Company details for:

Dantex Group

Quick Links:

Products / Services

PicoJet 1200

PICOJET 1200 is built on a modular platform, so is available as a reel to reel press or as a bespoke hybrid system: allowing the incorporation of features such as Die Cutting and Flexo Station options. It can also be custom configured in a variety of base and additional colour stations.

New PicoColour

Representing the next step in Pico technology development is built on the PicoJet platform and benefits from this advanced technology.

In comparison to PicoColour Classic, the all-new PicoColour provides an increase in print width to 254mm/10”, a resolution uplift to 600 x 600 dpi, and an increase in speed to 50m/164’ per minute.

In addition, the press offers a minimum droplet size of 2.5pl compared to 6pl.

Torelief

Letterpress Waterwash Plate

- Analogue & Digital formats

- High resolution

- Sharp and accurate print results

- Fast, clean processing

- Range of processing equipment available

- Efficient press performance and long life

- Up to 150lpi (Analogue)

- Up to 200lpi (Digital)

Rapidoflex

UV Flexo Waterwash Plate

- Efficient press performance and long life

- Very fast plate making time - fastest UV flexo plate processing on the market

- Excellent archival properties

- Low energy costs

- Up to 150lpi (Analogue)

- Up to 200lpi (Digital)

Aquaflex

- Highest quality

- Cost effective processing

- Faster and cleaner processing

- Processing time is 30 minutes

- Using Aquawash surfactant

- Naturally forms a FLAT TOP DOT for better ink transfer and print quality

- Environmently friendly processing

- HD Flexo certified

- Esko specialized + certified

- Dantex Group have trained personal to support you to achieve the highest possible print quality and to give you the best After-Sales Service

Varnica

The Varnica flexo plate is suitable for all coating applications and is ideal for spot varnishing. This material is superb quality and can be supplied in conjunction with a Dry Film System, which means you not only benefit from solvent-free plate processing, but there is also no need for an imagesetter.

Varnica also benefits from Dantex’s high speed, cost-effective processing. It has long run capabilities and eliminates the need for strippable blankets.

Using the Dantex Dry Film System, Vanica plates can be processed and press ready in around 15 minutes.

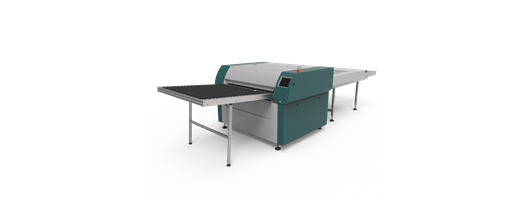

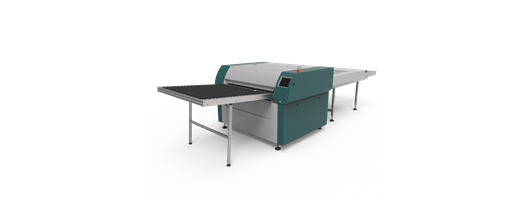

Marathon

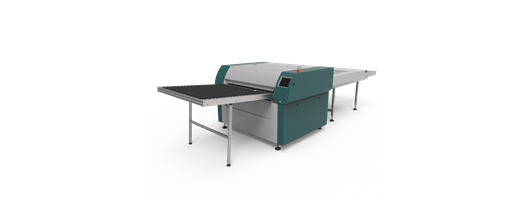

Automatic Letterpress Processing Systems

MODELS AVAILABLE

- 1000M - Max. plate: 900mm x 1200mm/35.43” x 47.24”

- 600M - Max. plate: 580mm x 1200mm/22.83” x 47.24”

Plate Cleaners

MODELS AVAILABLE

- AQFC 45 - Max. plate: 450mm / 17.72"

- AQFC 65 - Max. plate: 650mm / 25.59"

- AQFC 95 - Max. plate: 920mm / 36.22"

- AQFC 120 - Max. plate: 1150mm / 45.27

- PLC Controlled Electronics

- Stainless Steel tank construction

- Recirculation Filter

- Automatic water replenishment

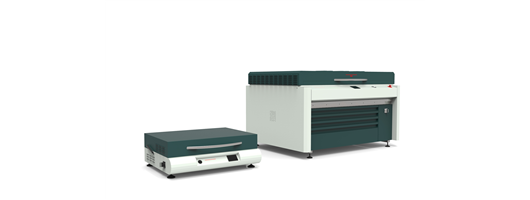

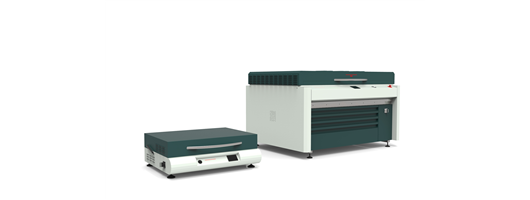

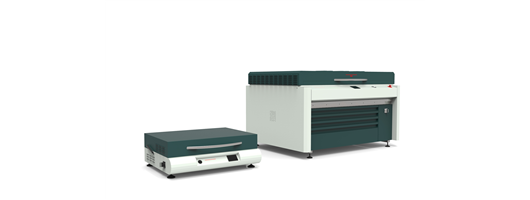

AQF - Exposure Units

For Letterpress & Flexo Printing Plates

Our Aquaflex exposure units have been designed and built for use with Torelief, Rapidoflex and Aquaflex plates. They are manufactured in two sizes and allow for plate production of up to 900mm x 1200mm.

Combination Processor AQF 2530

Our AQF processing range ensures our plates enjoy the fastest wash times in the world today with superb quality results, developed to fully comply with the latest environmental legislation.

Rotunda - Plate Cleaner

For cleaning metallic photopolymer plates

MODELS AVAILABLE

- R60 - 580mm/22.83" (Drum Length) / 1100mm/43.31" (Drum Circ.)

- R90 - 900mm/35.43" (Drum Length) / 1100mm/43.31" (Drum Circ.)

- Magnetic wash & dry rotary system

- Fully-automatic

- Solvent and brush action

- Magnetic Drum accepts multiple plates at one time

- Releases bar for easy plate removal

- Computer controlled speed and water temperature

- User-friendly touchscreen programming interface

- Stores preferred cleaning cycle parameters

- Automatic water replenishment

ESKO Spark 1712

HD Flexo option for the finest print quality in flexo

The smallest of the Spark family, the 1712 is a small footprint, cost-effective flexo plate and film imager specifically for narrow web tag and label printers.

ESKO Crystal 4835

Basis for reducing plate room complexity

The Esko Crystal 4835 lays the groundwork for full integration and automation of plate imaging and UV exposure. The 4835 is the basis for an impressive reduction of complexity in the plate room. It also produces the highest plate quality standard – based on HD Flexo and Full HD Flexo.

Sleeve Systems from Dantex

Carrier Sleeves give greater productivity and flexibility by using pre-mounted plates for quick changeovers. These are very effective for short-runs, repeat jobs and design alterations since the sleeves can be taken off press and stored with the plates mounted on the sleeves. Sleeves that serve solely as carrier rolls have imaged plates mounted to sleeves offline, which are then installed onto cylinders at the print station using compressed air to expand the sleeves for positioning.

Plate Mounting Tapes

Dantex supplies foam and solid mounting tape ranges from Scapa. You can read about our tape ranges below.

Star Proof

The #1 Flexo proofing technology - A swatch made in heaven!

- High-quality inkjet proofs

- Uses the same data integral ripped files that will be used to image the final film/plate

- Calibration to simulate printing press processes

- Excellent colour matching between proofs and press

- Offers traditional colour calibration and fine controls for matching inks via colour shade, calibration curve and dot gain compensation

- Superb blacks and grays reproduction

- Mis-registration preview to help avoid potential problems on press

- Extreme Dot Grain feature simulates plate pressure effects in processes such as carton or corrugated

- Calibrates spot colours using predefined lab values, industry-related colour libraries or spectrophotometry entered data

Star Plate

Chemistry-free HD films from inkjet devices

- Direct Imagesetter replacement

- Chemistry-free

- Imagesetter quality, high-density positives, and negatives (D.Max 4.0 - 5.5)

- High-quality halftone screening up to 200lpi

- Dot patterns, screening, text and fine lines, right down to 1pt type.

- Linear & Dot gain calibration

- User-friendly interface allows generation of multiple calibration curves

- Press dot gain function

- Perfect for Flexo, Letterpress and die platemaking or for Silk Screen exposure

- Uses high gauge nano-porous film specifically developed for easy handling and storage

About us

Leading letterpress and flexo plate distributor, Dantex Graphics has been serving the needs of the packaging industry for more than 40 years.

Located in Bradford, UK and subsidiary companies in Germany and France as well as sales offices in Austria, Holland, Poland and the USA, Dantex Graphics is ideally placed to offer a complete network of fully trained professionals across 30 countries all providing after sales service, technical and engineering support.

As a largest specialist in letterpresses and flexo plates we offer a range of solutions including water wash photopolymer plates and process equipment that offer excellent resolution and superbly printed results. Our flexographic printing solutions also include

- Photopolymer plates

- Plate process

- Digital printing solutions

- Pressroom solutions

- Flexographic plates

- EskoArtwork plate setter

- Water wash plates

- Proofing solftware

- FlexoCAM

Our experienced teams are all fully trained and knowledgeable within the printing and packaging field and have a reputation for understanding customer requirements and providing a tailored solution. Dantex Graphics has a hands-on approach to customer service and this is fully supported by after installation care programmes tailored to the individual needs of each customers’ printing requirements. We work directly with the customer to find out what they need to achieve repeatedly excellent results from their printing plates.

To find out more please visit the Dantex Graphics website or contact us for more details.

..

Images