Company details for:

Barwell Global Ltd

Unit 1,

9 Burrel Road,

St. Ives,

Cambridgeshire,

PE27 3LE,

United Kingdom

Quick Links:

Products / Services

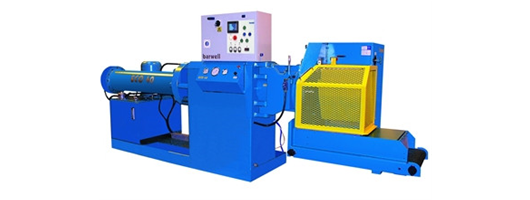

Gear Pump Preformers & Extruders

ECO Ram Preformers & Extruders

ECO-NX Smart Ram Performers

ECO Clean Room Ram Extruders

BVP Value Ram Preformers

Approved Used Machines

Rubber Strip Cutting Machine

VibraCool Spiral Cooling Conveyors

Specifically developed for the effective cooling, separation, and drying of hot rubber parts produced on a Barwell preformer or extruder.

Cryogenic Rubber Deflashing Machine

Spin Trim Rubber Deflashing Machine

Rubber Compression Moulding Machines

Rubber Bale Cutter

The normal use of a bale cutter is to cut the large slabs of raw material e.g. natural rubber and synthetic Rubber. The resulting smaller pieces are then mixed to make the compound needed for the processor’s final product.

It is ideal for production applications as well as high-volume laboratory applications.

Machine Ancillaries

RapidDry Industrial Drying Ovens

Complete Rubber Production Lines

About us

Based in Cambridgeshire, our company has over 5000 machines installed across the globe, each designed using the latest technologies as well as our years of expertise and skill. We take great pride in our ability to maximise efficiency as well as productivity and profitability.

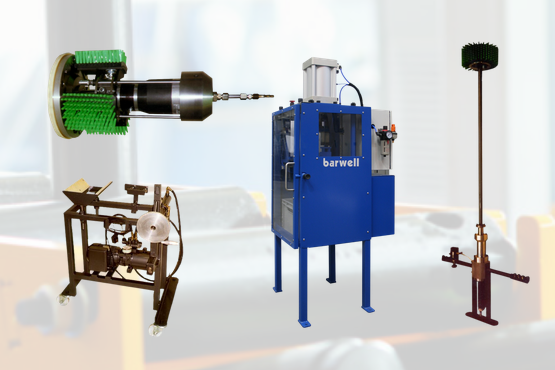

Here at Barwell Global, we offer a wide range of innovative machines that have been highly praised by our loyal customer base. Some of these include;

- Rubber Ram Preformers & Extruders

- Continuous Gear Pump Screw Extrusion & Preforming

- Rubber Strip Cutters

- Cryogenic Deflashing Equipment

- Spinning Rubber Deflashing Equipment

- Spiral Take-Off Cooling Systems

- Hydraulic Compression Presses

- Industrial Drying Ovens

- Tyre-Retreading Systems

- Ancillaries, Other Processing Equipment & Custom Design

Our services cover over 40 countries worldwide, catering for multiple industries and sectors across an international scale. Our innovative machinery and equipment is offered at very competitive prices that cannot be found anywhere else, ensuring excellent results at all time.

Images