13 November 2023 | FLUX Pumps International UK

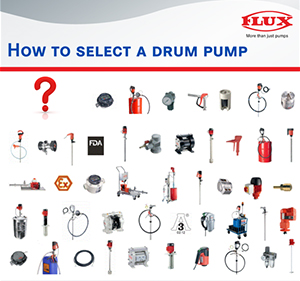

How to Select a Drum Pump

Transporting liquids is an essential part of the manufacturing process for many businesses.

Unlike solids, fluid cannot simply be stacked and moved. Transferring liquid isn’t just a case of pouring fluid from one vessel to another. Many factors play a part, such as time taken, the health and safety of workers, the size of storage containers and the application characteristics. That’s where a drum pump comes in. A drum pump is a portable pump used for transferring liquids from drums, barrels, IBC’s and tanks. They are often used for filling smaller containers and mixing vessels. If you are considering this efficient solution, you may be wondering how to select a drum pump.Flux invented the electric drum pump in 1950 and have since been one of the world’s leading manufacturers. In 2023, Flux Pumps were nominated for Product of the Year at the UK Pump Industry Association awards. As a customer-focused company, Flux takes the time to ensure each specific application receives the correct solution. So why does Flux consider the pump selection process to be important?

Why should you select a drum pump?

To protect employees and the environment, liquids should be handled in a safe manner with the appropriate dispensing equipment. Too often, avoidable workplace accidents result from the mishandling of liquids. In addition, many businesses waste product by using the incorrect equipment. Flux Pumps provides drum and IBC pumps, which are an efficient, safe and easy way to transfer fluids.

To ensure you have the right solution, there are many factors that should be considered. No two applications are the same and thus each may require a bespoke pump configuration. Flux always asks a series of questions about the application, in order to offer the best solution. Below we will investigate how to select a drum pump, including key aspects you should consider before making your purchase. Selecting the incorrect pump will result in workflow disruption and unnecessary extra cost.

How to select a drum pump

What are your requirements?

Firstly, at Flux we consider how and where the pump will be used and the application specifics. For example:

• Liquid characteristics − Our drum pumps are manufactured in a range of key materials, such as PVDF, stainless steel, aluminium and polypropylene. Knowing the type of chemical will allow us to select the correct materials and approvals - especially important if the fluid is flammable or corrosive. Our technical sales team consult resistance charts to check material compatibility. Using the wrong materials can cause the pump to fail. A mechanical seal extends pump life when abrasive media is being transferred. However, Flux seal-less pumps have a long service-life with clean liquids and will tolerate periods of dry running.

• Delivery pressure and flow - Some applications require higher flow rates to empty larger IBCs or tanks, whereas others may need higher delivery pressure in order to transfer the liquid vertically higher, through additional pipework or for transferring more viscous fluids. Our technical sales team consult pump performance curves and use a pipe loss calculator to work out pipeline pressure drop.

• Density and viscosity - Fluid density and viscosity will influence selection of pump design and motor power. Axial or semi-axial impellers are selected for liquids of different density and viscosity.

• Temperature - Temperature limits depend on pump construction and length. Hastelloy C is limited to 120 C, stainless steel and aluminium is 100 C, PVDF is 80 C and polypropylene is only 50 C.

• Power supply and motor approvals - Sites will have different motor preferences, for example, air driven vs electric. The location of the application is important. For example, an IP55 explosion-proof motor is required if the pump is used in a zoned area with concentrations of flammable vapours. If no power supply is available, Flux offers a battery-powered motor (the FBM 3100), which may be a useful option.

• Size of container- Depending on the container type, different length drum pumps can be provided. IBCs require longer pumps (usually 1200mm). Will you be switching between locations or containers? Will the drum be open or closed? This allows you to choose the correct clamping device or screw connection to secure the pump in the vessel. You will also need to ensure the pump will fit into the opening of the container by checking its diameter.

Pump selection

Next, identify which pump family suits the application best. Consider whether you need an impeller or progressive cavity pump. Impeller pumps, like the Flux 300 and 400 range, are typically specified for low viscosity applications (<1000 mPas). Progressive cavity pumps, such as our award nominated ViscoPower, are suitable for higher viscosity applications. Consider how often the pump will be used and for how long. What approvals are needed, e.g. EN1935 or FDA CFR 21 for food products, or Ex-certification if flammable vapours are present?

Moving onto the motor

Now select an appropriate motor. What voltage is required? Do you need an air-driven or electric-powered motor? Electric motors are typically 110v or 230v single-phase designs, however brush-less, three-phase and battery motors are available. Flux electric motors have an IP rating (dust and water ingress classification) of either IP24 or IP55.

Do you require the motor to be fully enclosed? Enclosed motors help protect the media from carbon dust and keep corrosive fumes out of the motor windings. Is variable speed control required, to adjust flow rate? What about duty cycle? All Flux commutator motors are S1 rated, therefore suitable for continuous running and will not cut-out during operation. Again, consider whether Ex-certification is required.

Compressed air motors are also available. Flux F416 air motors either have a ball valve to vary pump speed, or a lockable trigger. Our air motors are Ex-certified, therefore suitable for use in hazardous locations. However, they require a supply of dry, lubricated air for optimal vane life, plus they tend to be noisier and less efficient overall than electric motors.

Additional accessories

Accessories are also important when selecting a drum pump. Do you require hose? Conductive hose and fittings are required when pumping flammable liquids. Perhaps a flow meter is necessary for pumping accurate volumes? How about a hand nozzle to control dispensing? Would drum adapters or strainers be beneficial in your application? Flux Pumps provides a range of ancillary and accessories, allowing us to offer a complete system solution.

Additional thoughts on selecting the right drum pump

There are many other factors to consider when selecting the right drum pump. Those listed in this article are just a few examples. Flux technical support engineers are available to help with your enquiry. Our expertise and experience will guide you to the best pump for your individual task - particularly useful when handling dangerous or difficult high viscosity liquids. Contact us with your enquiry via email or visit our website to discover more about our product range.