Company details for:

Aluline Grease Management Services

59-62 Brindley Road,

Astmoor Industrial Estate,

Runcorn,

Cheshire,

WA7 1PF,

United Kingdom

Quick Links:

Products / Services

Above Ground Grease Traps

Under Ground Grease Traps

(As a manufacturer Aluline can make Grease Traps to suit any requirements of our clients)

Lint, Hair, Plaster & Starch Separators

We advise customers to check quantities of detergent used in the laundry programme to ensure minimum discharge of the chemical is achieved. The liquid products used in the dry cleaning process should not enter a drainage system unless approved by water companies and the environment agency.

Oil & Petrol Separators

The Hydrocarbons enter the trap with water.

Operations of the Trap

Hydrocarbons enter the trap with water. They strike the plate and this releases hydrocarbon globules which then float to the surface. Heavier silt and sludge sinks to the bottom of the trap. Most suspended solids will sink to the bottom of the trap as they absorb water and become heavier. The last compartment at the outlet allows only grey water to return to the waste water systems.

Fitting Units

The unit can be fitted into a space 75mm wider than the actual Separator.

Manufactured

Stainless Steel A1S1304 with pedestrian aluminium durbar lid. Screw fixed Stainless Steel screws.

(Heavier duty lids of galvanised mild steel on request).

Adjustments (extra cost in 100mm pedestrian increments)

Increase the T size or invert level to ensure the lid is at the finished ground level and the pipe meets the existing invert datum.

Coffee Catchers

BDN6 Dosing System

The reduction of food, oil and grease in sewer systems can be accomplished and the production of sulphuric acid / sewer gas producing anaerobic bacteria reduced.

SOGT Steam Oven Grease Traps

Specially designed and sized for streaming / convection ovens with either right or left hand side inlets. The Stainless Steel design is a simple and cost effective method of grease removal. Can be used in conjunction with Alubio-Blocks to assist cleaning. Available in both right and left Inlet / Outlet models.

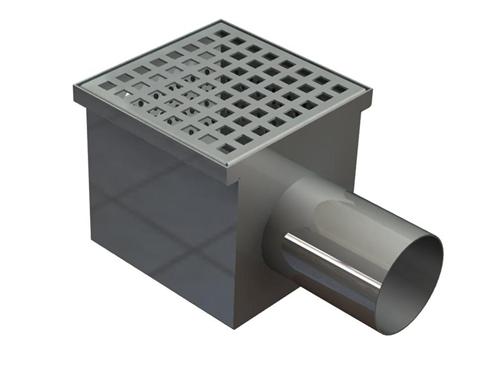

Gullies & Channels

Ideal for Commercial and Industrial Kitchens, Food and Beverage, Chemical, Pharmaceutical Industries, Building Exteriors, Parking Building and Under Ground Garages and more.

Survey

A survey can give real time information on existing installations and can be used as a guide for any maintenance requirements in the event of a problem.

Having information on existing equipment (asset) can give an indication on equipment usage and cost. The survey will give guidance on how to and how much to, bring the business into line with regulations.

Specification

Constructing tailor made solutions: Our services are entirely bespoke and based on individual delivery plans for each premises or project, we produce site surveys to ensure your understanding.

Installation

Installation can be carried out by onsite engineers, contractors, catering installers and plumbers.

We would be pleased to supply any assistance necessary. We carry out commissioning to sites on request and supply maintenance manuals.

Aluline Grease Management Systems will be installed at the customer’s request.

Training

• Why is it important to understand how drainage systems work?

• Why is it important to deal with a reputable company?

• Why is it important to know the legislation?

• Why is it important to know which inspectors are involved in drainage?

• How the costs of waste management affect the establishment.

• What is the impact if no measures are in place?

Design Considerations

The positioning of sinks and water draining equipment is a critical consideration. The idea of incorporating drainage into design is quite foreign to designers; however the specification of water draining units important to keep quantity of Above Ground Units low. Pipe work cannot cross walkways or door openings, also pipe work buried in concrete slabs must have rodding eyes, and pipe work under concrete slabs (sometimes in older establishments) should be able to be cleaned from above. Grease Traps should be floor mounted with access for cleaning.

The process for cleaning Grease Management Systems and access should be an important consideration.

Service

All of this is at no extra cost to guarantee equipment compliance.

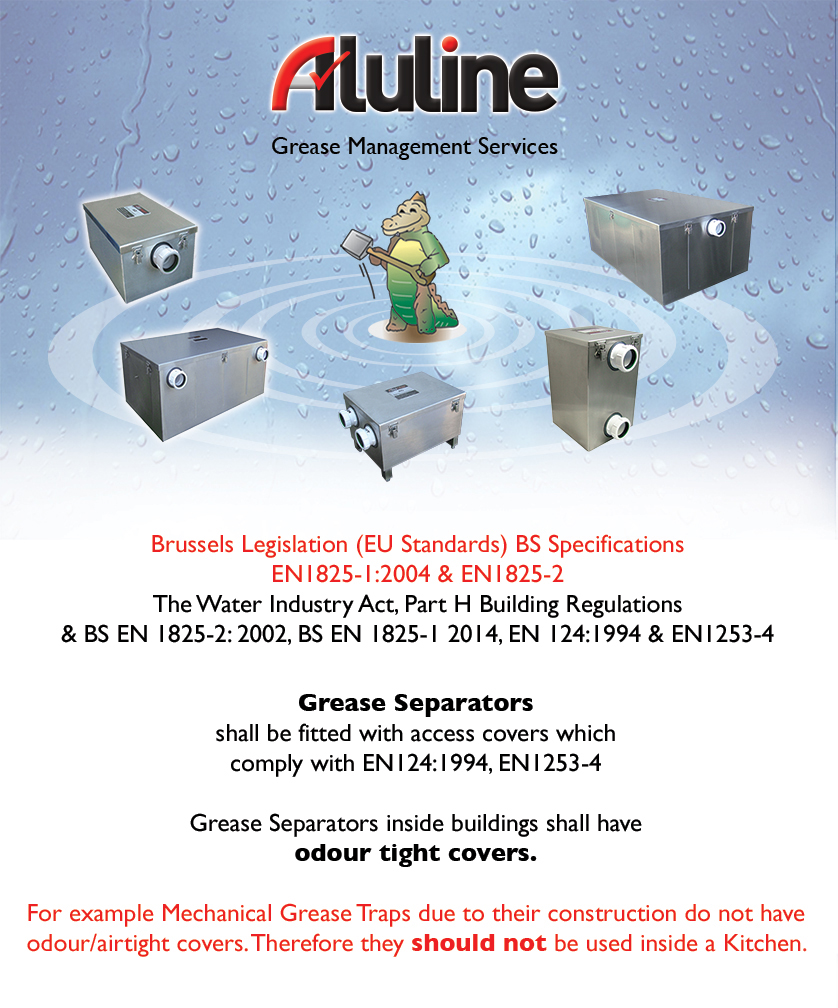

Compliance & the Law

of their equipment sizing formula.

Are you buying from a reputable, established company? If things go wrong, will your supplier stand behind you and your equipment? Will they still be in business in the next five years to do so? If you are unsure ask for a set of management accounts.

Is the equipment compliant? Does it cover all your equipment? Ensure these companies do provide you with a compliance statement issued in writing.

Is ‘dosing only’ acceptable to your areas water authority? In the majority of areas it is not! Please check it! Aluline can provide you with the department contact number and email for your relevant local water company to check this.

Cost

Our goal is to provide you with a complete drainage solution service providing you with the equipment and tools to ensure you meet with all current regulations and meet your environmental obligations at an economical and fair price. Twenty years specialising in solutions to FOG* issues in commercial kitchens has gained us valuable insight and understanding of how your operation works. We have been around for a long time, not by being expensive, but by being honest and caring about our customers and delivering a world class quality experience to every client at an economical price.

Our future is in providing a complete sustainable, economic solution and management system for our food service customers. A solution based on current and future compliance requirements. A solution consumerist with the aspirations of our customers, eg; advice, fact sheets, training and full management participation.

Engineers

• Grease Watch Tank Monitoring equipment.

•Urinal Dosing & Control equipment.

•Oil Separators, Monitors and Control Equipment.

•Septic Tank, WWTP Inspection and Servicing.

•Modular Public Toilets: Installation and Servicing.

•Wall and surface mounted Wash Hand equipment.

•Bio-Remediation Stations and Dosing equipment.

•Above Floor Stainless Steel Grease Trap Management Systems.

•Waste Water Audits and Advice.

•Compliance Auditing.

•Kitchen Staff Training on Waste Hygiene.

•Replacement of Grease Management Systems not compliant with Kitchen Environments.

•Treatment Plant Regeneration.

Health Check

For value for money and effective long term performance it’s essential you choose the optimum sewage treatment and disposal method for your business, as well as ensuring that it works efficiently to enable continuous discharge compliance.

Our scientific officer will provide confidential expert advice on how to ensure your system is working to its maximum efficiency.

Your Septic Tank / Treatment Plant will hopefully be fully compliant but it may suffer from erratic loads due to seasonality or it may require specialist advice on husbanding unit e.g. chemicals, fat, oil and grease. Variables are subject to your site usage being checked and a specific site programme being produced.

Discharge from WWTP is critical we can help you to ensure your site is designed to get maximum drainage from its size or if you are discharging to a watercourse you may want to consider a passive treatment system such as a reed bed. All systems no matter their age, size or capacity need to stay healthy and meet with current regulations. Monitoring is an essential part of maintenance.

In all cases we can offer assistance on effluent quality to ensure your plant will consistently comply with Environment Agency standards and to maximise its efficiency.

Waste Management

(an international company dedicated to providing environmental

solutions and best practice in a range of industries).

The groups’ main objectives include implementing and facilitating best management practices in waste management through:

• Providing and promoting detailed waste management plans.

•Introducing measures to rationalise policies relating to waste reduction, waste management and litter prevention.

•Developing strategies and action plans.

•Developing, implementing, supporting, and promoting waste reduction and recycling programs.

•Investigating and advising on landfill disposal costs and charges.

•Training any staff involved in waste management by the introduction of electronic data devices.

•Educating staff, residents and businesses as required.

About us

There are multiple reasons as to why customers recommend our services. For example, our high level of environmental knowledge has led to an increase in compliant kitchen drainage solutions, which can be installed in both large and small kitchens applications. We as a company ensure that all systems are fully compliant with the requirements of each individual establishment, whether commercial or industrial.

Here at Aluline, we make it our mission to ensure that our team of expert engineers and practitioners understand the requirements of our customers’ business, focusing primarily on cost, staffing, legislation and hygiene. We feel it is our duty to make sure that all customers receive the best quality service, which is why we maintain friendly working relationships with them as well as their health and water authorities.

We at Aluline understand that reducing blockages and pump faults are essential for a fully-functioning kitchen, which is why we have designed and distributed a number of excellent-quality products that are guaranteed to be long-lasting and effective, some of which include;

- Above Ground Grease Traps for Bio-Remediation

- Under Ground Grease Traps

- Lint, Hair, Plaster & Starch Separators

- Oil & Petrol Separators

- Coffee Catchers & Filters

- BDN6 Dosing Systems

- SOGT Steam Oven Grease Traps

- Kitchen Drains & Floor Gullies

At Aluline Grease Management, we are driven by our client’s needs. We as a company firmly believe that relationships can either make or break a project, which is why we offer friendly advice and support wherever possible and are more than happy to discuss new ideas and innovations with our customers. We understand that one size does not fit all, which has resulted in multiple solutions being discovered every day to meet the demands of the premises or project.

We at Aluline also have three sister companies, which are Barolympic, Aluline Precision Engineering & Aluline.net.

Sponsored Links

Trade Associations