Company details for:

Castle & Pryor Ltd

Quick Links:

Products / Services

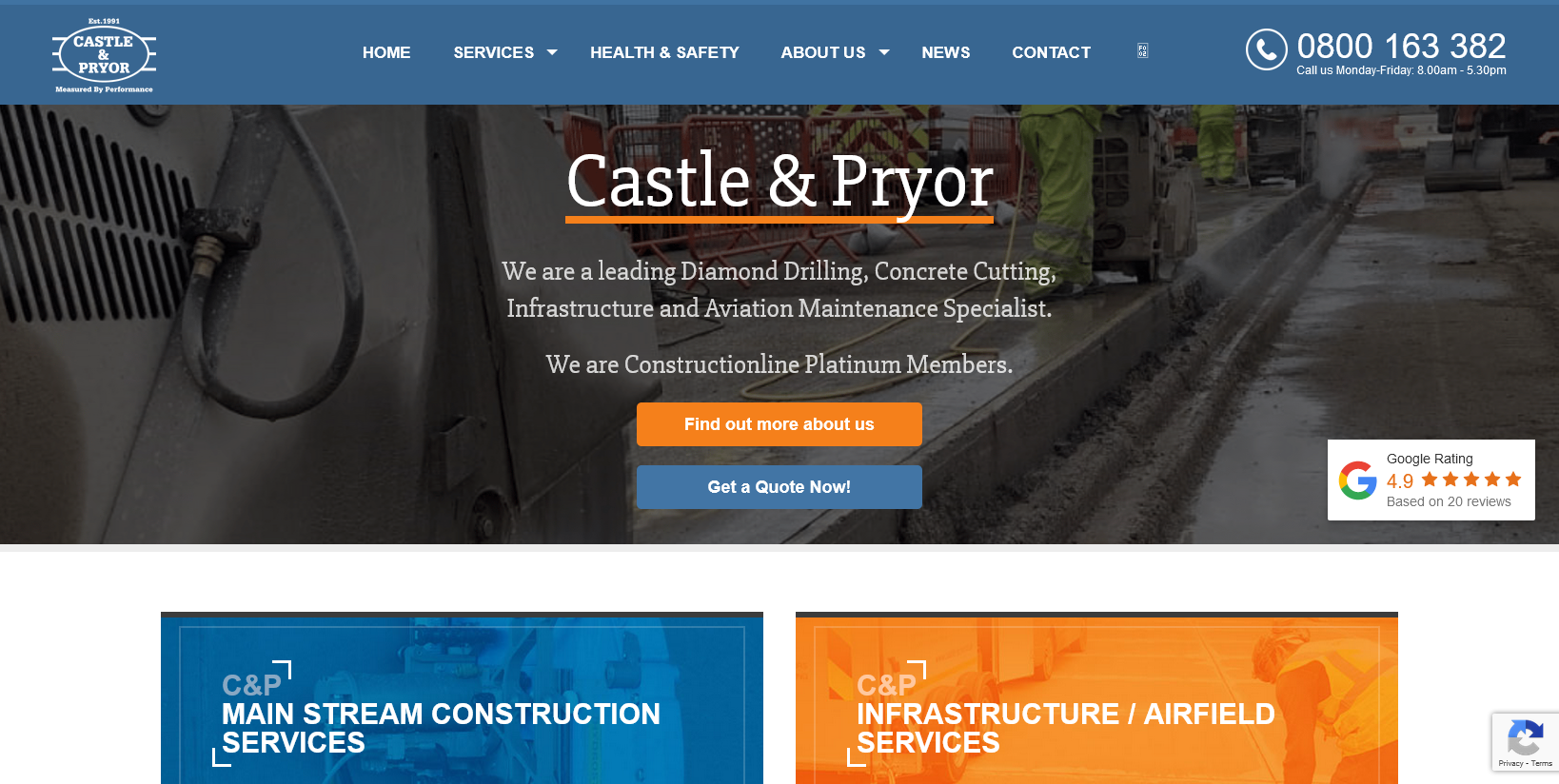

Concrete Floor Sawing

For main stream construction and infrastructure projects that require the precision of diamond floor sawing, Castle & Pryor offers a robust and reliable solution across the UK. Established in 1991, we’ve built a reputation for providing high-quality, reliable, and cost-effective concrete cutting on highways, industrial facilities, distribution centres, civil and utilities projects, and aviation stands, taxiways and runways. Also, our team of professionals have the expertise and the latest equipment needed to deliver a bespoke solution that meets your project’s exact requirements and specifications.

Efficient, safe, and precise

Utilising diamond sawing equipment to cut through surfaces up to a depth of 620mm with speed and efficiency ensures that Diamond sawing offers a range of benefits to our construction industry customers, including precision, accuracy, and cost-effectiveness. Secondly, we can also work around tight schedules and deadlines, ensuring that your project is completed on time.

Here are just a few of the many uses for our concrete floor sawing service within the main stream construction industry:

- Demolishing existing concrete or asphalt pavements to make way for new construction projects.

- Sawing concrete to create trenches and floor chases for services such as drainage systems, fuel mains, fire mains as well as fiber-optic networks.

- Sawing to form apertures in reinforced concrete structures, aiding their redesign or refurbishment.

- Forming induction cuts to newly laid concrete to prevent cracking to the concrete surfaces due to expansion and contraction caused by temperature changes.

- Making precise and accurate cuts for demolition or isolation purposes, such as removing damaged sections of concrete so they can reinstated.

- Joint widening existing contraction or isolation joints in preparation for sealing.

Whatever your floor sawing needs may be, Castle & Pryor can provide a tailored solution to help you achieve your project goals.

Call us today to get a free upfront quote.

Meeting all of your needs

We are dedicated to providing the highest level of service to the construction industry, ensuring that all aspects of your project are delivered to your exact specifications, quickly, safely, and also at a great price:

- Reputation and experience: With over 30 years of experience, Castle & Pryor is a trusted name in the UK construction sector.

- Quality and precision: Our skilled team will use the latest technology to ensure precise and high-quality sawing services.

- Responsiveness and ability to meet tight deadlines: We understand the importance of timely completion and can also work 24/7 to meet tight deadlines.

- Cost-effective: We offer competitive pricing, while surprisingly never compromising on quality. Speak to our team for an upfront quote.

- Safety and environmental compliance: We prioritise safety and environmental compliance ensuring we adhere to UK regulations and guidelines.

Moreover, our team is highly qualified and experienced, specifically holding certifications and accreditations from leading industry bodies, such as Advanced CHAS and SafeContractor. In addition, we are Gold members of Constructionline, and we are members of the Drilling & Sawing Association, Extruded Sealing Association, and Construction Fixings Association. Furthermore, each member of our team is NVQ 2 Certified, with our supervisors and managers holding Site Supervisor Safety Training Scheme (SSSTS) & Site Management Safety Training Scheme (SMSTS) Accreditations. We also offer full Quality Assurance on all work completed.

Joint Sealing

Our joint sealing services in combination with other preventative maintenance work offer an excellent alternative, helping you to safeguard your concrete and asphalt surfaces against unwanted damage and dilapidation, extending their lifespan and reducing maintenance costs.

How concrete joint sealing is used

Joint sealing is a vital process for ensuring the longevity of concrete and asphalt surfaces. It involves the application of sealant material to expansion or contraction joints, which allows the concrete or asphalt to move through natural expansion and contraction heat cycles while maintaining a seal, preventing water and contaminate ingress into the joint and slab sub-base. Joint sealing can be done during construction, or completed on failed joints by raking out existing material, preparing the joint and then re-sealing.

We provide high-quality joint sealing services using either bitumen-based N1, N2 and 95.25 Oxidised products or Polysulphide cold pour fuel-resistant material for use where fuel or oil spills may occur. Our team of experts has the equipment and experience to tackle any sealing job, including cable chasing and sealing, with both hot and cold pour capabilities.

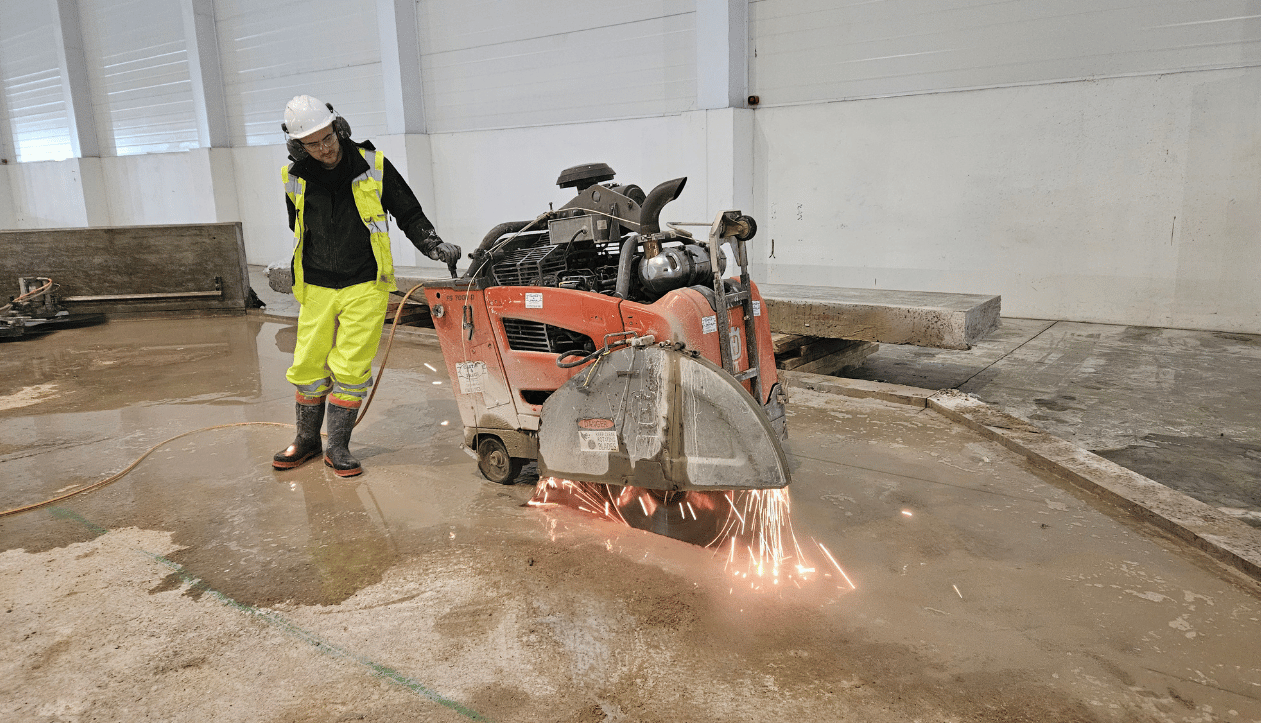

Pull Testing

Where We Can Help

At Design Stage − Preliminary / Ultimate Load testing

At the design stage of a project we can provide load testing to a specific rating or to failure to help establish specification of fixing required and allow changes to be made before build/installation stage.

At Installation Stage − Proof Load testing

After installation and to meet build regulations and specifications, fixings and/or anchors will often require inspection and testing by an approved independent contractor. We can fulfil this and attend site at short notice and test a given percentage to ensure design specifications are met. If they pass, we can provide test certificates to allow project sign offs.

Applications

Resin Anchors

Mechanical Anchors

Cladding systems

Dowel bar or reinforcement installation

Suspended ceiling systems

Eye Bolts

Scaffold Ties

Hand or Foot Support Brackets

Sign Brackets

Hand Rails

Access Ladders

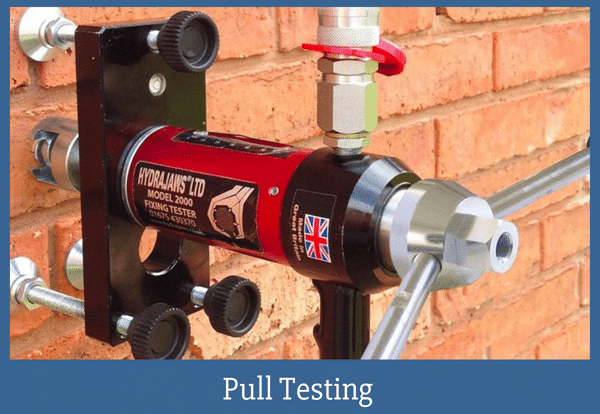

Robotic Demolition

Our Brokk robots come in many sizes and are just part of our impressive fleet - full of specially selected tech it means we’ll always have just what your project needs. We’re proud to in invest in our training, as well as our tech, having industry acclaimed credentials CHAS Certified and Construction Line Accredited. We’re BAA Authorised Signatories and DSA members, with NVQ 2 Certified Operatives, SSSTS & SMSTS Accredited Supervisors & Managers, and full Quality Assurance - so you always know you’re in safe hands with Castle & Pryor.

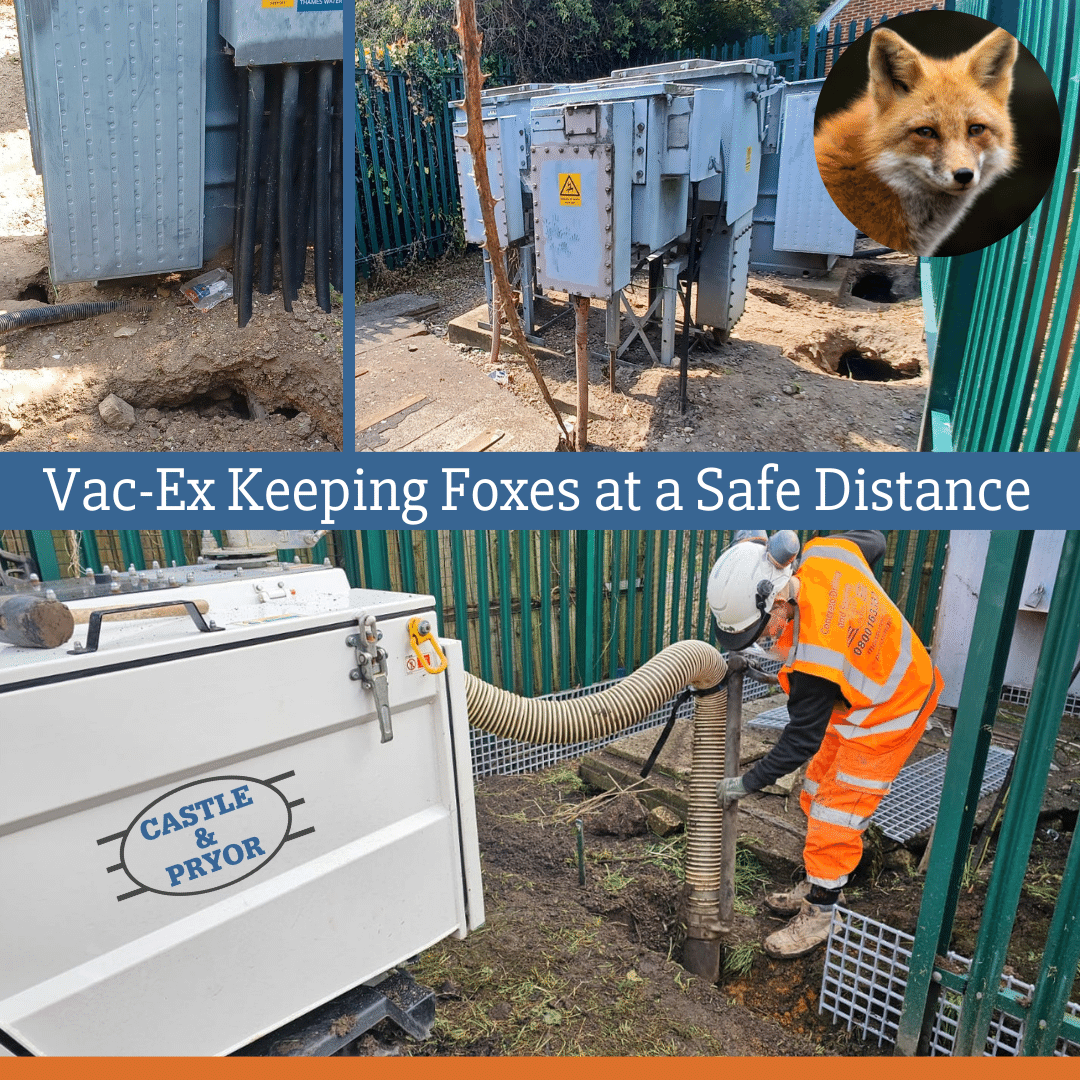

Vac-Ex Excavation

How we utilise Vac-Ex machines in Construction

Vac-Ex is a non-intrusive method of excavation that uses compressed air to loosen up the ground, followed by suction to remove the loose material. A Vac-Ex machine can generate a powerful stream of air with an operator controlling the intake nozzle, providing full control of the excavation while they remain at a safe distance. This method significantly reduces spoil and dust because all of the extracted material is sucked directly into sealed collection chambers on the machine, making it particularly suitable for use in confined spaces.

Diamond Drilling

Whether you need to form openings for redesign or refurbishment, or to isolate areas prior to demolition, we’ll work with you to achieve your goals accurately, safely, and at a competitive price.

Diamond drilling is a specialised drilling technique used to cut through the hardest reinforced concrete with utmost precision. The process involves using diamond-tipped drill bits, connected to either an electric or hydraulic drill motor and rig, allowing careful control over the location and speed of hole formation. Diamond drilling allows our team to make holes of varying diameters and shapes when linked together in a stitch-drilled pattern, and is a quiet and non-percussive technique.

Castle & Pryor uses only experienced and fully qualified engineers who have undergone extensive training to NVQ Level 2 in the use of diamond drilling tools. We’ll utilise a range of equipment, with electric and diesel-powered drills available in multiple sizes to suit the needs of every client.

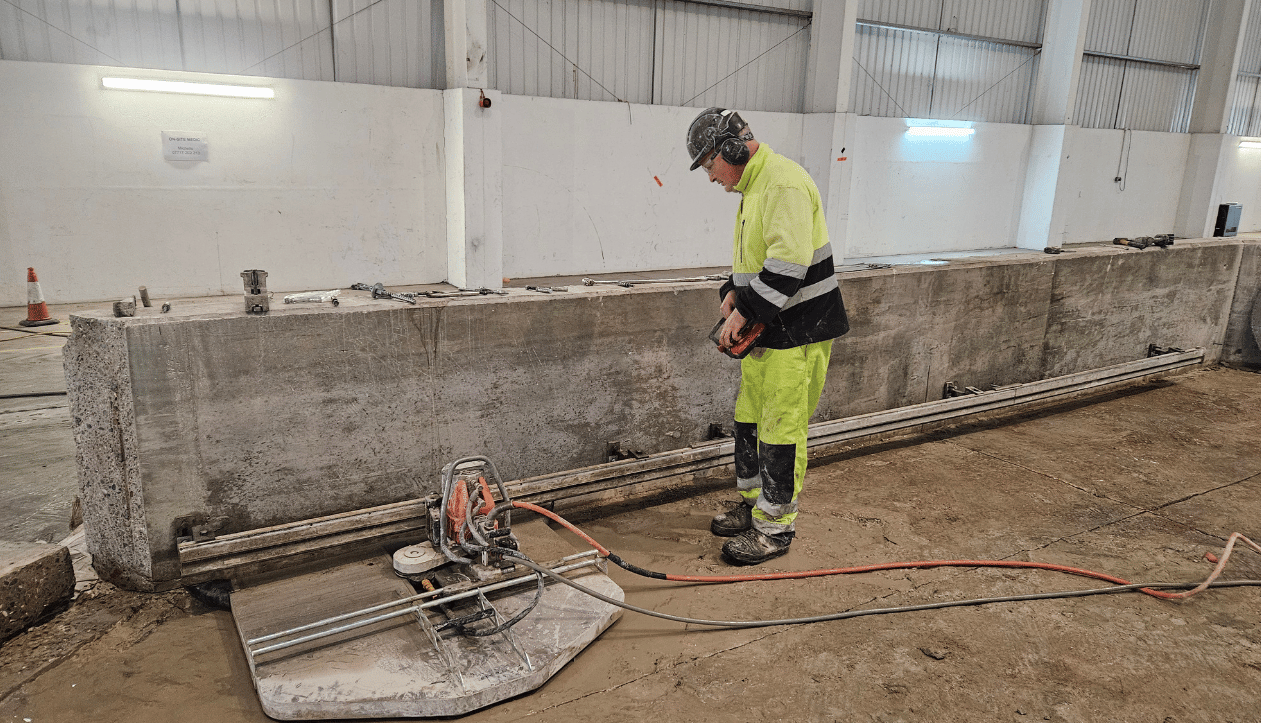

Concrete Wall Sawing

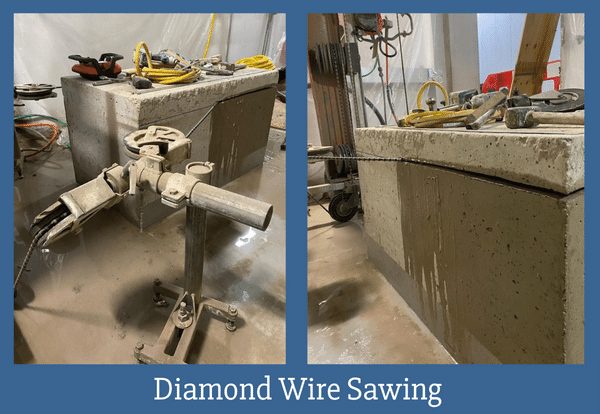

Concrete Wire Sawing

Diamond wire cutting is our technique of choice when we need to cut anything that’s particularly thick or awkward. It’s especially good when isolating and removing reinforced concrete in structures like bridge sections, jetties, columns or pipes

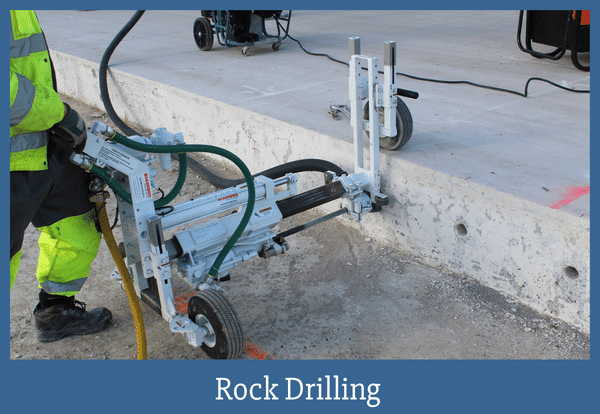

Rock Drilling

Percussive rock drilling is a technique that involves the use of specialised equipment to form cost-effective holes into concrete slabs and walls. We offer a range of drilling services for the aviation industry, including dowel bar drilling, induction line drilling, anchor hole drilling, and drilling holes to facilitate bursting operations.

Our selection of horizontal, vertical, and machine-mounted drilling rigs, ensures that we can tackle any job, quickly drilling holes between 16mm and 55mm in diameter.

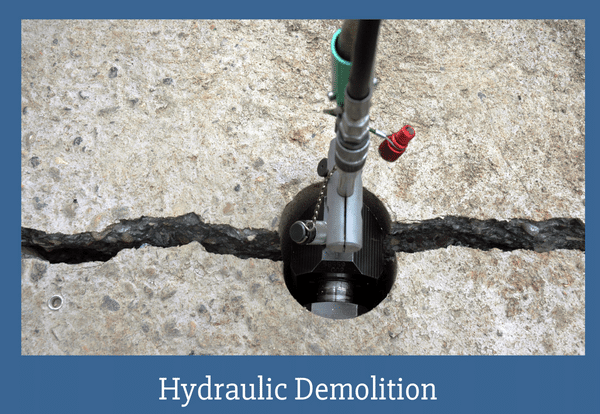

Hydraulic Bursting

Also known as hydraulic splitting, or hydraulic / silent demolition, bursting is a method used to burst large volumes of concrete in a controlled methodical manner.

AGL Installation

Airfield ground lighting ensures optimal visibility and safety for airfields across the UK, with upgrading to modern LED units offering significant cost-saving potential over time. We offer an all-in-one service that involves AGL installation, cable chasing and chase sealing, utilising our floor sawing, joint sealing, and diamond drilling capabilities.

Thin Bond Concrete Patch Repair

Ironwork Reinstatement

Firstly, a layer of grout is installed and then the blocks introduced with more grout to fill the voids to the top of the blocks. Dependant on the depth of the repair more layers of grout and blocks are added and then a final layer of grout with bitumen coated stones introduced and pushed into the grout to provide a high grip and wearing surface.

The blocks not only provide strength to the repair but they also absorb the heat from the grout allowing for the quick return to service. And it gets better, because this is a compaction free solution - no roller or plate compactor is required, so no damage is done to the existing ironwork. Overall the process is quick and easy to do, providing a quick return to service within 1-2 hours.

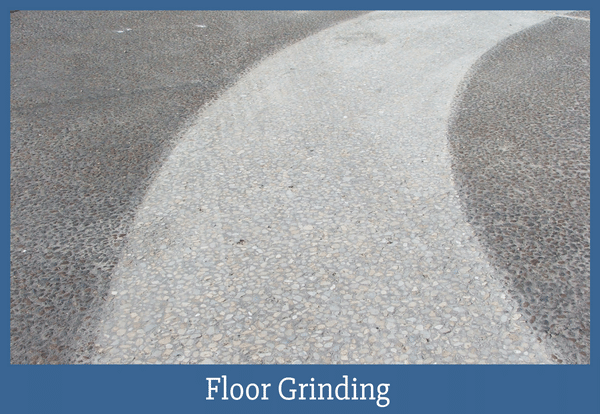

Floor Grinding

The operation is clean and fully self-contained allowing sensitive projects to be completed with little or no impact on surrounding areas of work. The diamond floor grinding method is effective on concrete leaving an open smooth profile for products and materials to adhere to.

Floor Stripping

The stripping is quick, clean allowing projects undertaken to be completed in a minimum time. The method is effective on both concrete and integral screed, stripping the material back clean to the subfloor.

Floor Planing

Concrete floor planing, cold milling, scabbling and flailing are some of the terms used to describe the methods to achieve the relevelling of concrete, removal of contaminants, coatings, screeds and to provide anti-slip flooring.

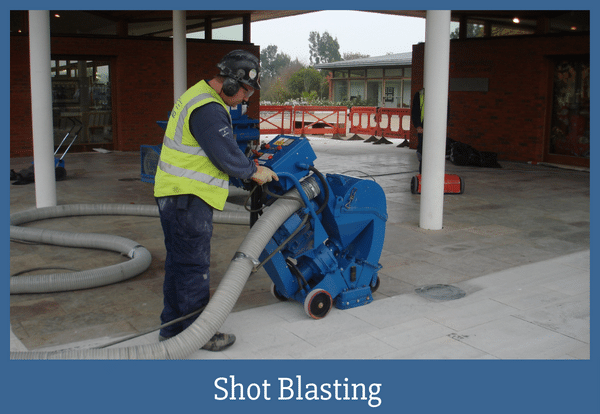

Shot Blasting

The shot blasting machines use a captivated system and utilizes dust collection and vacuum technology so that no dust or surface contamination becomes airborne. All debris are captured within the vacuum unit attached to the blaster, leaving the operation clean and dust free. Shot blasting is an ideal method for cleaning, stripping and preparing the surface of floors.

Industrial Pressure Washing

Our 4000psi (275 bar) petrol pressure washer, powered by a 420cc 4-stroke engine, is your solution to industrial sized cleaning tasks. Complete with the large Whirlaway head inc three rapidly-spinning jets achieve a deep, non- streak finish.

Pressure washers are tools that generate high-pressure water. The pressure comes from the pump in the machine which generates compression via a pressure carbide or ceramic element. This creates a large amount of pressure to reach the high-pressure water jet(s).

Industrial pressure washers are much more powerful than residential pressure washers and can handle tougher jobs. They’re commonly used in industrial environments to clean industrial equipment or highly trafficked areas which have become unsafe or aesthetically non pleasing.

The hose has an extra-large 24″ / 61cm stainless steel head, this powerful flat surface cleaner is able to offer a deeper and more comprehensive clean, saving you a huge amount of time in comparison to using a pressure washer alone.

Advantages of an Industrial Pressure Washer

Higher power, higher pressure and faster flow rates helps the industrial pressure washer stand head & shoulders above a domestic jet wash.

Our pressure washer can be used in conjunction with our other services, or independently to suit your project requirements. Either option will ensure that the area(s) treated will be far safer and cleaner than that what it was before we arrived.

Examples of areas that can be cleaned with our Industrial Pressure Washer

- Patios, Driveways, Decking.

- Concrete structures, Forecourts, Hard standings

- Exterior walls

- Outdoor staircases

- Roads, Pathways

- Garage, Workshop, Factory floors

- Vehicles, Fleet, Farming or Construction equipment, 4 wheel & all-terrain vehicles

- Roofing – Gutters & soffits

- Swimming pools

- Boats/trailers

- Outdoor spaces, Wooden fences, Decks, Outdoor furniture

Utility Sector Specialists

We are diamond drilling and concrete cutting specialists, with extensive utility sector experience, including projects for Southern Water and the National Grid. Services include structural alterations and penetrations to allow for replacing grates, grills, and filters, upgrades, refurbishments, and new service redesigns.

Previous Work in the Utility Sector

![]()

Location – Tideway Kind Edward Memorial Cofferdam, London

- Wire sawing – Assist with the removal of 750mm dia piles by cutting below river bed level using wire saw technique.

- Floor Sawing – Form demolition cuts in cofferdam floor slabs to allow for removal

Location – Aylesford Wastewater Treatment Works

- Percussion / Rock Drilling – Formed 690nr 18mm dia x 300mm deep dowel holes with no HAV exposure

- Floor Sawing – 550.0mts of floor sawing 250mm deep in reinforced concrete floor slab

Location – UKPM Substation, Amberley

- Diamond Drilling – Form 178mm dia holes 950mm deep through pit wall to accept new services

Location – Buntingford Sewage Treatment Works

- Diamond Drilling – Forming 300mm dia holes x 600mm deep in manhole walls to accept new services

- Percussion / Rock Drilling – Form 144nr 16mm dia holes 100mm deep in reinforced concrete with no HAV exposure

Location – Goddards Green WWTW

- Diamond Drilling – Form 350, 400 and 500mm dia holes in reinforced concrete floor slab

- Track Sawing, Diamond Drilling, Robotic Demolition – Form multiple openings in cake bed walls 6.4m x 2.1m x 200mm in reinforced concrete

- Floor Sawing – Formed 500mts of floor sawing 200mm deep in reinforced concrete roads and tank/bed slabs

Location – Buckhurst Avenue Substation

Vac Ex – We were tasked with the safe excavation of the perimeter fence, using non intrusive vac ex, so new fences could be installed.

Location – National Grid Bridgewater Substation

- Diamond Drilling and Track Sawing – Formed opening for new transformer base 7.8m x 1.2m x 1.0m deep in reinforced concrete

- Diamond Drilling, Fixing Installation, Pull Testing – Form holes to accept 24mm dia anchors, chem fix anchors and provide pull test results

Other Specialist Services For the Utility Sector

- Joint sealing is a vital process for ensuring the longevity of concrete and asphalt surfaces. It involves the application of sealant material to expansion or contraction joints, which allows the concrete or asphalt to move through natural expansion and contraction heat cycles while maintaining a seal, preventing water and contaminate ingress into the joint

- Diamond Wire Sawing is a powerful and flexible technique that uses linear wire embedded with diamond beads to cut through reinforced concrete, masonry, and other hard materials. It is a fast, quiet, and effective way to cut large structures and plinths with precision, and it is especially useful on projects where deconstruction work requires careful consideration.

- Hydraulic Bursting is also known as hydraulic splitting, or hydraulic/silent demolition. Bursting is a method used to burst large volumes of concrete in a controlled methodical manner.

- Floor & Wall Chasing utilises diamond sawing equipment to create accurate and precise chases in your floors and walls for ducting, cabling or pipes keeping them safe, tidy & hidden below the surface.

Shop Fit Out Partners

We are an established Fit Out contractor that specialises in structural alterations and refurbishment on fast track construction projects. Using the latest autonomous and innovative equipment we can ensure that difficult tasks can be carried out safely, efficiently, inside program and on budget.

Established for over 30 years and being at the forefront of construction innovation our expertise in fast track fit out projects ensures you have the right trading partner on site.

What does this all mean and how can it help you?

- We operate a large fleet of Brokk and Husqvarna demo robots that ensure high out puts and safe working because of their remote operation

- We use fume free equipment to alleviate toxic fumes

- We use battery operated excavators for excavation and loading

- We operate battery dumpers and self-tip barrows to remove debris from our operations to eliminate manual handling

- We use dust cowlings or water suppression to eliminate air-borne dust

- We offer minimal percussive demolition techniques to minimise noise

- Our machinery ( albeit mainly remote ) does not exceed HSE guidelines relating to HAV

Floor Preparation

We can lift floors, tiles and vinyl, remove paint, latex and adhesive and complete floor preparation for new surfaces. We offer grinding, stripping, planing and shot blasting.

Forming Openings

We can create new doorways and window openings, we can also re-direct drains to make room for new services. We can easily form openings in reinforced concrete with our sawing and robotic demolition services. All our tools are run on phase three electric motors so there are no concerns about fumes.

We can also form openings for new lift shaft or escalator installations, and remove any large area of concrete or masonry using our demolition robots.

Forming chases

We can create accurate & precise chases in your floors and walls for ducting, cabling or pipes keeping them safe, tidy and hidden below the surface. We can also create trenches and rebates in floors to accept new or redirect existing services such as air conditioning, plumbing and cables.

About us

Castle & Pryor Ltd was established in 1991 by the two principal Directors, Mark Castle and Graham Pryor. Both Mark and Graham identified the market changes in technology and the development of new initiatives that the diamond drilling and cutting industry was offering.

They saw that the new development was exciting and clearly leading the way in technology, which was transforming the way the construction industry was working. This philosophy has continued to this day where the Directors are at the forefront of engaging with new technology and techniques to improve safety and efficiency in the diamond drilling, cutting and controlled demolition industries.

Sectors / Services:

Mainstream Construction Sector

Diamond Drilling− Form holes from 6mm up to 1.0m in diameter.

Floor Sawing − Diesel powered for external work to a depth of up to 610mm and 3-phase powered for internal works up to 500mm deep.

Track/Wall Sawing − Forming cuts in walls through reinforced concrete or masonry up to 525mm deep.

Wire Sawing − Used for cutting large/deep sections of reinforced concrete or masonry such as piles, pile caps, foundations, beams and steel beams and structures.

Robotic Demolition − Full range of Robotic Demolition machinery to suit every requirement.

Controlled Demolition − Using drilling and bursting and crunching techniques we can remove concrete in a controlled, low vibration and quiet manner with minimal disturbance to local areas.

Pull Testing − Complete hole forming, fixing install and test service.

Infrastructure / Civil Sector

Joint Sealing − Hot or Cold Pour (fuel resistant) capabilities. Complete joint forming (sawing) widening and sealing service capabilities.

Thin Bond Concrete Pavement Repair − A long term, robust and quick return to service (1 hours) repair system to cracks, spoils, potholes and damaged joints using polymer hot mixed materials.

Ironworks Surround Repair − A long term, quick return to service (1 hour) and one-time solution to failed ironworks surrounds (manholes, access panels, gulley’s etc) using recycled materials.

AGL (Aircraft Ground Lighting) Installation − An aviation specific service with full AGL pot installation and using our sawing and sealing services we can also provide AGL cable chase and sealing capabilities.

Rock / Percussion Drilling − full range of automated drill units to form holes for dowel bars, starter bars or fixing holes avoiding any HAV issues.

The Future

Plans for 2024/25 are ambitious but achievable,” Will Richardson, Operations Director, states. “ We will continue to grow at a steady and reasonable pace, all the while providing the highest level of service to our customers, maintaining the integrity of the work that we deliver and supporting our greatest asset, the wealth of expertise in our work force'. Castle & Pryor will continue to promote our specialist sector utilising Eco initiative equipment, and vehicles.

Images

Videos

Articles / Press Releases

Brochures

Reviews

Trade Associations