Company details for:

Carbolite Gero Ltd

Parsons Lane,

Hope,

Hope Valley,

Derbyshire,

S33 6RB,

United Kingdom

Quick Links:

Products / Services

Laboratory Oven Range

The laboratory oven models are ideal for general laboratory work and routine heat applications. They all provide excellent temperature uniformity and comply with safety standard BS EN 61010-2-010:2003.

Each laboratory oven may be equipped with a number of options to meet customer requirements. This includes, for example, over-temperature protection, individual shelves and runners for different lab applications, digital timers or more advanced laboratory oven temperature control and programmer systems.

Industrial Ovens

The design is characterized by robust construction and lasting materials, making the industrial oven range ideal for heavy duty applications. Each industrial oven may be built and supplied with a wide range of options, including over-temperature protection, loading and handling mechanisms or advanced temperature control systems.

Clean Room Ovens

Controlled Atmosphere Oven - HTMA

Laboratory Furnaces

Whether you need a small bench mounted affordable solution or a high temperature furnace built to the highest quality, Carbolite Gero has a model that is sure to meet your needs and budget. Ranging from the entry level ELF models at 1100°C through to the laboratory sized HTF model with a maximum temperature of 1800°C our experience of building quality furnaces for customers around the globe over the last eight decades has ensured that the Carbolite Gero name is synonymous with Leading Heat Technology.

Whether you need a front, top or bottom loading chamber furnace our extensive portfolio virtually guarantees there is an appropriate standard solution that will meet your requirements but of course our bespoke design service allows us to meet almost every scenario we have ever been consulted about.

Industrial Furnaces

All of our industrial furnaces are designed and built to be extremely hard-wearing, safe, and easy to service. Our industrial furnaces are available in various sizes, from compact bench mounted models through to large floor standing models with heating chambers of up to more than 3000 litres in volume. Maximum temperatures of up to 1800°C are available.

Our industrial furnaces can be built and supplied with a wide range of options in order to closely meet customer needs. The options which are available vary from furnace to furnace but include over-temperature protection and a range of digital controllers, multi-segment programmers, and data loggers. Please choose a product from our industrial furnace range below to view details.

Ashing Furnaces

Maximum temperatures are as high as 1200°C with working volumes of up to 32 litres. A model with an integral balance for thermogravimetric analysis / loss on ignition testing is available and should you require an integrated afterburner to remove noxious fumes from materials such as biomass then Carbolite Gero's Afterburner Ashing Furnace could be perfect for your needs.

Annealing Furnaces

Carbolite Gero offers two different lines of annealing furnace, and within each line different models and options are available in order to meet your exact annealing requirements. The HRF air recirculating oven line contains bench-mounted as well as floor-standing models. The maximum temperature of each is 750°C, distributed across the chamber by powerful fans and horizontal air-guides for rapid heating and excellent temperature uniformity.

The GLO annealing furnace features CrFeAl heating elements in ceramic fibre insulation, providing a maximum temperature of 1100°C in the furnace’s vacuum tight chamber. There are three models in the GLO annealing furnace line: the standard GLO annealing furnace, the vertical VGLO, and the mobile GLO. Chamber sizes up to 260 litres are available. Please choose from our annealing furnace range below to view details.

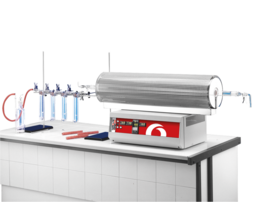

Tube Furnace Range

Each tube furnace in our range can be modified to meet your exact needs. When specified at the order stage our tube furnaces can be upgraded to include sophisticated digital controllers, programmers, and loggers. Over-temperature protection is also available along with additional safety features such as insulation plugs and radiation shields.

Some of our tube furnaces are designed with an integral work tube while others require a separate work tube. This is an extremely flexible arrangement; work tubes are available in different diameters and materials (quartz, ceramic or metal). When a work tube of an adequate length is used, a standard tube furnace can easily be upgraded for use with a controlled atmosphere or a vacuum.

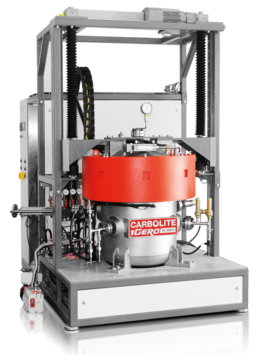

Vacuum Chamber Furnaces

Vacuum Hood Furnaces

Vacuum Furnaces with Bottom Loading Mechanism

Asphalt Binder Analyser - ABA

MTT - Carbon14-Tritium Furnaces

Computer control enables remote operation of multiple or individual units even in hazardous areas.

Coal & Coke Test Equipment

As a result, Carbolite Gero products are frequently specified as the reference equipment used in coal laboratories, inspection companies, power plants and steelworks throughout the world.

The range includes international coal and coke testing and iron ore evaluation test methods, including ISO, ASTM, EN, BS, and DIN. Please consult the Standards Overview Table to find the correct furnace for a particular standard.

If you have a question about a particular test method, please do not hesitate to contact our application specialists.

Crystal Growth Furnaces

Dental Furnaces - CDF

The dental crowns and frameworks are placed in sintering trays which are filled with a bed of zirconium support beads. The trays are designed to fit exactly in the furnace chamber. The bed of zirconia beads allows for a sintering process with low friction and results in distortion-free frameworks.

Precious Metal Furnaces

Thermocouple Calibration Furnaces - PTC

Metal & Ceramic Injection Moulding Furnaces

Soldering Furnaces

Uniformity & Heat

This experience is utilised in all of our standard furnaces and ovens as well as custom modifications where temperature uniformity needs to be improved even further. Some important design principles to improve the uniformity are as follows.

High Pressure Furnaces

In the standard version, the LHT vacuum chamber furnace just is designed for high, fine or rough vacuum operation and atmospheric pressure. This pressure furnace is additionally suited for high pressure operation up to 100 bars at maximum temperature.

The high pressure vessel is designed by the aid of finite element simulation of the vessel, increased wall thickness, cylindrical design with torospherical top and bottom and TÜV certification by a high pressure test of the vessel with an incompressible liquid.

Attached to the pressure vessel it is equipped with special flanges, gauges, valves, pressure reducers and a safe bayoneted closing.

Fast Cooling

Combined Furnace Racks

If toxic processes are carried out, Carbolite Gero can offer safe containment on one or several products.

About us

Over the years, we have designed and manufactured a full range of furnaces and ovens from 30°C to 3000°C, focusing primarily on vacuum and special atmosphere technology that has benefitted clients on a global scale. We have over 80 years of collective experience within the industry and continue to expand our services worldwide.

Here at Carbolite, our experience in thermal engineering has allowed for high quality innovations to be utilised in research laboratories, pilot plants and manufacturing sites across the UK and beyond. In association with Verder Scientific, our company is a well-established part of the Verder Group, which also consists of companies that specialise in materialography, hardness testing, heat treatment, elemental analysis, milling and sieving and particle analysis. Our well-recognised companies have served numerous research institutions and analytical laboratories over the years.

We at Carbolite are proud to be the UK’s leading manufacturer of bespoke heat technology. We offer a unique and innovative range of products including laboratory ovens, clean room ovens, industrial ovens, atmosphere-controlled ovens, ashing furnaces, industrial furnaces, annealing furnaces, laboratory furnaces, split tube furnaces, universal tube furnaces, vacuum hood furnaces, vacuum bottom loader furnaces, precious metal furnaces, soldering furnaces, crystal grown furnaces, dental furnaces, metal injection moulding furnaces and more.

Our company caters for numerous industries and sectors, such as aerospace, automotive, ceramics, glass, chemistry, steel, coal, energy, food, research, plastics, electronics, power plant, university and materials research.

Since establishment, our business has gained a strong, lasting reputation for our professional engineering expertise as well as our desire to provide clients with excellent customer service from start to finish. Catering locally and globally, our company works to solve customer’s individual requirements as efficiently and effectively as possible.

Sponsored Links

Articles / Press Releases

Reviews

Trade Associations