Company details for:

CCT Pipefreezing Ltd

Suite 303,

Brewery House High Street,

Westerham,

Kent,

TN16 1RG,

United Kingdom

Quick Links:

Products / Services

Pipe Freezing

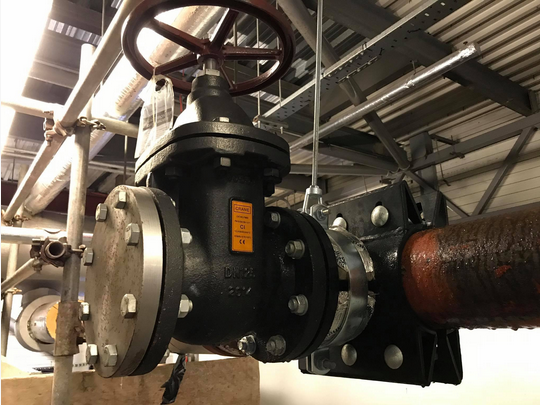

1. changing or installing valves

2. inserting new side branches in a pipe

3. pipework modification

4. radiator removal

5. testing for leakage by isolating different sections of a pipeline then pressure testing

6. isolation of one section of a fire-protection system without having to shut-down the whole system

7. providing secondary protection on critical water pipes within the nuclear and offshore industry

CCT Pipefreezing Ltd have designed and manufactured pipe freezing jackets to enable the above work to be completed safely and on time.

CCT pipe freezing jackets come in two designs, single skin quick release aluminium clamps, for pipe diameters from 15mm (1/2") up to 80mm (3").

The design takes into consideration the pipework clip distance, this enables CCT to be able to fit the clamps in very tight situations and close to ceiling voids.

The second design is for pipe freezing jackets 100mm (4") right up to 600mm (24"), these jackets are double skinned aluminium and bolted on to the pipe. They have bsp threaded outlet connections to enable the nitrogen gas to be removed under a controlled procedure. They also have 1/2" bsp valved connections in order to pump the nitrogen direct into the jacket via 1/2" insulated cryogenic stainless steel housing.

CCT have allowed in their pipe freezing jacket design, the ability to use insulated cryogenic hosing with both designs.

Hot Tapping

Comprehensive Options

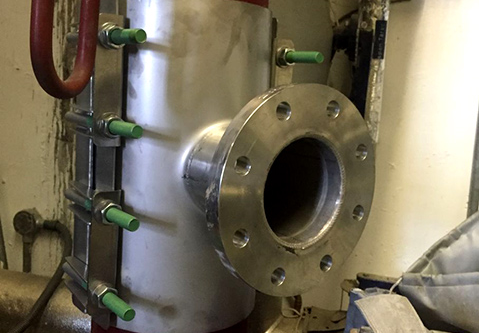

Our extensive range of branch connections using under pressure tees (UPT) are easily fitted onto pipes ranging from 15mm to 24" in diameter. For your ease of mind, we handle a wide variety of pipe materials, including:

Stainless steel

Carbon steel

Cast iron

PVC

MDPE

Cement

At CCT Pipefreezing Ltd, we tackle all jobs big and small. For your convenience, our engineers are trained to handle a wide variety of different systems, including:

Heating

Chilled water

HWS

Slurry

Sewage

Oil

Gas

Under Pressure Drilling

Comprehensive Options

Our extensive range of branch connections using under pressure tees (UPT) are easily fitted onto pipes ranging from 15mm to 24" in diameter. For your ease of mind, we handle a wide variety of pipe materials, including:

Stainless steel

Carbon steel

Cast iron

PVC

MDPE

Cement

At CCT Pipefreezing Ltd, we tackle all jobs big and small. For your convenience, our engineers are trained to handle a wide variety of different systems, including:

Heating

Chilled water

HWS

Slurry

Sewage

Oil

Gas

Changing or Installing Valves

1. changing or installing valves

2. inserting new side branches in a pipe

3. pipework modification

4. radiator removal

5. testing for leakage by isolating different sections of a pipeline then pressure testing

6. isolation of one section of a fire-protection system without having to shut-down the whole system

7. providing secondary protection on critical water pipes within the nuclear and offshore industry

CCT Pipefreezing Ltd have designed and manufactured pipe freezing jackets to enable the above work to be completed safely and on time.

CCT pipe freezing jackets come in two designs, single skin quick release aluminium clamps, for pipe diameters from 15mm (1/2") up to 80mm (3").

The design takes into consideration the pipework clip distance, this enables CCT to be able to fit the clamps in very tight situations and close to ceiling voids.

The second design is for pipe freezing jackets 100mm (4") right up to 600mm (24"), these jackets are double skinned aluminium and bolted on to the pipe. They have bsp threaded outlet connections to enable the nitrogen gas to be removed under a controlled procedure. They also have 1/2" bsp valved connections in order to pump the nitrogen direct into the jacket via 1/2" insulated cryogenic stainless steel housing.

CCT have allowed in their pipe freezing jacket design, the ability to use insulated cryogenic hosing with both designs.

Inserting New Side Branches in a Pipe

1. changing or installing valves

2. inserting new side branches in a pipe

3. pipework modification

4. radiator removal

5. testing for leakage by isolating different sections of a pipeline then pressure testing

6. isolation of one section of a fire-protection system without having to shut-down the whole system

7. providing secondary protection on critical water pipes within the nuclear and offshore industry

CCT Pipefreezing Ltd have designed and manufactured pipe freezing jackets to enable the above work to be completed safely and on time.

CCT pipe freezing jackets come in two designs, single skin quick release aluminium clamps, for pipe diameters from 15mm (1/2") up to 80mm (3").

The design takes into consideration the pipework clip distance, this enables CCT to be able to fit the clamps in very tight situations and close to ceiling voids.

The second design is for pipe freezing jackets 100mm (4") right up to 600mm (24"), these jackets are double skinned aluminium and bolted on to the pipe. They have bsp threaded outlet connections to enable the nitrogen gas to be removed under a controlled procedure. They also have 1/2" bsp valved connections in order to pump the nitrogen direct into the jacket via 1/2" insulated cryogenic stainless steel housing.

CCT have allowed in their pipe freezing jacket design, the ability to use insulated cryogenic hosing with both designs.

Pipework Modification

1. changing or installing valves

2. inserting new side branches in a pipe

3. pipework modification

4. radiator removal

5. testing for leakage by isolating different sections of a pipeline then pressure testing

6. isolation of one section of a fire-protection system without having to shut-down the whole system

7. providing secondary protection on critical water pipes within the nuclear and offshore industry

CCT Pipefreezing Ltd have designed and manufactured pipe freezing jackets to enable the above work to be completed safely and on time.

CCT pipe freezing jackets come in two designs, single skin quick release aluminium clamps, for pipe diameters from 15mm (1/2") up to 80mm (3").

The design takes into consideration the pipework clip distance, this enables CCT to be able to fit the clamps in very tight situations and close to ceiling voids.

The second design is for pipe freezing jackets 100mm (4") right up to 600mm (24"), these jackets are double skinned aluminium and bolted on to the pipe. They have bsp threaded outlet connections to enable the nitrogen gas to be removed under a controlled procedure. They also have 1/2" bsp valved connections in order to pump the nitrogen direct into the jacket via 1/2" insulated cryogenic stainless steel housing.

CCT have allowed in their pipe freezing jacket design, the ability to use insulated cryogenic hosing with both designs.

Radiator Removal

1. changing or installing valves

2. inserting new side branches in a pipe

3. pipework modification

4. radiator removal

5. testing for leakage by isolating different sections of a pipeline then pressure testing

6. isolation of one section of a fire-protection system without having to shut-down the whole system

7. providing secondary protection on critical water pipes within the nuclear and offshore industry

CCT Pipefreezing Ltd have designed and manufactured pipe freezing jackets to enable the above work to be completed safely and on time.

CCT pipe freezing jackets come in two designs, single skin quick release aluminium clamps, for pipe diameters from 15mm (1/2") up to 80mm (3").

The design takes into consideration the pipework clip distance, this enables CCT to be able to fit the clamps in very tight situations and close to ceiling voids.

The second design is for pipe freezing jackets 100mm (4") right up to 600mm (24"), these jackets are double skinned aluminium and bolted on to the pipe. They have bsp threaded outlet connections to enable the nitrogen gas to be removed under a controlled procedure. They also have 1/2" bsp valved connections in order to pump the nitrogen direct into the jacket via 1/2" insulated cryogenic stainless steel housing.

CCT have allowed in their pipe freezing jacket design, the ability to use insulated cryogenic hosing with both designs.

Testing for Leakage

1. changing or installing valves

2. inserting new side branches in a pipe

3. pipework modification

4. radiator removal

5. testing for leakage by isolating different sections of a pipeline then pressure testing

6. isolation of one section of a fire-protection system without having to shut-down the whole system

7. providing secondary protection on critical water pipes within the nuclear and offshore industry

CCT Pipefreezing Ltd have designed and manufactured pipe freezing jackets to enable the above work to be completed safely and on time.

CCT pipe freezing jackets come in two designs, single skin quick release aluminium clamps, for pipe diameters from 15mm (1/2") up to 80mm (3").

The design takes into consideration the pipework clip distance, this enables CCT to be able to fit the clamps in very tight situations and close to ceiling voids.

The second design is for pipe freezing jackets 100mm (4") right up to 600mm (24"), these jackets are double skinned aluminium and bolted on to the pipe. They have bsp threaded outlet connections to enable the nitrogen gas to be removed under a controlled procedure. They also have 1/2" bsp valved connections in order to pump the nitrogen direct into the jacket via 1/2" insulated cryogenic stainless steel housing.

CCT have allowed in their pipe freezing jacket design, the ability to use insulated cryogenic hosing with both designs.

Pressure Testing

1. changing or installing valves

2. inserting new side branches in a pipe

3. pipework modification

4. radiator removal

5. testing for leakage by isolating different sections of a pipeline then pressure testing

6. isolation of one section of a fire-protection system without having to shut-down the whole system

7. providing secondary protection on critical water pipes within the nuclear and offshore industry

CCT Pipefreezing Ltd have designed and manufactured pipe freezing jackets to enable the above work to be completed safely and on time.

CCT pipe freezing jackets come in two designs, single skin quick release aluminium clamps, for pipe diameters from 15mm (1/2") up to 80mm (3").

The design takes into consideration the pipework clip distance, this enables CCT to be able to fit the clamps in very tight situations and close to ceiling voids.

The second design is for pipe freezing jackets 100mm (4") right up to 600mm (24"), these jackets are double skinned aluminium and bolted on to the pipe. They have bsp threaded outlet connections to enable the nitrogen gas to be removed under a controlled procedure. They also have 1/2" bsp valved connections in order to pump the nitrogen direct into the jacket via 1/2" insulated cryogenic stainless steel housing.

CCT have allowed in their pipe freezing jacket design, the ability to use insulated cryogenic hosing with both designs.

Isolating Systems in Sections

1. changing or installing valves

2. inserting new side branches in a pipe

3. pipework modification

4. radiator removal

5. testing for leakage by isolating different sections of a pipeline then pressure testing

6. isolation of one section of a fire-protection system without having to shut-down the whole system

7. providing secondary protection on critical water pipes within the nuclear and offshore industry

CCT Pipefreezing Ltd have designed and manufactured pipe freezing jackets to enable the above work to be completed safely and on time.

CCT pipe freezing jackets come in two designs, single skin quick release aluminium clamps, for pipe diameters from 15mm (1/2") up to 80mm (3").

The design takes into consideration the pipework clip distance, this enables CCT to be able to fit the clamps in very tight situations and close to ceiling voids.

The second design is for pipe freezing jackets 100mm (4") right up to 600mm (24"), these jackets are double skinned aluminium and bolted on to the pipe. They have bsp threaded outlet connections to enable the nitrogen gas to be removed under a controlled procedure. They also have 1/2" bsp valved connections in order to pump the nitrogen direct into the jacket via 1/2" insulated cryogenic stainless steel housing.

CCT have allowed in their pipe freezing jacket design, the ability to use insulated cryogenic hosing with both designs.

Secondary Protection on Critical Water Pipes

1. changing or installing valves

2. inserting new side branches in a pipe

3. pipework modification

4. radiator removal

5. testing for leakage by isolating different sections of a pipeline then pressure testing

6. isolation of one section of a fire-protection system without having to shut-down the whole system

7. providing secondary protection on critical water pipes within the nuclear and offshore industry

CCT Pipefreezing Ltd have designed and manufactured pipe freezing jackets to enable the above work to be completed safely and on time.

CCT pipe freezing jackets come in two designs, single skin quick release aluminium clamps, for pipe diameters from 15mm (1/2") up to 80mm (3").

The design takes into consideration the pipework clip distance, this enables CCT to be able to fit the clamps in very tight situations and close to ceiling voids.

The second design is for pipe freezing jackets 100mm (4") right up to 600mm (24"), these jackets are double skinned aluminium and bolted on to the pipe. They have bsp threaded outlet connections to enable the nitrogen gas to be removed under a controlled procedure. They also have 1/2" bsp valved connections in order to pump the nitrogen direct into the jacket via 1/2" insulated cryogenic stainless steel housing.

CCT have allowed in their pipe freezing jacket design, the ability to use insulated cryogenic hosing with both designs.

Draining Down

Liquid nitrogen pipe freezing can be a quick and efficient way to undertake work on piped systems that removes the following problems

Draining down - Disposal of contents - Filling and venting

When pipe freezing is not the solution, then CCT can offer Hot Tapping (Under pressure drilling)

This allows us to make a branch connection whilst the system is live and in use. We can supply an under pressure tee (UPT) complete with valve or the branch connection can be welded.

Filling & Venting

Liquid nitrogen pipe freezing can be a quick and efficient way to undertake work on piped systems that removes the following problems

Draining down - Disposal of contents - Filling and venting

When pipe freezing is not the solution, then CCT can offer Hot Tapping (Under pressure drilling)

This allows us to make a branch connection whilst the system is live and in use. We can supply an under pressure tee (UPT) complete with valve or the branch connection can be welded.

CCT PipeFreezing Special Projects

CCT PipeFreezing Case Studies

About us

Our Services Include:

Pipe Freezing

When routine maintenance or repairs would be time-consuming or expensive to drain the contents of a pipe, liquid nitrogen pipe freezing is an effective alternative.

Pipe freezing jackets are designed and manufactured by CCT Pipefreezing Ltd in order to carry out the above work in a safe and timely manner.

Hot Tapping / Under Pressure Drilling

We can connect your pipe system with minimal disruption to your existing services at CCT Pipefreezing Ltd. In addition to performing hot tapping on site, our highly-trained engineers can connect a branch and valve using the most up-to-date under pressure drilling equipment.

Professional Pipe Freezing London Regional

In the London Regional area, we provide quality pipe freezing services. We use the latest cryogenic technology to ensure that your pipes are frozen efficiently and safely. We guarantee that all the work we do is carried out in accordance with the highest industry standards, thanks to our highly trained cryogenic technology team.

A comprehensive range of pipe freezing services is also available from us, including installation, inspection, and maintenance of pipes. Our experienced technicians are available to provide assistance with all aspects of pipe freezing in the London regional area.

With CCT Pipefreezing, we strive to provide our customers with the highest quality pipe freezing in London's regional area. For our customers, we are committed to providing quality services.

The pipe freezing solutions we offer in the London region are suitable for any size project, whether it is a small residential project or a large industrial one. All of our customers receive the highest level of service and satisfaction thanks to our experience and expertise.

With several successful ventures completed in the North Sea and abroad, we have established a global reputation for excellence in the pipe freezing of the local commercial and industrial M&E industries in London and the South East.

By combining quality and investment with internal and external training, we consistently deliver the best on-site engineering solutions for today's pipeline and M&E industries. You can rely on our dedicated staff and comprehensive resources to deliver professional results every time.

Sponsored Links

Articles / Press Releases

Reviews

Trade Associations