Company details for:

Dantex Group

Danon House,

5 Kings Road,

Bradford,

BD2 1EY,

United Kingdom

Quick Links:

Products / Services

Picocolour

Picojet

Rapidoflex

Very fast plate making time - fastest UV flexo plate processing on the market

Excellent archival properties

Low energy costs

Up to 150lpi (Analogue)

Up to 200lpi (Digital)

Aquaflex

For use with UV Flexo, alcohol/ester & Co-solvent inks

Analogue & Digital formats

Fastest UV Flexo processing on the market

Fine resolution

Fast, clean processing

Long run capability

Up to 150lpi (Analogue)

Up to 175lpi (Digital)

Varnica

Varnica also benefits from Dantex’s high speed, cost-effective processing. It has long run capabilities and eliminates the need for strippable blankets.

Using the Dantex Dry Film System, Vanica plates can be processed and press ready in around 15 minutes.

Torelief

High resolution

Sharp and accurate print results

Fast, clean processing

Range of processing equipment available

Efficient press performance and long life

Up to 150lpi (Analogue)

Up to 200lpi (Digital)

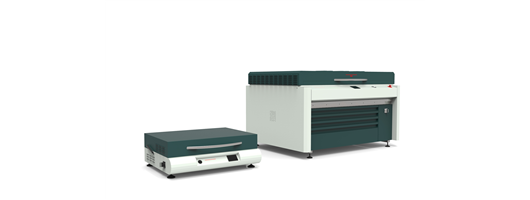

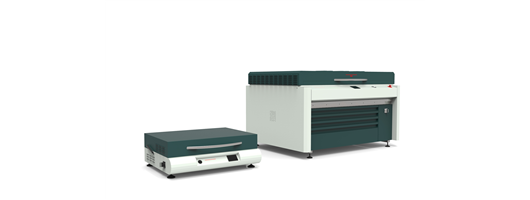

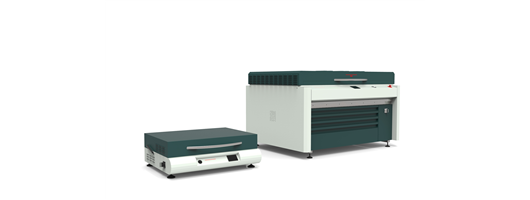

ESKO Spark 1712

The smallest of the Spark family, the 1712 is a small footprint, cost-effective flexo plate and film imager specifically for narrow web tag and label printers.

ESKO Spark 2420

The Spark 2420 is designed to image plate sizes up to 609 mm x 508 mm (24“ by 20“) and also handle a wider range of plate materials. These include digital flexo plates, chemistry-free film, digital foil-based letterpress plates, digital metal-based letterpress plates and digital silk screens.

ESKO Spark 2120

The digital plate has a mask layer − sensitised to the Spark’s laser light − on top of its surface. After imaging, this mask takes the function of the traditional film negative. Due to the integration of the image carrier a digital plate has sharper image definition and steeper relief shoulders than conventional plates produced with film.

ESKO Spark 2530

The digital plate has a mask layer − sensitised to the Spark’s laser light − on top of its surface. After imaging this mask takes the function of the traditional film negative. Due to the integration of the image carrier a digital plate has sharper image definition and steeper relief shoulders than conventional plates produced with film.

ESKO Spark 4835

The digital plate has a mask layer − sensitised to the Spark’s laser light − on top of its surface. After imaging this mask takes the function of the traditional film negative. Due to the integration of the image carrier a digital plate has sharper image definition and steeper relief shoulders than conventional plates produced with film.

ESKO Crystal 4835

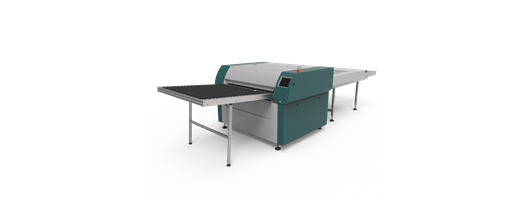

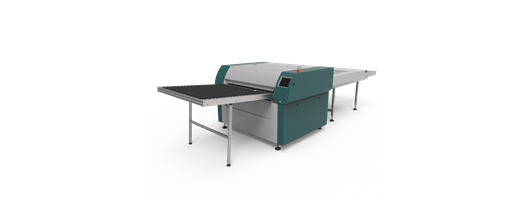

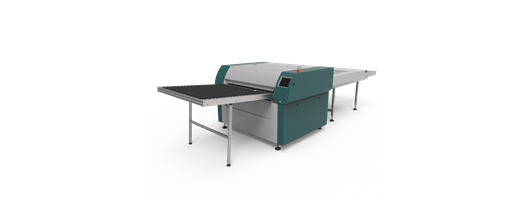

AQF Inline Processors

Dantex AQF automatic processing ensures our plates enjoy the fastest wash times in the world today.

AQF Plate Processors

DigiWash

AQF - Exposure Units

AQF Combination Processors

Sleeve Systems

Hard Printing Sleeves

Construction: One-layer

Surface: Ground or not ground polyester

Finishing: Cut notch

ThermaFlo − 60 degree

ThermaFlo is all about giving you better control and consistency; this has become essential for the printing of highly detailed graphics, especially within the flexible packaging and narrow web markets.

EFlo UV − 75 degree

Plate Mounting Tapes

SCAPA Tapes

ORAFOL Tapes

Star Plate

About us

As a largest specialist in letterpresses and flexo plates we offer a range of solutions including water wash photopolymer plates and process equipment that offer excellent resolution and superbly printed results. Our flexographic printing solutions also include

- Photopolymer plates

- Plate process

- Digital printing solutions

- Pressroom solutions

- Flexographic plates

- EskoArtwork plate setter

- Water wash plates

- Proofing solftware

- FlexoCAM

Images