Company details for:

Arrow Valves Ltd

York House,

Northbridge Road,

Berkhamsted,

Herts,

HP4 1TA,

United Kingdom

Quick Links:

Products

Midi-Break®

Ablution Plant

Boost-A-Break®

DC Pipe Interrupter

"Conceal-A-Tap®"

Autofill®

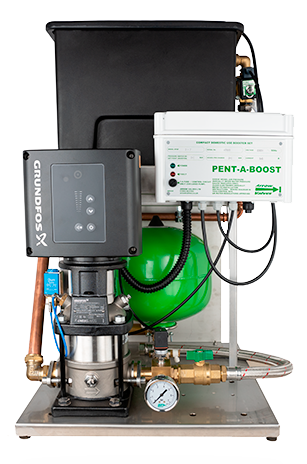

Pent-A-Boost®

Dose & Fill® Pressurisation & Dosing Unit

Midi-Fill Digital® Pressurisation Unit

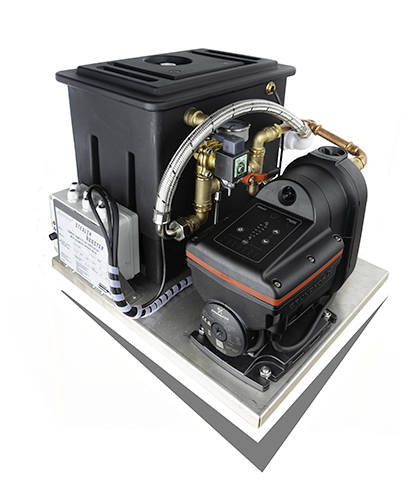

Arrow Stealth Booster

RPZ Valve - "Option B"

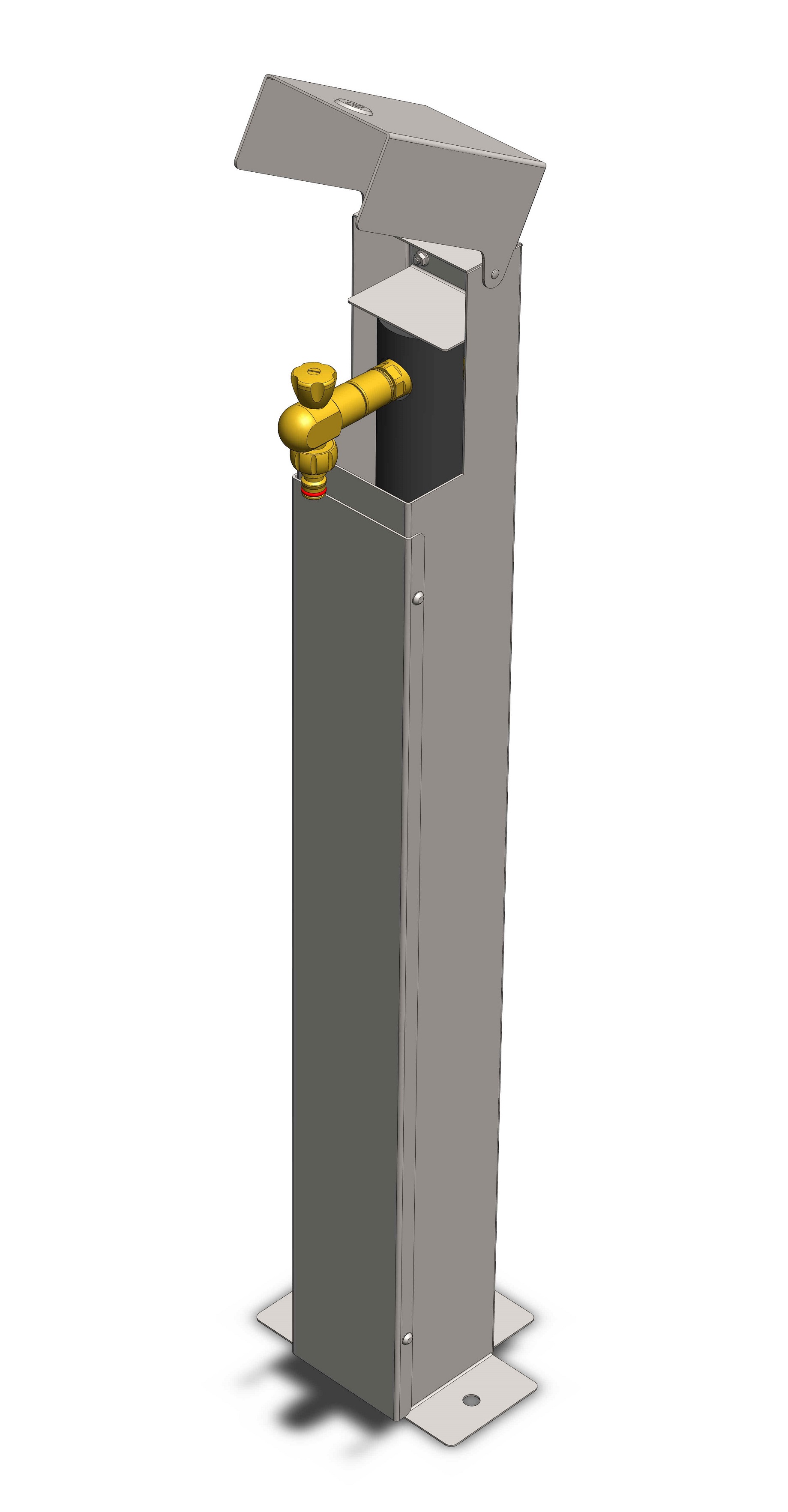

Pillar Standpipe

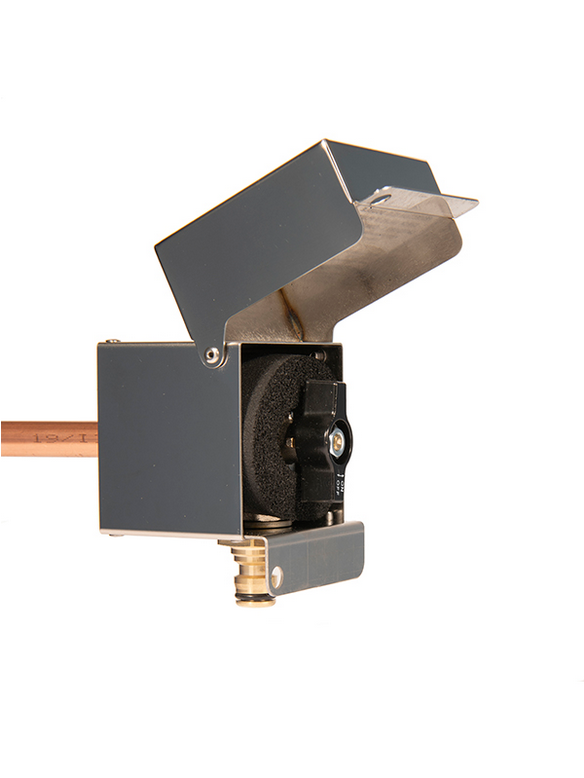

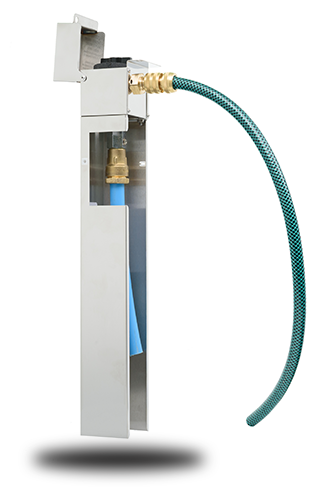

Hose Tap Box − 500 Copper Tube

Standpipe FC3 - SPED

Standpipe Tap Box

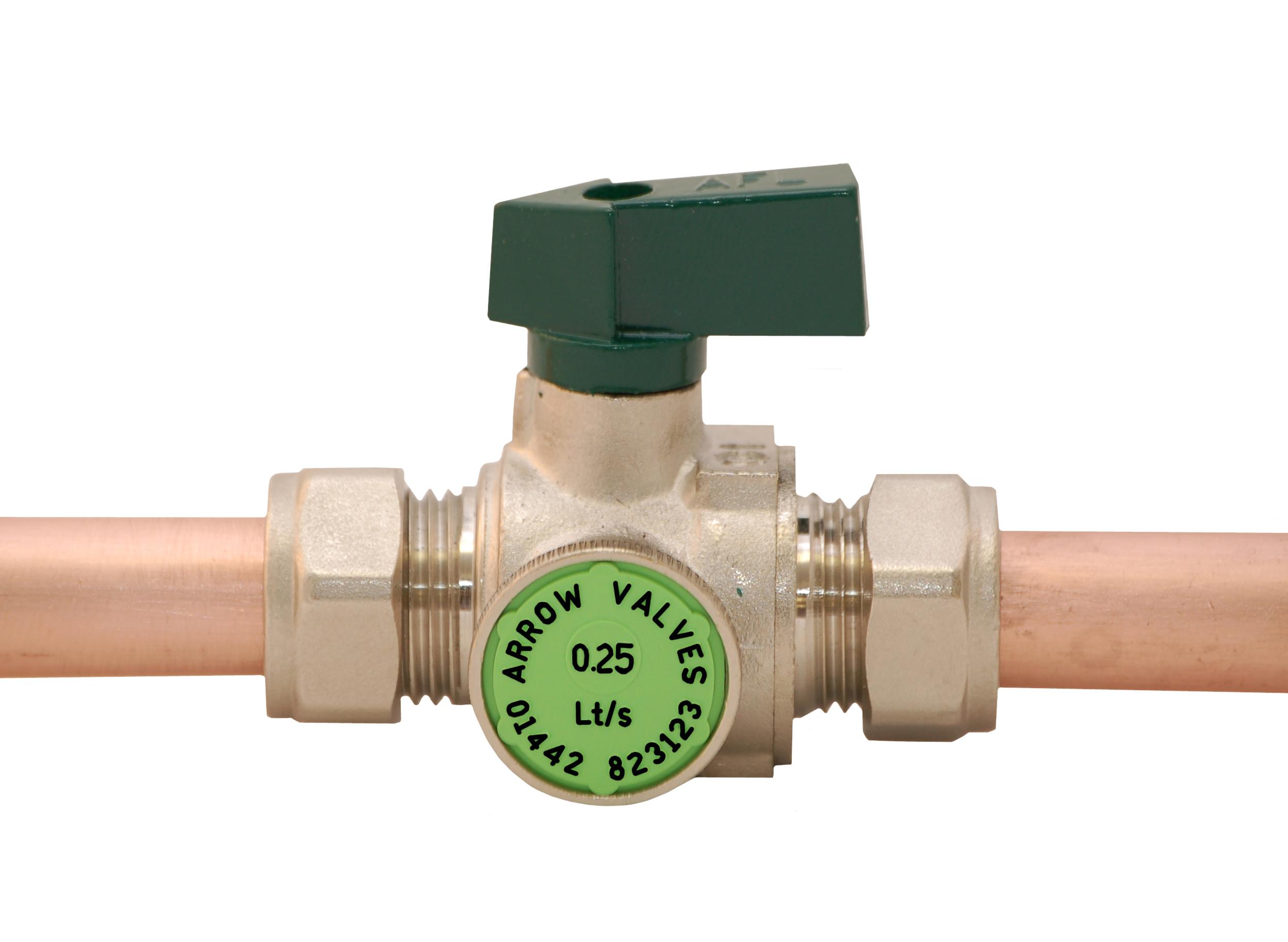

Automatic Flow Limiting Valves

“Equi-Flow” Shower Limiter

Automatic Shower Flow Limiter with integral variable orifice cartridge, which limits the flow of water according to one of three selected flow rates; 0.13 Lt/s (white), 0.1 Lt/s (black) or 0.17 Lt/s (blue). Fitted between the tap and hose "Equi-Flow" limits the amount of water to each shower, ensuring even distribution. This prevents some showers (e.g. on the ground floor) from receiving excessive flow whilst others (e.g. on the top floor) receive very little. Saves water and energy making it ideal for for multiple occupancy building such as hotels, flats and student accomodation. Easily installed; simply screw onto the inlet of shower hose. Supplied with rubber sealing washer.

Rainwater Header Break Tank Wall Tray

ByPass Valve Assembly

Dosing Pot

Expansion Vessel

FilterBall

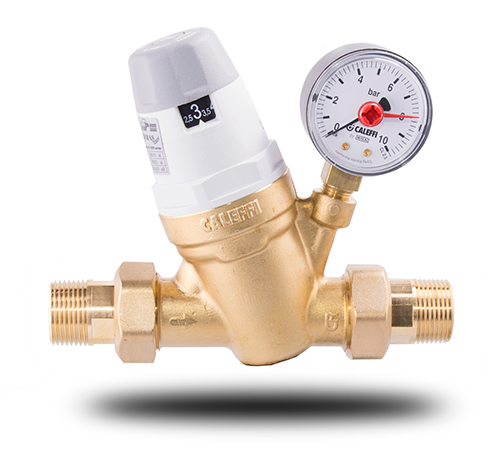

Pressure Reducing Valve (PRV)

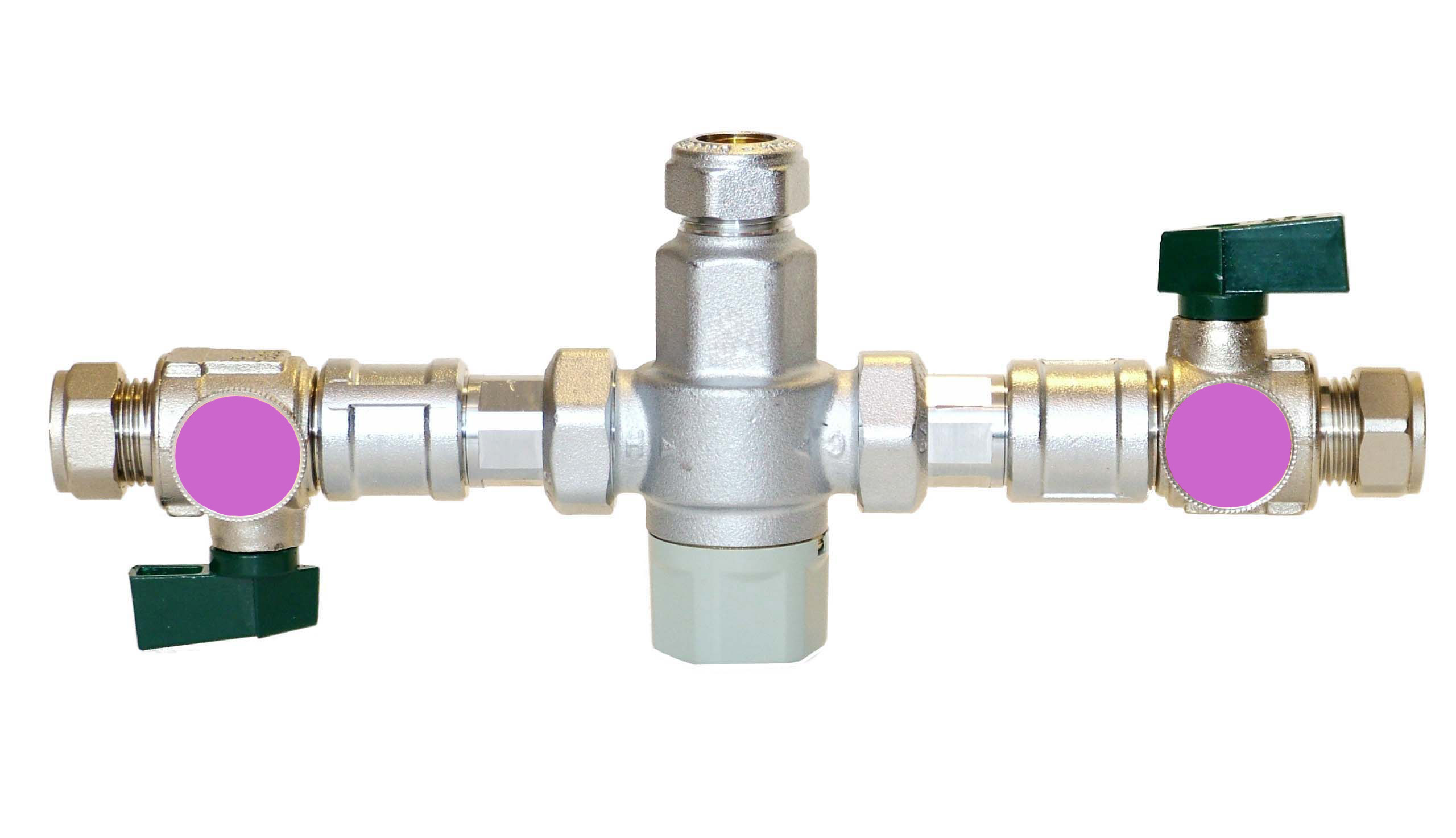

Thermostatic Mixing Valve 5213 c/w AFL

536 PRV Gauge 0.5-6 bar Compression

About us

Our comprehensive range, many water and energy saving (KIWA UK / WRAS Approved), include products for:

Backflow Prevention (Categories 5-4 and 3-1) − Booster Pumps −Non-Return Valves − Pressure Regulating − Flow Control and Measurement − Washroom − Care Shower - Heating − Isolating − Standpipes & Taps (Conceal A Tap & Tamperproof Standpipes & Hose Union Bib Tap)

From specifying through purchasing and onto after sale servicing you can rely on Arrow Valves to ensure the smooth running of any project no matter how large or small. We have accredited Service Engineers nationwide to undertake necessary annual testing.

Arrow Valves Team is BPEC qualified in Water Regulations - You will receive precise information and advice from our team, giving you peace of mind.

For high standard products, specialist expert service to assist with the essential task of adhering to the Water Regulations, contact Arrow Valves Ltd. For immediate technical information on products, quotations and more details on Water Regulations please visit our website.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations