Company details for:

AMJ Maters

17 Elizabeth Court,

Eaton Socon,

Saint Neots,

Cambridgeshire,

PE19 8PF,

United Kingdom

Quick Links:

Products

Streamline Your Packaging Process

Lantech C-300 Case Erector

Lantech C-1000 Case Erector

Lantech C-2000 Case Erector

Lantech C-3000 Case Erector

Lantech Rembrandt C-3000 Case Erector for Very Large Cases

Lantech CS-300 Case Tape Closer

Lantech CS-1000 Case Tape Closer (Modular)

Lantech CS-1000-HMG Case Tape Closer (Sealing with Hot Melt Glue)

Lantech CS-1000-RCTC Random Case Closer

Lantech RCP-2 Case Packer (Top Loader)

Lantech RCP-3 Case Packer (Side Loader)

Lantech CP-300 Case Packer

Lantech LF-1000 Lid Forming & Placing Machine

Lantech LF-2000 Lid Forming & Placing Machine

Lantech LA-1000 Lid Application Machine

Lantech Q-300 Semi-Automatic Pallet Stretch Wrapper

Lantech Q-300 XT Semi-Automatic Pallet Stretch Wrapper

Lantech Q-1000 Fully Automatic Pallet Stretch Wrapper

Lantech S-300 Semi-Automatic Straddle Pallet Stretch Wrapper

Lantech S-3500 Semi-Automatic Straddle Pallet Stretch Wrapper

Lantech TP-1000 Tray Former

Lantech TP-2000 Tray Former

Lantech TE-1000 Tray Former

Lantech TE-2000 Tray Former

About us

We provide excellent project management as well as a comprehensive detailed survey and after-sales support to all clients, ensuring that they are 100% satisfied with their overall service. Some of our best known clients include Lantech, Niverplast and Buhrs.

Established in 1980, we at AMJ Maters have over 40 years’ experience in the distribution of packaging machinery, palletising and materials handling systems and a vast array of other products, all of which are supplied across multiple industries including food, beverages/drink, dairy, bakery, confectionery, pharmaceutical, cosmetics, toiletries, hardware and electrical appliances. We have a team of professional and skilled specialists who have enough knowledge and experience to provide exceptional service from start to finish.

Our Packaging Machinery Solutions Include:

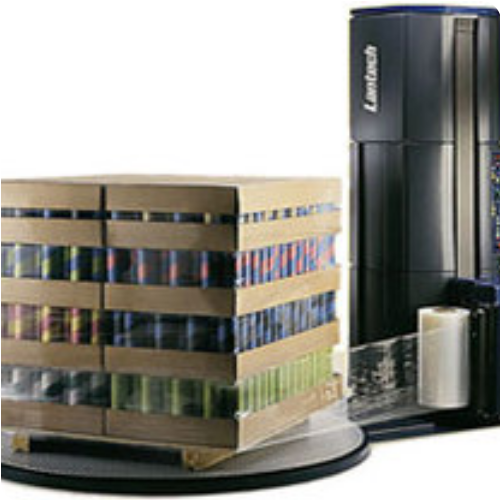

Pallet Stretch Wrappers

Pallet stretch wrappers are crucial in the industrial packaging sector, guaranteeing the secure wrapping of products, preparing them for transport. These devices automate pallet wrapping with stretch film, offering a swift and dependable solution for businesses seeking to enhance their packaging processes. This article will explore the features, variations, and advantages of employing pallet stretch wrappers in the industrial domain.

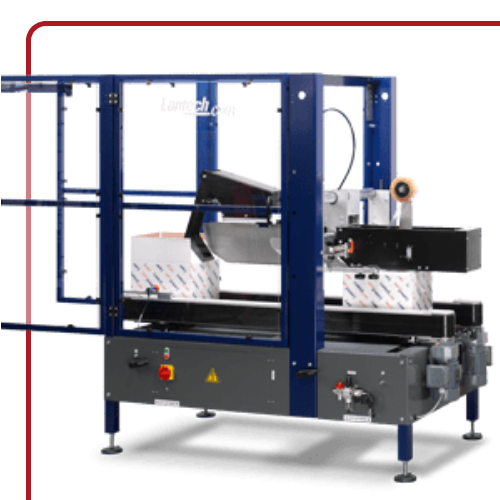

Case Erectors

In the dynamic realm of industrial packaging, optimal efficiency and accuracy are essential. A case erector, alternatively referred to as a carton erector, assumes a vital function in automating the packaging procedure, furnishing businesses with a dependable and swift method for readying boxes for product placement. This article will explore the definition of a case erector, its operational mechanisms, and the advantages it offers to packaging processes.

Palletisers

A palletiser is a specialised machine created to arrange and stack items onto a pallet in a predetermined fashion. This automated apparatus is pivotal in optimising the packaging and distribution procedures across diverse industries such as food and beverage, pharmaceuticals, and manufacturing.

Some of our machinery we provide here at AMJ Maters includes bag in a box and crate machines, case closing machines, case erectors, case loaders and packers, conveyor systems, lid forming and applying machines, pallet stretch wrappers, palletisers and tray formers.

Based primarily in the UK, our company is more than capable to repairing and refurbishing a number of packing, palletising and materials systems no matter how complex or challenging. We also provide a range of parts that are available to view online.

Images