Company details for:

Blackfast Chemicals Ltd

Unit B,

121 Roebuck Road,

Chessington,

KT9 1EU,

United Kingdom

Quick Links:

Products / Services

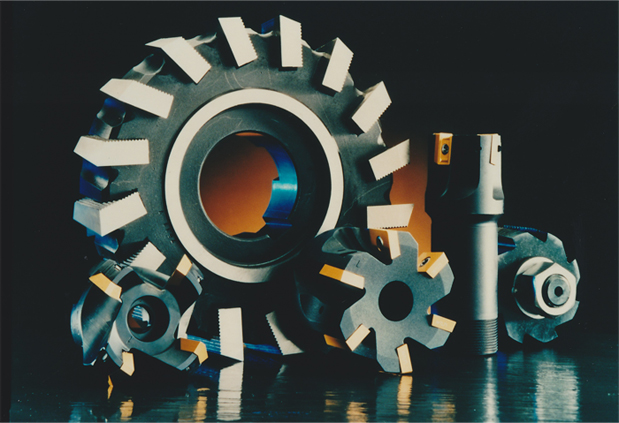

Metal Blacking

Iron & Steel Blacking

Aluminium Blacking

Stainless Steel Blacking

As with the Iron and Steel Blacking process, the stainless-steel blacking process operates with a 7- stage dipping process.

The process equipment required is a simple arrangement of polythene tanks and ideally running water rinses.

Processing entails degreasing, pickling, blacking and lastly an immersion in a dewatering oil, all with intermediate water rinses. For the stage of Pickling, it is recommended that you have extraction over this tank as a strong acid pickle is used.

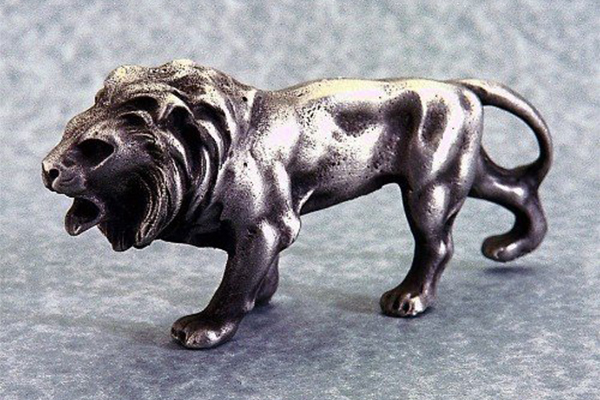

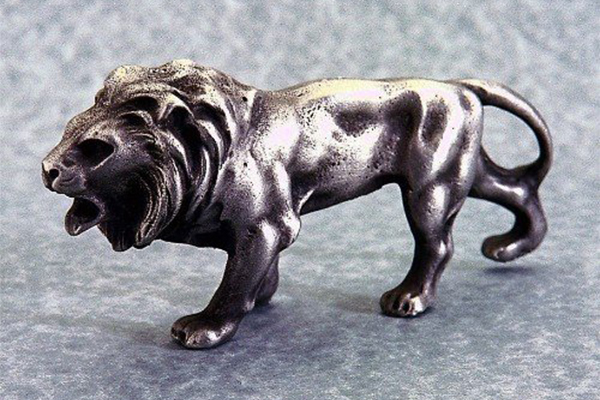

Brass Antiquing

At lower temperatures, the process is slower and the recommended immersion time of 5 minutes exceeded.

On removal from the solution, the brass is allowed to dry then lightly abraded to remove some of the coating on proud surfaces. What remains will be within the crevices and surface of the brass revealing an antiqued surface.

Copper Antiquing

Silver Plate Antiquing

Nickel Plate Antiquing

Pewter Antiquing

About us

A history of the blackoxide process

Throughout history weapon manufacturers have explored different metal finishing processes to protect their carefully crafted products from oxidisation. Their solution to the problem was to oxidise the metal surface and render it inactive from further attack.

The secrets of the chemical blacking processes known to the ancient alchemists are nearly all lost. There are a few artisans who still practice some of the traditional methods of blueing. Their metal blacking process involves dissolving copper nails in acid into which the item to be cold blacked is immersed, followed by burial in the soil for a number of weeks. The result is a deep blue black colour which when oiled has a lustrous appearance.

Etymology

This cold blacking process is known in the English language as blueing, or more recently, chemical blacking, or chemiblacking. Whilst the hot oxide process is known as black oxidising or black oxide, illogically, many Europeans have adopted the old French term, brunissage for the name of the process, which literally translated means 'browning'. In German it is brünierprozess or brünierung and in Scandanavian brunering.

The Spanish have a more colourful slant to their term pavanado, which is a very similar word to peacock with its magnificent deep iridescent purple blue plumage.

The future

With the growth in popularity of the Blackfast process during the last 10 years and its ubiquitous use throughout Europe there has been the development of yet one more name for the process - Blackfasting.

Our product range includes; alloy wheel refurbishment systems, alloy wheel refurbishment chemicals, anti-rust, antiquing, anti reflective finishes, chemi blacking (chemical blacking), cold blacking, conversion coatings, colouring products, Black electroplating, bluing, browning, black finishes, blacking, black oxide, black coatings, black conversion, bonderising, heat treat, hardening, matt black finishes, metal blacking, non dimensional coating, parkerising preservation, protective finishes, surfacing preparation, surface finishing, steel blacking,steam blacking, tool blacking.

Here at Blackfast Chemicals, we offer a unique range of services that are designed to provide excellent quality chemical blacking, some of which include;

- Iron & Steel Blacking

- Aluminium Blacking

- Stainless Steel Blacking

- Brass Antiquing

- Copper Antiquing

- Nickel Plate Antiquing

- Pewter Antiquing

- Silver Plate Antiquing