Company details for:

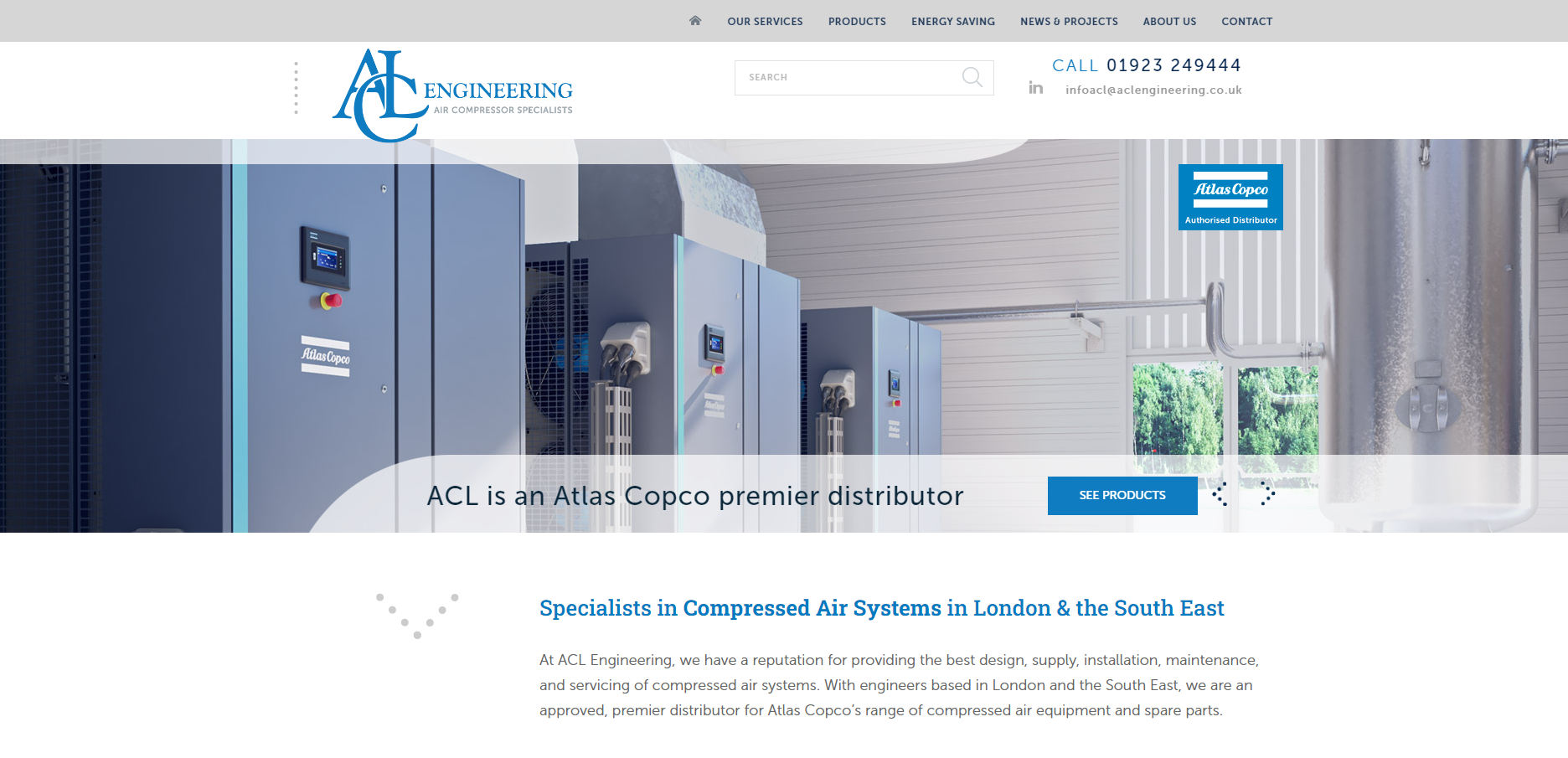

ACL Engineering Ltd

Anglia House,

Sandown Road,

Watford,

Hertfordshire,

WD24 7UA,

United Kingdom

Quick Links:

Products / Services

Air Compressors

Oil-Lubricated Air Compressors

GA FLX (Dual-Speed) Air Compressors

VSD (Variable Speed Drive) Air Compressors

Variable Speed Drive compressors are the energy-efficient future for businesses that don’t require continuous operation at full speed.

Oil-Free Air Compressors

100% Pure Clean Air

Atlas Copco Oil-free compressors provide 100% pure, clean air that meets the ISO 8573-1 CLASS 0 (2010) standard. CLASS 0 means zero risk of contamination; zero risk of damaged or unsafe products and zero risk of losses from operational downtime.

Air Treatment

Air Dryers

Atlas Copco air dryers remove moisture from the air providing clean, dry air, to protect and extend the life of your equipment and ensure the quality of your products. Each dryer system:- refrigerated dryer, adsorption dryer and membrane dryer, uses its own technique.

Air Filters

Condensate Treatments

Nitrogen Generators

Nitrogen Generator SKID

Oxygen Generators

Oil-Free Air Blowers

“Up to 80% of a blower’s lifecycle cost is consumed by its energy usage.”

Industrial Vacuum Pumps

Industrial Chillers

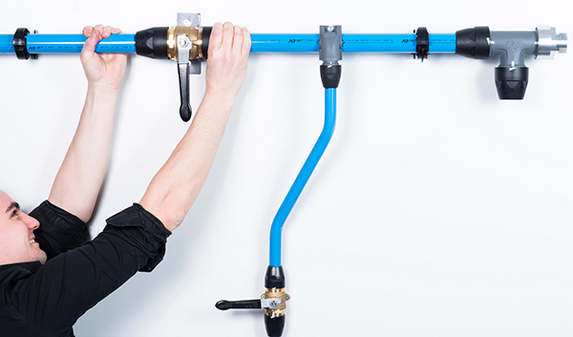

AIRnet Pipework

It is lightweight, robust, adaptable, easy to fit and comes with a 10 Year Warranty.

Compressed Air Energy Audits

At ACL we find that in many cases, this cost can be substantially reduced through various methods including: energy recovery, pressure reduction, air leak reduction, as well as the optimisation of operations through the appropriate choice of compressor size plus system control and regulation.

Digital Air Leak Detection

Accurate deduction of air leaks leads to a reduction in energy consumption and costs, as well as minimising CO2 emissions.

System Design & Specification

New Compressed Air System Installations

Whether your business involves manufacturing, production lines, conveyor systems, power tool operation, food production and brewing, medical laboratories, water treatment or metal fabrication, to name but a few − we are the experts when it comes to specifying a new system.

Supply & Installation

Planned Maintenance

Service & Repair

Breathing Air Quality Testing

WSE & WSE Inspection

Compressed Air Pipe Installation

About us

Atlas Copco is a global leader in industrial air compressor technology, recognised for its quality, reliability, and efficiency. Their range of air compressors, gas generators, and vacuum pumps provides versatile solutions for businesses of all sizes, from small enterprises to multinational corporations.

ACL Engineering proudly serves as a leading distributor for Atlas Copco.

Our Product Include:

Air Compressors

Atlas Copco is a globally recognised leader in air compressor manufacturing, trusted across the industry. Below are some of the top products that ACL Engineering frequently supplies, installs, and maintains.

Air Treatment

Ensure optimal air quality with Atlas Copco’s filters, dryers, and condensate treatments, expertly designed to provide clean, dry air tailored to your requirements.

Nitrogen Generators

Meet your nitrogen demands efficiently with an Atlas Copco nitrogen generator. These cost-effective, durable, and reliable units ensure a steady supply of high-quality nitrogen around the clock.

Oxygen Generators

Considering switching from purchased oxygen to on-site production? ACL Engineering offers comprehensive solutions, featuring Atlas Copco OGP+ units with advanced features that deliver exceptional benefits and substantial cost savings per unit of oxygen.

Oil-Free Air Blowers

ACL Engineering specialises in specifying, installing, and maintaining air blowers tailored to your exact requirements, ensuring maximum energy efficiency and cost savings.

… And more.

For over 40 years, ACL Engineering Ltd has been delivering expert compressed air services to diverse industries. Our extensive knowledge and experience enable us to provide cost-effective and energy-efficient solutions for all your compressed air system requirements.

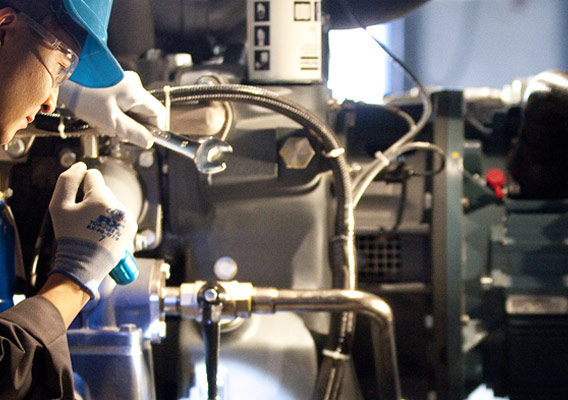

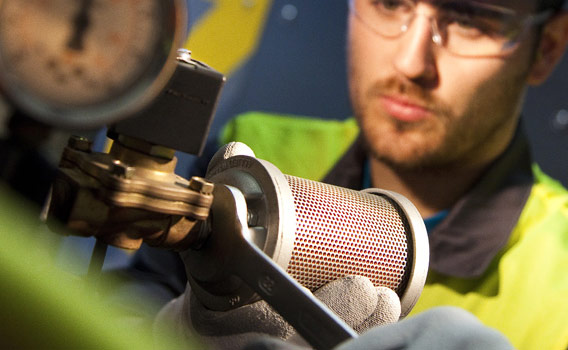

We specialise in every aspect of industrial compressed air supply, including consultation, system design, product specification, installation, maintenance, and repair. As an Atlas Copco Premier Distributor, we also service and maintain compressors, ancillary systems, and pipework from all manufacturers.

Compressed air systems are essential across various sectors, powering processes that keep businesses running smoothly. When issues arise, they can disrupt operations and productivity. Our engineers are experienced in troubleshooting all types of systems to quickly resolve problems and minimise downtime.

Images