Company details for:

Cadman Solutions Ltd

176a Wendover Road,

Weston Turville,

Aylesbury,

Buckinghamshire,

HP22 5TG,

United Kingdom

Quick Links:

Products / Services

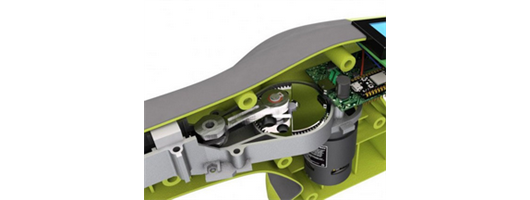

3D Scanning Services

Our customers include Aerospace, Arts/Sculpture, Automotive, Consumer Products, Manufacturing, Medical and Military/Defence.

We can read and write a variety of different mesh formats and have specialist software to improve and tidy the data if required. 3D laser scanning allows data to be captured digitally without damaging the physical object being scanned. 3D scanning is the perfect solution if you wish to:

Digitally capture the exact size and shape of any physical object.

Create a “Family of Parts” from existing samples

Create 3D CAD models of components or tooling where no drawings are available

Capture 3D forms as a basis for designing mating parts

Capture data for 3D printing

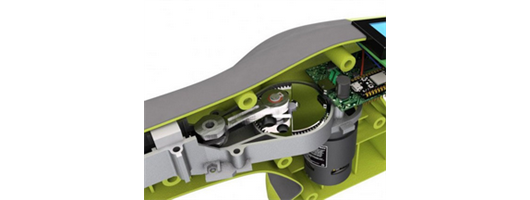

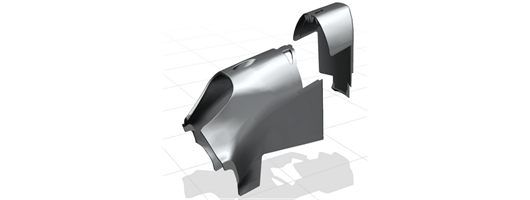

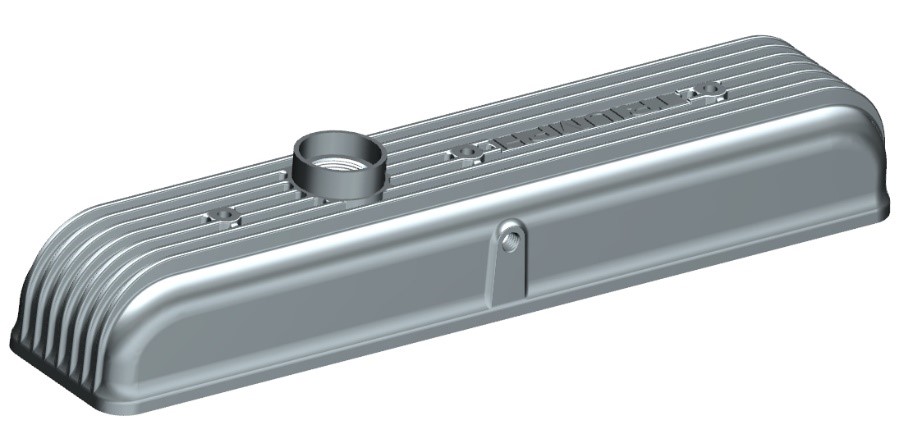

3D Modelling & Design Services

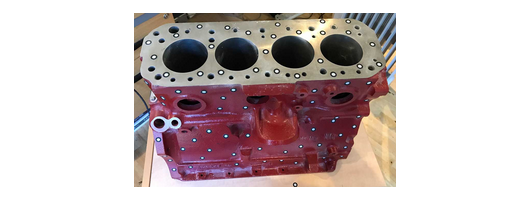

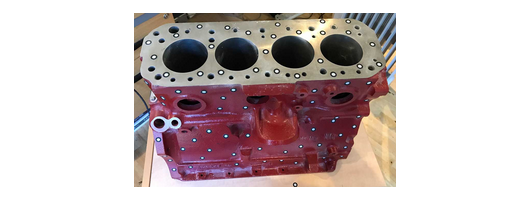

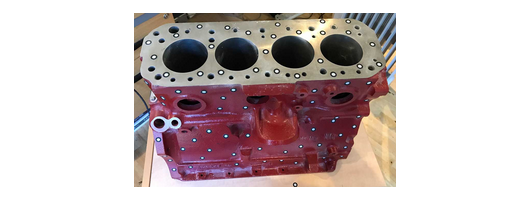

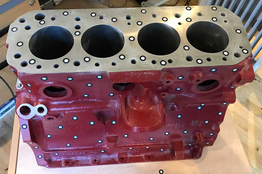

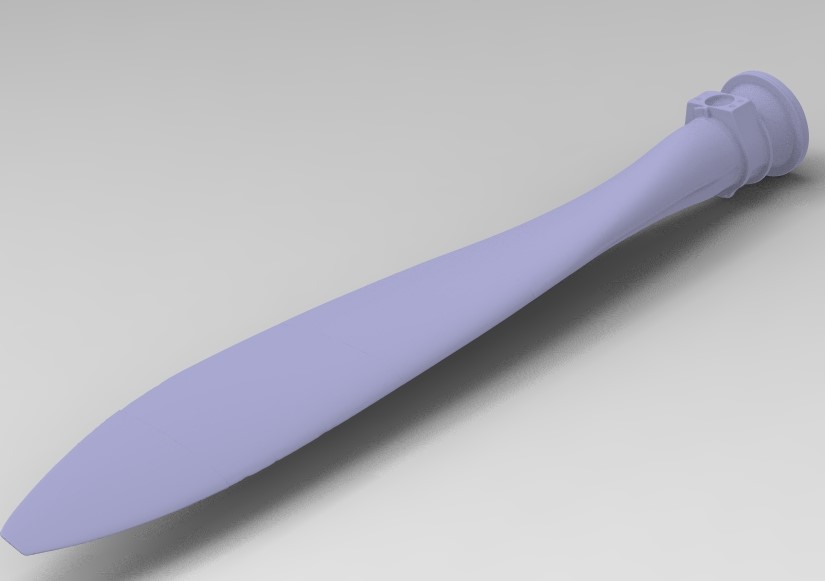

3D Scanning & Reverse Engineering Services

We can read a variety of different mesh formats and have specialist software to improve and tidy the data.

3D laser scanning allows data to be captured digitally without damaging the physical object being scanned. 3D laser scanning is the perfect solution if you wish to:

Digitally capture the exact size and shape of any physical object.

Create a “Family of Parts” from existing samples

Create 3D CAD models of components or tooling where no drawings are available

Capture 3D forms as a basis for designing mating parts

Capturing data for 3D printing.

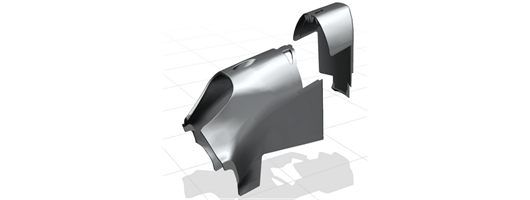

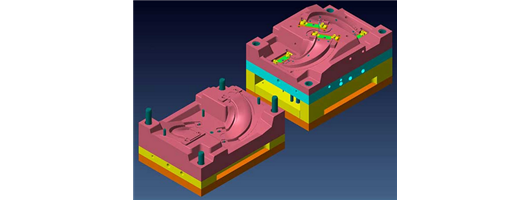

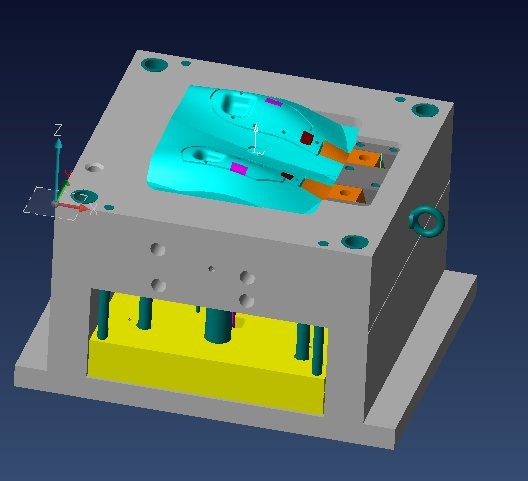

Manufacturing Services

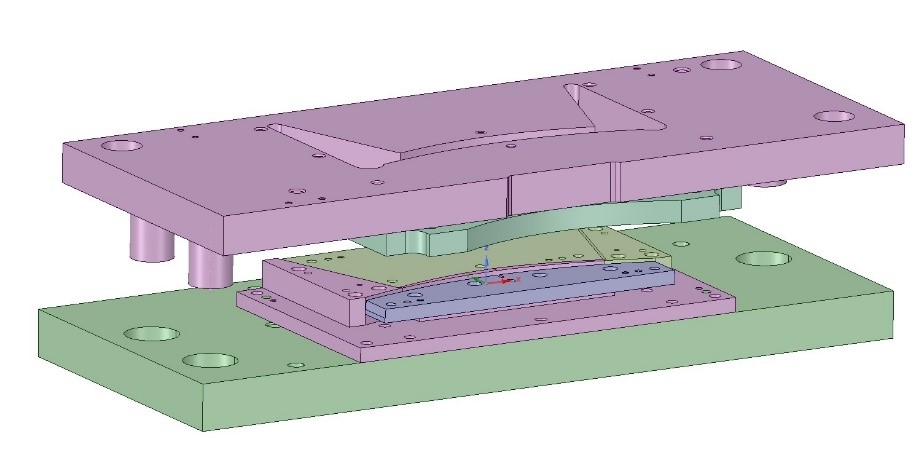

We will work closely with you to ensure that we fully understand your requirements and, most importantly, provide a solution that can be successfully manufactured. Over the years, we have worked with a variety of clients including:

Mould Toolmakers

Press Toolmakers

Vacuum Forming companies

Blow Mould companies

Model & Pattern makers

Our focus is delivering a great service to our clients. It doesn’t matter whether it’s producing a product design, prototype or production tooling, we believe in working closely with a client to make sure that the most practical and cost-effective solution is achieved and their expectations are met.

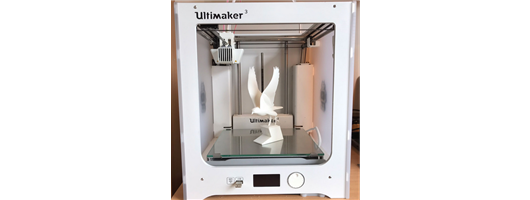

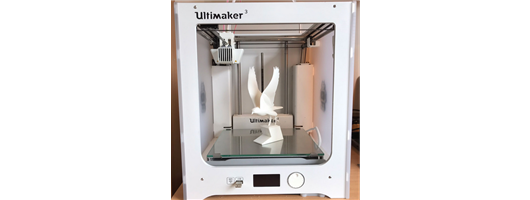

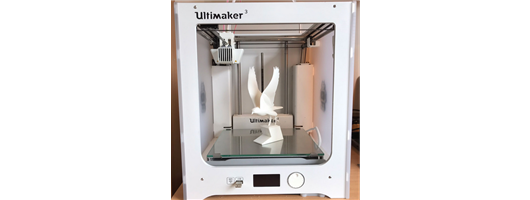

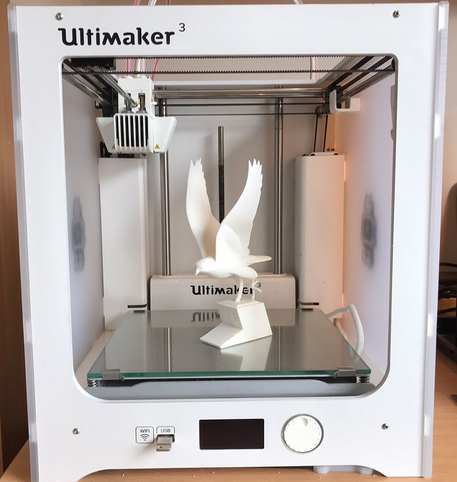

3D Printing & Mesh Preparation

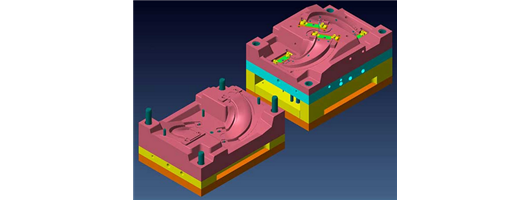

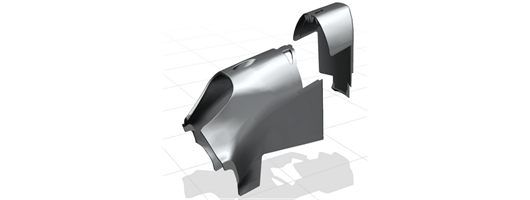

Having produced a high-quality STL mesh file we offer several options:

We can create cutter paths directly on the STL file − no need to reverse model

Prototype models can be supplied, including using our in-house 3D Printing facility.

Nurb surfaces can be mapped onto the mesh to set tolerances. This is a good solution where the form is very organic and is similar to shrink-wrapping

Parametric CAD models can be created using the mesh surface. This is the most versatile and popular method as it creates a feature-based CAD model − ideal for geometric shapes.

A hybrid CAD model can be created mapping Nurb surfaces onto complex organic areas and uses parametric methods for the remainder of the part.

Both Nurb & Parametric surface and solid models are compatible with industry standard CAD systems and can be supplied in several Neutral or Native CAD formats.

Tool Re-Construction

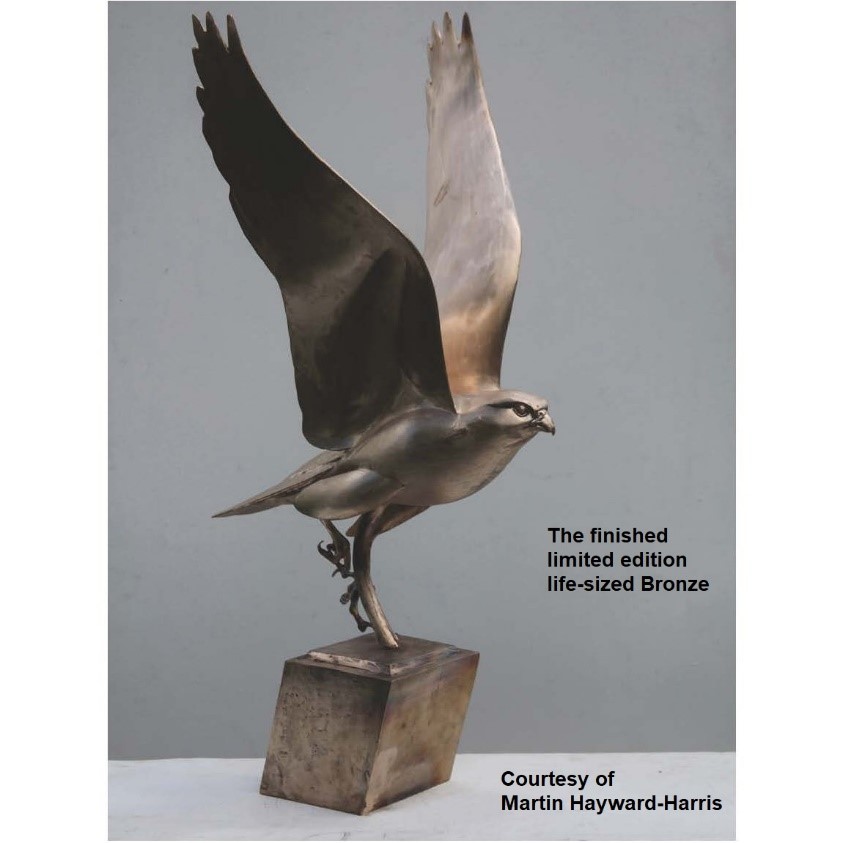

Sculptures

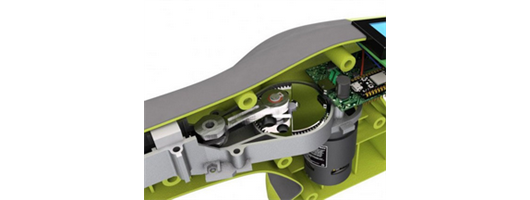

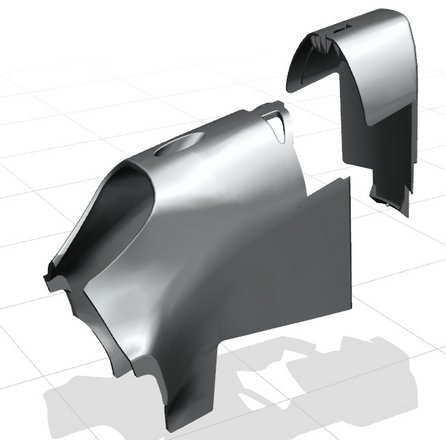

Product Design

3D Scanning Organic Forms

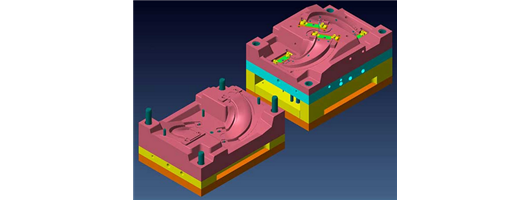

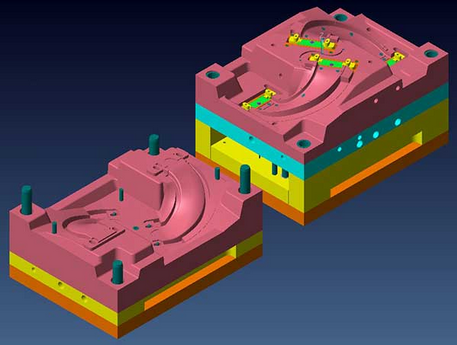

Mould Tool Design

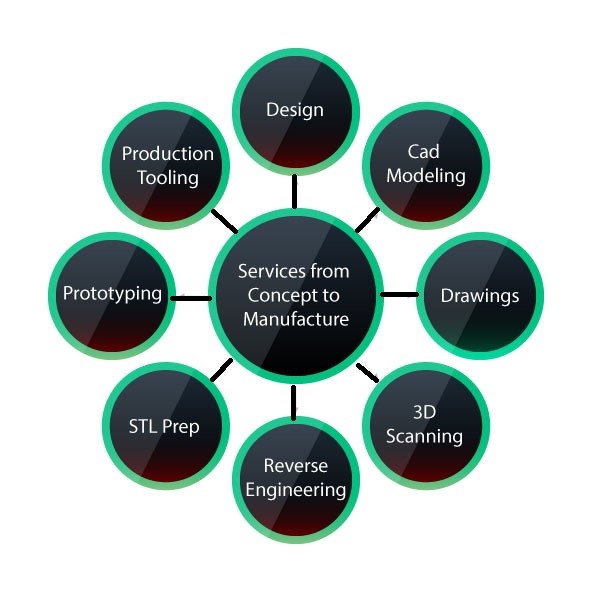

From Concept to Manufacture

CAD Modelling

Bottle Design

Automotive Scanning

Aerospace

About us

We soon realised that our services would appeal to any company who needed a reliable and professional programming service but were not ready to invest in the technology, so we started working across a variety of industry sectors.

Our Services Include:

- 3D Design

- Cad Modelling

- 3D Scanning

- Reverse Engineering

- 3D Printing

- Prototype Modelling

As more advanced technology came onto the market, we responded by expanding our range of services to include reverse engineering and 3D scanning and 3D Printing.

Our move into industrial design was inspired by a client who came to us with a wonderful design which just couldn’t be manufactured. We realised that our technical knowledge and expertise could be used to advise clients on the best ways of achieving their vision.

This approach, which we use to this day, is appreciated by our clients, as it sees us working closely with them from the outset to explore their ideas and coming up with a solution that is both practical and meets their expectations.

Images