Company details for:

Croft Filters Ltd

2 Beech Court,

Taylor Business Park,

Risley,

Warrington,

Cheshire,

WA3 6BL,

United Kingdom

Quick Links:

Products / Services

Y Strainers

They are most commonly used in pressurized lines, gas or liquid, but can also be used in suction or vacuum conditions.

They are intended for applications where small amounts of solid particulate are expected, and where clean-out will be infrequent.

If solids will flush easily from the screen, and fluid can be exhausted to atmosphere, a blow-down valve on the drain port will allow clean-out without removal of the screen, and without interrupting the process flow.

Self Cleaning Filters

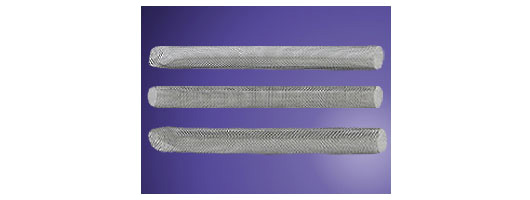

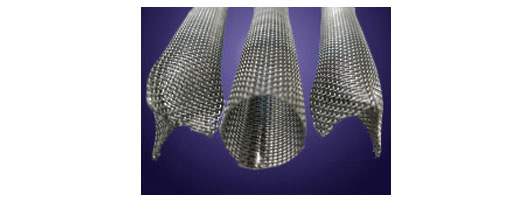

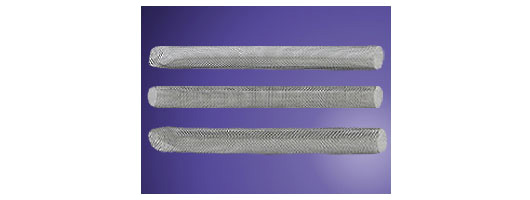

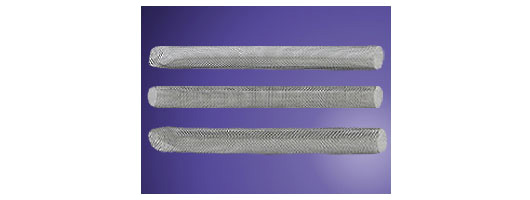

Anchor Mesh Tubes

Commonly referred to as ‘bonded anchor mesh sleeves’ our mesh sleeves provide a high-performance solution for adhesive anchoring into hollow materials.

While we stock mesh sleeves with diameters of 6mm-32mm, we can manufacture sleeves to your specifications: of various lengths and diameters, and with crimping styles to suit your specific requirements.

Last Chance Filters

Water Absorption Filters

It has a double layer structure, with an outer layer of super absorbent material processed by a special method to a inner layer of acrylic fibre substance. When it comes into contact with water it rapidly absorbs the water and swells to about 12 times its diameter - see photographs on the right.

To find out more about this special filter you can download our datasheet here or alternatively call us to discuss your requirements in more detail on 01925 766265.

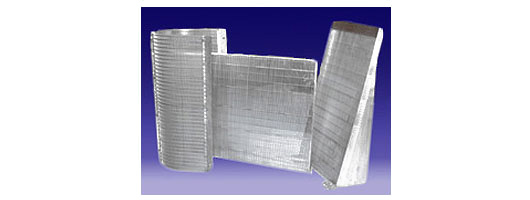

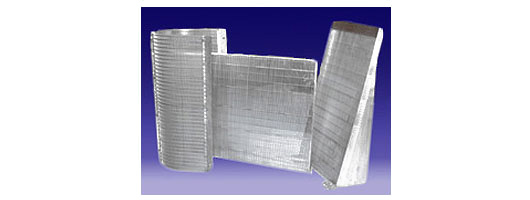

Baskets, Strainers and Cylinders

With a well-established design, each filter comprises an assembly of a perforated metal cylinder or cone that supports one or more layers of very fine wire mesh.

Cone Filters

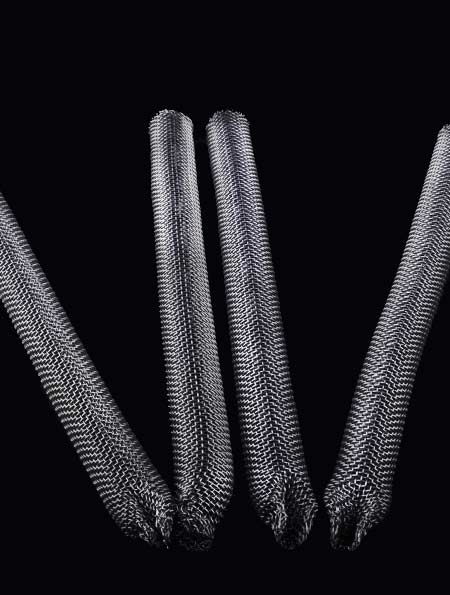

Duplex & Duplex Housings

Not to be confused with the material Duplex, Croft also have a big demand for Duplex Filter Housings. Duplex Type strainers are used for pipelines operating continuously, where a single strainer cannot be used as the flow would have to be interrupted to clean the element. Twin filtration chambers each rated for 100% capacity and two disk type changeover valves operated by interconnected screwed shafts for simultaneous operation, eliminate any possibility of shutting off the flow.

Custom Filtration

These days, a wide range of industries require custom filtration, including the water treatment, power generation, pharmaceutical, oil and gas, food, automobile and nuclear industries.

Filtration requirements vary greatly from one industry to the next. To maintain the integrity of the products manufactured, they must be clearly designed and specified to meet the needs of each application.

The high-pressure conditions in the nuclear industry, for instance, require filters made of super alloys - while the water treatment sector generally deals with much lower pressures and often utilises unsupported mesh filters.

To serve such a variety of industries, a customised manufacturing capability is clearly essential: manufactured to specific customer requirements, each of our filters is carefully designed to address a specific filtration challenge.

Filter Screens

These filters can be manufactured using perforated plate supporting a fine woven wire mesh. The material and the specification of the mesh depend on the type of fluid as well as the type of impurity to be filtered.

These types of filters are generally used as an in-line process. They are found in a wide variety of applications − to give just one example, they are used in the pharmaceutical industry to separate microbial organisms from laboratory chemicals.

Filter Housings

With a comprehensive range of products we can manufacture high quality Simplex, Duplex, ‘T’ Strainer, ‘Y’ Strainer, Bag and Cartridge Housings as well as custom made special orders. Strainers are available with various types of connections, materials of construction, gasket composition, closure covers, and screen openings set in the orientation to suit the process.

Croft Filters offer a design/quotation service for all new filter applications. Each system is sized according to requirements. Why not try us out? − just complete the enquiry form for a free quotation.

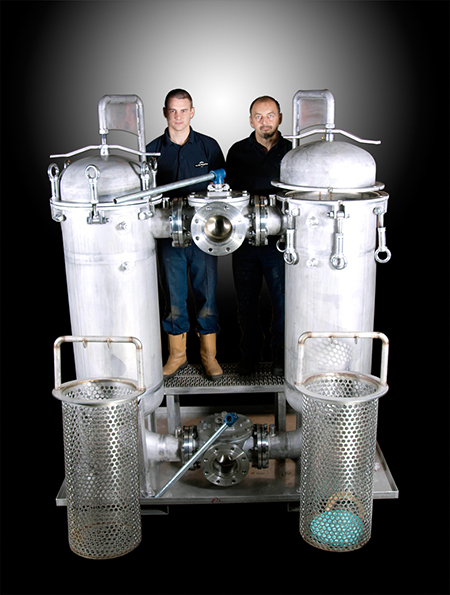

Dixon Rings

Historically, the sheer cost of manufacturing these tiny components in any great quantity was a major obstacle. Today, this is no longer the case.

At Croft Filters, we have developed a machine that automates the entire process of making Dixon Rings at high speed. As a result, we can produce Dixon Rings in very high volumes - something we could never have achieved without our employees’ outstanding design skills and manufacturing excellence.

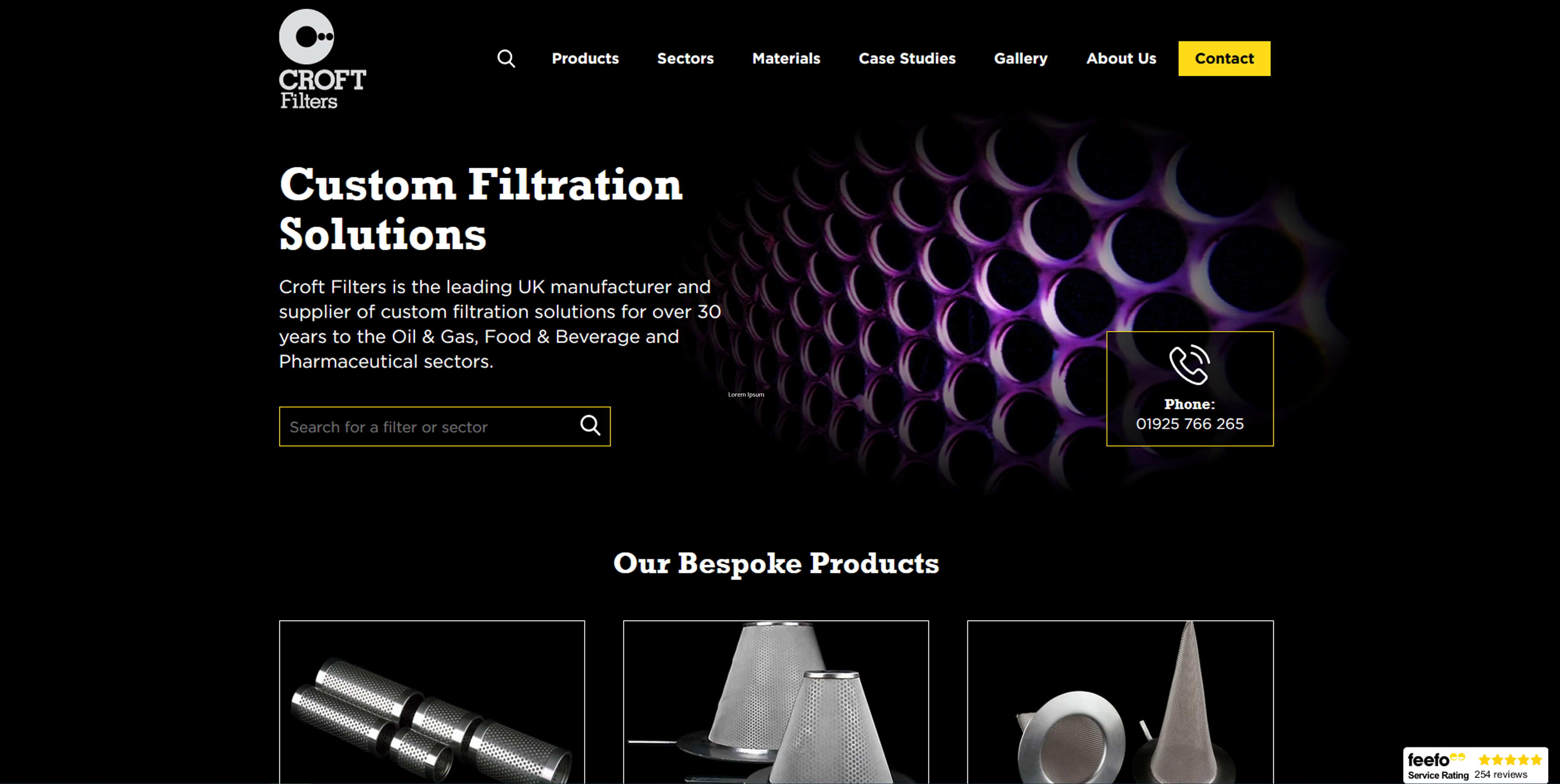

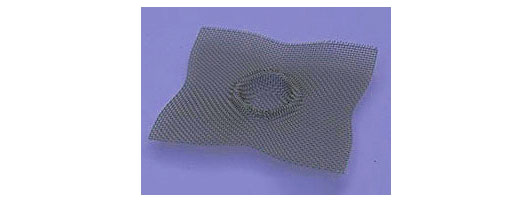

Knitted Wire Mesh

Knitted Wire is often used in filtration as a coalescer filter because of the high density that can be acheived by compressing the material.

Quick Release Filters

Available in many different fittings makes this arrangement highly desireable as it can be made to fit straight into your existing application with ease.

Providing some flexibility has been allowed upon installation, it is very easy to remove the internal filter disc for cleaning or replacement.

A quick release clamp allows seperation of the two halves with little effort

You have a choice to use the internal filter disc as provided or to combine it with mesh to achieve different levels of filtration as required

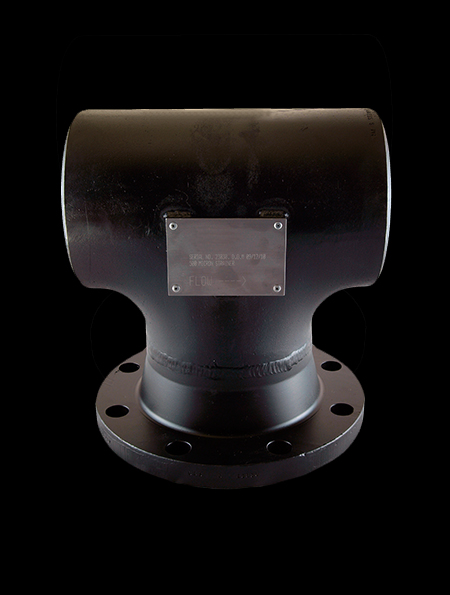

Tee Strainers

Tee strainers are typically used where space is limited and a strainer is needed for protection of pumps, valves and similar equipment.

Tee strainers normally have either a bolted cover or a quick opening cover for to suit the application.

We can basically custom make a Tee Strainer to suit many applications please call for more information.

Perforated Tubes

Pleated Filters

Croft can do the maths and work out what is needed to obtain a high level of open area so your filter can be made to your size requirements and are experienced in manufacturing many different types of pleated filters.

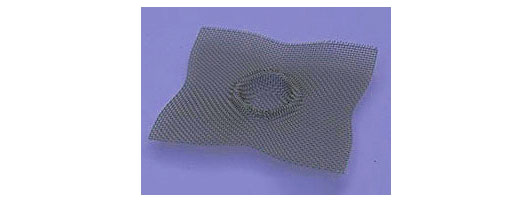

Leaf Filters

Croft can supply a new filter leaf or remesh existing filter leaves where possible. Filter leaves are often used in the Chemical industry but have many other uses in other industry sectors too

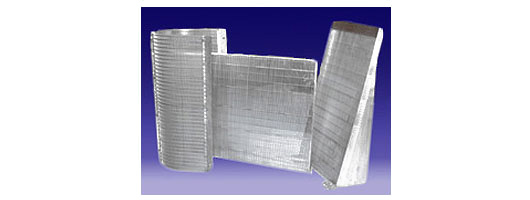

Wedge Wire Slot Tubes

Slot tubes are in particular very popular to the petrochemical and food processing industry as they provide efficient filtration systems for liquid and solid separation.

There are essentially two different slot tubes designs frquently used - Radial Slot and Axial Slot.

Wedge wire slot tubes are advantageous for users that demand bigger filter areas without having to worry about the possibility of clogging of impurities.

Easy maintenance can also be achieved with slot tubes through the use of back flushing techniques.

Our sister company Croft Additive Manufacturing can even 3D Metal print slot tubes to custom specifications.

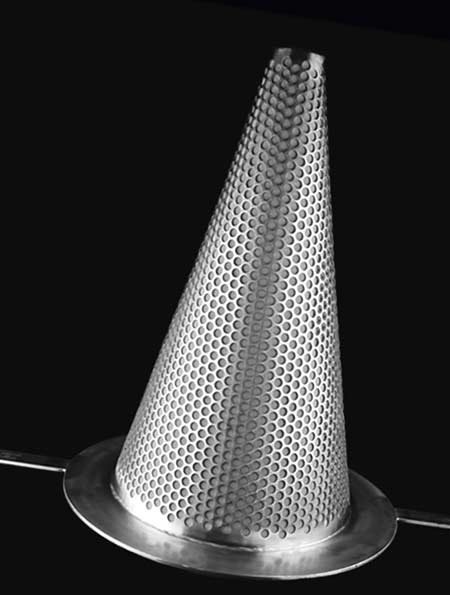

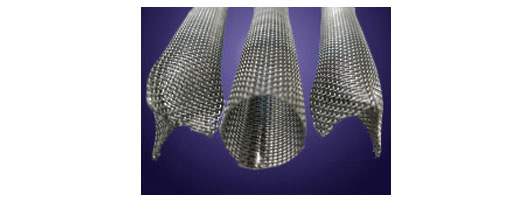

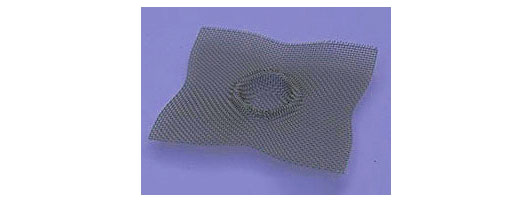

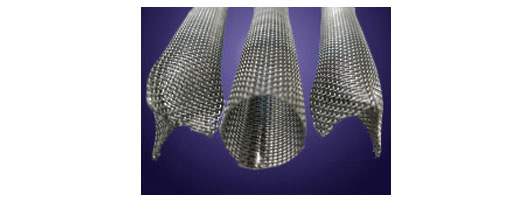

Witches Hats

Qitches' hat strainers can be used for softening, desalination, water filtration and water pre-treatment systems, as well as less-demanding industrial water supply and oil fine filtration equipment. They are primarily used to provide a filtering layer that removes solids suspended in water, oil and adhesive resin.

As a specialist producer of witches' hat strainers, Croft Filters can manufacture them for a wide variety of applications. In stainless Steel 316, we can make them with a pore size of as little as 1 micron, using a single mesh or a number of meshes to achieve the required micron rating.

About us

Bespoke Filtration Solutions

Croft specialise in custom filtration solutions, these are manufactured specifically to the Customer’s unique requirements and can be ordered as ‘one-off’s’ to large batches. Typical filter designs include: basket strainers, duplex filters, cone filters, cylinder filters and screen filters in perforated plate, wedge wire and woven wire mesh.

Croft’s experience within the market alongside their drive for innovation allows the company to solve unique filtration problems that Customers are faced with. Croft can design and manufacture specific filtration solutions for Customers in order to maximise the potential of Customer’s filtration processes.

Self Cleaning Filters

In 2013 Croft became distributers for HiFlux Filtration A/S, a Danish manufacturer backed with 50 years experience within the filtration industry. As a result of this Croft have been supplying many industries with quality Self-Cleaning filters designed to reduce downtime and operating costs for the user.

With different models available for a wide range of applications such as: Cooling, Refining and Filtering, the Self-Cleaners use a plunger or a series of scrapers to remove waste caught on the filter element inside the process. This improves the flow through the filter and the lifetime of the element. The captured particles are then be ejected from the system without the need to stop the process or change the element, saving on downtime within the system.

Additive Manufacturing − Metal 3D Printing

In 2013 Croft invested into Additive Manufacturing, specifically Selective Laser Melting (SLM) in order to develop new innovative filtration solutions. Additive Manufacturing (AM), also known as metal 3D printing, is the process of creating a 3 dimensional component through a series of layers.

Benefits of the Additive Manufacturing process, such as: part weight reduction, multi-part to single component and expanded design capabilities, allow Croft’s customers to re-think their approach to their designs in order to improve the efficiency and utility of their parts or to deliver other supply chain advantages. Croft can advise on how to get the most out of the AM technology in order for Customers to achieve their desired advantages.

Whether that means to improve the function of a filtration solution or to develop a new solution all together.

Quality of both product and service has been the key to Croft’s success; the Company takes great pride in understanding their customer’s needs, quickly supplying them with a high quality product that exceeds Customer’s expectations.

Images

Articles / Press Releases

Brochures

Trade Associations