Company details for:

LAND®

Quick Links:

Products / Services

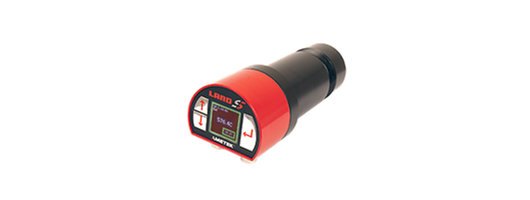

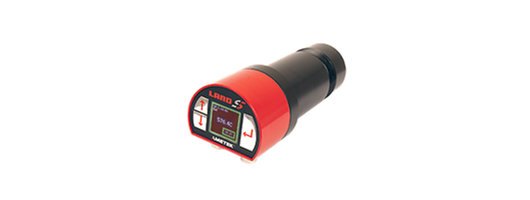

Cyclops L - Portable Non-Contact Thermometers

SPOT+ - Fixed Spot Non-Contact Thermometers / Pyrometers

SPOT+ AL - Aluminium Production & Processing Application Pyrometer

System 4 - Fixed Spot Non-Contact Thermometers / Pyrometers

Overview

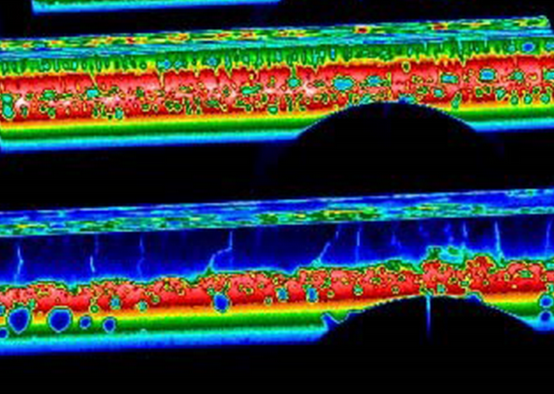

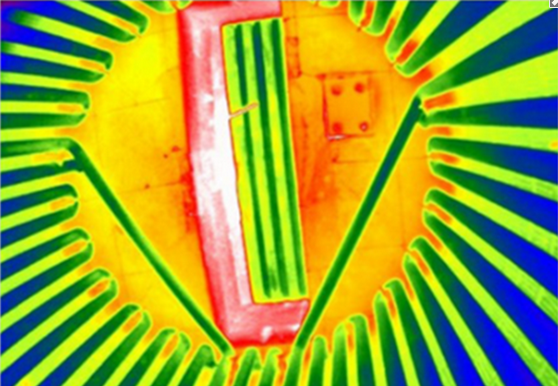

NIR-656 & NIR-2K - Fixed Stationary Thermal Imagers

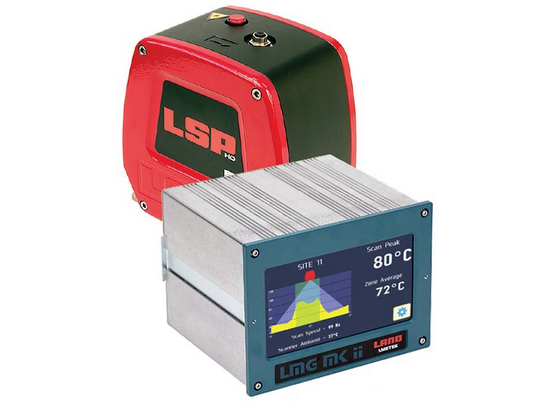

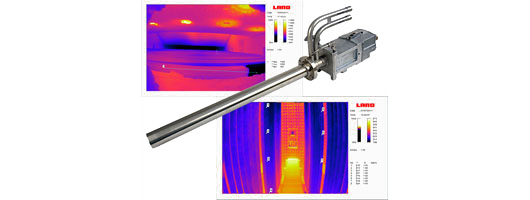

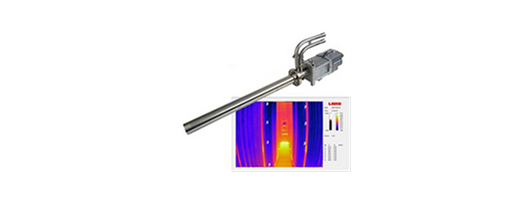

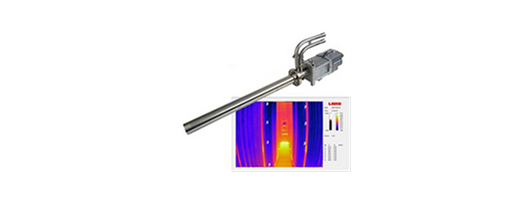

LSP-HD Linescanner

HotSpotIR 9000 - Linescanners & Systems

Portable Furnace Thermal Imaging System

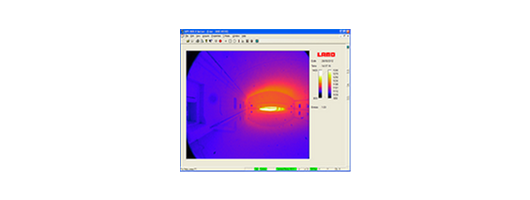

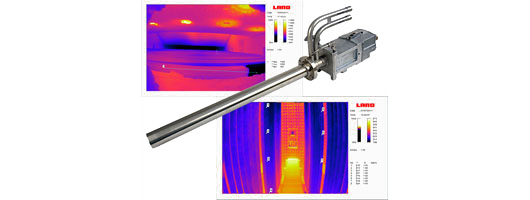

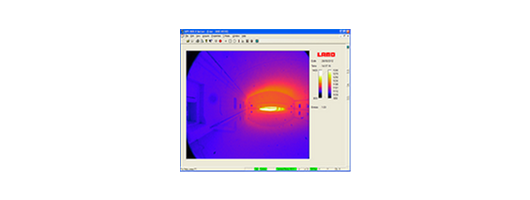

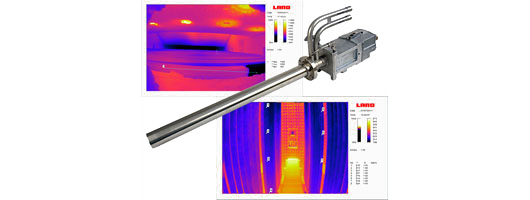

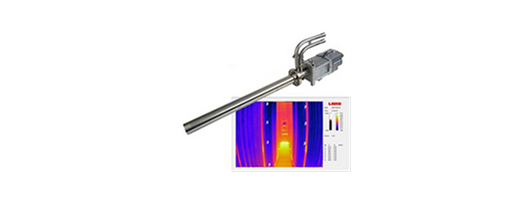

MWIR-Borescope-640 - Fixed Furnace Thermal Imagers

NIR-Borescope-640 - Fixed Furnace Thermal Imagers

NIR-Borescope-640-EX - Fixed Furnace Thermal Imagers

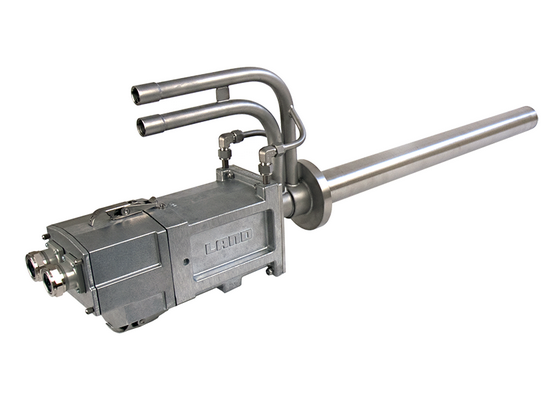

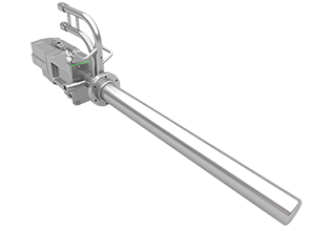

Retraction Systems for Furnace Thermal Imagers

As components of a full furnace imaging system or as an upgrade to existing furnace camera systems AMETEK Land offers complete auto-retraction system solutions, in either pressured air or electrically driven configurations.

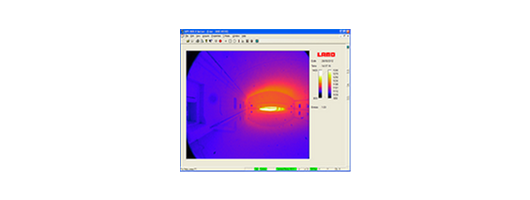

NIR-Borescope-2K-Glass - Application-Specific Thermal Imaging Systems

The NIR-Borescope-2K-Glass (NIR-B-2K-Glass) is a short-wavelength radiometric infrared borescope imaging camera, designed to produce high definition (1968 x 1476 pixels) thermal images, along with providing accurate temperature measurements from any of the three million temperature points in the image.

The camera measures temperatures in the range 1000 to 1800 °C (1832 to 3272 °F) and is suitable for float glass, container glass, borosilicate glass, and fibre glass melt furnaces.

SDS - Slag Detection System (SDS V2) - Application-Specific Thermal Imaging Systems

At the end of the tap the levels of slag and steel rapidly reverse. Quick termination of the tap after the alarm has been triggered is necessary to prevent excessive levels of slag in the ladle.

SDS uses a high-resolution thermal imaging camera to detect the transition between steel and slag. The dedicated thermal imaging camera has been specifically designed to survive in the harsh operating conditions and utilizes a particular wavelength to reduce obscuration caused by smoke and fume. Data is presented to the operator in real time enabling them to make informed decisions about the tapping process and the system provides clear alarm notifications.

EX SPOT - Hazardous Areas

The new EXSH1 flame-proof housing allows EX SPOT pyrometers to be used in hazardous areas. Its high specification means that it is suitable for use in almost any application in the harshest of environmental conditions. Multiple certifications mean that a common specification can be used for worldwide applications, greatly simplifying the task of specifying and quoting the product.

The enclosure has a certified temperature range of -40 to +70 °C (-40 to 158 °F) without additional cooling.

Ingress protection to IP66 and IP68 means that it can be exposed to dust, water immersion and high-pressure water jets. The enclosure is manufactured from 316 / 316L stainless steel and is highly resistant to corrosion.

EX LWIR - Hazardous Areas

The new EXSH1 flame-proof housing allows the LWIR-640 imager to be used in hazardous areas. Its high specification means that it is suitable for use in almost any application in the harshest of environmental conditions. Multiple certifications mean that a common specification can be used for worldwide applications, greatly simplifying the task of specifying and quoting the product.

The enclosure has a certified temperature range of -40 to +70 °C (-40 to 158 °F) without additional cooling.

Ingress protection to IP66 and IP68 means that it can be exposed to dust, water immersion and high-pressure water jets. The enclosure is manufactured from 316 / 316L stainless steel and is highly resistant to corrosion.

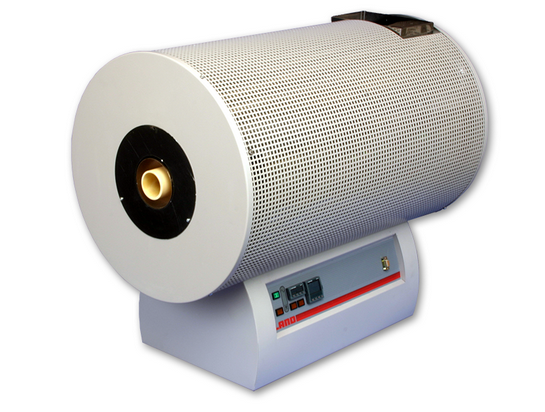

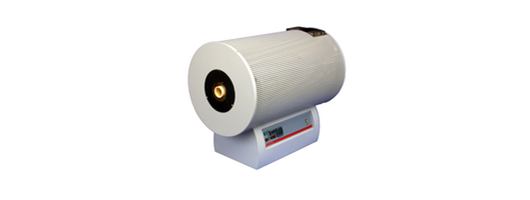

Landcal - Calibration Sources

Providing the same high precision as our advanced temperature monitoring products, a comprehensive range of six calibration sources lets you calibrate radiation thermometers across a temperature range of -10 °C to 1600 °C (15 °F to 2900 °F).

As Landcal blackbody sources are perfect absorbers and emitters, calibrations are made with an extremely high level of stability; all calibrations are traceable to National Standards, delivering confidence to your measurements.

All calibration requirements are covered, with low, medium and high range temperature versions available in bench-mounted, portable and transportable versions.

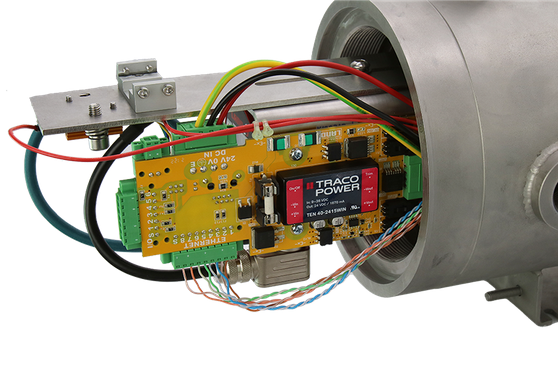

FGA Series - Combustion Efficiency Monitors

The FGA provides accurate, reliable measurement of carbon monoxide, nitric oxide and oxygen in flue gases. It is an integrated solution for Continuous Emissions Monitoring Systems (CEMS) applications in smaller combustion processes.

Easy to install and operate, the FGA also calculates values for combustion efficiency, NOx and carbon dioxide. This information allows better process control, which lowers fuel costs and keeps emissions within compliance levels.

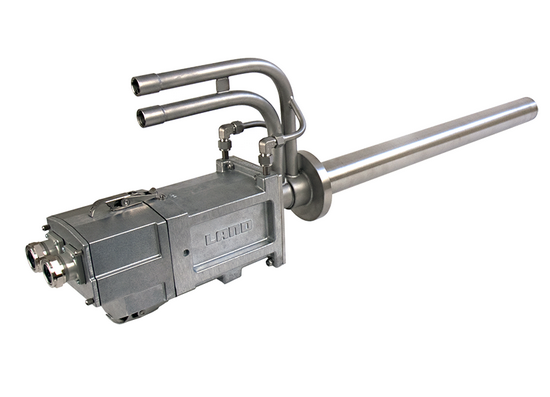

WDG 1200 & 1210 (Oxygen) - Combustion Efficiency Monitors

Using AMETEK’s industry-proven zirconium oxide sensor technology, the WDG-1200/1210 range provides the world’s first fully-integrated, standalone flue gas oxygen analysers. The user interface is mounted onto the probe, lowering installation costs.

The unique design allows the sensor assembly to be removed without disturbing the outer protection tube. This means maintenance can be carried out easily on-site, with all parts replaceable in the field, reducing costs and downtime.

The WDG-1200/1210 offers local control via the simple user interface attached to the probe, with a remote-control unit available for less accessible locations. Advanced communications options allow straightforward integration into plant control systems.

The WDG-1200/1210 range provides the essential measurements for combustion efficiency, NOx reduction, excess air measurement and pollution control applications in the hydrocarbon processing, industrial processing and power generation industries.

Lancom 200 (Sulphuric Acid Dewpoint) - Combustion Efficiency Monitors

Designed specifically to provide the unique but vital measurement of sulphuric acid dewpoint temperature, the portable Lancom 200 supports boiler efficiency checks, corrosion protection and the management of high-cost fuel additives.

Easy-to-use ADT monitoring lets boiler operators balance acid emissions with efficiency, reducing the risk of corrosion in the boiler and wasted heat/fuel. This lowers operational costs and reduces harmful sulphate aerosol emissions.

Incorporating 40 years of AMETEK Land’s application expertise, Lancom 200 obtains an accurate reading in minutes. By generating a measurable current when sulphuric acid forms on the conductive cell, it makes a direct measurement for ADT.

Specially developed for plants requiring only periodic monitoring of sulphuric acid dewpoint temperature for boiler efficiency, the Lancom 200 is suitable for applications in the hydrocarbon processing and power generation industries.

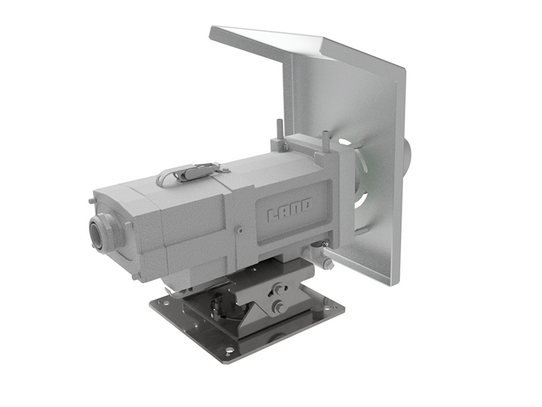

4500 MkIII (Opacity - US EPA PS-1 & ASTM D6216) - Opacity and Dust Monitors

4500 MkIII is the most accurate and reliable continuous opacity monitor available, combining AMETEK Land’s ground-breaking innovation and simple design for precise, problem-free operation.

Unmatched, class-leading accuracy ensures compliance limits for dust emissions and stack opacity are met with confidence. This avoids the risk of regulator fines while lowering costs through operational efficiencies.

The 4500 MkIII employs a highly homogenous LED light source to minimize sensitivity to optical misalignment. The multi-prism retro-reflector reduces thermal drift for the lowest possible detection limit. Together with a flood LED to minimize electronic drift, these technologies provide you highly stable, highly accurate results.

Fitting stack diameters of 0.3m-15m (1 ft-50ft), 4500 MkIII is suitable for the continuous monitoring of dust and opacity in boilers, heaters, furnaces and other combustion applications in the power generation, hydrocarbon processing, industrial boilers, and steel industries.

Millwatch - Carbon Monoxide Detectors

Specifically designed for early detection of potential fire risk in pulverizing mills in coal or biomass processes, Millwatch monitors and quickly responds to sudden carbon monoxide (CO) build-up, allowing preventative action to be taken before a hazardous condition develops.

Using AMETEK Land’s unique detection system, Millwatch provides continuous, accurate monitoring of CO levels − improving process safety, protecting expensive mill equipment, and preventing costly downtime from unnecessary shutdowns.

Millwatch continuously extracts sample gases from the mill outlet for a constant, dual-sensor CO measurement. Customisable alarms adapt to individual plant process conditions, while automatic calibration ensures high measurement integrity is maintained 24/7.

Specifically designed for power generation operators who need to improve process safety in mills and pulverisers using coal and biomass fuels, Millwatch ensures the protection of people, plant and process.

Silowatch - Carbon Monoxide Detectors

Specifically designed for detection of early-stage fire risk in storage silos for coal and biomass fuels, Silowatch continuously monitors and quickly responds to sudden carbon monoxide (CO) build-up, allowing preventative action to be taken before a fire develops.

Silowatch provides fast, accurate monitoring of CO in the silo, using AMETEK Land’s unique dual-sensor detection system. The detection of sudden CO build-up enables operators to act quickly, protecting your personnel, securing expensive silo equipment and avoiding costly downtime.

Silowatch works by extracting the sample gas from the silo headspace and continuously monitoring the CO level. Automatic calibration ensures high measurement integrity, while alarms can be customised to individual silo conditions.

Designed specific for use in coal and biomass storage silos, Silowatch ensures the protection of people, plant and process.

About us

LAND® AT A GLANCE

LAND, a business of AMETEK Inc, has been a global leader in industrial infrared temperature measurement for over 75 years, delivering unmatched infrared temperature measurement accuracy and reliability.

Our advanced pyrometers, line scanners, and thermal imaging systems are designed to perform in the harshest conditions, helping industries improve product quality, boost production, and enhance process efficiency.

Calibrated in ISO17025-certified laboratories, our instruments set the standard for precision and offer extended protection for critical operations. We provide expert support to help businesses design, install, and maintain our smart solutions, ensuring seamless integration and long-term reliability.

From sustainable steelmaking to battery production for electric vehicles, LAND’s innovative solutions are trusted across a wide range of industries. We empower businesses to protect their people, reduce their environmental impact, and achieve their production goals with confidence.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations