Company details for:

CST Automation Ltd

Unit 14 Crown Business Centre,

George Street ,

Failsworth,

Manchester,

Lancashire,

M35 9BW,

United Kingdom

Quick Links:

Products / Services

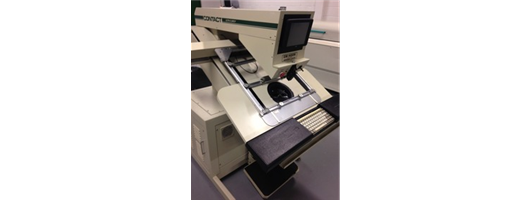

GLW EC65 Crimping Machine

The EC 65 is an ideal device to securely crimp wires and cable terminals such as:

Insulated cable lugs to 6 mm 2 / 10 AWG

Tubular cable lugs, solderless terminals to 10 mm 2 / 8 AWG

Flat tab terminals to 6 mm 2 / 10 AWG

Wire end sleeves to 50 mm 2 / 1 AWG

The EC 65 can be operated in one of two modes.

Mode 1: controls the entire crimp process by pressing down the pedal switch.

Mode 2: allows the user to fix the terminal on the cable by actuating the foot switch once. To finish the crimping process, he presses down the foot switch once again. Mode 2 is used for more complex terminals.

The onset of compression force can be adjusted for each new terminal to satisfy crimp integrity. That way, damage to dies and terminals can be minimised.

Simply press a button to select the opening for each die.

Since some female terminals are more difficult to crimp, a moveable locator can be utilised to ensure proper crimping.

Various standard dies are available, as well as dies designed to customer specifications.

Accessories: Locator for crimping female disconnects / Its carrying handle converts the EC 65 into a portable crimping tool.

GLW MC25 Crimping Machine

It does not require pressurized air, but only a 230 V mains connection.

It takes only 1.5 seconds to crimp and strip the insulation.

The MC 25 processes wire end sleeves with a cross section of 0.5 to 2.5 square millimeters and a standard length of 8 mm.

You can change the applicatior for the diameter of the sleeves in a matter of seconds without any additional tools. Just snap it in and off you go!

All applicators are clearly arranged in a kit that comes with the crimper.

Reliable operation thanks to an advanced microprocessor-controlled cam drive.

The stripping unit is fitted with V-blades. It can be used for most commercially available conductors.

Tape-mounted wire end sleeves are fed into the machine via a dispenser fitted to its right side.

GLW DC125 Duct Cutter

- Your workplace remains clean at all times because no chips are produced when cutting.

- DC 125 operates silently and without emissions.

- Thanks to its optimised cam drive, the force required for cutting wire ducts is low.

- A 1 m long scale with length stop ensures cutting exactly true to length.

- The hardened cutting blade has a cutting width of 125 mm.

- A folding blade guard ensures safe operation.

- The DC 125 has been TÜV-tested.

GLW DR 30K Cable Dereeler

The DR30k is an useful supplement to the Cross Cutting Machine LC 100 and makes wire feeding easier for both loose hanks or reel mounted cable

Smooth acceleration and deceleration of the rotary mounting plate is achieved by running the cable around a spring mounted pulley.

This also provides constant tension to prevent twisting or slippage at the clutter unit.

Quick reel change is possible as the reel and plate can be replaced together.

A reel and plate holder makes cable storage easy and convenient.

GLW MC40 Automatic Stripper & Crimper

The standard version comes with crimping tools with cross-sections of 0.5/0.75/1.0/1.5 mm 2 and a sleeve length of 8 mm.

Stripping and crimping takes place in one operation.

It just takes a few seconds to set it to the desired cross-section.

Extension sets are available for processing cross-sections of 0.25/0.34/2.5/4 mm². All variable parameters can be set automatically and correctly when changing the crimping insert.

Thanks to its modular design and its maintenance and wear-free components, the unit is extremely reliable.

AC25 Pneumatic Crimper

The crimping mechanism is easily activated, making it perfectly suited for work in control cabinets and electrical equipment.

Crimp range:

0,25−2,5 mm² / 24−14 AWG

Weight: 400 g

Dimensions: Ø 44 x 200 mm

Incl. spiral hose: 2 m

S20105RD Ferrule Slide Box

0.25 x 6mm - 50 Pieces

0.34 x 6mm - 50 Pieces

0.5 x 8mm - 50 Pieces

0.75 x 8mm - 50 Pieces

1.0 x 8mm - 50 Pieces

GLW RC300 Din Rail Cutter

- DIN rails can be cut to the desired length quickly and without burr. Thanks to its optimally designed lever ratio, RC 300 requires little force, so anyone can operate it.

- Because of the 1 m long scale, with length stop, the DIN rails can be cut exactly true to length.

- The cutting edges are correctly angled, and no subsequent machining is required.

GLW CS60 Stripping Machine

The setting knobs are clearly positioned on the front panel.

Short feed-in lengths and a clearly visible working area facilitate fast, effortless work.

The clamping force is automatically adjusted to the necessary stripping force. This prevents indentations on sensitive insulations.

Specially shaped stripping blades guarantee reliable wire stripping.

The on-screen counter gives a visual display of how many pieces that have been processed.

The carrying handle allows the CS 60 to be transported

GLW LC100 Cable Cutting Machine

Two driven transport rollers and separately running measurement rollers guarantee precise cutting length.

A material change could not be simpler. As the front flaps swivel down, the drive and measurement rollers are automatically moved away from each. The material being cut is inserted and when the front flap closes, the driven and measurement rollers position themselves automatically.

For cutting sensitive materials, the application force of the drive roller can be readjusted.

With the software supplied with each LC 100 it is possible to process and document repeat cutting orders directly on the PC and to transfer them to the LC 100.

GLW Bootlace Ferrules

Crimmboss Hand Held Electric Crimper

• The CrimmBoss CB2 crimping process is only activated by mechanical contactors when the cable end sleeves have been completely and correctly inserted

• Magnetic holder MHC for simple assembly of the CrimmBoss

• Contact tongue, small, for diameter range AWG 26-18 (0.14−1.0 mm²)

• Contact tongue, large, for diameter range AWG 21-19 (0.5−2.5 mm²)

• Contact tongues included in delivery

CrimmBoss CB2

Supply voltage 230V / 50Hz

Long mains cable: 9.2 ft. (2.8 m)

Wirmec W1500 Crimping Unit

Crimping Force 15KN Max

Working Stroke 40mm

Centesimal Regulation

Electronic Counter

Quality ontrol QCD (Optional)

Size mm: H1020 x L390 x 350

Weight 35KG

Wirmec WSC15 Stripper Crimper

OTJ-1029 Cutting & Stripping Machine

Very easy to use protective membrane keypad and a large LCD display.

All parameters such as cable lengths, stripping lengths, cable cross section, quantities and batch quantities are entered using the keyboard.

Wire Cutting Length: 0.5mm-9999.9mm

Cutting and Stripping Tolerance:±(0.2+0.002×wire cutting length)mm

Stripping Length:0.2- 39.9mm (according to the core wire and insulation type)

Global Cut 100 Cutting Machine

The user friendly control panel makes it easy to program and operate.

Dimensions:350x260x250mm

Weight:35Kg

Max cutting width:100mm

Tolerence(0,2+/-0,002xL)mm

Max cutting diameter:10mm

Maxspeed:1,8m/s

Number of programs:99

Wirmec W100 Pull Test Device

Motorized 30mm/min

Printer with customizable header

Dimensions mm (WxHxD) 225 x 245 x 470

Weight 16kg

Wirmec W200 Micrograph Laboratory

Saw size 100 x 0, 6mm

Replaceable abrasive disc

USB microscope

Accident prevension protection

Removable universal clamp

Dimensions mm (WxHxD) 500 x 250 x 400

Power 230V 50/60Hz

Weight 15KG

Wirmec AM300 Quattro Cut Strip & Terminate Machine

It is suitable for processing of very thin cables, with lengths up to 15mm andstripping of more than 40mm.

Savotec SSC4000 Cutting & Stripping Machine

About us

As a leading cable specialist we work closely with some of the worlds largest suppliers of cable preparation production equipment such as Schleuniger, Ulmer, GLW and Tekuwa bringing you top quality cable machines that meet and exceed your requirements.

CST Automation, situated in Manchester offer an extensive range of both new and used cable prepping equipment tailored to suit your budgets, products include;

- Assembly Benches

- Cable Marking

- Cable Twist Machines

- Coaxial Stripping Machines

- Crimping Machines

- Cut & Strip Cable Machines

- Cut Strip Terminate Machines

- Cutting Machines

- Coiling & Stacking Cable Machinery

- Ferrules and End Sleeves

- Fibre Optic Preperation

- Hand Tools

- Hot Knife Cutting

- Karl Enghofer Terminals

- Prefeeding & Dereeling Machines

- Production Aids

- Solder Pots

- Stripping Machines

- Stacking Machines

In addition we have now developed a PF2B, a heavy duty cable pre-feeder with a capacity to hold 100KG cable reels. The PF2B de-reeling speed and automatic braking is controlled by the PF2 Pulley system, enabling smooth tension free cable prefeeding to your production line.

We pride ourselves on our customer service, due to our committed and experienced sales and service team being on hand to give technical support and advice, if and when required.

For more information, please give us a call or visit CST Automation website. If you are looking to sell any second user preparation equipment, either manufactured by Schleuniger, GLW, Ulmer or Tekuwa please contact us.

Images