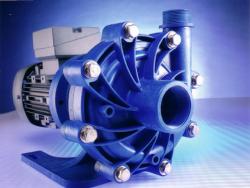

The Finnish Thompson range of plastic magnet-drive centrifugal pumps has recently been expanded following the addition of a new DB22 model, which is capable of handling capacities up to 50m3 /hr at maximum differential heads up to 45 metres.

Available through pump specialists MICHAEL SMITH ENGINEERS these robust, leak-free pumps are ideal for most challenging liquids transfer applications occurring in corrosive and challenging environments.

As a result of the non-metallic materials used for both the housing and all the key wetted components, they are ideal for pumping corrosive liquids in chemical manufacturing, metal plating, surface treatment, wastewater treatment, electronics manufacture or wherever hazardous liquids need to be transferred safely and efficiently. They are available in a close-coupled design configuration for optimum magnet alignment and provide extended dry-running capability when specified with a carbon bushing and are therefore protected from system upsets.

Other features and benefits include; high operating efficiency resulting in lower energy consumption, improved hydraulic coverage for both 50 and 60 Hz operation, with evenly spaced impeller trims enabling duty points to be precisely met and a two-piece impeller design which allows the impeller or inner drive magnet to be individually replaced.

DB Series pumps offer high working pressure capability which means fluids with a high specific gravity can be easily pumped without the need for impeller trimming.

The Pumps are designed for either horizontal or vertical installation (vertical when equipped with an IEC motor), they have a maximum operating temperature of 180°F (82°C) for the polypropylene model and 220°F (104°C) for the PVDF option.

Further information is available from the Michael Smith Engineers website.

Released By

Michael Smith Engineers