Company details for:

Carrs Welding Technologies Ltd

Unit 2-3 Henson Park,

Telford Way Industrial Estate,

Kettering,

Northamptonshire,

NN16 8PX,

United Kingdom

Quick Links:

Products / Services

Laser Welding

Tooling Repairs

Laser Cladding

Laser Marking & Engraving

There are several applications that benefit from this process, but it is mostly used in the labelling of work pieces and materials. There are diverse techniques available at Carrs that can produce many different surface finishes. Techniques such as annealing, result in a colour change without material removal due to a local oxidization process, caused by heat from the laser source. As a subset technique of laser marking, Carrs can also laser engrave, which is the removal of a layer by layer until a maximum depth of 0.25 mm is achieved (further depths will lead to burnt edges and loss of surface definition).

TIG Welding

Design & Prototypes

Testing & Weld Analysis

Carrs can leak test with Helium and give a leak rate.

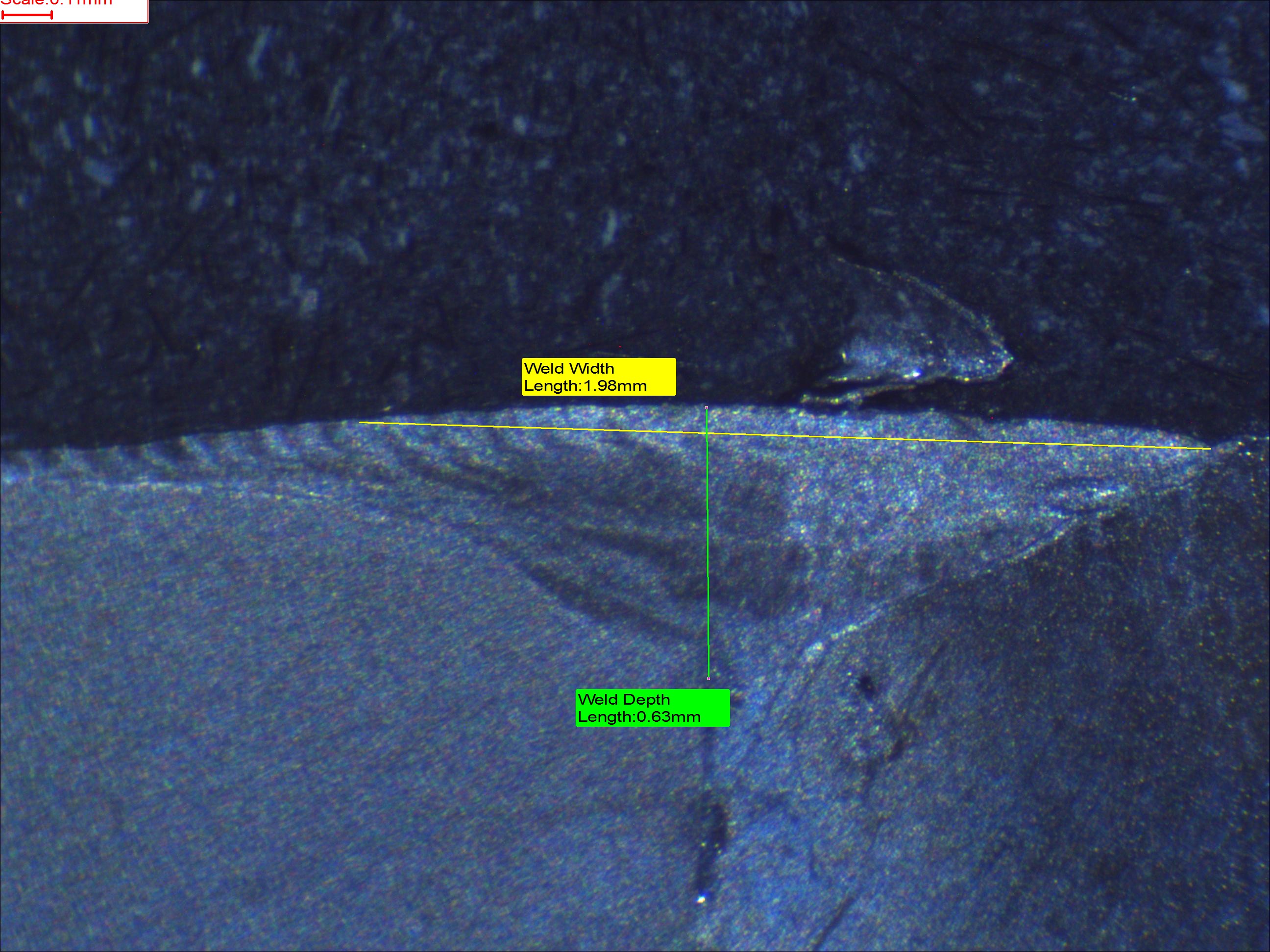

Carrs can cut up a sample weld and mount it for viewing and inspection upto 250X.

Carrs can carry out Non-destructive testing, like dye penetrant, for weld inspection.

SEM and EDX analysis can also be arranged to order.

Welding

For more information go to the Carrs' site.

Arc Welding

Collection & Delivery

Our experienced team is here to help, just call 01536 412 828 for a quote.

About us

Benefits of Using Carrs Welding Technologies:

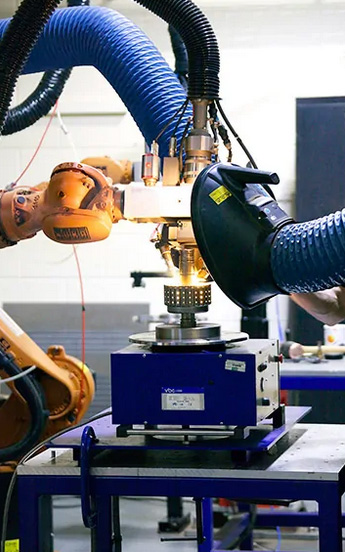

- Pinpoint accuracy

- Low energy / heat input when welding

- Low or no distortion to your product

- Welding in proximity of heat sensitive components or electronics

- Welding of dissimilar metals or dissimilar thicknesses

- Minimal or no refinishing

Carrs Welding Technologies provides robot production laser welding, testing, macro and micro analysing producing laboratory reports.

Carrs have also been accredited with the environmental standard EN14001/2015, in 2021, to reduce our mark on this planet. Green energy, increased re-use /recycling and where possible, we reduce our gas usage and fuel for cars.

Sponsored Links

Articles / Press Releases

Reviews

Trade Associations