Company details for:

Marshalls CPM

Mells Road,

Frome,

Somerset,

BA11 3PD,

United Kingdom

Quick Links:

Products / Services

Concrete Pipes

All precast concrete pipes manufactured to class 4 (DC4) sulphate resistance in accordance with the recommendations of BRE Special Digest

CPM is able to offer precast concrete pipes in BIM (Building Information Modelling) which is now a requirement for all government construction projects.

For Sales into England and Wales please call 01179 814500 or email sales@cpm-group.com

For Sales into Scotland please call 01698 386922 or email scotland@cpm-group.com

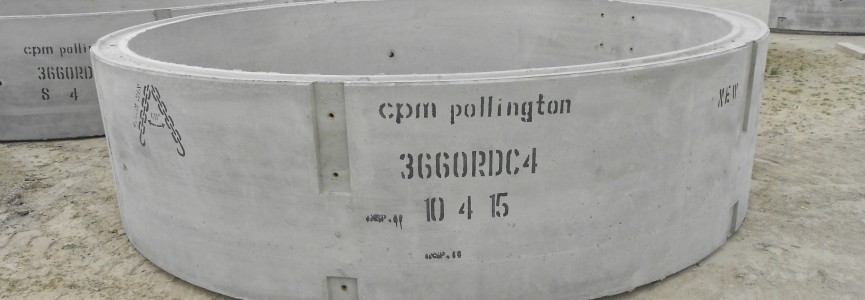

Chamber Rings/Soakaways

The 3660mm and 4000mm chamber rings are not covered by the British Standard (therefore not kitemarked), but comply with all the relevant provisions of the European Standard. 4000mm chamber rings are supplied in two halves.

CPM manhole chamber sections are supplied with 3 number nominal 50mm diameter holes for lifting purposes.

Crane off-load is available up to DN3000 diameter upon request, please speak to our sales team regarding off-loading on site.

Soakaway units are available in 500mm, 750mm and 1000mm depths with 75mm diameter holes, providing a minimum area of exfiltration of 50,000mm² per metre of nominal diameter per metre of depth.

Shaft/chamber sections can be supplied:

- with or without fixed double steps or integrated ladder system

- with holes or cut-outs

- with bases cast-in

Cover Slabs

The reinforced concrete ‘biscuits’ are used to cap a manhole chamber and provide a base for regulating brickwork or seating/adjusting rings prior to installing the manhole cover and frame.

Special Cover Slabs

A wide range of special cover slabs can be manufactured to customer’s specifications.

Typical examples of special cover slabs supplied are:

- Pumping stations incorporating davits and/or rebates

- Extra heavy duty slabs for airports and ports

- Extra large accesses

- Slabs designed to comply with Highways Agency Specifications.

- Multiple accesses

- Non-circular slabs

- Slabs with customers own reinforcement design

Landing/Reducing Slabs

Landing slabs to suit 1500mm chamber sections and above are manufactured with a 900mm circular access and are typically used in deeper manholes, with a limiting depth of a maximum of 6 metres and provides a safe landing platform

Reducing slabs

Reducing slabs to suit up to and including DN 4000 chamber sections are generally manufactured with a 900mm, 1050mm or 1200mm circular reducing section and are used to reduce the access point opening size into the chamber section

For sales into England and Wales please call 01179 814500 or email sales@cpm-group.com

For sales into Scoland please call 01698 386922 or email scotland@cpm-group.com

Adjusting Units- One Piece Units

Adjusting units are available for the following access sizes (mm):

600 x 600, 675 x 675, 750 x 600

600 x 600 Eccentric/Corbel units have an eccentric opening which is used in conjunction with a 750 x 600 cover slab opening.

The advantages of adjusting units are:

- They can be quickly and easily installed by semi-skilled labour

- There are fewer joints which reduce the likelihood of infiltration

- All concrete manhole units can be ordered from one source

- There is a reduced risk of on site damage and pilferage

Catchpits

The reinforced watertight one-piece structures offer greater design flexibility with a range of cored or pre-formed holes/cut-outs for inlet/outlet holes which come complete with seals.

CPM modular catchpits save money and time as they are built under factory conditions to your specification ensuring dimensional correctness as well as a high quality finish.

Design options include:

- 1050mm to 3000mm standard tongue and groove complete with a cast-in reinforced base

- 1200mm, 1500mm and 1800mm sealed manhole joint complete with cast-in reinforced base

- Pipe inlet/outlet diameters covered by system 100mm to 1800mm

Rectangular Manholes

For sales into England and Wales please call 01179 814500 or email sales@cpm-group.com

For sales into Scoland please call 01698 386922 or email scotland@cpm-group.com

Sealed Manholes- The Perfect System

This unique system of products combines to form the CPM Perfect Manhole system; designed and manufactured to last a minimum of 120 years that provides a sealed manhole system that gives up to 40% savings on green house gases compared to traditional manhole construction and eliminates the need of ready mixed concrete to form the traditional base, chamber benching and further concrete to surround the manhole. A complete manhole can be installed in as little as 30 minutes, making safe site practice a real winner when using the Perfect Manhole as it reduces the need to work in confined spaces and eliminates the need for wet trades resulting in rapid construction compared to traditional methods as well as a reduction in the time the excavation is open.

The Perfect Manhole complies with BSEN 1917:2002 and BS5911-3 and has been accepted for use by all major UK companies.

Sealed Manholes- Preformed System

The benefits of the wide wall section include:

- An established and proven product range that is Quality Assured

- Wide wall products are supplied with a Butyl sealant which removes the - need for a concrete surround

- The chamber is supplied with a reinforced cast-in base.

- The chamber system provides performed inlet and outlet holes to suit pipe requirements

- The chambers are manufactured in fixed steel moulds that give a superior dimensional accuracy.

- Wide wall chambers have an inherent structural concrete strength with a 120 year design life.

- Chamber units are supplied with cast-in brackets for a lifting loop system.

- AutoCAD drawings can be provided

- Kitemarked product range

Product specifications include:

- Chamber sections are available in 2100mm, 2400mm, 2700mm, 3000mm, 3660mm and 4000mm diameters

- The chamber sections can be supplied in 500mm, 750mm and 1000mm depths.

- All chamber sections are manufactured to the requirements of BS5911-3, 2100mm, 2400mm, 2700 and 3000mm are kitemarked.

- The base chamber is manufactured with a 200mm deep; grade C40, reinforced concrete base doweled into the chamber unit. Concrete has a minimum cover to reinforcement of 30mm.

- Chamber units can be bolted together using a minimum 4No T16 Grade 8.8 continuous threaded rods if required.

- The inlets and outlets are either pre-scored, pre-formed or cored holes (depending on size) to suit the customer’s requirements.

- Cover slabs are manufactured to the requirements of BS EN 1917:2002 and BS 5911-3:2010

Caissons

This is achieved by using a shaft sinking plate system and is made in accordance to BS EN 1917:2002 and kitemarked where relevant to BS 5911-3:2010.

Advantages of the systems include:

- Suited to weak soils, high-plasticility clays, silts, sands and gravel

- Minimal site labour costs

- Quick and easy to install

- Fast, clean accurate construction

- Immediate permanent shafts

- Suitable for jacking pits

- The caisson shaft sinking system was originally designed for use in microtunnelling, but is now more widely used for construction of pumping stations, wet wells and manholes, particularly in difficult ground conditions.

House Inspection Chamber

HIC units can be supplied banded as detailed in the tables on weights and dimensions.

The chambers, which are economic and versatile to meet the demands of domestic drainage installation, are easily handled and excavation below ground level is reduced to a minimum.

Gully Pots/Covers

Precast concrete road gullies can be supplied with adaptors for connection to clay or plastic pipes.

CPM gullies are manufactured to BS5911:2004 Part 6

Box Culverts

CPM is able to offer end walls, access points, vent holes, inlets, outlets, double rungs, splayed ends, starter bars and threaded sockets, a range of different inverts, dry weather flow and dished inverts. The culverts can be supplied as standard units or vertical chambers and if being used as a chancel, cover slabs can be supplied separately. CPM box culverts are available in square or rectangular units and can be used as single of multi-unit runs, giving excellent mechancial and hydraulic performance.

All precast concrete box culverts are manufactuerd to class 4 (DC4) chemical resistance in accordance with the recomendations of BRE Special Digest 1.

Retaining Wall Series

CPM’s Redi-Rock™ natural stone looking retaining wall is versatile enough to achieve height without compromising on strength, with fully engineered plans pre-drawn for different heights and ground conditions, CPM can work with you to provide a fully designed and engineered solution to any project requirement, from planning to installation.

CPM’s Redi-Rock™ retaining wall series offers low project costs and a high quality solution that brings the following advantages:

Fast and easy to install

- Space saving designs with geogrid rarely needed meaning walls take up less space.

- Concrete blocks delivered ready to build

- The interlocking blocks do not need cement, so can be laid in any weather

- Aesthetically pleasing, with the look of natural stone.

- Can be colour at source or on-site to match different local environments

- Minimal maintenance required

- Engineered strength, achieving height without geogrid

- Risk reduced as number of people and time on site reduced

- If plans alter, just pick up and build in a new location − the ultimate sustainable solution

Reinforced Walls- Redi-Rock™

Benefits of Redi-Rock PC System walls include:

Corrosion-free reinforcement

- Enables simplified wall construction

- Increased wall height achieved with reduced geosynthetic reinforcement requirements

- Can use in conjunction with freestanding walls to create a complete solution for your project

CPM’s Redi-Rock™ modular reinforced walling can improved the overall aesthetic look with a variety of standard face textures and colour options, and delivers an attractive, cost effective, high performance retaining wall structure.

This Redi-Rock™ system combines the massive stability with the natural appearance of stone with the established performance of geogrid reinforcement through a simple and highly efficient positive connection with the Redi-Rock™ reinforced block. The Redi-Rock™ product is single but massively effective.

This result is a superior retaining wall system developed to meet the most demanding structural needs of highways, harbours, flood defence, bridge abutments, rail projects, embankments, airports and as well as industrial and commercial projects.

Redi-Rock™ Vehicle Security Barriers

The Redi-Rock™ Force Protection system has been successfully tested by the Transport Research Laboratory (TRL) using the BSi specification PAS 68:2007, and achieved a classification of V/7500[N2]/48/90:1.6/0.0. To achieve this the freestanding concrete blocks systems interconnected with steel cable successfully arrested a 7.5 tonne lorry at impact speed of 48 kmph (30mph) with only 1.6m penetration of the load carrying space.

System advantages

- Fast to install Lego™ like system (30m can be laid in circa 1.5 hours by 2-3 men)

- Removable / Relocatable

- No ground anchor − uses its own weight

- Integral cable dissipates kinetic energy

- Proven to stop a 7.5 Tonne truck at 48 kmph (30mph)

- Aesthetically pleasing, with the look of natural stone

- Can be coloured to blend with local environment

Easy to install

The 703kg freestanding blocks can be deployed, or picked up and moved, very quickly, with no ground work required.

All block styles are available with 75mm Horizontal Tube (for post tension cable) and/or 150mm Vertical Tubes (for mechanical tie-down bolts) to allow the blocks to be used in a Force Protection application.

L Shape Retaining Walls

L Shape walling offers

- Soil retention

- Storage

- Cladding

- Security

- Blast/Fire walls

- Agricultural applications

CPM’s L Sections are both simple and quick to install, as well as being easy to handle. The L shape walling requires a suitable concrete foundation to ensure they match both ground bearing and stability requirements which should be sourced from a qualified engineer.

The L- Shape units are manufactured from C50 concrete with 50mm nominal cover to reinforcement up to 2.5m, 30mm nominal cover to reinforcement for 3.0m standard sections, a 3.0m bespoke unit can be made to order with a 50mm nominal cover upon request. 50mm cover provides a 100 year design life (exposure class XD3), 30mm cover provides a 50 year design life (exposure class XC3/4) in accordance with BS 8500-1.

Off Site Solutions

Whether it is a precast chamber with a hydro brake pre-fitted or a bespoke manhole section which has been specially designed, that speeds up installation whilst offering a safe working environment or a flatpack system that is correct to the millimetre and reduces the site time programme and disruption to local residents the off-site solutions team are able to offer practical solutions based on sound design and engineering knowledge that results in minimal site installation costs with increased health and safely benefits, whilst being cost effective, please call 01538 380503.

CPM’s technical team, made up of qualified civil engineers are on hand to give advice and CPM offers a complete design service with AutoCAD drawings and BIM that is fully supported by professional indemnity insurance for your peace of mind.

CPM offer CPD style presentations on a variety of precast concrete solutions, if you would like to know more please contact marketing@cpm-group.com or call 01902 356220.

Ground Heat Exchangers

This is achieved by passing air below ground through an underground tube; the temperature below ground is lot more stable compared to the extreme outside temperatures, thus allowing the building to be cooled or heated. Precast concrete pipes have been used for this purpose around the world because they have good thermal conductivity to the ground and CPM can provide concrete pipes and shafts to suit any design required.

Modular Flood Walls

Concrete has a proven track record of performance in water applications, and the blocks are 100% concrete and not steel-reinforced. As the blocks are dry laid, they can be easily moved should the situation on the ground change. Stainless steel lifters are available if required.

Whether you are looking to heighten river banks, build new sea walls or construct flood plain defences, Redi-Rock™ offers considerable benefits over alternative solutions, not least an aesthetically pleasing finish that blends perfectly into the local environment.

Combined Pump & Valve Chamber

The valve chamber is incorporated into the top two meters of the shaft, thereby reducing the overall footprint of the project and considerable savings in time and cost. The combined pump and valve chamber system is available in 3000mm, 3660mm, and 4000mm diameter depending upon the valve and pipe work requirements.

Basic Rainwater Harvesting

CPM offers many different types of precast systems for both domestic and larger schemes i.e. schools, offices, commercial developments etc. The system works by collecting rainwater from roofs and occasionally hard standing areas, which are usually gravity fed though a cleaning filter into the Oasis chamber and via calmed inlet. In a typical installation it is then pumped through a floating filter directly on demand to the required supply areas i.e. non-potable applications such as toilet systems, washing machines, vehicle washing and garden taps.

There are a number of backup systems that can be planned into the system if there is insufficient rainwater stored in the holding chamber. This can be either via a header tank or directly into the holding tank, therefore always ensuring continuity of supply.

The Oasis system is designed using the very best equipment to provide cleaned rainwater with the minimum of maintenance. Water quality is maintained by the removal of organic matter and also by the action of the incoming water through the calmed inlet which introduces oxygen into the stored water. Rainwater is very soft and chlorine free, making it excellent for washing machines.

Bomac Beams

As with most of CPM’s rail products, bomac beams (also known as edge beams) can be used on new projects as well as on existing contracts.

Supplied to the requirements of the rail contractor, for use on rail crossings and in association with infill panels, bomac beams are built under factory conditions, offering a safe and confident manufacturing process.

Bespoke Precast

We help architects, builders, contractors and engineers get the precast solution they are after, whether it be for a large construction project or a single item to complete a project,

The only limit to the size of products we can produce is transportation or crane capacity. Our design team provide structural designs and drawings which are process mapped from enquiry to invoice, to ensure on-site schedules are met. To meet our objectives, the company applies a quality management system which has been developed in accordance with the requirements of ISO 9001:2008 certification.

Bollards

The smooth finish precast concrete bollards are suitable for the following applications:

- Traffic bollards

- Landscape bollards

- Garden bollards

- Parking bollards

Installed buried depth is typically 300mm. In paved areas the installation depth should be increased by the paving thickness.

For sales into England and Wales please call 01179 814500 or email sales@cpm-group.com

For sales into Scoland please call 01698 386922 or email scotland@cpm-group.com

About us

Drainage

Marshalls CPM supply, manufacture and design precast concrete drainage products. We offer precast concrete products in BIM (Building Information Modelling) as required by all government construction projects. In addition to BIM, we also offer design services for special applications which include AutoCAD drawings. All CPM products comply with current National and European standards.

Products include Concrete Pipes, Traditional Manholes, Sealed Manholes, Caissons, House Inspection Chamber, Gully Pots/Covers, and Box Culverts

Retaining Walls

CPM’s BBA approved Redi-Rock™ modular wall system is aesthetically pleasing, strong, space saving, can be matched to suit different environments, cost effective and requires very little maintenance.

Products include Retaining Wall Series, Freestanding Wall Series, Reinforced Walls, Vehicle Security Barriers, Landscaping & Flood Protection

Off Site Solutions

CPM’s off site solutions are designed to provide skilled labour with minimal costs and increased health & safety benefits.

Water Management

Marshalls CPM have created a range of solutions for water management including harvesting, storage, flow control and treatment. We are also committed to offering products for stormwater management, flood protection, wastewater management and flood prevention.

Products include Ground Heat Exchangers, Flood Protection, Wastewater Management, Rainwater Management & Stormwater Management.

Rail Products

Marshalls CPM are manufacturers of precast concrete signal bases, modular retaining walls, bridge components, bank revetments, bomac level crossing beams and precast concrete bespoke products.

Products include Bomac Beams & Redi-Rock for Rail.

Specialist Precast

Marshalls CPM are experts in the design and manufacture of high quality structural and non-structural elements.

Products include special cover slabs, bespoke precast, precast concrete bollards, precast concrete landfill shaft sections and bespoke flat pack chamber systems.