Company details for:

B2B Injection Moulding Ltd

Felling Shore Industrial Estate,

Nest Road,

Gateshead,

Tyne & Wear,

NE10 0ES,

United Kingdom

Quick Links:

Products

Initial Modelling

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

Economic Plastic Friendly Design

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

Rapid Prototype

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

Tooling Design

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

First Off Samples

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

Full Production

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

Tooling Procurement & Validation

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

Fully Hardened Production Tooling

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

Low Cost Tooling for Small Volume Production

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

Advice on Cost Effective Tooling Design

We work closely with several UK and Chinese partner companies in order to improve our services for our customers.

We aim to supply customers with components which are delivered on time and to full specification. This sometimes means additional post moulding operations are required for example, packaging and assembly.

We can undertake several sub-assembly and finishing operations in-house. For those requiring special equipment we can organise this on a sub-contracted basis through our network of contacts.

About us

In spite of the fact that B2B Injection Moulding Ltd only started up in July 2019, its staff, management, and directors have extensive experience in the plastics industry.

There is easy access to all major cities and national road networks from our premises in Throckley, Tyne & Wear, just 2 minutes away from the A69 and 5 minutes away from the A1. Providing all the necessary support, B2B Injection Moulding Ltd can help take an idea from conception to production.

We Provide the Following Services to Our Customers at B2B Injection Moulding Ltd:

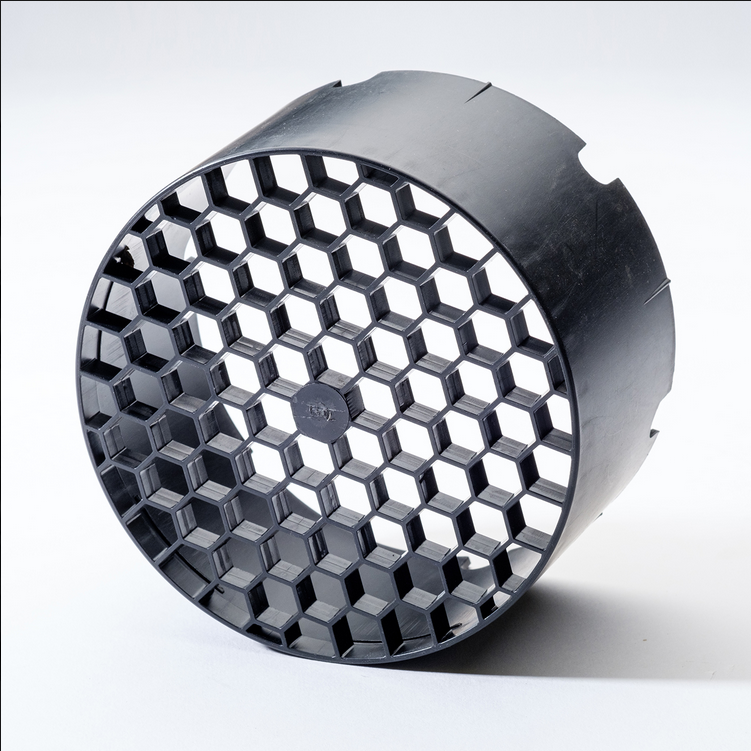

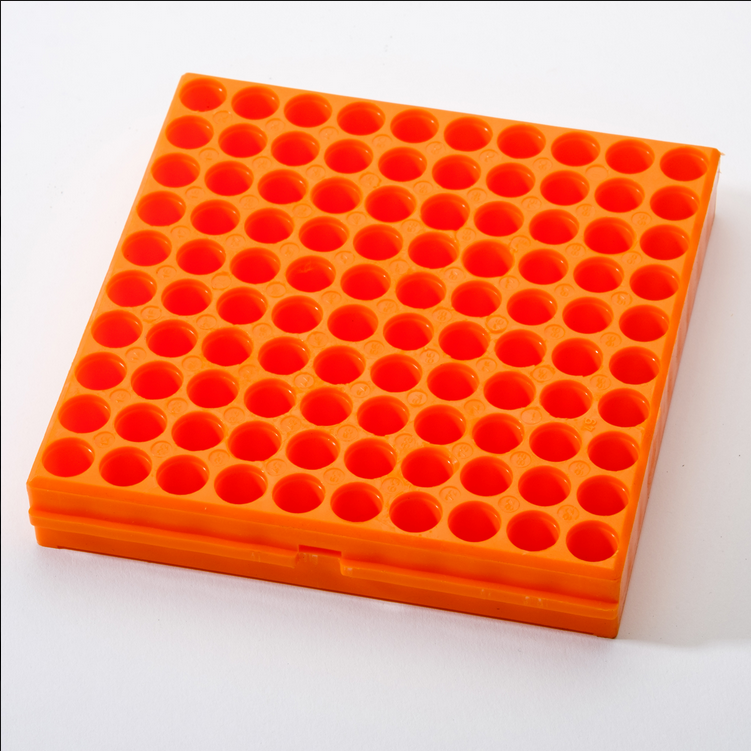

- Moulded plastic products at competitive prices.

- In almost any plastic material, precision parts from 1 to 450g are available.

- Service that is fast, reliable, friendly, and aligned with the needs of the customer.

- Producing short or long runs on an ongoing or temporary basis.

- Transfer of components from existing tooling.

- Procurement of new tooling.

- Offer a friendly, reliable, flexible service that is easy to deal with.

- Having a high level of technical competence means we can often offer innovative solutions for most cost-effective component production.

- Offering sound advice on topics such as product design for manufacture, best material choice, etc., is something we are well known for among our existing customers.

- Our 3D coordinate measuring machine allows us to validate tools in-house.

- Taking on "problem jobs" and resolving issues as they arise.

- Ability to mould specialist materials, such as thermally conductive plastics and high-temperature plastics.

- We can source services we cannot offer directly to our customers (e.g. tooling manufacture) from long-standing partners at very competitive prices.

Sponsored Links

Reviews

Trade Associations