Company details for:

A&R Engineering Services Ltd

Unit 2a,

Nutwood Trading Estate,

Limestone Cottage Lane,

Sheffield,

South Yorkshire,

S6 INJ,

United Kingdom

Quick Links:

Products / Services

Sub Contract Metal Pressing

Our production capability ranges from batches of hundreds to many thousands.

We also work closely with our chemical finishing and powder coating partners, enabling a complete start to finish process.

Milling

Tool Room Services

Toolmaking and component design are also available.

With over 30 years of experience in press working and toolmaking we are confident of achieving a high level of customer satisfaction.

Sub Assemblies

Simple hand assemblies and fly press work.

For more information please contact us or fill in our contact form

Press Braking

Areas of industry that we supply include:

Catenary Hanging Systems

Top of the range children’s push chairs/prams

Spot Welding

All our spot welding dies & fixtures are made in house using our fully equipped tool room facilities.

Hi-Torque Stainless Steel Clamps

The materials used to manufacture our clamps are sourced only from the best suppliers and material test certificates are available for inspection at all times. Every part of the clamp is manufactured in-house using our own tooling.

Our clamps are easy to fit and contain no loose parts that other nut and bolt systems have, ensuring they do not fall apart once undone. Perfect for those jobs in hard to reach places!

All the band edges are fully round edge, which not only protects the hands of the person using the clamps, but importantly protects the rubber or other material that the clamp is gripping.

Extension Wear Plates

Our extension wear plates clip into place on the machine for ease of use and efficiency.

These are just a few reasons why we supply the largest of the leading glass manufacturers.

Construction Sector

High Torque Stainless Steel Clamps

Extra Large Coupling Systems

Specialised Coupling Systems

Industrial Sector

Materials range from 1mm to 4mm and can be manufactured from spring shim steel, stainless spring steel, carbon steel and phosphor bronze. Please contact us to discuss your exact requirements.

About us

A&R Engineering Services Ltd has been producing high-quality metal pressings since its establishment in 1988.

Metal pressings are manufactured alongside our selection of spring clips, fasteners, and Hi-Torque clamps. Every item we offer is custom-made to precise specifications through thorough collaboration and development with our customers.

We manufacture a wide array of pressings using a diverse range of materials, including mild steel, hardened and tempered spring steel, as well as stainless steel of different grades such as BS304 (EN1.4301-A2) and BS316 (EN1.4401-A4).

Our Services Include:

We provide clients with various services, including subcontract metal pressing, press braking, milling, spot welding, sub-assemblies, and tool room services.

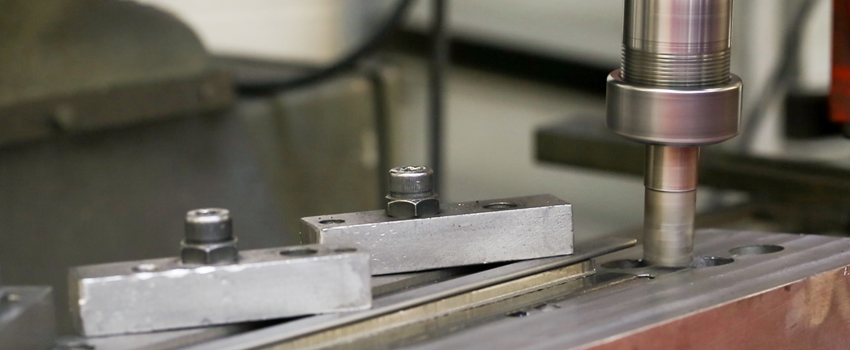

Sub Contract Metal Pressing

We possess a variety of presses, ranging from sets of basic fly presses to power presses with capacities ranging from 6 to 75 tonnes. All our power presses are equipped with either air feed attachments or servo roll feed systems, ideal for high-speed automatic material feeding. This versatility enables us to meet the diverse needs of our customers. Our production capacity spans from small batches numbering in the hundreds to large-scale production in the thousands. Additionally, we collaborate closely with our partners in chemical finishing and powder coating, offering a comprehensive start-to-finish process.

Milling

From basic individual milling tasks in mild and stainless steel to the machining of hardened tempered plates in larger production runs.

Tool Room Services

We handle regrinds and repairs internally using Bridgeport milling machines and surface grinders. Additionally, we offer toolmaking and component design services. With over 30 years of experience in press working and toolmaking, we are confident in delivering a high level of customer satisfaction.

Sub Assemblies

We also undertake sub-assembly tasks, which may involve drilling and tapping, as well as standard riveting and orbital riveting. We handle simple hand assemblies and work with fly presses as well.

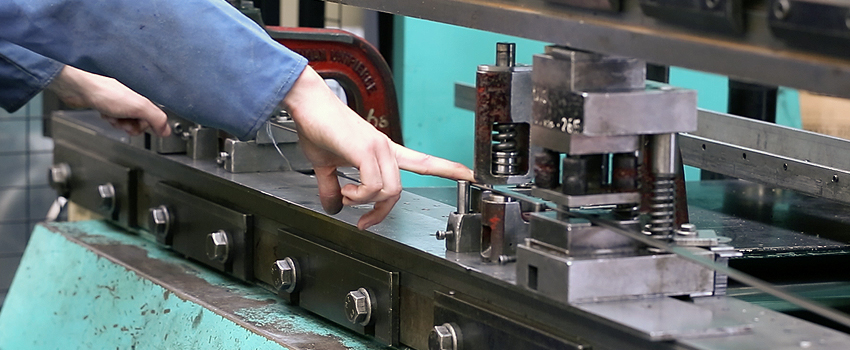

Press Braking

We integrate single punching systems alongside single-operation bends, up to multiple bends utilising our CNC press brake. Industries we cater to include Catenary Hanging Systems and high-end children's pushchairs/prams.

… And more.

Our Products Include:

We produce a variety of items available for direct purchase from our inventory. This facilitates quick and streamlined ordering for customers in need of parts on a regular basis.

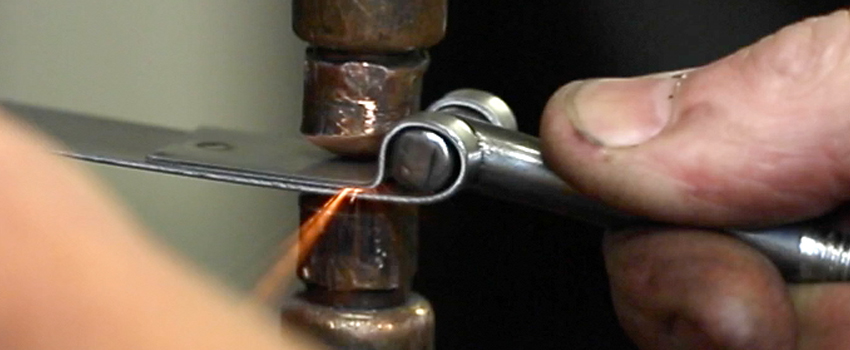

Hi-Torque Stainless Steel Clamps

Our hi-torque stainless steel clamps are engineered to provide peace of mind precisely where it's needed. Specifically designed for durable and reinforced hoses, they offer excellent, uniform tightening for enhanced sealing pressure. We source materials exclusively from top suppliers, with material test certificates readily available for inspection. Every component of the clamp is produced in-house using our own tooling. Our clamps are simple to install and feature no loose parts found in other nut and bolt systems, ensuring they remain intact even when undone. Ideal for applications in challenging-to-access areas! Additionally, all band edges are fully rounded, safeguarding the hands of the user and, importantly, protecting the rubber or other materials gripped by the clamp.

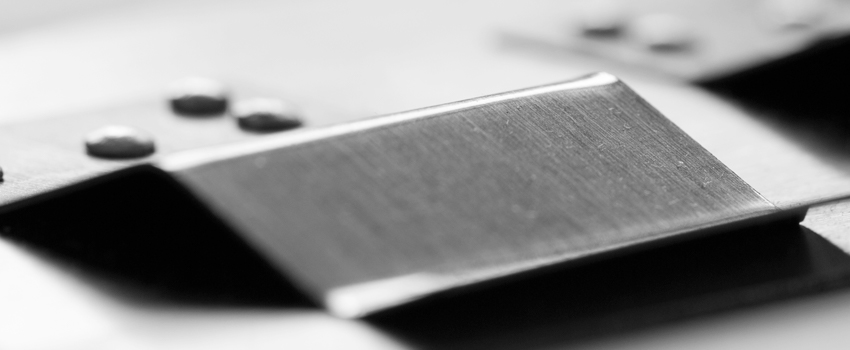

Extension Wear Plates

All our wear plates are crafted from high-tensile steel at competitive rates and are designed for cold-end operation. We offer a wide range of sizes with fast delivery turnaround times. Our clientele spans across the majority of the UK, and we also export to glass packaging manufacturers internationally. Our extension wear plates easily clip into place on the machinery, ensuring convenience and efficiency. These are just a few factors contributing to why we are the preferred supplier for some of the largest glass manufacturers in the industry.

The Sectors We Cover Include:

- Construction

- Industrial

- Glass Packaging

- Electrical

- Groundworks

- Lifestyle

At A&R Engineering Services Ltd, our commitment revolves around crafting products of impeccable quality. We meticulously select materials such as mild steel, hardened and tempered steel, and stainless steel of diverse grades to ensure durability and performance.

This dedication to excellence has led to a notable enhancement in our reputation over recent years. Our team of specialists possesses the expertise to design products precisely tailored to the stringent specifications outlined by our clients, who rely on our services across a spectrum of applications.

Whether it's a small-scale endeavour or a large-scale project, we accommodate all requirements, delivering unparalleled customer service that sets us apart from the competition.

Images