Company details for:

Adnet Precision Engineering Ltd

Unit B3,

Nexus Court,

Gloucester Business Park,

Gloucester,

Gloucestershire,

GL3 4AG,

United Kingdom

Quick Links:

Products / Services

Precision Engineering Services

Adnet Precision Engineering operate from a 4200 square foot manufacturing facility based in Gloucestershire, England. Our engineering facility has a combination of quality management systems in place, along with the latest machining technology and finishing processes. We have also obtained the latest in surface measuring equipment (Marha Pocket Surf), along with Match IT MRP One CNC computer system.

Adnet have invested in computer systems to aid the service that we can offer.

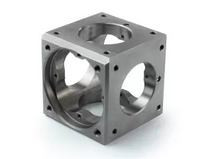

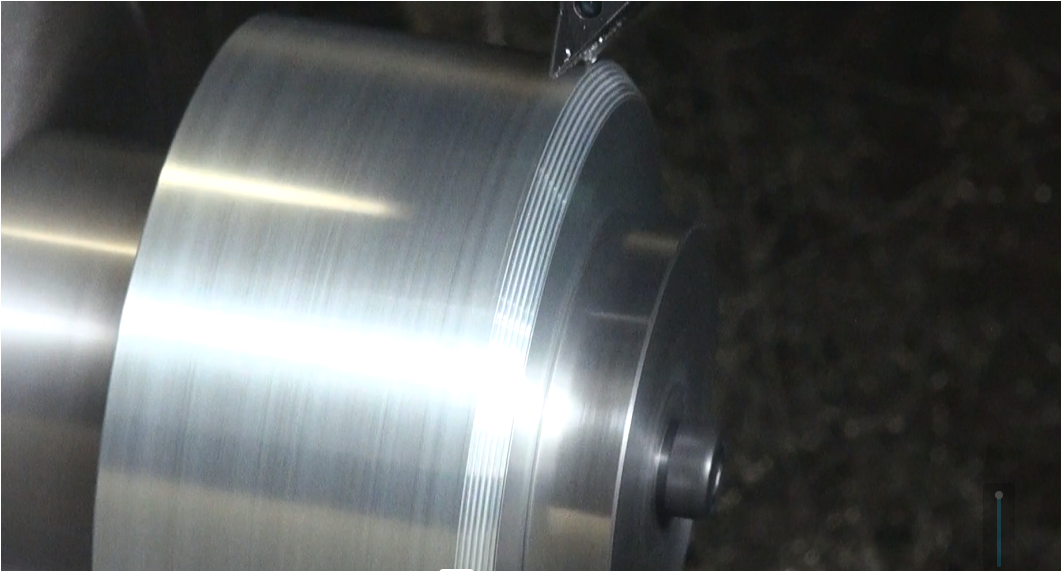

Extensive CNC Machining Capabilities

We provide a complete CNC machining and engineering solution, from customer ideas, drawings, sample products, right through to the manufacture of quality precision components.

CNC Milling in Various Material Grades

Aluminium alloys

Stainless steels 300 and 400 series 17-4PH

Aerospace material grades

Coppers

Brass

Engineering plastics

Titanium

Carbon & alloy

Steels

Colsibro

If your company requires a comprehensive CNC machine shop with good customer service and fast turnaround times, do get in touch. As a leading machine shop we serve the following markets: Aerospace, Defence, Pharmaceutical, Medical, Oil & Gas, Metrology, Telecoms, Special Purpose Machinery, Semiconductor, Seismology, Liquid and Powder Rheology, OEO and more.

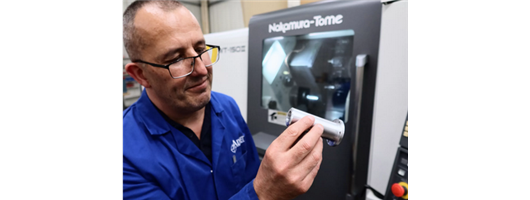

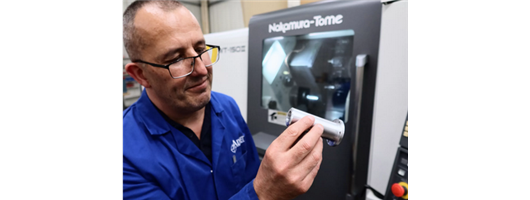

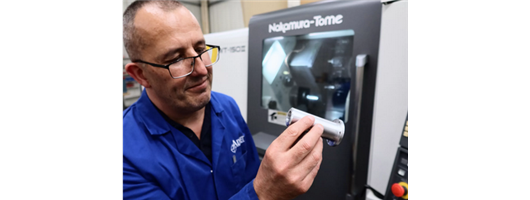

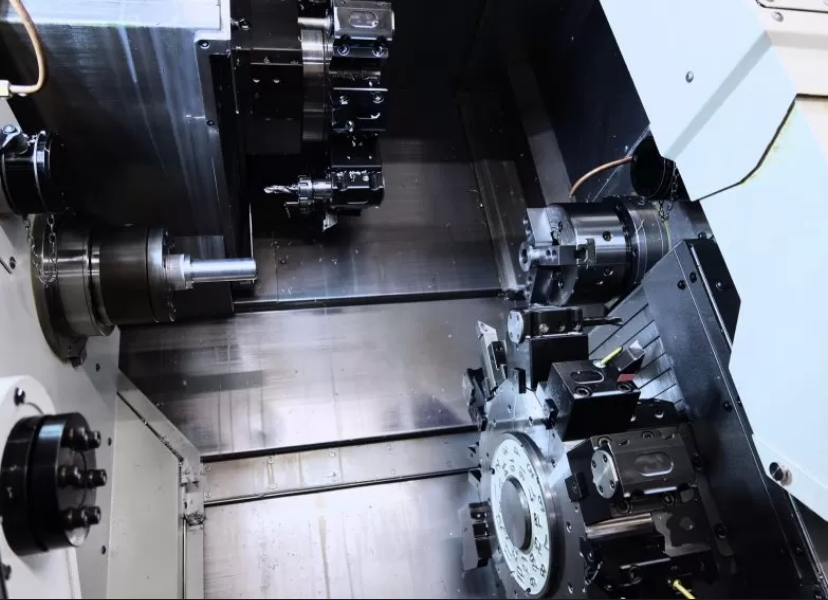

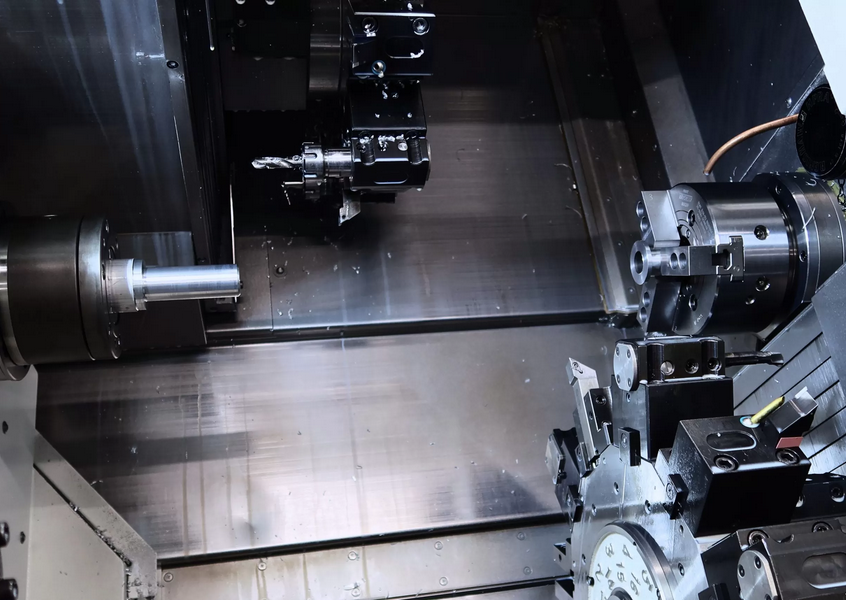

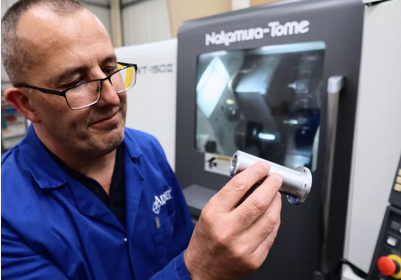

To compliment our machining facilities, we have also obtained the latest in CNC machining technology with a Maier ML32C2 sliding head and Nakamura twin spindle. For more information on how we can deliver quality milled & turned parts do get in touch.

CNC Sliding Head & Twin Spindle Turning

Our well equipped CNC turning facility enables us to provide CNC turning services or a complete subcontract engineering solution. This could include multiple processes being put in place, such as: 3 & 4 axis CNC milling, CNC turning, grinding, finishing & assembly, quality control with reliable communication processes and systems, altogether helping reassure customer satisfaction levels are high and deadlines are being met.

Volume Turned Parts Production

Our Maier sliding head machining capabilities enable us to provide a fast turn around service on complex turned parts and machined components in most materials, including:

Mild steel, brass, copper, aluminium, engineering plastics, titanium, stainless steel, steel alloys and duplex.

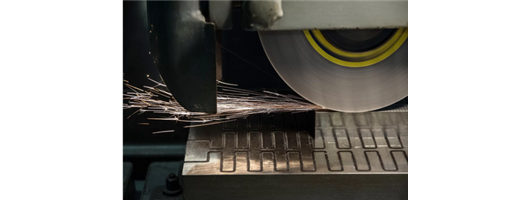

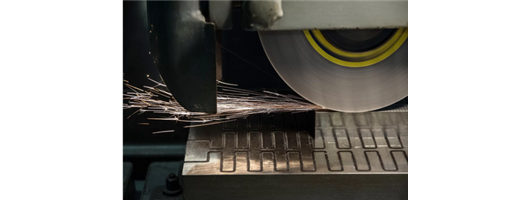

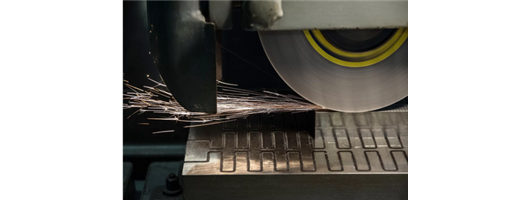

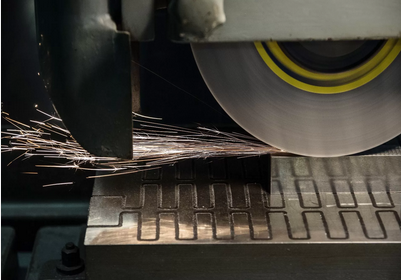

Various Grinding Capabilities

Our CNC machining and grinding capabilities enable us to machine in stainless steel and aluminium alloys, in batch sizes from single items up to 2000.

Component Assembly & Finishing

We have a dedicated clean area for fitting and finishing of assembly components. Adnet can offer the following finishing services, anodising, zinc and electroless nickel plating, gold and copper plating, chemical blacking and painting. Our products are fully assembled, tested and calibrated.

If you require top quality precision machined components and finished assembly parts manufactured to exact requirements, please contact us today for a friendly and efficient service.

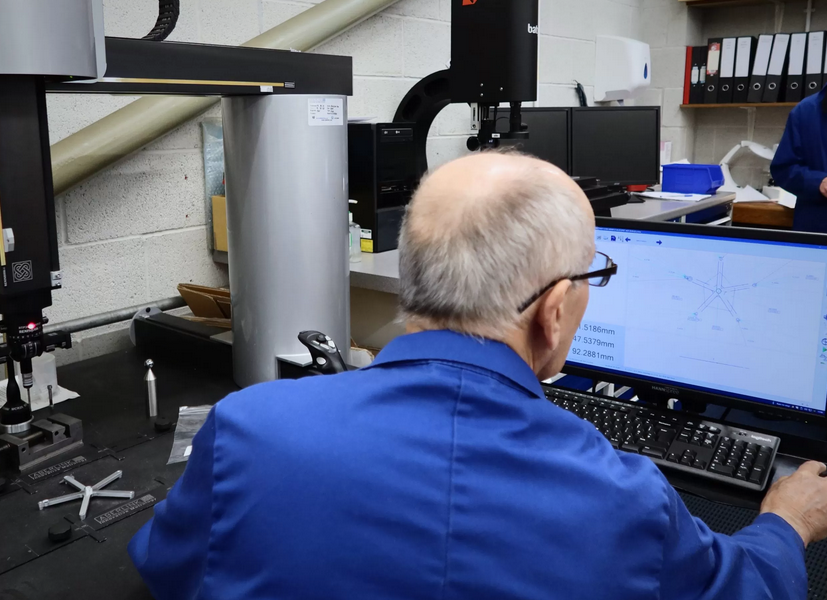

Dedicated Quality & Inspection Department

Our inspection department has all the latest metrology equipment needed to measure machined components. This includes a CNC CMM Aberlink Axiom fitted with a Renishaw touch trigger probe.

We have invested in a Baty venture camera, allowing none contact measuring of small components. The Baty none contact measuring machine is ideal for picking up of fine details which can be stored and shared with our customers.

CNC Machines

Turned Parts

CNC Sliding Head Machining

CNC Turning

CNC Milling

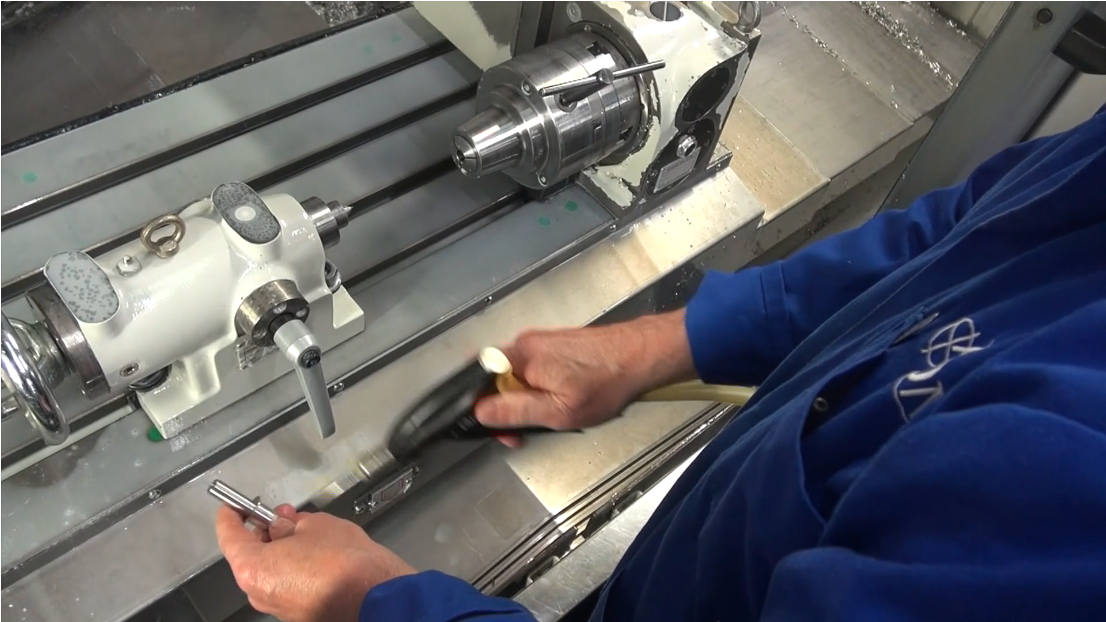

Conventional Turning

Conventional Milling

Adnet Precision Engineering Ltd is a trusted provider of conventional milling services, offering precise and versatile manufacturing solutions. With their expertise in precision engineering and machining, they specialise in utilising conventional milling machines to produce a wide range of components with exceptional accuracy and quality. Adnet Precision Engineering Ltd understands the importance of traditional milling techniques and their applicability to various industries. Their skilled team of engineers and technicians proficiently operate conventional milling machines to deliver precise and intricately machined parts. Whether it's for prototyping, small-scale production, or specialised applications, Adnet Precision Engineering Ltd provides conventional milling services that adhere to the highest standards of craftsmanship and precision. With their commitment to customer satisfaction and their focus on delivering reliable and top-quality milling solutions, they are a trusted choice for businesses seeking exceptional conventional milling services.

Jig Boring

Adnet Precision Engineering Ltd is a reputable provider of jig boring services, offering precise and accurate manufacturing solutions. With their expertise in precision engineering and machining, they specialise in utilising jig boring machines to produce components with exceptional precision and fine detailing. Adnet Precision Engineering Ltd understands the critical importance of accuracy and tight tolerances in various industries. Their skilled team of engineers and technicians expertly operate jig boring machines, which are designed specifically for precision boring and hole machining. By utilising advanced measuring systems and meticulous techniques, they ensure that each component meets the exact specifications of their clients. With a focus on delivering high-quality results, Adnet Precision Engineering Ltd provides jig boring services that exceed expectations. With their commitment to customer satisfaction and their dedication to precision engineering, they are a trusted choice for businesses seeking reliable and top-quality jig boring solutions.

Drilling

Surface Grinding

Cylindrical Grinding

Fitting, Assembly & Finishing

About us

Quality Rapid Engineering Service

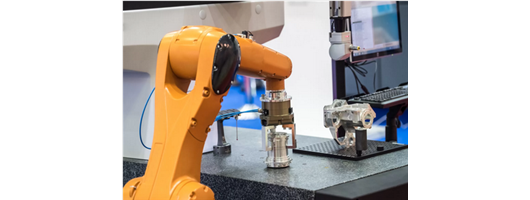

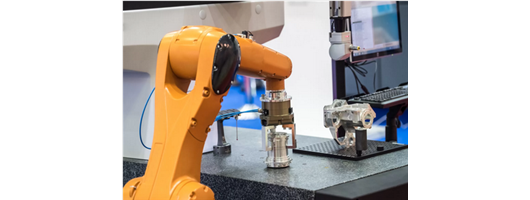

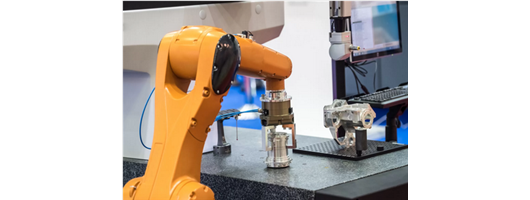

Adnet Precision Engineering recognizes that our customers demand superior quality and exceptional service, which is why we have made significant investments in the latest CNC machines, cutting-edge technology, and apprentice training programs. Our goal is to not only meet but exceed customer expectations. With our expertise, extensive experience, and abundant resources, we are capable of producing intricate CNC turned and milled components for challenging applications worldwide.

We have made significant investments in our quality department, which is solely dedicated to ensuring top-quality parts. This department is equipped with advanced equipment such as CMM and Baty vision inspection systems. Our precision engineering facility boasts a variety of capabilities, including CNC twin spindle multi-tasking machining, CNC sliding head mill/turn, CNC turning, CNC milling, grinding, conventional machining, jig boring, drilling, fitting, and assembly areas.

At Adnet Precision Engineering, we have the capability to machine prototypes, low volume runs, and large production runs in a range of material grades. These grades include stainless steels, aerospace grades, aluminum alloys, copper, brass, engineering plastics, titanium, carbon and alloy steels.

Our product range can be used in a variety of markets, including Aerospace, Metrology, Semiconductor, Pharmaceutical, Oil & Gas, Rheology, Seismology, Telecommunications, and Defence industries.

Our Capabilities Include:

CNC Machining

At Adnet Precision Engineering, we take great pride in our precision machining services for high-quality CNC milled, turned, and finished parts. We can produce batches of 1 to 2000 components runs in both standard and exotic materials.

CNC Milling

Our company boasts an extensive selection of both conventional and CNC milling capabilities, which allows us to promptly address our customers' requirements.

CNC Turning

Our team of CNC turning operators and engineers has significant expertise in CNC machining and turning complex parts and precision components.

Turned Parts

We manufacture a broad range of standard and intricate turned parts, as well as precision machined components, for numerous critical industry sectors in the United Kingdom.

Grinding

In addition to our diverse range of CNC machinery, Adnet Precision Engineering also offers surface and cylindrical grinding services for precision machined components and parts of superior quality.

Assembly

Adnet Precision Engineering provides a comprehensive service for the assembly, fitting, and manufacturing of finished components for companies across the nation.

Throughout the years, we have formed strong partnerships with our clients, and we take immense pride in our ability to effectively communicate and deliver high-quality machined products.

If you are seeking top-quality precision engineering services, please do not hesitate to contact us.

Images