Company details for:

Beechcraft Ltd

Units 27/28,

Westfield Industrial Estate,

Midsomer Norton,

Bath,

Somerset,

BA3 4BS,

United Kingdom

Quick Links:

Products / Services

Product Design

As we are accredited with ISO 9001 we are confidently able to offer not only guidelines and help with product design advice but also a fully controlled and inclusive design service right through to finished product.

We can provide initial rough concept drawings through full colour design illustrations to detailed working drawings, in 2D or CAD format for final customer approval.

Our long experience − over 30 years in this field − enables us to maximise the styling potential of PU with optimum functionality in a cost-efficient format.

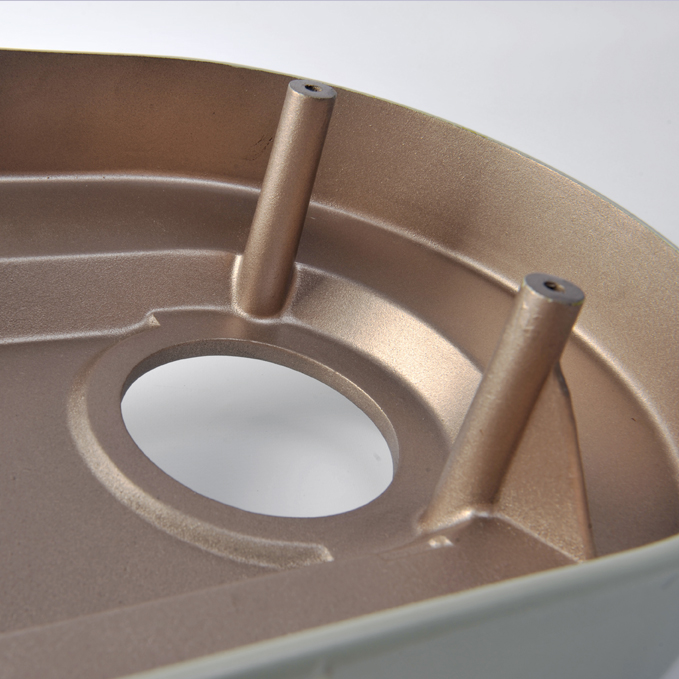

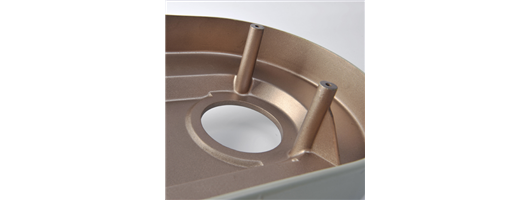

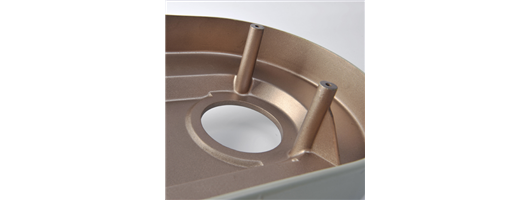

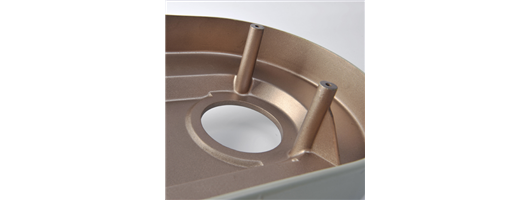

Cast Resin-Aluminium Composite Tooling

Cast Resin-Aluminium Composite Tooling

- A low-cost, quick-start, yet fully production-orientated option to produce custom designed enclosures.

- With a typical 6 to 8 week turnaround from go ahead to first-off samples we offer a guaranteed minimum of 500 impressions − yet often twice or three times this amount can actually often be produced from a single tool before refurbishment or replacement is required.

- Utilising an SLS or SLA, CAD-generated pattern, oversized to allow for shrinkage, our in-house toolmakers will produce an accurate and highly finished mould tool complete with pin-locations so that threaded inserts can be moulded-in, ejector pins, and any side-cores called for by the design.

Machined Aluminium Tooling

- Timescales for this option are generally from 10 to 12 weeks from go ahead to first off samples.

Moulding Manufacture

What is it?

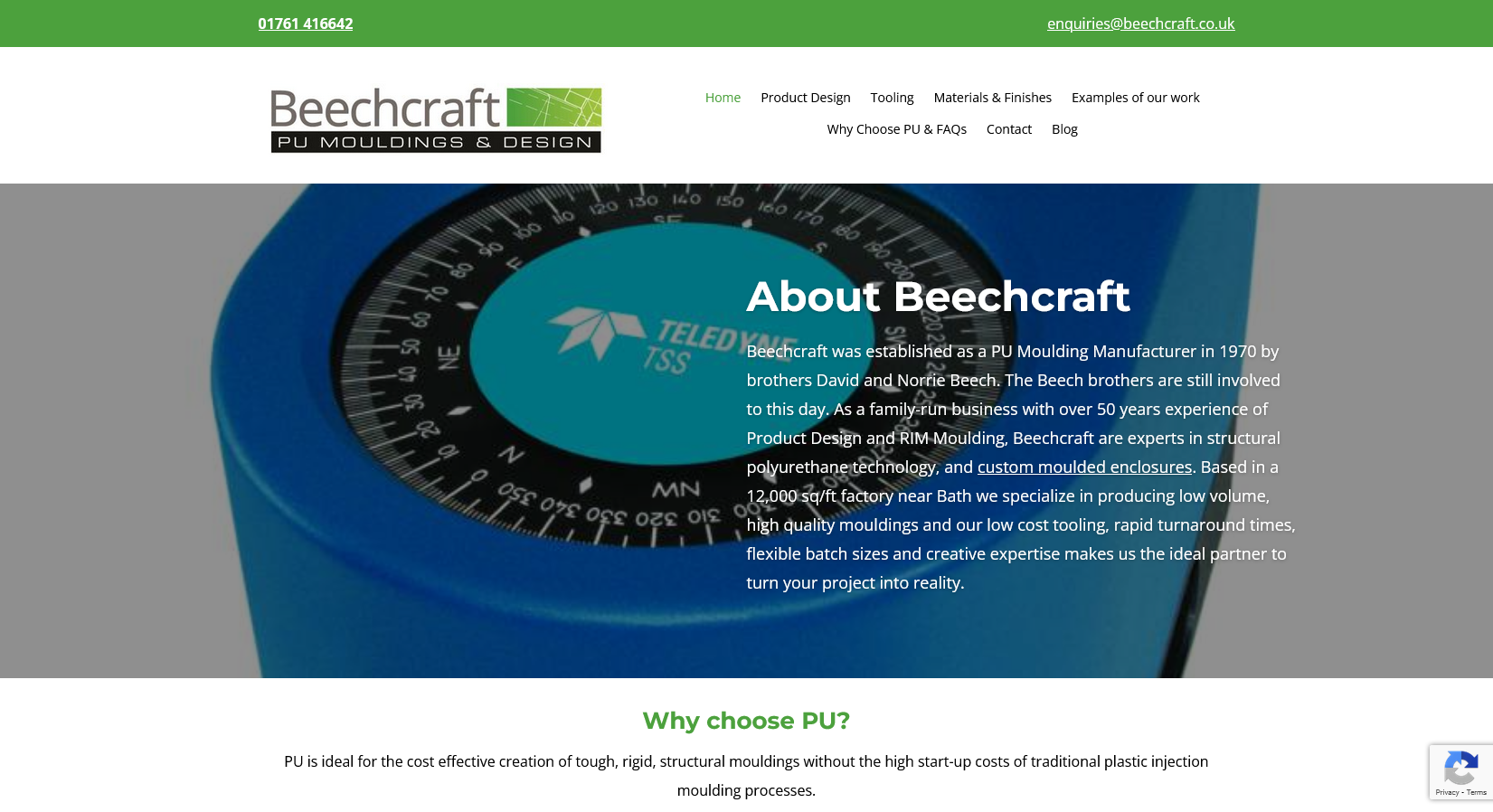

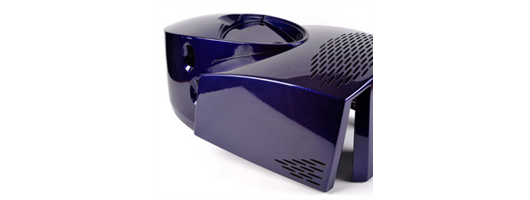

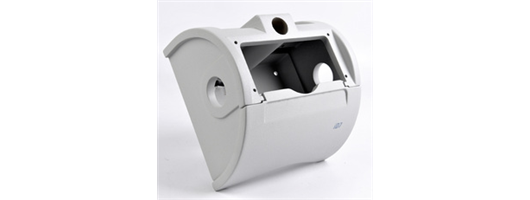

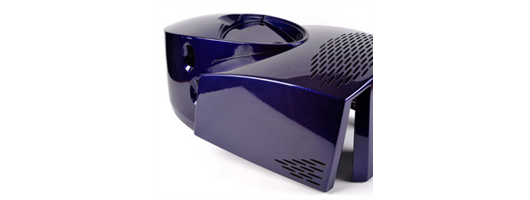

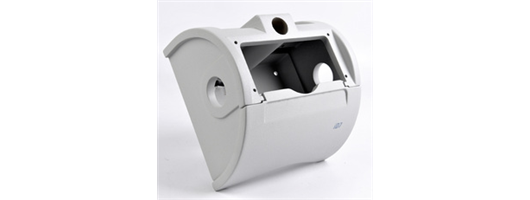

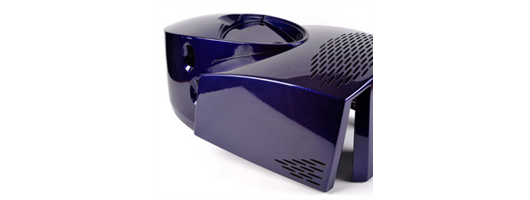

Our PU (or RIM) is a rigid, self-skinning, thermosetting, expanded foam system specifically blended to produce tough, rigid and structural mouldings.

What is it good for?

Low-run batch quantities, from two or three, up to two or three hundred, moulded covers, instrument cases and awkwardly-shaped components that have to perform strongly, be very cost-effective and still look great!

What’s the process?

We inject a reactive mixture of resin polyol with an ISO curing agent into a closed mould-tool. The mixture instantly reacts and greatly expands, filling the tool cavity to a density of around 600 kg/m3 and at the same time forming a hard, solid resin skin all round.

Why is it cost-effective?

For small batches of mouldings for high-value products PU is extremely cost-effective due to the low start up costs of our resin/aluminium mould-making process − considerably less than for injection moulding tooling.

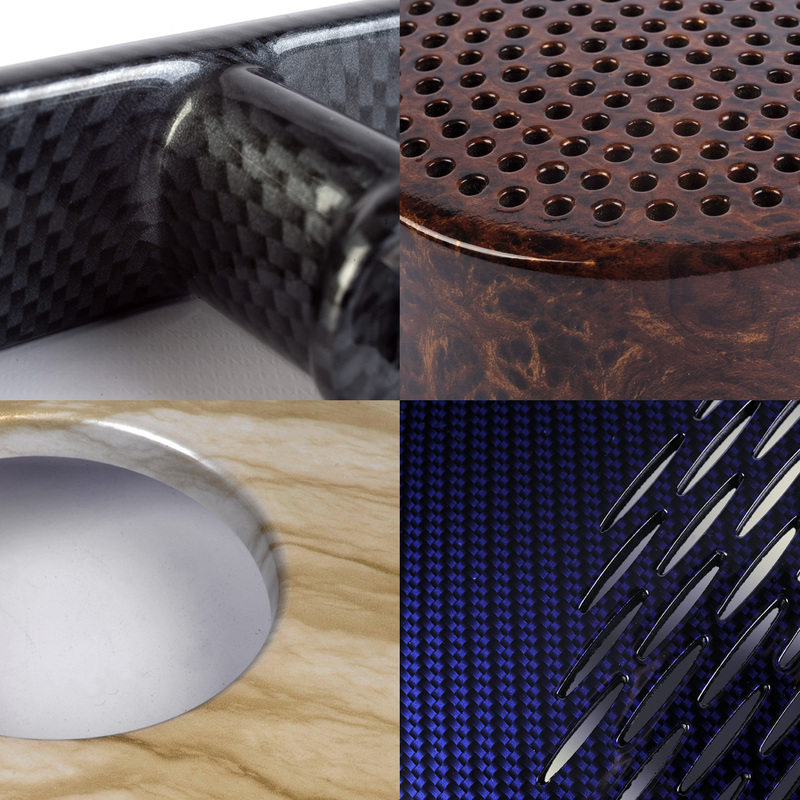

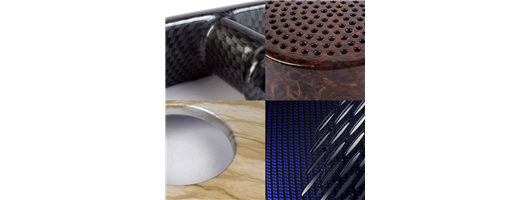

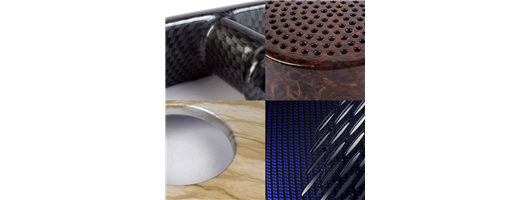

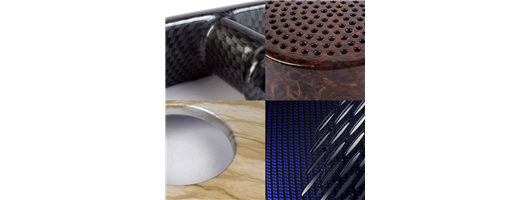

EMC Coatings

- Our standard nickel/acrylic based RFI paint is a popular coating providing standard level of EMC protection down to a resistivity of <5 ohms square, adequate for normal purposes.

- If necessary, other protective materials such as silver/gold coatings can be applied which will provide a much higher level of EMC protection.

Paint Finishing

- Various finishes can be specified using these paints varying from the popular traditional hard-wearing spatter/texture right up to a variety of high gloss

level finishes.

Silk Screen Printing

Speciality Finishes

Moulded-in Threaded Inserts

Tappex Yardley C type inserts (blind to minimise PU ingress) are our preferred choice although shorter or through inserts can be used where appropriate to

the design.

About us

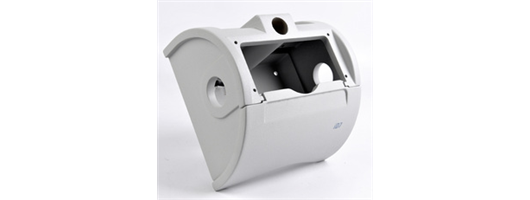

We are a family run company specialising in a range of services including Product Design, Tool Design & Manufacture, Moulding Manufacture, EMC Coatings, Paint Finishing and Silk Screen Printing. We also offer Prototyping and Assembly Operations.

Beechcraft use only the finest mould tools including Cast Resin-Aluminium Composite Tooling for producing custom designed enclosures and Machined Aluminium Tooling for producing more than 5,000 impressions.

We Design & Manufacture Products Such as:

• Moulded Enclosures

• Moulded PU Cases

• Polyurethane Foam Mouldings

• PU Mouldings

• Custom Moulded Enclosures

• High quality mouldings

• Cost effective moulding

• Fast turn around

• 50 years’ experience

• Flexible batch sizes

• Free technical advice and ideas

Images

Articles / Press Releases

Reviews

Trade Associations