Company details for:

Brightworks Product Designers

Newminster House,

27-29 Baldwin Street,

Bristol,

Avon,

BS1 1LT,

United Kingdom

Quick Links:

Products / Services

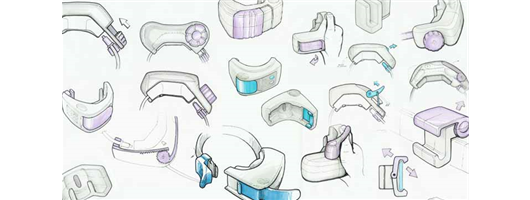

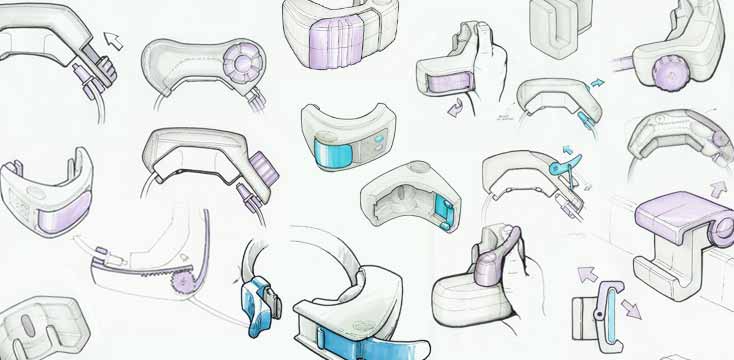

Creative Concept Generation

Product Styling

Product Visualisation

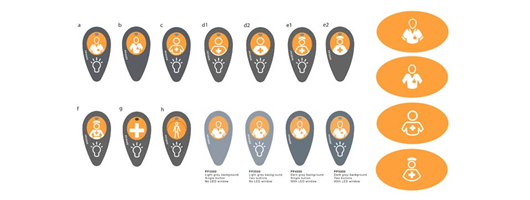

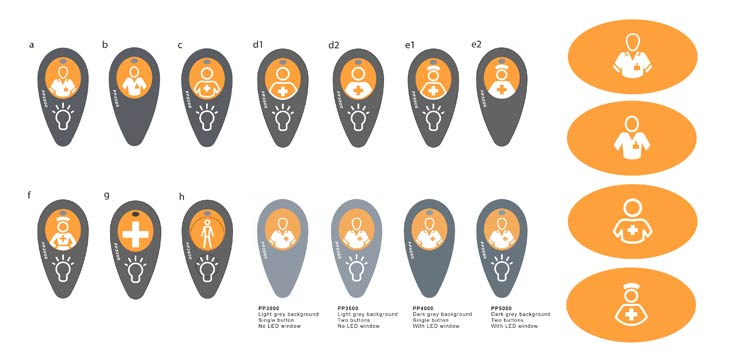

User Understanding

At Brightworks we have several structured methods to investigate all aspects of our target users. One such method is the use of in-depth product analysis matrixes. These allow us to asses subjects such as similar product competition or product configurations, and evaluate them against certain criteria such as cost, style and functionality. This process highlights the keys areas of the product or market, enabling better user understanding.

Ergonomics & Usability

Graphical User Interface

Product User Testing

Product Graphic Design

Brand Integration

Packaging Design

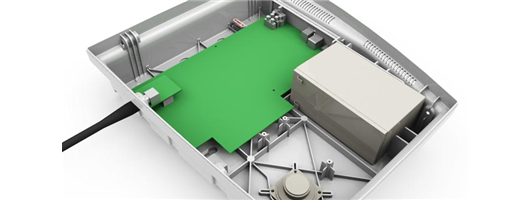

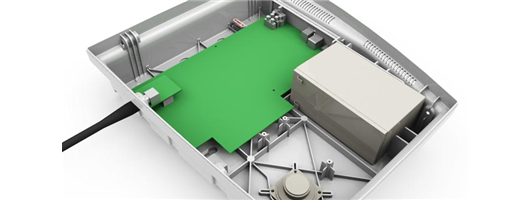

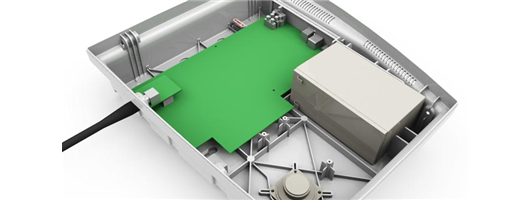

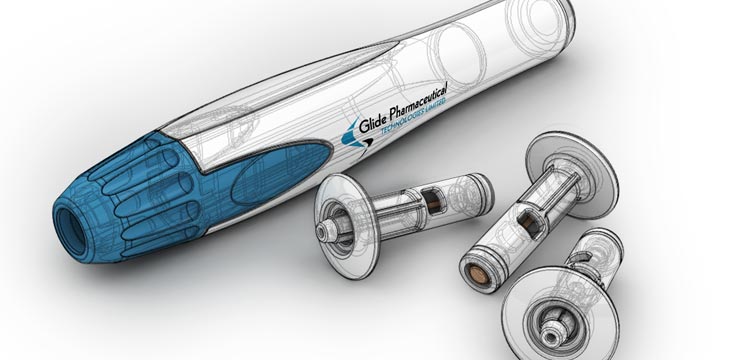

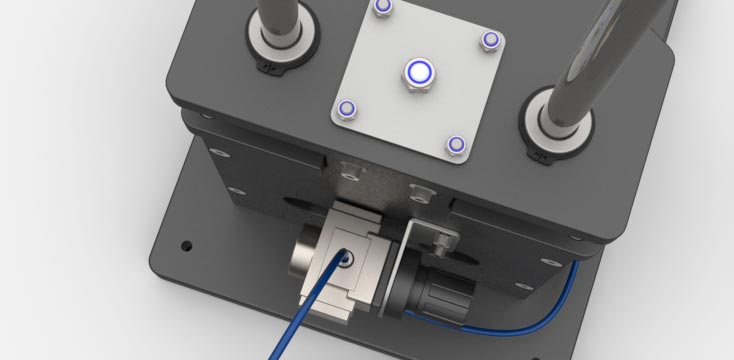

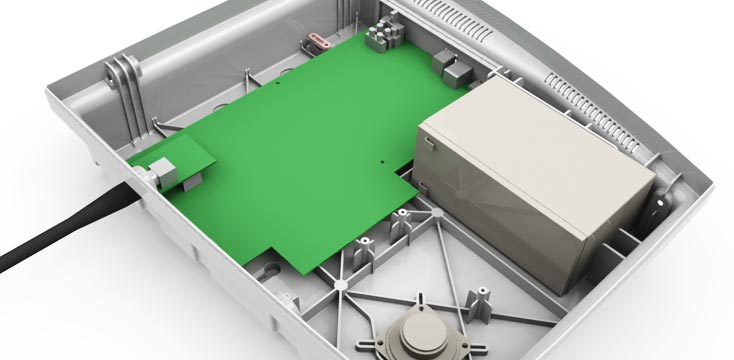

3D CAD (SolidWorks)

Brightworks are expert users of SolidWorks; a 3D CAD program that enables to us to create complex geometrical forms in a fast and cost effective manner.

Technical Innovation

Mechanical Engineering

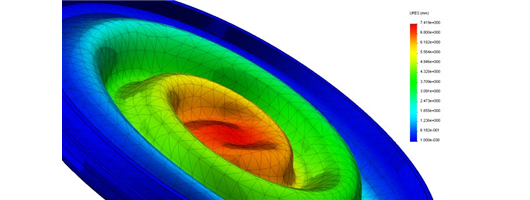

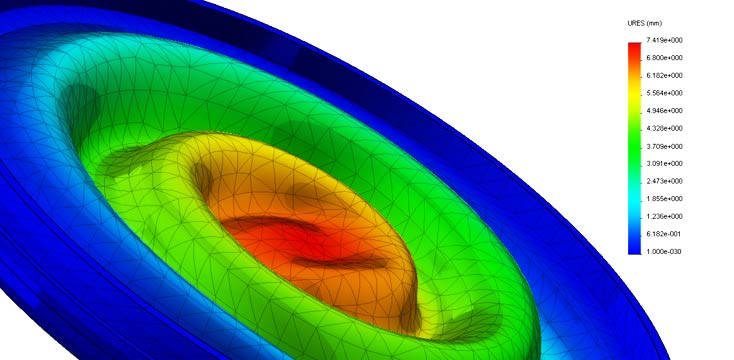

Brightworks are firm believers that the knowledge of these principles goes hand-in-hand with design. Efficient use of calculations to incorporate engineering principles into the design of a part will ultimately reduce development time and produce parts that will work and perform as intended.

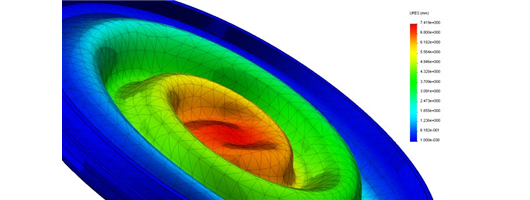

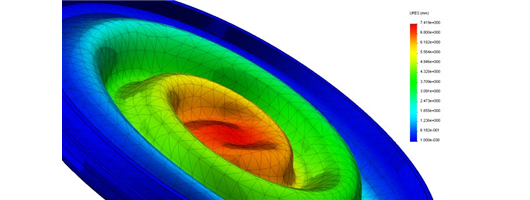

FEA & Simulation

Design for Manufacture & Assembly

Brightworks always strive to add value to your project and drive down cost where possible. Our knowledge of manufacturing and assembly techniques allow us to design in clever ways to reduce production time, improve assembly methods and save you money.

Space Models

Visual Models

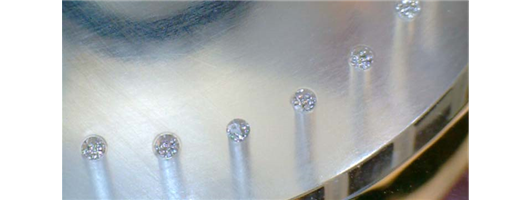

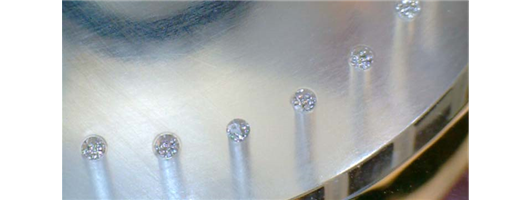

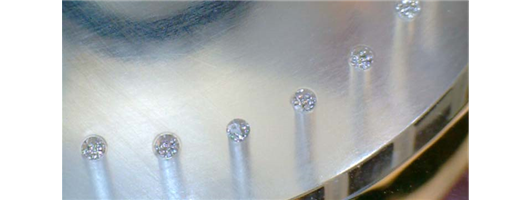

Our extensive experience in 3D Printing/Rapid Prototyping techniques allows us to advise you on the best process to achieve the finish and quality you require. Be it SLA, SLS or CNC machining, we can prototype your product to the desired level of finish.

Development Models

Brightworks produce a range of development prototypes on a regular basis. Our knowledge of design and rapid prototyping techniques ensure we get the most out of every model produced. Each one of our models created has a defined purpose, allowing Brightworks and our clients to make clear and calculated decisions, to progress the project onto the next stage.

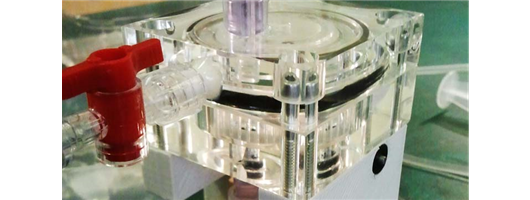

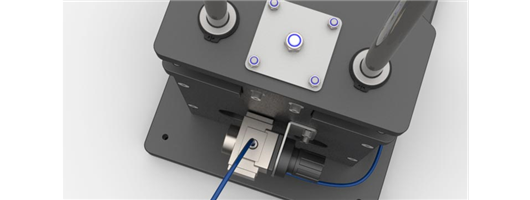

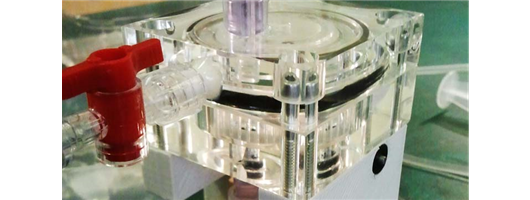

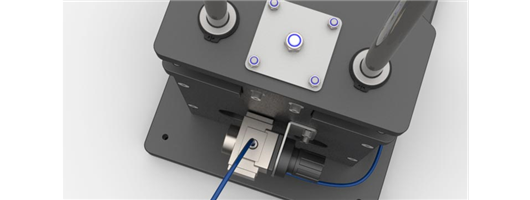

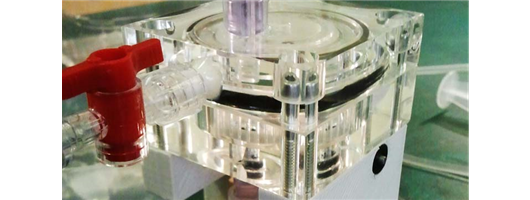

Test Rigs & Technical Prototypes

Fully Functioning Models / Pre-Production

Batch production can be done at a prototyping stage through resin casting or prototype tooling, with a wider range of materials than rapid prototyping alone. These processes allow for multiple prototypes to be made to a high standard, without the significant investment of full production tooling.

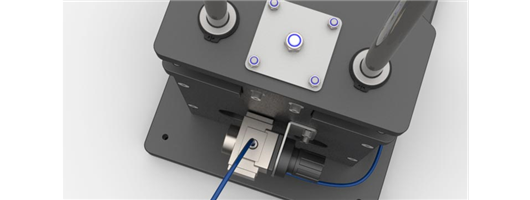

Production Specification

With the majority of manufacturing based outside of the UK, we understand the importance of clear and precise drawings so that information is not lost through communication errors. Our drawings provide all the data required for prototyping, production or tooling development, reducing the amount of correspondence required during a time when timescales are increasingly more demanding.

Jigs & Fixtures

Supplier Sourcing

Material Selection, Testing & Validation

At Brightworks we are not material specialists as such but we have a good working knowledge covering a wide variety of different materials. In particular we are very familiar with the extensive range of polymers, plastics and rubbers that are commercially available.

Manufacturing Liaison

About us

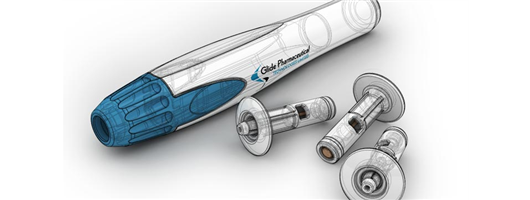

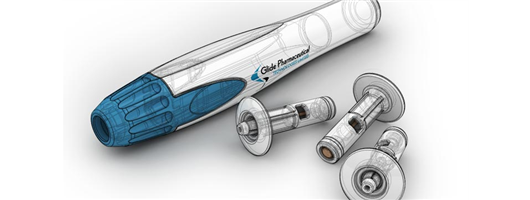

Established in 2003, Brightworks Product Designers have almost 20 years’ experience in providing a wide range of quality new product development services.

We are an award-winning team of development consultants, mechanical designers and production engineers based in Bristol, offering our services throughout the entirety of the UK. We provide a flexible company structure which allows us to keep overheads to a minimum and meet the needs of our customers as productively and efficiently as possible.

Some of our main services here at Brightworks include creative concept generation, product styling, product visualisation, user understanding, ergonomics and usability, graphical user interface, product user testing, product graphic design, brand integration, packaging design, 3D CAD, technical innovation, mechanical engineering, FEA and simulation, design for manufacture and assembly, space models, visual models, development models, test rigs and technical prototypes, fully-functioning models, production specification, jigs and fixtures, supplier sourcing and more.

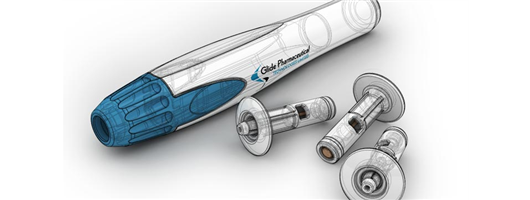

Over the years, we have built up strong relationships with clients who have praised our services for being reliable, efficient and professional. Some of these clients include well-established brands such as OptiNose, Glide Pharma, Aid Call, Anim Alarm, Limbs & Things, Clarks, Kelda Showers, XMOS, EcoEgg, Winnku, ICF Tech, Empak Ltd, Lansinoh, Avon Protection, EnModus, Forecourt Solutions and many more.

All products and services we provide are tailored to the exact specifications of our clients and we strive to exceed their expectations time and time again.

Images