Company details for:

Magnet Applications

Northbridge Road,

Berkhamsted,

Hertfordshire,

HP4 1EH,

United Kingdom

Quick Links:

Products / Services

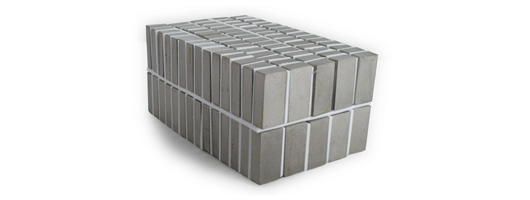

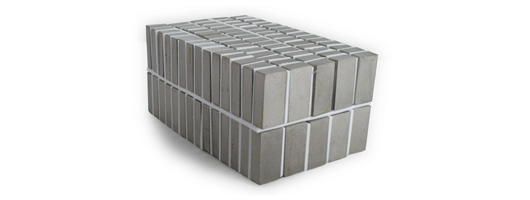

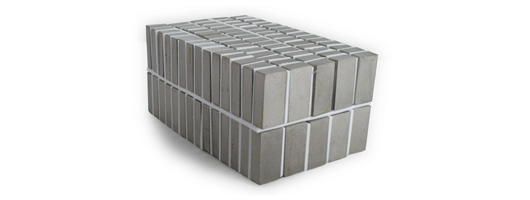

Neodymium Magnets

Neodymium magnets are the most powerful magnets available. They are the first choice for maximum performance from minimum size.

Full range of Neodymium Magnet Grades available.

Radially Aligned Magnets Available to replace Arcs.

2 rare earth magnets available; Neodymium magnets and Samarium Cobalt

Grain Boundary diffusion now available in commercial quantities

Neodymium magnets maximum recommended temperature ratings from +60°C up to +230 °C, depending on grade.

All Bunting Magnetic’s neodymium magnets are REACH and ROHS compliant and do not contain SVHC’s.

All Manufactured at ISO9001, ISO14001 and TS16949 accredited audited partners.

Certificates of Conformity, MSDS and PPAP’s available.

Grain Boundary Diffused Magnets

Grain Boundary Diffused magnets employ a secondary manufacturing process to concentrate the Heavy Rare Earth Element Dysprosium into the grain boundaries of the magnet microstructure, hence the name. This not only nets a performance increase but uses less Dysprosium making them more price stable than traditional method magnets.

All GBD Neodymium NdFeB is REACH and ROHS compliant and does not contain SVHC’s whilst licensed grades are produced to ISO9001 and ISO14001 Quality Control Standards. Certificates of Conformity, MSDS and PPAP’s can be supplied on request.

GBD Neodymium grades exist with the maximum recommended temperature ratings - from +60°C up to +230 °C but these ratings are GUIDELINE values only. The actual maximum temperature rating depends on the shape of the magnet and the design of the application. GBD magnets are limited in thickness to 8mm, and certain grades are not available with some magnet geometries.

Please contact us for the highest available grade in your magnet design.

Plastic Bonded Neodymium Magnets

especially suited to minimise cogging torque in motors for example. Injection moulded magnets are particularly suitable for high volume applications.

Bonded NdFeB magnets are either compression or injection moulded to net shape high, tolerances are achieved, require no

further machining.

Injection Moulded Neo and Ferrite Magnets Available.

Injection Moulded Ferrite has high durability and resistance to shock.

Injection moulded Ferrite is low cos and offers extreme resistance to corrosion and low density

High Tolerance and complex shapes available.

Bonded and Injection Moulded Neo is Isotropic so, multipole magnetisation available, including skew angled poles.

Bonded Magnets are manufactured in the UK, USA or our accredited partners.

Certificates of Conformity, MSDS and PPAP’s available.

No coating required, Compression bonded magnets can be Black Epoxy or Parylene coated for extra protection.

Samarium Cobalt Magnets

Latest High Grades available now.

SmCo Magnets can be used in high temperature applications, typically up to 350C.

Start to outperform Neodymium magnets at temperatures above 150C.

High Tolerances can be achieved.

Very good corrosion resistance.

Can be coated for specific automotive and marine applications.

All Manufactured at ISO9001, ISO14001 and TS16949 accredited audited partners.

Certificates of Conformity, MSDS and PPAP’s available.

New XGS33 grade of Samarium Cobalt for higher stability and magnetic performance at raised temperatures;

Samarium Cobalt Magnets can be made in blocks, discs, rings, arcs, spheres, triangles, trapezoids and many other shapes. Please call or contact us for your specific requirements or for any technical assistance. Rapid prototyping and UK stock holding for Kanban / JIT deliveries is available. All customer specific magnets are inspected at our UK magnetic inspection facility. For full details of our capabilities visit: bunting-berkhamsted.com/magnets-experts

Ferrite Magnets

All Ferrite Grades available, including Isotropic and Anisotropic.

Suitable for high volume applications.

High working temperatures, typically up to 300C

High resistance to corrosion, they cannot corrode in water.

Ideally suited to use in motors, loudspeakers, clamping devices and for use with reed switches.

Certificates of Conformity, MSDS and PPAP’s available.

Alnico Magnets

Full range of sintered and cast Alnico magnets available

Alnico is especially suited to customer specific or bespoke complex shapes and sizes

Alnico is suited to anything requiring high field output and operation at really high temperatures. Up to 500C.

High Magnetic Performance due to High Br Values - although low coercivity.

High Corrosion resistance.

Alnico is easy to “tune”. Which is important in some applications e.g. spectrometers and other specialist testing equipment.

Typically used in sensors, generators, loudspeakers, electric meters and even dc motors.

Can be ground to very tight tolerances.

Manufactured at ISO9001, ISO14001 and TS16949 accredited audited partners.

Certificates of Conformity, MSDS and PPAP’s available.

Flexible Magnets

Full range of flexible materials suitable for sensors, motors and Point of Sale displays, packaging products and signage.

Low Cost

Temperature use range is typically -20C to 70C.

Suitable for low and high-volume applications

Can often be rolled.

Adhesive backings available

Options include vinyl finish, dry wipe, printed.

Certificates of Conformity, MSDS and PPAP’s available.

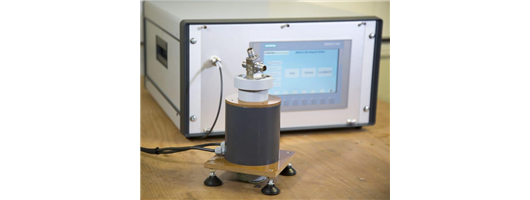

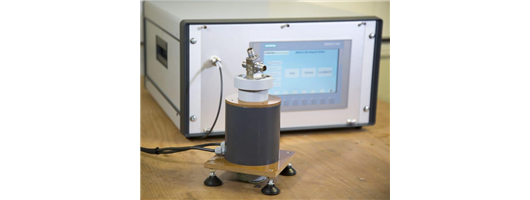

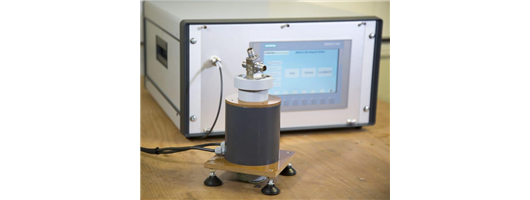

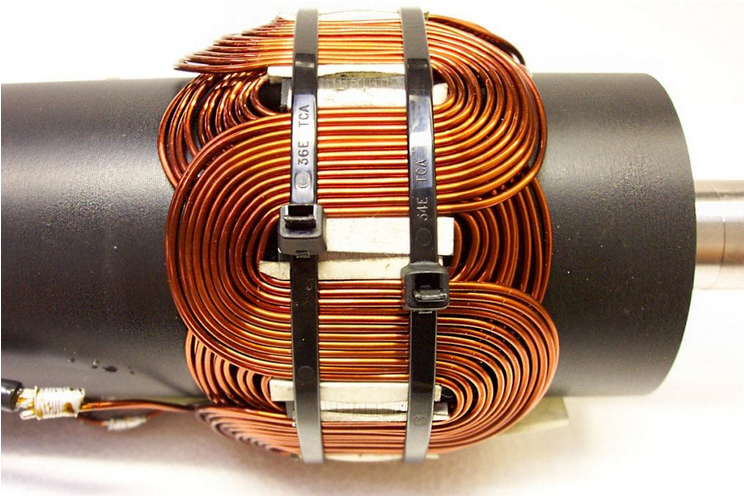

Magnetising & Testing

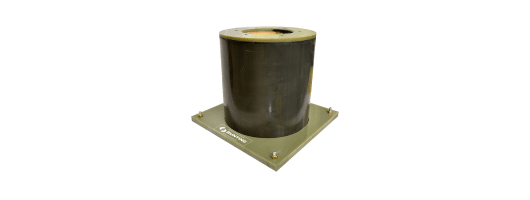

For the prototyping of new products we can build prototype fixtures capable of magnetising small volumes of samples or full production fixtures when volumes increase. Certain types of prototype fixture can be upgraded to production fixtures at a later stage to reduce cost.

All our production fixtures are water cooled and are automatically programmed to the run at the correct operating voltage by the magnet charger for quality control purposes. Certain magnets require to be magnetised with poles aligned with some feature on the magnets. The magnetising fixtures can be error proofed to guarantee the alignment of the poles.

The Quality Control Department also has an extensive range of magnetic testing equipment which is available for the testing of customer’s magnetic products.

Design Consultancy

The software is compatible with most mechanical CAD packages so customers own designs can be directly imported. We also have the facilities to measure the BH curves of permanent magnets on site, so we can use real measured data in the calculations, both at room temperature and at elevated temperatures.

When applicable, magnetisation data which has been generated from the design of the magnetising fixture can be used to model the magnet. This is a very powerful tool and is particular important for the modelling isotropic magnets such as bonded NdFeB where the direction of magnetisation is defined by the magnetising fixture and can vary considerably throughout the magnet volume.

Design & Services

With an exceptionally strong technical team and having been in business for over 60 years, we understand magnets and their applications.

At Bunting, we can share this knowledge and experience with our customers through our design consultancy or testing services. This can take many forms, whether it is simply magnetic field calculations to verify the performance of the customer’s own device, testing of customer’s magnets, assistance with magnetic material selection, optimisation of the magnet geometry, mechanical assembly, post assembly magnetisation, prototyping or the complete design and manufacture of a magnetic assembly.

Design & Manufacture

With an exceptionally strong technical team and having been in business for over 60 years, we understand magnets and their applications.

Manufacturers of Magnets UK

Manufacturing plastic bonded magnets (Bremag 10) as well as designing and manufacturing for those who are seeking a bespoke service when it comes to magnetisation fixtures, we offer a wide range of configurations. With high quality service and ISO9001 & ISO14001 accreditation combined with an enthusiastic passion for all things magnetic, Bunting offer all of the benefits and assurances required when seeking an established long term partner to supply all of your magnetic requirements. We can also call on a supremely reliable supply chain which enables the company to go on delivering high volume magnets in all of their various types and grades.

Magnetising & Testing

For the prototyping of new products we can build prototype fixtures capable of magnetising small volumes of samples or full production fixtures when volumes increase. Certain types of prototype fixture can be upgraded to production fixtures at a later stage to reduce cost.

All our production fixtures are water cooled and are automatically programmed to the run at the correct operating voltage by the magnet charger for quality control purposes. Certain magnets require to be magnetised with poles aligned with some feature on the magnets. The magnetising fixtures can be error proofed to guarantee the alignment of the poles.

The Quality Control Department also has an extensive range of magnetic testing equipment which is available for the testing of customer’s magnetic products.

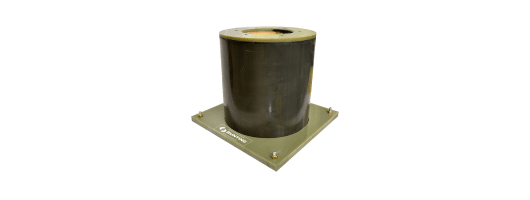

BMC Series - Industrial Range

BMCL Series− Laboratory/Volume Small Part Production

Standard safety interlocks prevent fixtures from being operated when over temperature.

For situations where multiple magnetizing fixtures may be used, additional safety interlocks are recommended. The process of setting individual fixture parameters can be automated such that all the operating parameters are stored in the fixture control plug, which once connected to the magnetizer, automatically sets the machine ready for production. This prevents fixtures from ever being operated at too high a voltage or when over temperature which could damage the magnetizing fixture.

These magnetizers are particular suitable for magnetizing small multipole magnets up to diameters of approximately 50mm, fine pole pitch magnetisation, and more general 2 pole magnetization of most permanent magnet materials including rare earths.

BMCS Magnet Setter

Energy 100 - 200J

Mag / Demag Operating Modes

For Production or Laboratory Use

Optional Dual Fixture Outputs

Optional automatic calibration

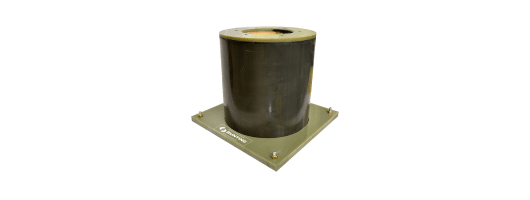

Magnetising Fixtures

Calibration, Service and Repair

Annual Service Contracts

Calibration Audits

On Site or return to factory repair service

Critical Spares Pack

Pro-StartTM

Commissioning

1-year warranty

2 years of telephone support

Pro- MaintenanceTM

Service

Calibration

Software Updates

Gold Plan − Annual service and calibration

Platinum Plan − Twice yearly service and calibration

Magnetic Separation

Belt Conveyor Metal Detectors

Free Fall Metal Detectors

Pneumatic Metal Detectors

Textile Metal Detectors

Metal Cleaning Systems

Soft Magnetics

With our strategic partners we can also supply powder cores including sendust, MPP, and the latest powder alloy cores for chokes; carbonyl iron cores for high-frequency applications; strip wound cores in silicon steel and nickel alloys; and our most recent addition of amorphous and nanocrystalline cores.

We can assist with the design and supply of high frequency and high power chokes and transformers for various applications such as rail and renewable energy. These are manufactured by one of our strategic partners; we will then manage the entire supply chain to ensure products are available from our facility in Swindon, UK.

About us

Magnet Applications focuses on the creation and production of magnets, magnet assemblies, and magnetisers.

Situated in Berkhamsted, UK, Magnet Applications is affiliated with the Bunting Group, a globally renowned supplier for over 60 years, operating manufacturing facilities across the globe. What sets Magnet Applications apart is its exceptional role in designing and supplying magnets, magnet assemblies, and magnetisers, a distinctive combination.

Our Products & Services Include:

- Magnet Manufacturer: Magnet Applications engages in the creation, production, and distribution of a wide and comprehensive assortment of magnets, positioning itself as a prominent player in Europe. This magnetic range encompasses Neodymium, Samarium Cobalt, Ferrite, Alnico, and Plastic Bonded Neodymium Magnets (Bremag). Standard magnets are conveniently available through the pioneering Bunting-eMagnets, the UK's inaugural online magnet store. Through plastic bonded magnet technology (Bremag), the company enables the customisation of Neodymium magnets into bespoke shapes and configurations, catering to specialised needs within various engineering sectors.

- Magnet Assemblies: The Bunting engineering group comprises professionals with extensive magnet and magnetic-related experience spanning decades. Leveraging this profound engineering knowledge, Bunting creates and produces customised magnet assemblies to cater to businesses across diverse sectors, encompassing automotive and aerospace industries. The dimensions of a standard magnet assembly vary, ranging from a few millimetres in length and beyond. Numerous individualised designs are meticulously crafted to match distinct sizes and magnetic intensities, ensuring a tailored fit.

- Magnetisers: Magnet Applications provides an exceptionally extensive collection of magnetisers, encompassing a global scope. This array comprises Industrial Magnetisers, Bench-top and Laboratory Magnetisers, in addition to Magnet Setters and Magnetising Fixtures. This equipment, designed for precise functions, is frequently tailor-made to suit particular applications. The Bunting team undertakes the complete creation process, including the magnetiser, its control panel, and the magnetising fixture. A rigorous testing phase is conducted at the Berkhamsted facility. These magnetisers find widespread utility across the electronics, automotive, and aerospace sectors.

Future Magnet Development

The engineering team at Bunting consistently evaluates progress in magnet technology, aiming to bring improved and advanced magnetic materials to the market. Currently, the company plays a significant role in the EU-supported SUSMAGPO initiative. This project focuses on developing techniques to recover, reutilise, and recycle rare earth magnets extensively employed in electronics, vehicles, and other technological applications.

Magnet Applications holds accreditations for ISO45001 (management of health and safety), ISO9001 (management of quality), and ISO14001 (management of environmental concerns).

Images