Company details for:

Advanced Plastic Technology

44 Potters Lane,

Kiln Farm,

Milton Keynes,

Buckinghamshire,

MK11 3HQ,

United Kingdom

Quick Links:

Products / Services

Design Compatibility

We have in-house Sales Engineers to help you create your product, providing key information to enable you to make a decision on material selection and provide you with any questions you may have on Plastic or processing types.

For drawing solutions we use Solidworks™, Coral Draw™, AutoCAD™ among others and for machining we use Corel, CADCAM™ Etc.

If you need assistance designing your plastic part, we can help you by providing information on manufacturing capabilities for specific features you are trying to achieve or material property’s that your design requires from a particular plastic type.

Our expert staff can help determine the optimal method for producing your part and establish realistic tolerances for building it in plastic.

Our team has been greatly applauded for our continued high standards in helping clients achieve their vision. We are capable of creating a range of specialist bespoke products, from initial prototypes and one offs to full production runs. We can offer clients a one stop shop for new projects, complex assemblies and also solutions to problems with existing products.

Materials

Virtually all Industrial Engineering Plastics Materials available today can be Machined and Fabricated at Advanced Plastic Technology. We offer customers a wealth of knowledge in the huge range of plastic materials in sheet, rod, fabricated and machined form.

If you are a Design Engineer and you are looking for advice on selecting a suitable plastic material, we can advise you quickly on the most appropriate plastic for your component or assembly. We are not tied to any one material manufacturer − we work with more than a dozen. As such, we can offer you impartial advice on the most suitable material for your needs.

We have not listed every grade and every trade name, so if you are unsure if we can process your chosen plastic, just give us a call.

Supply Chain

Our goal is to fully meet your supply needs. We have the ability to supply components, sub-assemblies and full general assemblies. We have the ability to pack and label to your requirements. We have the ability to supply kits of parts. We have the ability to supply one or more items from a bill of materials. We have the ability to supply semi-finished components to your nominated third party for further processing. We have the ability to supply you with raw materials and then for you to send us part processed items for completion by us. Chances are, whatever your supply chain need, we will be able to help.

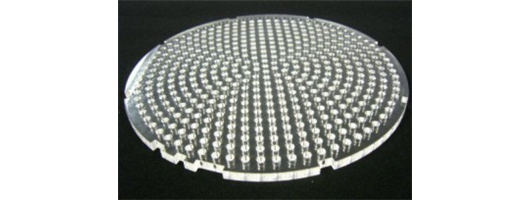

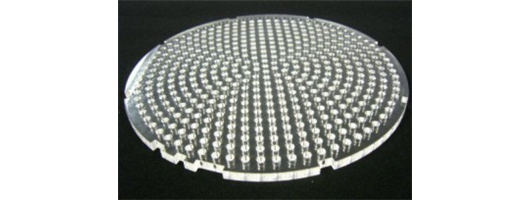

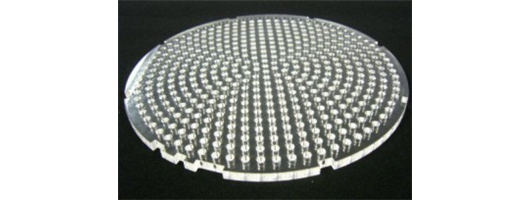

CNC Routing

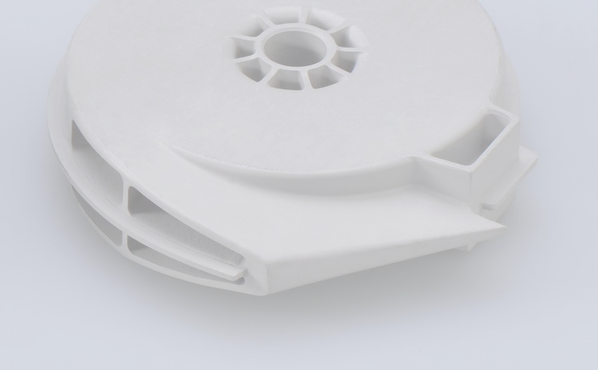

Injection Moulding

Most thermoplastics can be processed by Injection Moulding. The table below lists some of the commonly used materials:

Acrylonitrile-Butadiene-Styrene ABS

Nylon PA

Polycarbonate PC

Polypropylene PP

Polystyrene GPPS

Injection mouldings count for a significant proportion of all plastics products from micro parts to large components such as bumpers and wheelie bins.

Virtually all industry sectors use injection moulded parts - below is a few examples of the most common sectors that we supply:

Aerospace

Hospitalities/Catering

Medical

Industrial equipment

Automation

Consumer Electronics

The flexibility in sizes and shapes possible through the use of this process have consistently extended the boundaries of design in plastics and enabled significant replacement of traditional materials thanks to light weighting and design freedom.

Whether you are looking to source a new supplier for an existing product or you have a new product that you are developing we can help.

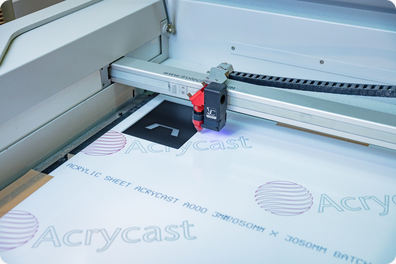

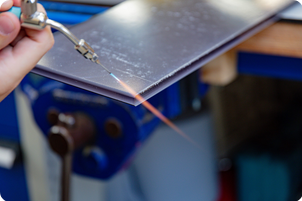

Laser Cutting

Laser Engraving

Key benefits

the quality feel of an engraved component

ability to engrave small font sizes

superior reproduction of fonts and logos

There are many applications for laser engraving, from equipment and component marking though to promotional products. Control panels and equipment fascias are a speciality.

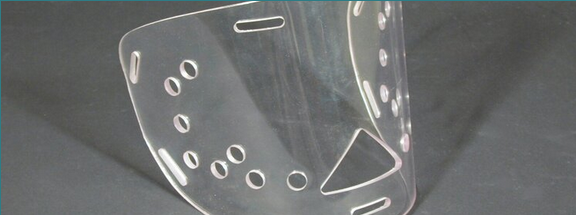

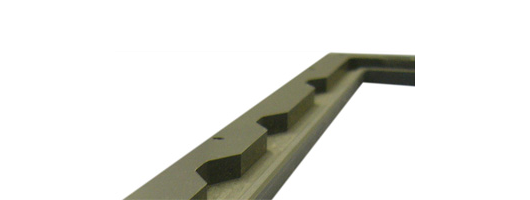

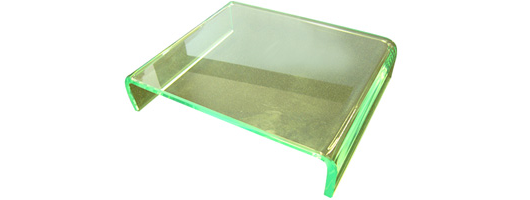

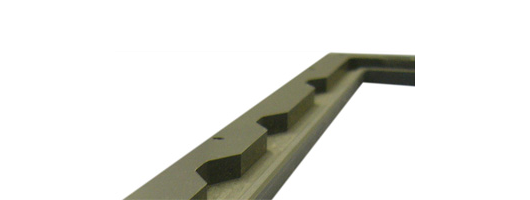

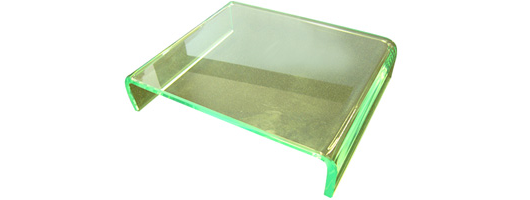

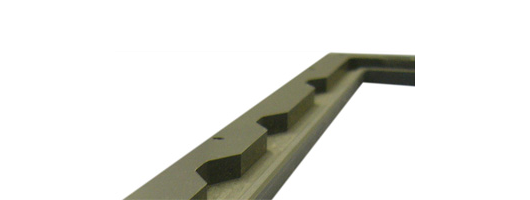

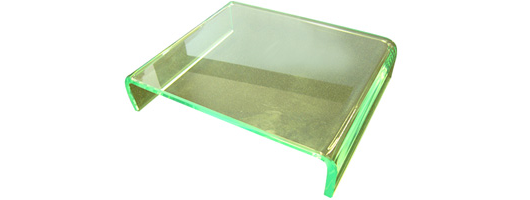

Plastic Fabrication

Chemical bonding provides good mechanical strength and can create mitre, face, lap and butt joints. It also has the benefits of being a quick process, can be used to produce clean-looking joints on clear materials and does not ‘contaminate’ the plastic with metal parts.

Mechanical fixing is achieved with a range of well-known fasteners. This is generally used when superior mechanical strength is required.

Edge polishing is used to give a desirable polished look to a component. This is mainly used for acrylic components since they polish well and are often used for highly visual applications. We flame polish, wet sand and buff polish.

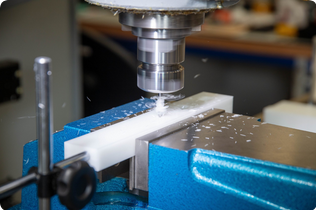

Multi-Axis CNC Machining

Multi-axis CNC machines are typically more complex and expensive than 3-axis machines, but they offer several advantages, including:

The ability to produce complex parts in a single setup, which can save time and money

Increased accuracy and repeatability

Improved surface finishes

Reduced tool wear

Increased productivity

Assembly & Packing

Assembly & packing services can offer a number of benefits to businesses, including:

Reduced costs: Assembly & packing services can help you to reduce your costs by eliminating the need to invest in your own assembly and packaging equipment and personnel.

Increased efficiency: Assembly & packing services can help you to increase your efficiency by freeing up your time and resources to focus on other aspects of your business.

Improved quality: Assembly & packing services can help you to improve the quality of your products by ensuring that they are assembled and packaged correctly.

Reduced risk: Assembly & packing services can help you to reduce the risk of damage to your products during shipping and handling.

About us

Through developing new and innovative methods of designing plastic components, we at Advanced Plastic Technology are able to keep all operations and technologies flexible enough to ensure a wide variety of supplies and sub-assemblies.

Here at Advanced Plastic Technology, we believe that cost, quality and fast delivery are absolutely essential for excellent customer service, so we have a team of experienced specialists who are devoted to improving these factors and offering help and support wherever possible. We as a company ensure that all employees participate in ongoing improvement activities so that they can provide consistently reliable service.

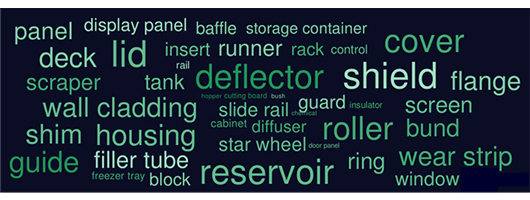

Here at Advanced Plastic Technology, we supply our wide range of products to a vast array of industries and sectors, which include Capital Equipment, Print, Construction, Shop Fitting, Aerospace, Industrial Equipment, Water, Electronics, Audio Equipment, Lighting, Nuclear, Specialist Automotive, Engineering, Lab Equipment, Chemical Plant, Food Processing Machinery, Oil and Gas, Rail, Building Materials, Kitchen Equipment and Medical Devices. Each of these industries have a need for plastic components and sub-assemblies, and rely on our extensive knowledge and experience as well as our excellent process capabilities.

Through the use of plastic products and services, these industries and sectors will gain better quality, more reliable delivery and advanced materials expertise. For example, one advantage of choosing polycarbonate over glass is that it is a clear plastic material which is much stronger and more durable. Plastic panels are also less expensive to make and are more beneficial than using painted sheet metal.

Advanced Plastic Technology has supplied a wide range of plastic-related services for over twenty years, including Plastic Laser Cutting, Laser Engraving, CNC Machining Plastic, CNC Routing Plastic, Line Bending, Drape Moulding, Fabrication, Welding and Assembly. We as a company work closely with clients and maintain positive working relationships to ensure that their needs are met quickly and efficiently. We are able to review designs and point customers in the right direction so that they can find the best fit for them.

We at Advanced Plastic Technology are always willing to offer and suggest a variety of options for clients to choose from and tweak designs to maintain high quality and low costs. Throughout the design process, our company offers product packaging, insert fitting, mechanical assembly, polishing, heat treatment and printing to all clients, which results in meeting their requirements and exceeding their expectations, therefore boosting our reputation and leaving customers satisfied every time.

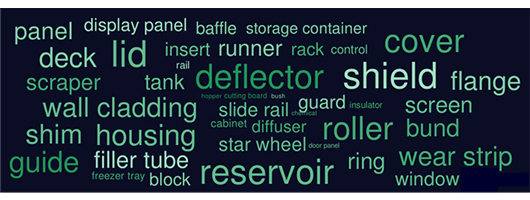

Images

Brochures

Trade Associations