Company details for:

Aquajet Machining Systems Ltd

Unit C2 Binary Court, Matrix Park,

Western Avenue,

Buckshaw Village,

Chorley,

Lancashire,

PR7 7NB,

United Kingdom

Quick Links:

Products / Services

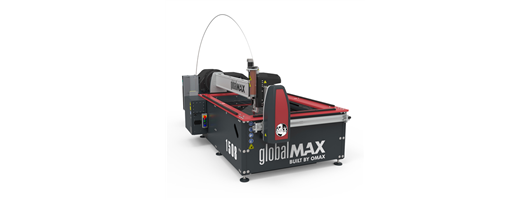

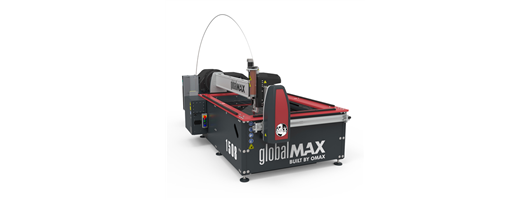

GlobalMAX 2040 Abrasive Waterjet System

For further information and orders, please contact 01257 248480.

GlobalMAX 1530 Abrasive Waterjet System

For further information and orders, please contact 01257 248480.

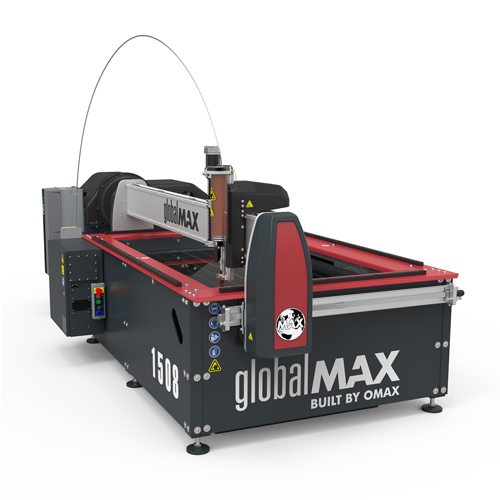

GlobalMAX 1508 Abrasive Waterjet System

For further information and orders, please contact 01257 248480.

MAXIEM 3060 Waterjet Cutting Machines

The exclusive advanced Intelli-TRAX® digital linear encoder provides one-micron resolution instant feedback to the motor control system so the machine knows precisely where the cutting head is at all times. The mobile control station with widescreen display provides flexibility in controller positioning.

Optional accessories such as the A-Jet® for 5-axis cutting and taper compensation, Collision Sensing Terrain Follower for accurate machining of warped materials, and DualPUMP options that provide up to 80 hp of power expand your JetMachining capabilities and dramatically improve production.

For further information and orders, please contact 01257 248480.

MAXIEM 2080 Waterjet Cutting Machines

The exclusive advanced Intelli-TRAX® digital linear encoder provides one-micron resolution instant feedback to the motor control system so the machine knows precisely where the cutting head is at all times. The mobile control station with widescreen display provides flexibility in controller positioning.

Optional accessories such as the A-Jet® for 5-axis cutting and taper compensation, Collision Sensing Terrain Follower for accurate machining of warped materials, and DualPUMP options that provide up to 80 hp of power expand your JetMachining capabilities and dramatically improve production.

For further information and orders, please contact 01257 248480.

MAXIEM 2060 Waterjet Cutting Machines

The exclusive advanced Intelli-TRAX® digital linear encoder provides one-micron resolution instant feedback to the motor control system so the machine knows precisely where the cutting head is at all times. The mobile control station with widescreen display provides flexibility in controller positioning.

Optional accessories such as the A-Jet® for 5-axis cutting and taper compensation, Intelli-VISOR EX for expanded system monitoring, and DualPUMP options that provide up to 80 hp of power expand your JetMachining capabilities and dramatically improve production.

For further information and orders, please contact 01257 248480.

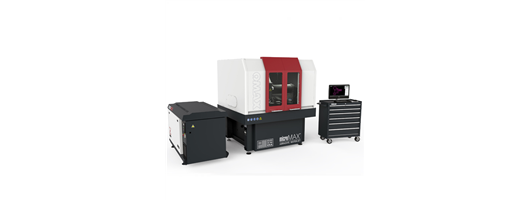

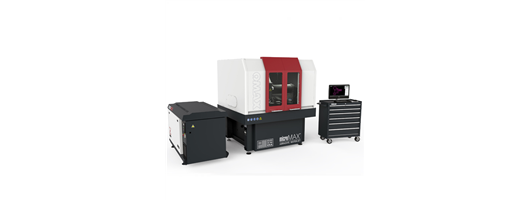

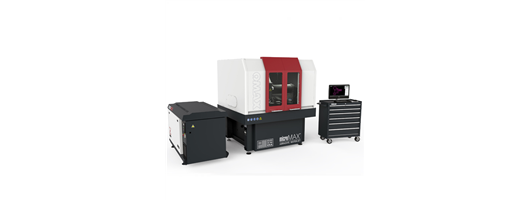

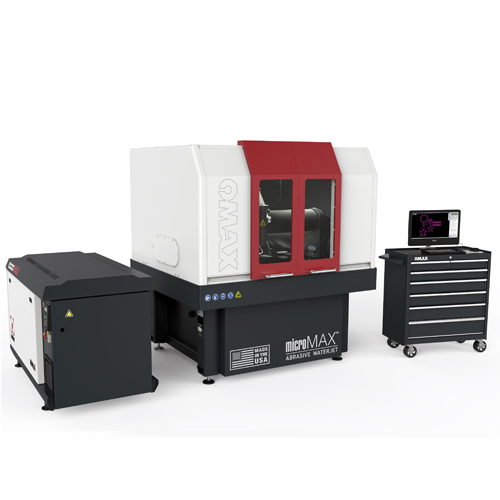

OMAX MicroMAX Waterjet Cutting Systems

The MicroMAX JetMachining Centre is the ideal solution for ultra-precision abrasive waterjet machining. Utilising advanced high-precision optical linear encoders, innovative vibration isolation, and proven software control systems, the MicroMAX JetMachining Centre is capable of a positioning accuracy of less than five microns while retaining all the advantages of abrasive waterjet machining. The MicroMAX can machine stainless steel, titanium, carbon fibre, PEEK, glass, nitinol, graphite, copper, composites, laminates, and more, with high precision and smooth finishing, for either prototyping or production.

Ideal for production runs and prototype development, the MicroMAX is a highly rigid machine with a table size of 2 feet 4 inches by 2 feet 4 inches and an X-Y cutting travel of 2 feet by 2 feet.

For further information and orders, please contact 01257 248480.

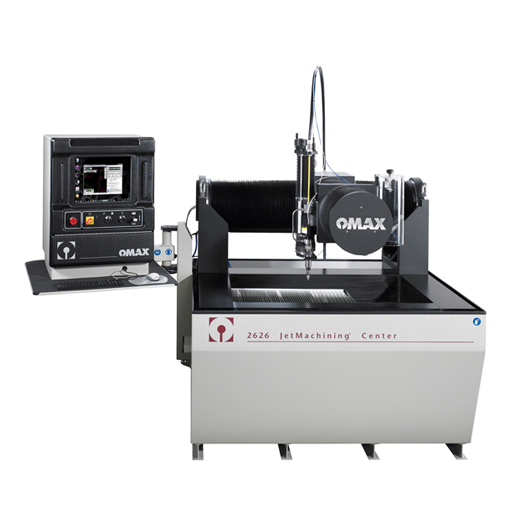

OMAX 2626 Waterjet Cutting Systems

For further information and orders, please contact 01257 248480.

OMAX 2652 Waterjet Cutting Systems

For further information and orders, please contact 01257 248480.

OMAX 5555 Waterjet Cutting Systems

For further information and orders, please contact 01257 248480.

OMAX 55100 Waterjet Cutting Systems

For further information and orders, please contact 01257 248480.

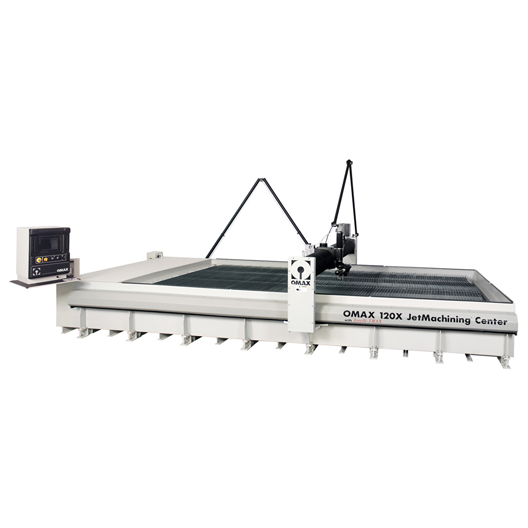

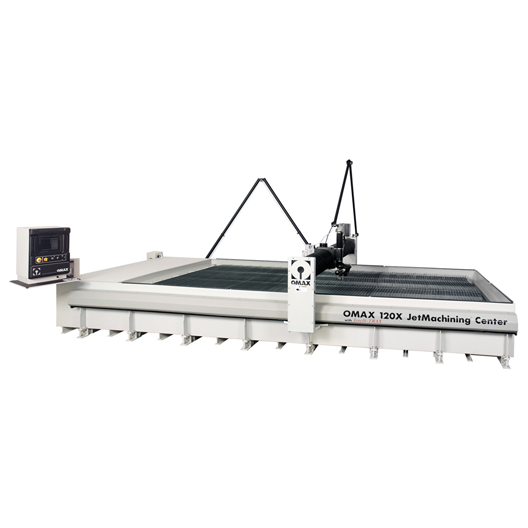

OMAX 120X Series Waterjet Cutting Systems

For further information and orders, please contact 01257 248480.

OMAX 160X Series Waterjet Cutting Systems

The modular design tailors the 160X to your specific space requirements, while the exceptional drive system maximises performance: Intelli-TRAX® drive technology, an innovative system designed for the abrasive waterjet environment, is durable, reliable, and precise.

Features such as EnduroMAX® technology and Intelli-MAX® software, along with optional accessories such as the multi-axis A-Jet® and the DualBRIDGE system, all are designed to deliver lower operating costs and increased profits with the 160X JetMachining Center.

For further information and orders, please contact 01257 248480.

OptiMAX 80X Waterjet Cutting Systems

For further information and orders, please contact 01257 248480.

OptiMAX 60X Waterjet Cutting Systems

For further information and orders, please contact 01257 248480.

ProtoMAX Compact Abrasive Waterjet

For further information and orders, please contact 01257 248480.

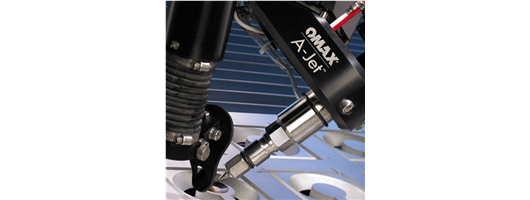

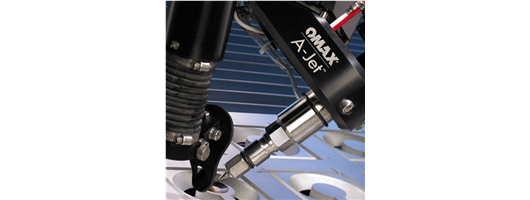

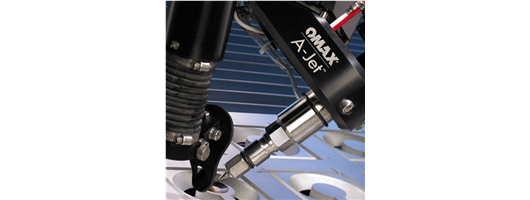

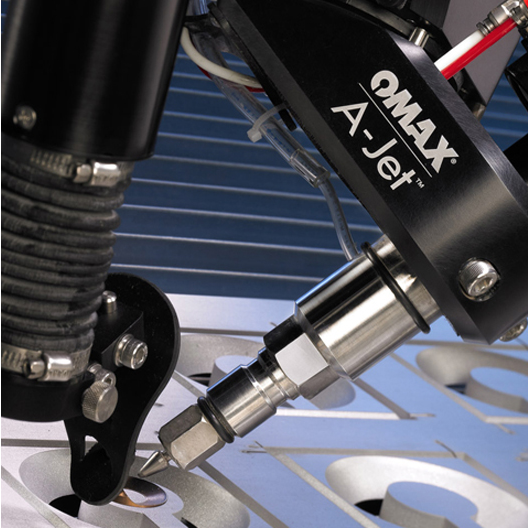

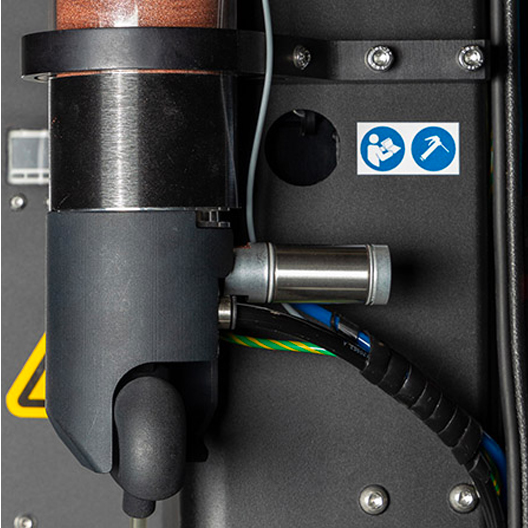

A-Jet - Multi-Axis Accessory

The A-Jet cuts countersunk holes and precision shapes with beveled edges at angles specified by the user. The accessory supplies additional axes of motion, allowing the operator to fabricate and shape metal edges for weld preparation.

The dynamic A-Jet is capable of a high level of positioning accuracy, resulting in parts that need no secondary finishing.

For further information and orders, please contact 01257 248480.

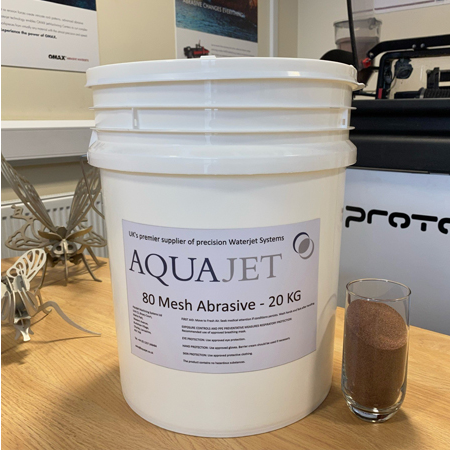

80 Mesh Abrasive

Garnet sand is a mineral and iron-free product which has universal uses. As an abrasive sand, its main area of use is high-pressure water jet cutting.

Available in quantities from 20 kg Tubs up to multiple tonnes.

Please contact us on 01257 248480 for further details and prices.

A-Jet - Automated Air Sweep

For further information and orders, please contact 01257 248480.

EnduroMAX 5 Series Pump

For further information and orders, please contact 01257 248480.

OMAX 100HP Direct Drive Pump

Delivering 30% more JetPower to the cutting head compared to the best intensifier pump designs, the EnduroMAX 100HP Pump cuts faster, smoother, and more efficiently than any other 100HP pump at any pressure.

For further information and orders, please contact 01257 248480.

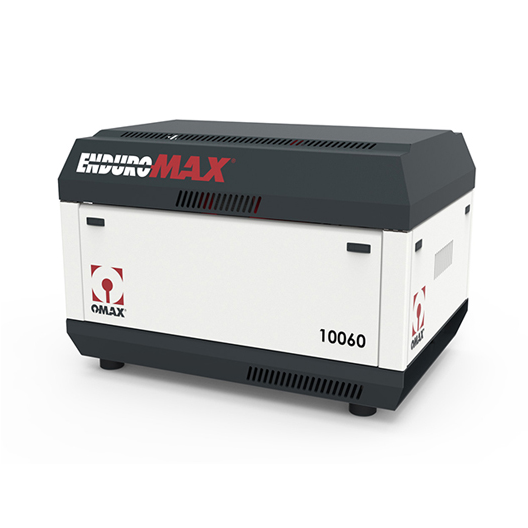

OMAX EnduroMAX Pump

Maximize your waterjet machine uptime with the pump’s 1,000-hour operating range between pump rebuilds when run at 55,000 psi (3,800 bar).

For further information and orders, please contact 01257 248480.

Spare Parts for Accustream

We offer AccuStream™ replacement parts for abrasive delivery products, cutting heads, pumps and high-pressure tubing & plumbing for all major brands of waterjet.

Spare Parts for BFT

We offer AccuStream™ replacement parts for abrasive delivery products, cutting heads, pumps and high-pressure tubing & plumbing for all major brands of waterjet.

Spare Parts for Flow

We offer AccuStream™ replacement parts for abrasive delivery products, cutting heads, pumps and high-pressure tubing & plumbing for all major brands of waterjet.

About us

Based in Lancashire, our company is best known as the distributor of the OMAX Waterjet Machining and MAXIEM JetCutting Centres, designing and producing state-of-the-art machine controllers, software, pumps and tables. Every product we design here at Aquajet is powered by the company’s unique control software, which allows for varying industries to experience our inventive systems at an incredible value.

For many years, Aquajet have been achieving maximum efficiency, flexibility and reliability by utilising our skills and strive for excellence. Our impressive product range of waterjet machines, pumps, accessories and spare parts are globally recognised for their high performance and quality, offering quick and precise abrasive waterjet cutting. Our company has worked with several sheet metal fabricators and trade schools, which has benefitted our reputation greatly.

Here at Aquajet, we understand that outstanding customer service is the key to success. We have a highly-skilled team of experts who will work closely with clients all over the country to ensure that their requirements are met quickly and efficiently. One of our widely recognised products is the ProtoMAX, which is specifically engineered to utilise advanced cutting models and similar control software in order to offer a more intelligent and fully-functional system.

We as a company have distributed our products and services to an impressive amount of industries and sectors over the last 20 years. Some of these include small job shops, engineering classrooms and makerspaces. They can also be used for personal use, whether for domestic, commercial or industrial purposes. Our versatile range has endless opportunities and benefits to take into consideration.

We at Aquajet offer excellent quality cutting systems that are fully flexible and can cut through almost any given material. Some of these materials include carbon fibre reinforced plastics, glass-reinforced plastics, carbon steel, stainless steel, hardened tool steel, alloys of all types, aluminium, titanium, copper, brass, glass, stone, concrete, ceramics and rubber.

We urge all potential clients to get in touch as soon as possible to discuss potential projects in greater detail.

Images