Company details for:

Coler Supply Solutions International Ltd

2nd Floor, White House,

16-20 Church Street,

Tamworth,

Staffordshire,

B79 7DH,

United Kingdom

Quick Links:

Products

Manufacturing Solutions

Backed by over 35 years’ experience as a manufacturer of high precision components, this has led to our growth in both provision of UK manufacture and overseas manufacturing. We are a leading figure in the procurement supply and project management of both bespoke and standard components, assemblies, fasteners and fittings.

We have full Computer Aided Design and Computer Aided Manufacture. We also have a real time communications link to ensure that even with our key overseas manufacturing facility being in China that language and distance ceases to be a problem.

We specialise in the manufacture of components both here in the UK and incorporation of Components from our facilities overseas to the UK and indeed globally.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

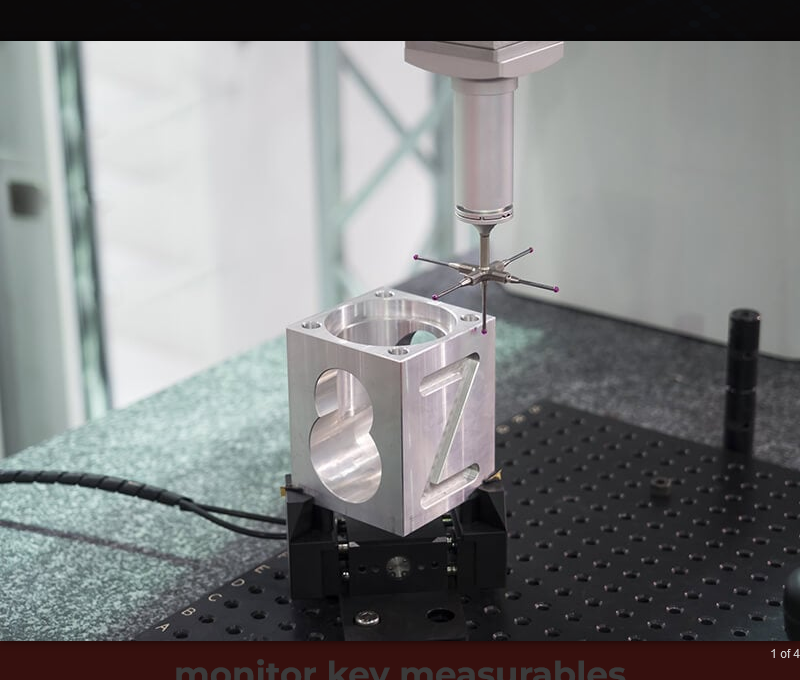

Quality Engineering Solutions

We have a proactive approach to quality within Coler as it is our firm belief that quality should be designed into a product, not sought after manufacture. In order to achieve this, we firstly assure ourselves that we can achieve our clients brief, via a process of contract review.

If we are confident that we can achieve the specifications outlined in the brief, we utilise our experience and knowledge of global sourcing in order to maximise quality, cost and delivery expectations of our client.

Upon shortlisting supplier companies we match the clients brief to the supplier’s abilities, via our bespoke computerised database, built up over twenty years of procurement in both the UK, Europe and now globally.

Through this process, we always ensure that client specifics can be met − including supply companies accreditation levels, with most of our supply companies holding ISO9001:2000 or its equivalent.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

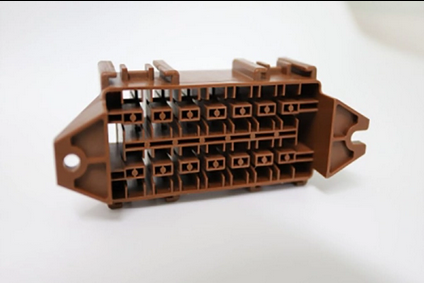

Plastic Injection Moulding Service

We are currently equipped with 64 state-of-the-art horizontal and vertical injection moulding machines, ensuring a continuous output of high-quality products.

Our focus extends beyond round-the-clock efficiency for bulk orders to include the utilisation of advanced technology for the manufacture of sophisticated plastic moulded parts.

The engineering prowess we offer, along with a comprehensive range of secondary operations, has provided substantial value to our clientele.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

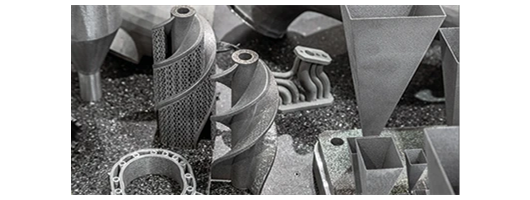

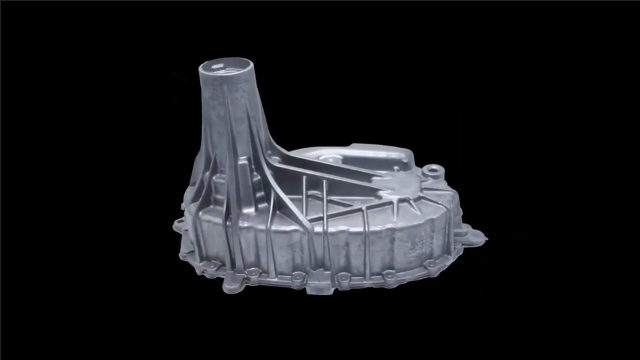

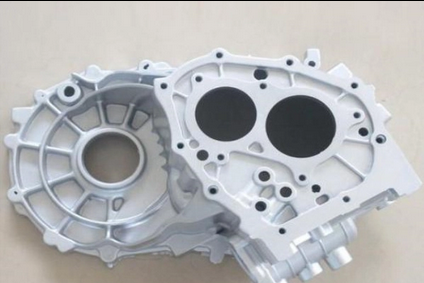

Die Casting Service

With over 15 years experience in die casting Coler has built up its production capacity, utilising are experience to offer mold design, mold-making, die casting, surface finishing and inspection all available at a competitive price.

We specialise in deep cavity products, high rib profiles, thin-walled devices, offering a precision solution no matter the complexity of your part.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Aluminium Die Casting

We are currently equipped with 64 state-of-the-art horizontal and vertical injection moulding machines, ensuring a continuous output of high-quality products.

Our focus extends beyond round-the-clock efficiency for bulk orders to include the utilisation of advanced technology for the manufacture of sophisticated plastic moulded parts.

The engineering prowess we offer, along with a comprehensive range of secondary operations, has provided substantial value to our clientele.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Zinc Die Casting Service

Provide services for customers from more than 40 countries all over the world

Providing products weight from 0.05KG to 16KG.

Coler Supply Solutions holds 7 Zinc die casting machines, with 7*24 working.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Rapid Tooling Service

Coler Supply Solutions has been dedicated for over a decade to the rapid injection molding sector. We offer expert services in rapid moulding and low-volume injection moulding.

This is significantly reducing new product launch times, cutting R&D expenses and cycles. This facilitates swift iterations and tailored production for our clients.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Rapid Prototyping Service

Rapid Prototyping (RP) refers to the creation of a tangible part that accurately reflects the intended design. This process involves producing one or several samples based on the CAD drawings to evaluate the design's appearance and structural soundness.

Typically, the primary objective is to assess the viability of a newly developed or designed product. Prototyping plays a crucial role in this phase, as it allows for the effective identification of any flaws or irregularities. It helps in pinpointing deficiencies and shortcomings in the product design, facilitating the rectification of defects at an early stage. Conducting a small trial production is common to refine any issues in bulk production, as new products often present challenges.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

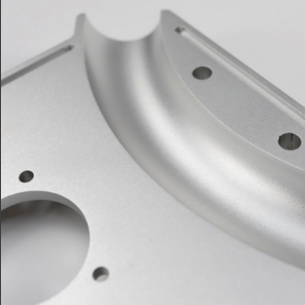

CNC Machining Service

We are currently have access to over 200 CNC machines, including lathes, mills, grinders, EDMs, tapping machines measuring projectors and more.

Our focus extends beyond round-the-clock efficiency for bulk orders to include the utilisation of advanced technology for the manufacture of sophisticated parts with no minimum order quantity.

The engineering prowess we offer, along with a comprehensive range of secondary operations, has provided substantial value to our clientele.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

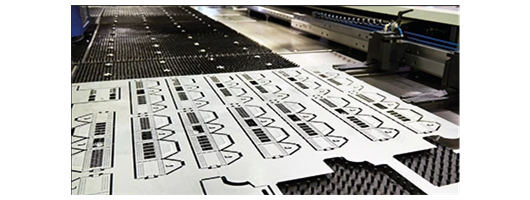

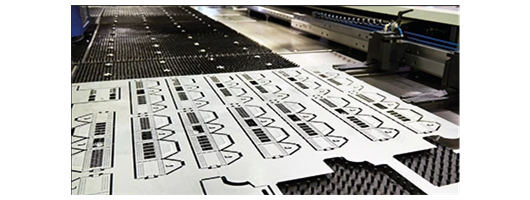

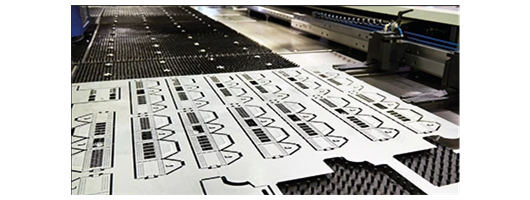

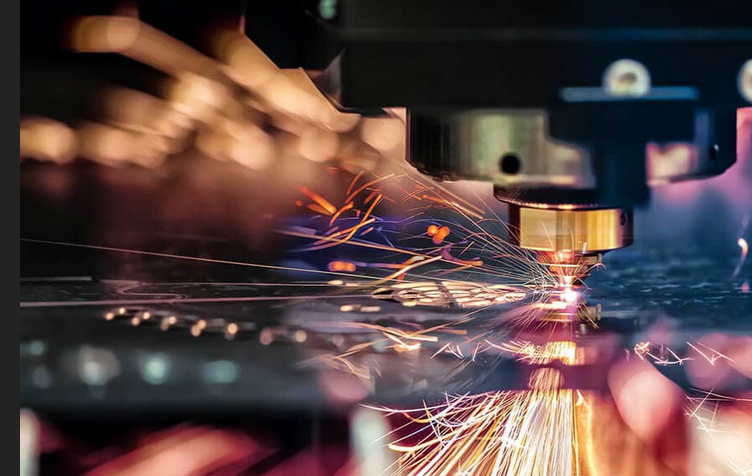

Sheet Metal Service

Sheet metal processing is an essential and versatile technique in manufacturing, utilised by businesses like Coler Supply Solutions to create a wide array of products. This process involves transforming flat sheets of metal into various shapes and components, which are then used in industries such as construction, automotive, and electronics.

At the heart of sheet metal processing is cutting, a crucial step where sheets are precisely sliced into desired shapes and sizes. Coler Supply Solutions uses advanced cutting methods like laser and plasma cutting, ensuring high precision and efficiency. After cutting, the next step is bending or forming the metal. This shapes the metal into specific angles or forms, allowing for the creation of diverse and complex designs.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

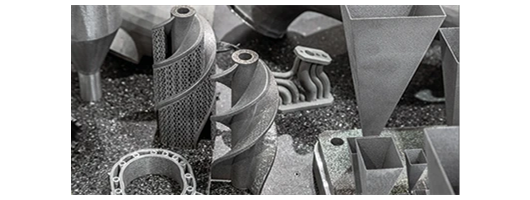

3D Printing Service

3D printing, also known as additive manufacturing, is a transformative technology that has revolutionised various industries, from healthcare to automotive production. This technology functions by creating three-dimensional objects from a digital file, layer by layer. It offers unparalleled flexibility in design, allowing for the production of complex geometries that would be impossible or prohibitively expensive with traditional manufacturing methods.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

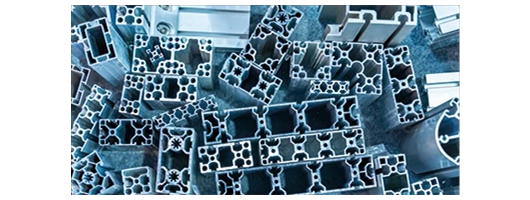

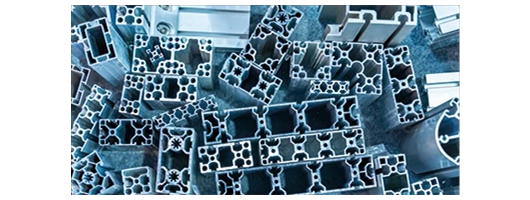

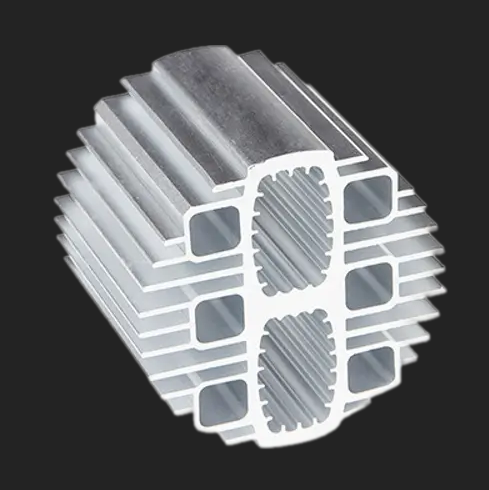

Aluminium Extrusion Service

Extrusion processing stands as a pivotal technique in manufacturing, leveraging the principle of plasticity forming. This method involves pushing materials through a die to shape them into specific profiles. Through extrusion, a variety of products with distinct shapes such as tubes, rods, and profiles with T, L, or U shapes can be fabricated. The versatility of this process allows for the use of a wide range of materials, including aluminium, copper, stainless steel, iron, and various plastics.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Anodic Oxidation

Anodic oxidation, also known as anodising, is an electrochemical technique used to increase the natural oxide layer on metal surfaces, especially aluminium. In this process, the metal acts as the anode in an electrical circuit while submerged in an electrolytic solution. When an electric current passes through, it causes an oxide layer to form on the metal's surface. This layer enhances the metal's resistance to corrosion and wear and can be dyed for aesthetic purposes, making anodising a popular choice in various industries like aerospace, automotive, and consumer goods.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Sandblasting

Sandblasting plays a crucial role in post-treatment processes and is effective in cleaning residues from parts after heat treatment, such as oxidised skin, residual salts, and similar contaminants. It also serves to strengthen the surface of components, thereby enhancing their fatigue strength. Additionally, sandblasting is beneficial for rectifying issues in thin, elongated parts as well as correcting deformations in thin-walled components.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Plastic Electroplating

Compared to their metal counterparts, electroplated plastic parts offer not only a superb metallic texture but also the benefit of reduced product weight. This process not only enhances the aesthetic appeal of plastic, catering to decorative needs, but also improves its electrical, thermal, and corrosion-resistant properties. However, the choice of material for electroplating hinges on several factors, such as the material's processing characteristics, mechanical properties, cost-effectiveness, precision of dimensions, complexity of processing, and other considerations. Thanks to its advantageous structural properties, electroplated plastic not only boasts excellent overall performance but is also easy to shape. This ease of shaping allows for high coating adhesion, as seen in chrome-plated plastic and electroplating on ABS plastic, making it highly sought-after in electroplating applications.

In designing plastic parts for electroplating, it's crucial to ensure that their appearance and functionality are not compromised while meeting these specific requirements.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Metal Electroplating

Electroplating harnesses the power of electrolysis to apply a thin layer of one metal or alloy onto the surface of another. This process is key in preventing metal oxidation - think rust and corrosion - and is also used to enhance qualities such as wear resistance, electrical conductivity, and reflectivity. A notable application of electroplating is the outer layer of coins, which is achieved through this method. Electroplating comes in various forms, depending on the materials used and the desired outcome, such as metal chrome plating or gold electroplating. The choice of electroplating method can also be influenced by factors like the location of the plating, its intended use, and the environmental conditions it will face. The two main categories of electroplating are 'wet plating' and 'dry plating', each with its unique processes and applications.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Automotive Parts

At the heart of Coler Supply Solutions' operations lies a commitment to quality and efficiency. Our manufacturing prowess is evident in the precision and reliability of the parts they produce. Utilising cutting-edge technology and innovative techniques, the company is adept at creating components that not only meet but often exceed industry standards. This attention to detail is critical in an industry where the safety and performance of vehicles hinge on the quality of their parts.

Coler Supply Solutions excels in the procurement aspect of the automotive supply chain. We understand that timely and cost-effective sourcing of parts is crucial for our clients. To this end, they have developed a robust network of suppliers and partners, enabling them to source a wide range of high-quality automotive parts at competitive prices. Our procurement team is skilled in navigating the complexities of the global supply chain, ensuring that the necessary components are delivered where and when they are needed.

Medical Parts

The cornerstone of Coler Supply Solutions’ reputation is our unwavering commitment to quality and precision in manufacturing medical parts. In an industry where accuracy and reliability are non-negotiable, the company employs state-of-the-art technology and stringent quality control measures. Our manufacturing process adheres to the highest standards, ensuring that every component they produce meets the rigorous demands of medical applications. This focus on quality is not just a business requirement but a moral imperative, considering the critical role these parts play in saving lives and enhancing patient care.

Procurement is another area where Coler Supply Solutions excels. The company recognises the importance of timely and cost-effective sourcing of medical parts. They have established a comprehensive network of suppliers and partners, allowing them to procure a wide range of quality medical components at competitive prices. Our procurement team is adept at navigating the complexities of the global supply chain, ensuring a steady and reliable supply of essential parts. This capability is particularly crucial in the medical field, where delays or shortages can have serious implications.

Die Casted Parts

The manufacturing capabilities of Coler Supply Solutions in die casting are marked by precision, efficiency, and innovation. The company employs advanced die-casting processes, including high-pressure, low-pressure, and gravity die casting, to produce parts that meet exacting specifications. Their use of top-grade materials, combined with cutting-edge machinery, ensures that each component is of the highest quality, boasting durability and optimal performance. This commitment to manufacturing excellence is crucial in industries where the integrity and reliability of die-cast parts are essential.

In addition to their manufacturing prowess, Coler Supply Solutions is highly adept in the procurement of die-cast parts. Understanding the critical nature of supply chains in the die-casting industry, they have developed a robust network of suppliers and strategic partners. This network enables them to source a diverse array of die-cast components efficiently and cost-effectively. Their procurement team, skilled in supply chain management, ensures that clients receive their parts on time and within budget, which is vital in maintaining uninterrupted production lines and meeting market demands.

Precision Parts

At the forefront of Coler Supply Solutions' offerings is our manufacturing capability in precision parts. The company employs advanced techniques such as CNC machining, precision casting, and injection moulding to produce components that meet the highest standards of accuracy and consistency. Their state-of-the-art facilities are equipped with the latest machinery, enabling them to handle complex and intricate designs with ease. This capability is crucial in industries where even the slightest deviation in component dimensions can significantly affect the performance and safety of the end product.

In addition to ourmanufacturing expertise, Coler Supply Solutions is highly proficient in the procurement of precision parts. They understand the critical importance of timely and efficient sourcing in maintaining smooth operations for tour clients. To this end, they have established a vast network of trusted suppliers and partners, allowing them to source high-quality components at competitive prices. Our experienced procurement team excels in supply chain management, ensuring that all parts are delivered on schedule and conform to the required specifications.

Banjo Bolts

Banjo bolts are commonly used in automotive, oil and hydraulic applications, and we supply any metric or imperial sized banjo bolts that can be used across these industries.

We have the capabilities to manufacture any standard size and are able to work with your team to meet your exact specifications − our speciality is custom sizes of banjo bolts.

We can also supply any metric or imperial sized washers, these are supplied across many different sectors such as automotive, health care, agriculture and more.

We can manufacture banjo bolts out of plastic, steel, aluminium or brass. We can offer a range of plating options, with anything from zinc plating to GeoMet 500 to phosphating. Let us know your plating requirements and we will be able to find a solution that suits you.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

P-Clamps Manufactured & Supplied

Pressed parts, crafted through the precision of pressing and stamping processes, are integral components in various industries, including automotive, aerospace, and electronics. This method involves shaping metal sheets into specific forms by applying high pressure, a process that ensures accuracy and consistency in mass production.

The versatility of pressed parts is remarkable, allowing for a wide range of shapes and sizes. From small intricate components used in electronic devices to larger structural parts in automotive manufacturing, the adaptability of this technology is key. The process not only accommodates different metals, like steel, aluminium, and brass, but also allows for complex designs that would be challenging or impossible to create through traditional machining methods.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Fasteners & Spacers

The range of materials used by Coler Supply Solutions is extensive, encompassing alloy steel, aluminium, brass, bronze alloys, carbon steel, copper, and stainless steel. This diverse material selection allows them to tailor their products to specific industry requirements, ensuring both durability and performance.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Bearings

Coler Supply Solutions, a specialist in the field of bearings, offers an extensive range of precision and customised bearings. These high-quality bearings are primarily supplied to Original Equipment Manufacturers (OEMs) across a diverse array of industries. The sectors benefiting from their products include gearboxes, where the precision bearings play a crucial role in enhancing performance and reliability. Similarly, in electric motors, these bearings are essential for ensuring smooth operation and longevity.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

Pressed Parts

Pressed parts, crafted through the precision of pressing and stamping processes, are integral components in various industries, including automotive, aerospace, and electronics. This method involves shaping metal sheets into specific forms by applying high pressure, a process that ensures accuracy and consistency in mass production.

The versatility of pressed parts is remarkable, allowing for a wide range of shapes and sizes. From small intricate components used in electronic devices to larger structural parts in automotive manufacturing, the adaptability of this technology is key. The process not only accommodates different metals, like steel, aluminium, and brass, but also allows for complex designs that would be challenging or impossible to create through traditional machining methods.

For advice or more information call us today on +44(0)1827 712910 or email us at sales@coler.co.uk

About us

Our philosophy is centred on ensuring that our manufacturing capabilities can produce a wide range of products that consistently meet our customers' specifications in key areas: Quality, Cost, Communication, and Delivery.

Coler Supply Solutions International Ltd offers a holistic supply chain solution, providing end-to-end visibility and management from material acquisition to final delivery at your specified location. We leverage tailored systems integration to maintain complete control over every aspect of your supply chain, offering transparent tracking and adaptability to accommodate changes during delivery. Our aim is to forge enduring, mutually beneficial partnerships by emphasising customer collaboration and meeting individual requirements whenever feasible. Choose us for a streamlined and transparent supply chain experience.

Our Capabilities Include:

Injection Moulding

We possess a comprehensive array of over 60 high-precision injection moulding machines, varying in capacity from 50T to 3200T, housed within medical-grade clean rooms and oil-free environments. In addition to injection moulding, we provide product assembly services, enabling us to achieve a monthly production capacity of 4.5 million shots.

Die Casting

We have access to a total of 16 automated die-casting machines, ranging in capacity from 100T to 3500T, complemented by extensive expertise in post-treatment and surface finishing techniques. Our specialisation lies in die casting using aluminium, zinc, and magnesium alloys.

Rapid Tooling

Coler Supply provides a rapid prototyping service tailored for low-volume production, spanning from 20 to 5000 shots. We can quickly deliver injection moulding samples to keep your project moving forward efficiently and without delays.

Rapid Prototyping

By leveraging CNC machining, 3D printing, vacuum casting services, and other advanced manufacturing techniques, Coler Supply Solutions can swiftly and efficiently produce high-quality prototypes. We offer a variety of surface finishing options to meet your specific requirements, ensuring premium results.

CNC Machining

Coler Supply Solutions provides an extensive selection of more than 200 numerical control applications, including 3-axis, 4-axis, and 5-axis machining services. Our capabilities encompass CNC Milling, Turning, wire cutting, EDM, and more. We offer a wide range of material options, ensuring precision with an accuracy of 0.005mm.

… And more.

At Coler, we adopt a proactive quality approach, designing quality into products from the outset rather than seeking it post-manufacture. We start by conducting detailed contract reviews to ensure alignment with client specifications. Drawing on our extensive global sourcing expertise built over two decades, we carefully select suppliers using our comprehensive database to match client needs. This process guarantees that supplier capabilities meet specific client requirements, including accreditation levels like ISO9001:2000, optimising quality, cost, and delivery outcomes.

With over 35 years of experience in high precision component manufacturing, we specialise in providing bespoke and standard components, assemblies, fasteners, and fittings through both UK and overseas production. Our capabilities include full Computer Aided Design and Manufacture, supported by real-time communications for seamless collaboration with our overseas manufacturing facility in China. We excel in integrating components from global facilities to serve clients globally.

At Coler Supply Solutions International Ltd, we prioritise quality control for parts sourced from our European and overseas operations. Through advanced manufacturing and procurement solutions, we implement rigorous quality measures to uphold high standards throughout production.

Images