Company details for:

AMT Ltd

Calder Road,

Ravensthorpe,

Dewsbury,

West Yorkshire,

WF13 3JT,

United Kingdom

Quick Links:

Products

OEM Machine Spares

Tilghman

Pangborn

OMSG

Geitart

Modena

Spencer & Halstead

Schlick

SES

VacuBlast

We can also manufacture a wide range of parts, ie. Slats, Screws, Pulley’s, etc. for the above OEM’s.

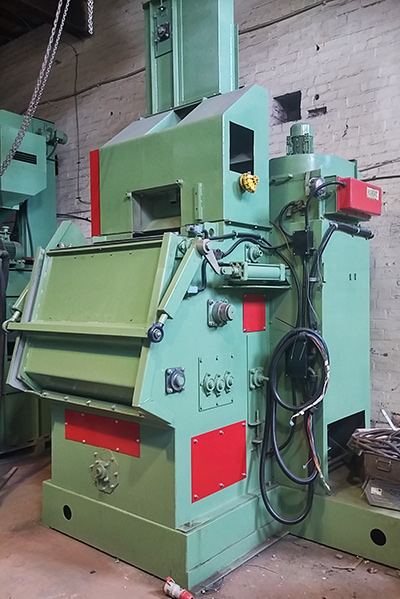

Tilghman Wheelabrator T170 Fully Refurbished

Max Charge - 225kg, Max Part Size - 16 cu inches, Max Part Weight - 15Kg, 3ph - 26Amp - 415V 50Hz.

Can be used with or without included plinth.

ALFA 14 TURBO TECNICA

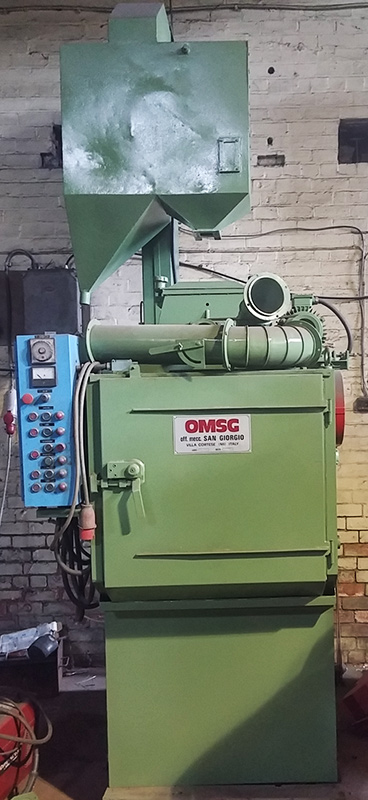

OMSG Tumblast Rubber Belt

Guyson Euroblast 4PF

Cabinet Height: 1655mm, Width: 815mm, Depth: 560mm

Filter - 2 cartridge reverse air jet.

36" Centriblast Barrell Machine

0.17 cubic meters capacity, individual item weight - 50Kg, cleaning time of 5-7 mins for grey iron castings or fabrications. Output of upto 1000Kg per hour is easily obtained.

Tilghman WTB0 Fully Refurbished

A low cost high efficiency machine for small items.

Capacity 2ft³ (0.05m³)

Barrel size 20in. dia. x 27in. long (508mm x 686mm)

Load capacity (approx.) 300lb (136kg)

Largest single component 25lb (11.5kg)

Wheel Power 5hp (3.57kW) or 10hp (7.5kW)

Conveyour - perforated, heavy duty reinforced rubber.

Pitless installation.

Pre-owned Vacu-Blast PBA-06 Machine

About us

AMT Ltd manufacture and supply a range of wear resistant parts for your machines from brands including Tilghman, Pangborn, OMSG, Geitart, Modena, Spencer & Halstead, Schlick, SES and Vacublast. We also manufacture a range of parts such as slats, screws, pulley’s etc. plus a large range of manganese steel and shotblast rubber at competitive prices.

Services include:

• Plasma Cutting

• Mig and Stick Welding

• Electrical Control Panels

• Band Saw

• Powder Coating

• Spray Painting

• Shotblasting

• Centre Lathe

• General Maintenance

• Machine Relocation

• Wheel Retrofits

• Electrical Services

• Independent advice on new equipment

• Periodic servicing to a full and extensive refurbishment

• Design and build electrical control panels

• Re wire machines

• 24 hour breakdown response and more!

AMT stock a pre-owned range of shotblast machines and filters, refurbished to a high standard and all complete with a 12 month warranty. If you would like to know more, please contact us for the latest stock list and prices.