Company details for:

Bunting - Redditch

Burnt Meadow Road,

North Moons Moat,

Redditch,

Worcestershire,

B98 9PA,

United Kingdom

Quick Links:

Products

Magnetic Separation

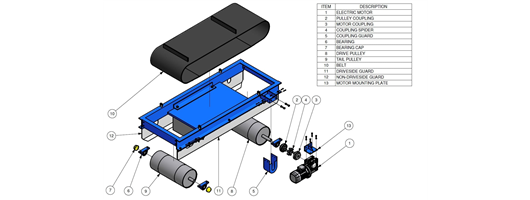

Eddy Current Separators

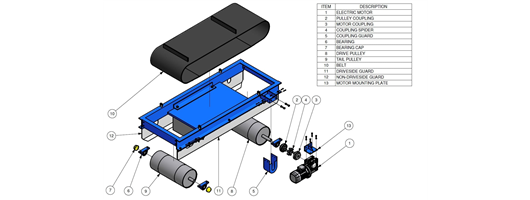

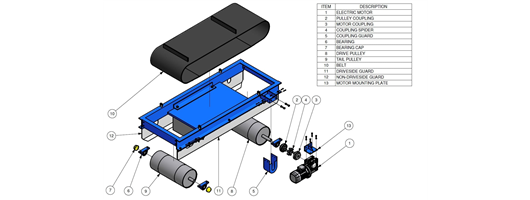

Bunting’s range of eddy current separators include both concentric and eccentric rotor designs that have evolved over a 30 years period of manufacture and supply. The range also includes laboratory-scale eddy current separators, examples of which are located in the UK Recycling Test Facility.

Electrostatic Separators

Belt Conveyor Metal Detectors

Food Metal Detectors

Free Fall Metal Detectors

Pneumatic Metal Detectors

Textile Metal Detectors

Metal Cleaning Systems

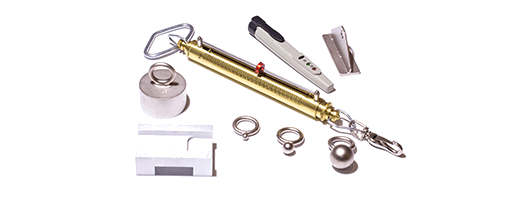

Metal Detector Service & Calibration

Magnetic Sweepers

Stock Equipment

Forklift Stabilising Magnets

The magnet system is constructed from low carbon steel. The former wound copper magnet coil is fixed into the magnet system & encapsulated in resin to insulate, protect from impact and prevent movement.

Magnetic Components

Next day delivery

Volume pricing available online

Magnet selection tools

Technical advice line

Live Chat

Magnet Assemblies

World-Class Engineers and Facilities

3D Finite Element Modelling Software

Rapid Prototyping & 3D Printing Capabilities

Design & Build Magnetising Systems

Free Magnetic Separation Audits

Checking each magnet for magnetic strength

Checking the structural integrity of magnets

A location review

Checking the effectiveness of the cleaning regime

Fully trained and experienced Bunting engineers will conduct each audit. These engineers will have in depth knowledge of the relevant industries and applications as well the installation and manufacturing processes.

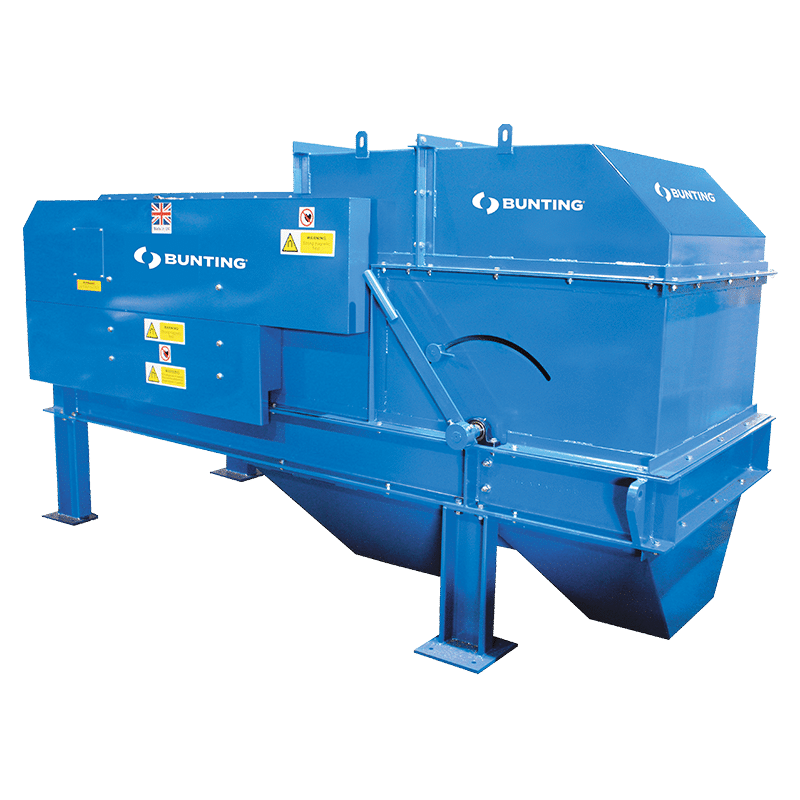

Magnetic Separator Repair & Refurbishment Service

Bunting understands that replacing machines that are no longer performing efficiently can be very costly and because of this, we feel that customers should be given the option to simply repair their existing machines, saving them a significant amount of money. Below there are some photos, which were taken of a previous Overband Separator that had been refurbished by Bunting for one of its customers.

Here are also some 'before and after' photos of a Fragmentiser Electro Drum that had been in operation for over 20 years. The Drum was sent to our Redditch facility for a complete refurbishment and is now back in operation at a steel recycling plant in Israel.

All magnetic separators that are sent in to us for refurbishment are fully restored and tested to ensure that they are working as well as brand new units.

Servicing & Repair

Site Evaluation Services - Magnetic Separation

This also enables one of our company representatives to hold a personal meeting with a client, explaining face to face how our machinery will perform within an application. This service is free within the UK.

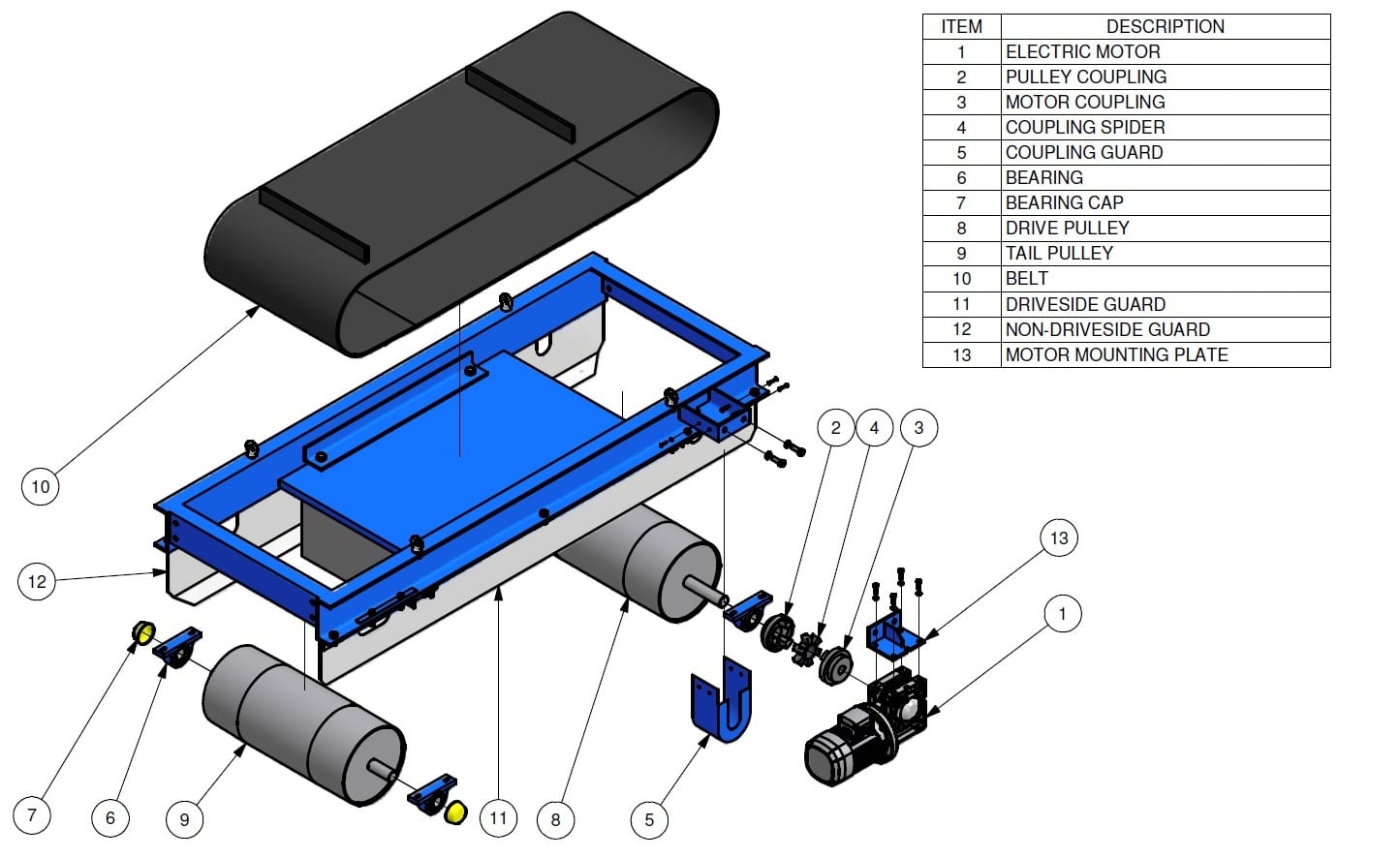

Magnetic Separator Spares

With over 2000 genuine spares held in stock at our Redditch manufacturing facility, our customers can expect any of these parts to be sent out on a same day dispatch*.

We also maintain comprehensive records of all supplied machines, dating back over 30 years. Accompanying this with skilled and experienced sales engineers, our customers can have peace of mind in knowing that replacement parts will be to the exact same specification and to the high-quality standards as those originally supplied on the machine.

*Spare parts can be sent out on a same day dispatch if ordered before 12pm.

About us

Since the company’s conception in 1959, we at Bunting have gained an outstanding reputation for our high-quality products as well as our customer service. We take great pride in our ability to exceed customer expectations and have over 60 years’ collective experience within the industry.

Here at Bunting, we offer an impressive range of products that are available to view online, some of which include magnetic separation, non-ferrous separation, magnetic sweepers, stock equipment, belt conveyor metal detectors, food metal detectors, free fall metal detectors, pneumatic metal detectors, textile metal detectors, metal cleaning systems, metal detector servicing, forklift stabilising magnets, magnetic components and more. We also specialise in a variety of services such as custom design, free magnetic separation audits, laboratory testing and repair and refurbishment.

We at Bunting are proud to serve a vast array of industries and sectors, some of which include packaging, wood processing, mining and minerals, ceramic, steelworks and SLAG processing, recycling, power stations, food processing, aggregate and quarrying, plastic and glass.

Using our world-class test and laboratory facilities to our advantage, we as a company have carried out numerous successful projects over the years and have improved our overall knowledge of magnetic separation technologies.

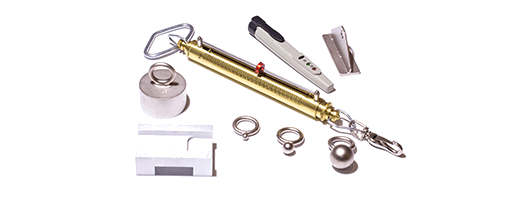

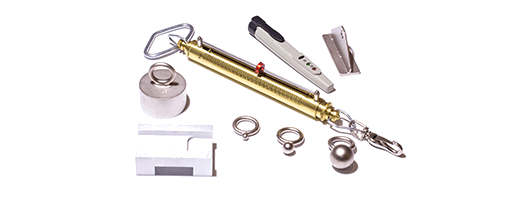

Images