Company details for:

Algar Air Compressed Air Engineers Ltd

Unit 2,

Bessemer Court,

2 Trent Street,

Sheffield,

South Yorkshire,

S9 3XU,

United Kingdom

Quick Links:

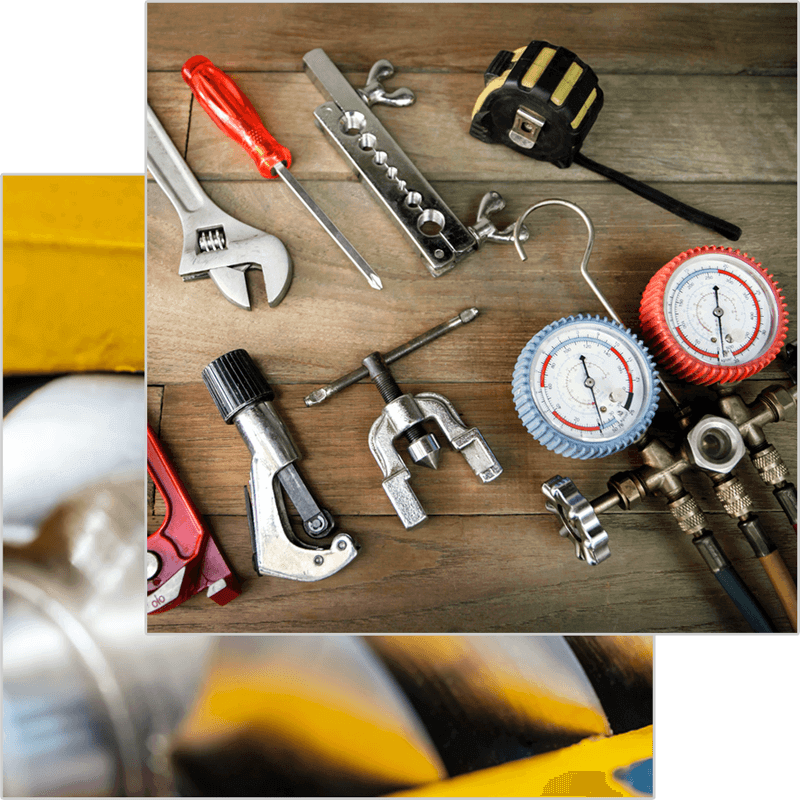

Products / Services

Breakdowns

That’s why we’re on hand, 24/7 to get you back up and running − so you keep downtime and lost productivity to a minimum.

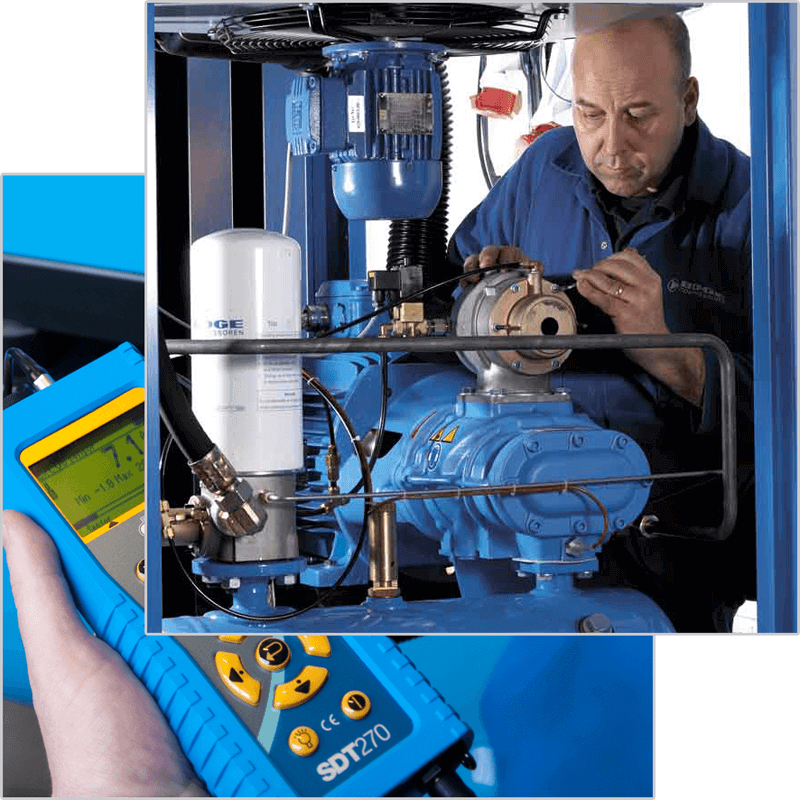

Servicing & Service Contracts

Since 1984, we’ve been helping businesses across the UK do just that. And because your business’ compressed air demands are different to any other, we tailor the servicing so it matches your business needs, your equipment and your budget.

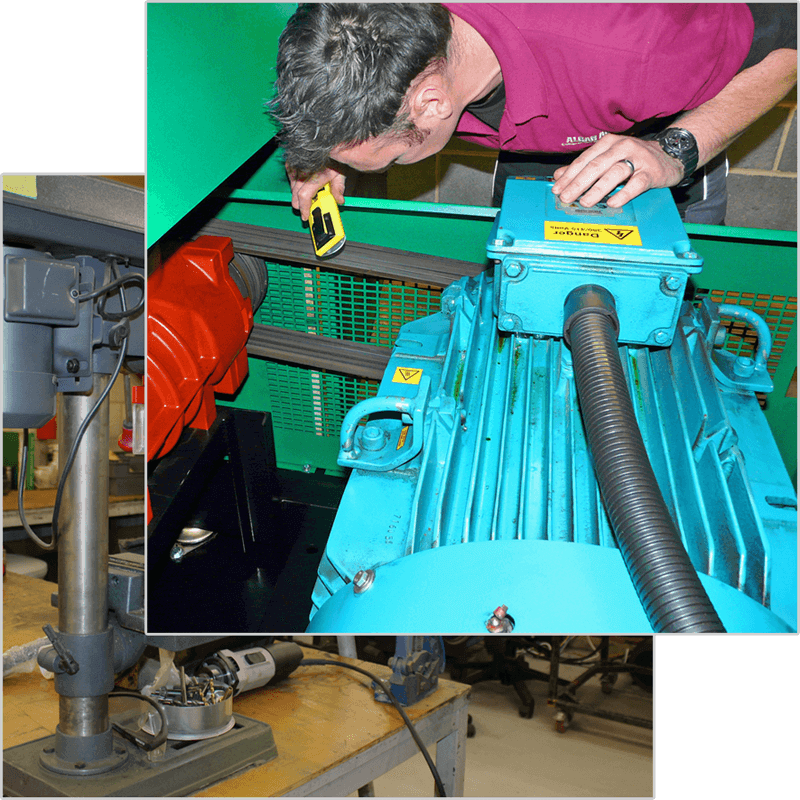

Repairs

Maintenance

How much easier would it be if, no matter what the problem, you had just one name to remember, and one number to call?

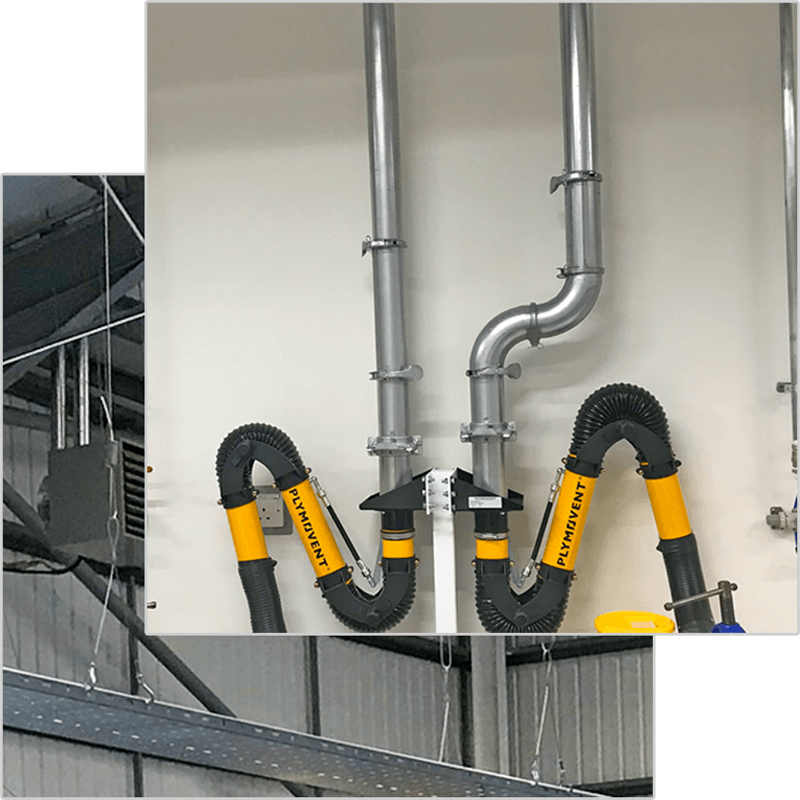

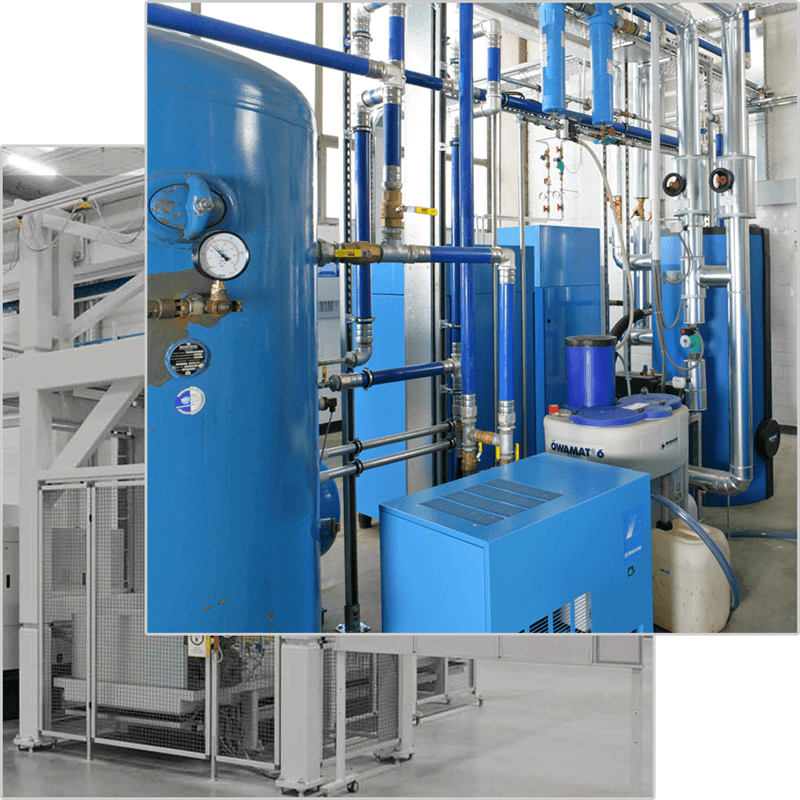

Pipework Installations

But with the right design you can improve power and efficiency and cut operating costs. That’s why, before our engineers clip a single pipe in place, we’ll work with you to design the system that will work harder for your business.

All our engineers are skilled pipe-fitters and experienced air compressor engineers. We believe that’s important because it means the pipework systems they install aren’t designed in isolation. They’re built to work perfectly with existing compressors and ring mains.

Ducting

Inlet air needs to be clean. It also needs to be cool, but it can’t be so cool that it freezes because that would cause havoc with condensed moisture in the system. Exhaust air is hot, so it’s important to ensure air vented by the compressor isn’t sucked straight back into the system as the compressor will overheat. So how do you separate hot air from cold, and maintain the right balance to keep your compressor working effectively? With ducting.

Ducting ensures hot air is driven away from your compressor, and that cool, clean air is fed to it. It helps keep the air that feeds your compressor free from contaminants. It helps reduce motor wear. And it helps ensure your compressor can keep doing its job reliably for longer.

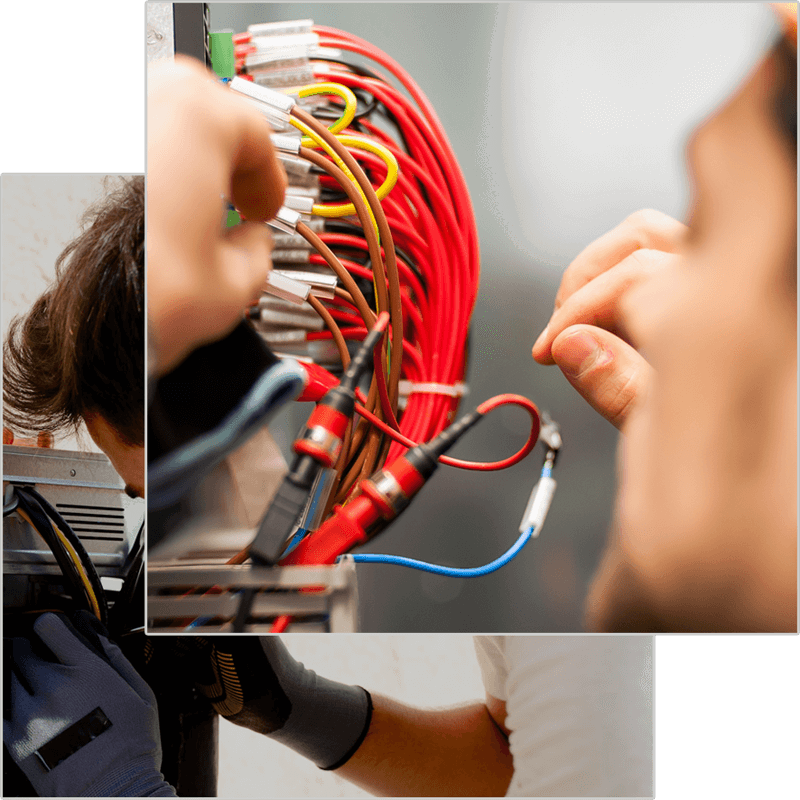

Electrical

Every air compressor needs connecting to the power supply. But beyond electrical power, there are a host of factors that also need considering if your compressed air installation is to be able to do its job effectively and efficiently.

Fortunately, Algar Air’s engineers have both sides of the equation covered − the electrical know-how to get your compressor up and running, and the expertise to ensure every other element, from siting the compressor to pipework, ducting and wate management is in place too.

And when you have your electrical and air compressor expertise all in one place you save time and money.

Removal, Transportation & Reinstallation

Most importantly, when a move to larger premises means you need more air power, a new pipework layout, expanded ducting or more, we’ll ensure the system is fit for the new premises.

If you’re planning a move, and whether you need one air compressor shifting or an entire factory floor, call us for a free estimate.

Testing & Certification

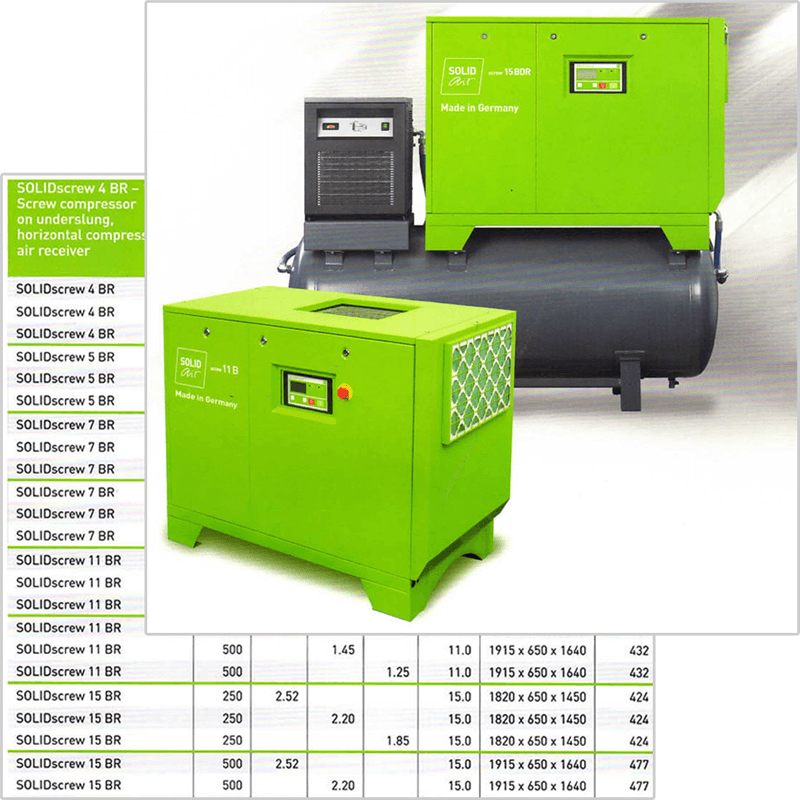

New Equipment

That’s where we come in.

With decades of expertise, we’ll make creating, expanding or upgrading your system simple.

Used Air Compressor Equipment

Take the gamble out of buying used compressed air equipment. Talk to us.

Staying in control of your business budget means keeping costs low. One way of doing that is by choosing used air compressor equipment rather than brand new machinery. But used air compressors only save you money if they’re capable of doing the job you need, and are reliable enough to keep doing it.

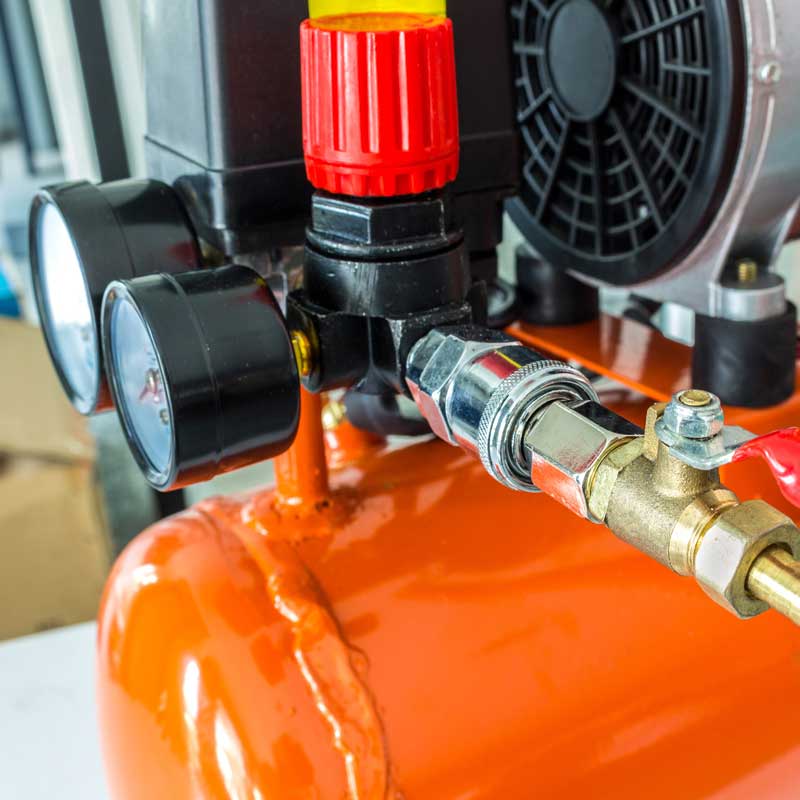

Air Receivers

Inline Filtration

If your compressed air system is to perform at its best it needs clean air. Yet as most air compressors are on factory, garage and workshop floors, clean air can be tricky to come by.

Our air compressor filters protect your production lines and processes from contamination, removing everything from dust particles to fine oil vapour.

Because every business’ filtration requirements vary, so do our filters.

So whether you need carbon activated filters to scrub the oil from the air flow or clean air filters that conform to respiratory protection standard BS EN 529:2005, we’ll be able to help.

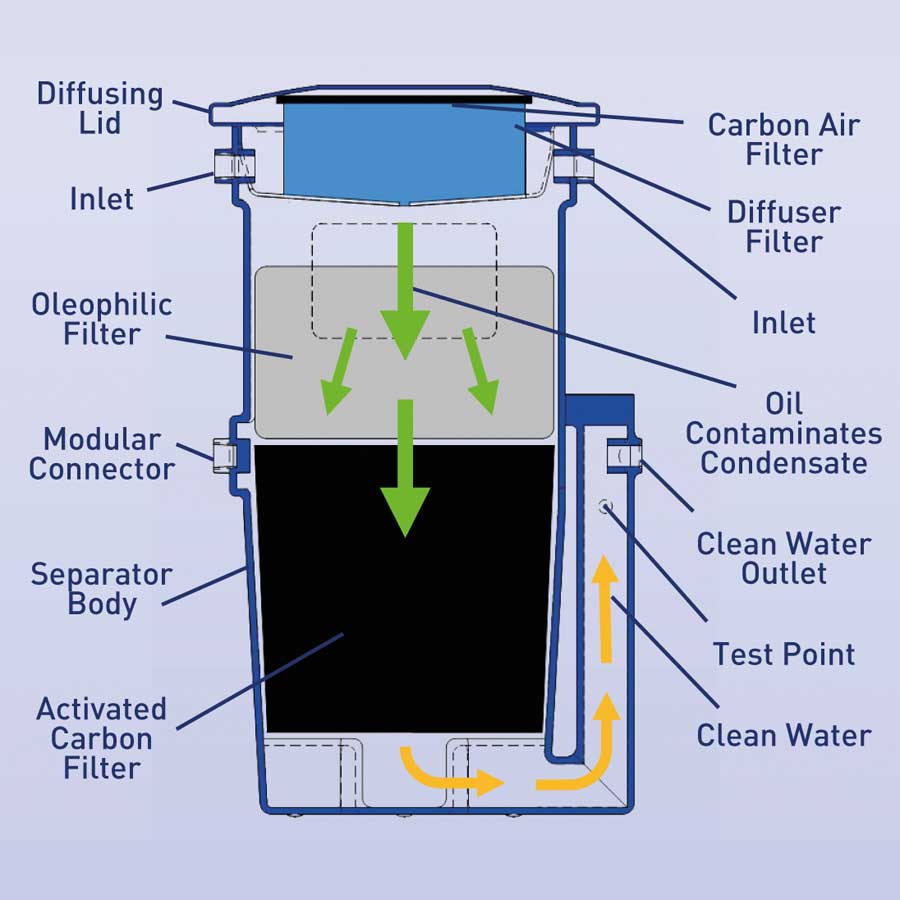

Oil & Water Separators

Fail to meet your Condensate Drainage Regulations responsibilities and it won’t just be the water your business discharges that is contaminated. Reputations and business performance can be affected too.

Algar Air supplies the oil/water separators that ensure your compressed air system produces only clean waste. Our separators are available to buy independently as one-off purchases, or as part of a comprehensive compressed air installation package.

Refrigerant & Desiccant Dryers

The combination of heating and cooling that is part of every air compression system results in condensation.

That could be bad news for your air compressor because moisture can damage its working life. And it could be bad news for your products, because moisture could damage them too.

That’s why you need the right dryer.

Hire Air Compressor Equipment

When your air compressor is a crucial piece of equipment in your business, it pays to ensure your choice of compressor is the right one.

We can help you with expert advice.

But if you want to be doubly sure, ask us about hiring your air compressor to check it’s exactly the right option for you.

And trying before you buy isn’t the only reason our customers choose to hire an air compressor with Algar Air. You’ll find more reasons below.

Air Compressors for Every Purpose

Oil-Free Air Compressors

What is an oil-free compressor?

Traditional air compressors are lubricated by oil that protects the pistons or rotors from wear.

Oil-free compressors may use water as a lubricant, or tough materials like carbon fibre piston rings, to avoid the need for oil. Without oil in the compressor, no oil can escape to contaminate the products you are manufacturing.

Piston Air Compressors

What is a piston reciprocating air compressor?

Reciprocating air compressors use a piston to generate pressure by positive displacement. Air is drawn into the cylinder and ‘squeezed’ by the piston, increasing pressure.

Screw Air Compressors

What is a screw air compressor?

Screw air compressors generate pressure using two screws (or rotors) − one male, one female. These draw in and trap air between them as they spin together. The trapped air is forced along the screws while the space between the rotors decreases. This compresses the air.

Vane Air Compressors

Why choose a vane air compressor?

Vane (also known as sliding or rotary vane) compressors have several benefits:

Good for continuous air supply: Need a steady, reliable supply of air? Vane compressors do the job particularly well.

Good for moderate pressure applications: Tyre inflation, conveyors, paint shops, agricultural applications and air knives − vane compressors are ideal for situations like these; less so where constant high pressure is required.

Durability: Regular maintenance is particularly important for a vane compressor, but the advantage is that it should be a good while before you need to replace it, as they typically enjoy long working lives.

Low noise: Modern vane compressors are relatively quiet.

Knowledge Hub

Is renting reliable? And how can you troubleshoot problems? Find out in the Algar Air Knowledge Hub.

We want to make choosing your next air compressor, or maintaining the one you’ve got, easier. When you don’t know the answers, we do. Just call us on 0114 243 2347 or contact us.

But before you email or call, take a quick look at the posts in the Knowledge Hub. You may find the answer’s already here.

Air Compressor Types

There are several ways of compressing air.

What’s the difference between them, and which is best for your application?

Air Compressors, The Law & You

The law relating to compressed air systems is covered by The Pressure Systems Safety Regulations 2000 and the Pressure Equipment Regulations 1999.

The regulations are designed to improve safety in relation to air compressor systems by reducing the risk of failure. They do that by requiring employers to comply with the following:

Provide safe and suitable equipment: that is suitable for its purpose, made from suitable materials and capable of being operated safely (e.g. without having to clamber through cables and pipes to get to it).

Know the operating conditions: including the operating limits of the compressed air system, operating instructions, and processing conditions including correct pressures and temperatures.

Fit suitable, correctly functioning safety devices: and ensure they are set correctly, that warning devices are noticeable, that they are in good working order, and that they cannot be tampered with.

Carry out suitable maintenance

Train users appropriately

Have your compressed air equipment examined by a “competent person”: you can find out more about certification of your compressed air system, and how our chartered engineer can be your “certified person” if you don’t have one, here.

About us

Equipment

Air Compressors

We have a variety of different types of Compressors on offer. Our most common types are Piston/Reciprocating, Screw and Vane Air Compressors.

Air Receivers

Our Air Receivers are available as a package or individually. New Compressed Air Receivers from our standard range are available at 50 to 5000 litres. Bespoke Service Designing and Supplying can be arranged to you specific requirements. All our Air Receivers comply with BS5169 standards and are supplied with Safety Valve, Auto Drain and a test certificate.

Refrigerant/ Desiccant Dryers

We offer a range of Refrigerant/ Desiccant Dryers to suit your requirements.

Oil Water Separators

Oil Water Separators are a must have if you own Filtration Equipment, Air Receivers or Refrigerant Dryers.

Used Compressed Air Equipment

To find out our current range of second hand equipment, please call us on 0114 243 2347 or fill out the contact form on our website.

Installation & Services

• Bespoke Servicing

• Service Contracts

• General On-site Maintenance

• Breakdowns

• Electrical Installations & Work

• Removal, transportation & re-installations

Sponsored Links

Articles / Press Releases

Reviews

Trade Associations