Company details for:

Destec Engineering Ltd

Five Mile Lane,

Washingborough,

,

Lincoln,

Lincolnshire,

LN4 1AF,

United Kingdom

Quick Links:

Products / Services

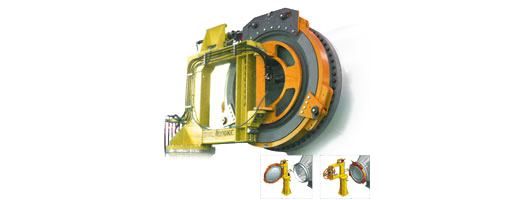

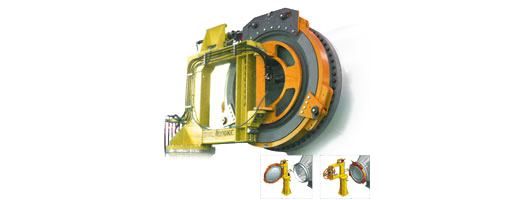

GSB Subsea Single Bolt Connector

The GSB Connectors are supplied with a mounting plate which can if required accommodate guidance / pull-in systems for ease of alignment and provision for stab connectors for electrical and hydraulic circuits.

Standard G-Range or D-Range metal to metal Seal Rings can be used, or the customers own sealing arrangement can be employed.

Larger sizes and special designs (Dual Bore / Multi Bore / Concentric Bore) can also be accommodated. For example some GSB Connectors have been supplied with fabricated Spool pieces for mating to flexible risers.

For Subsea applications the GSB Connectors would be supplied with a combination of Molykote and Epoxy resin coatings. Designed for remote operations in the most demanding deep and ultra-deep water.

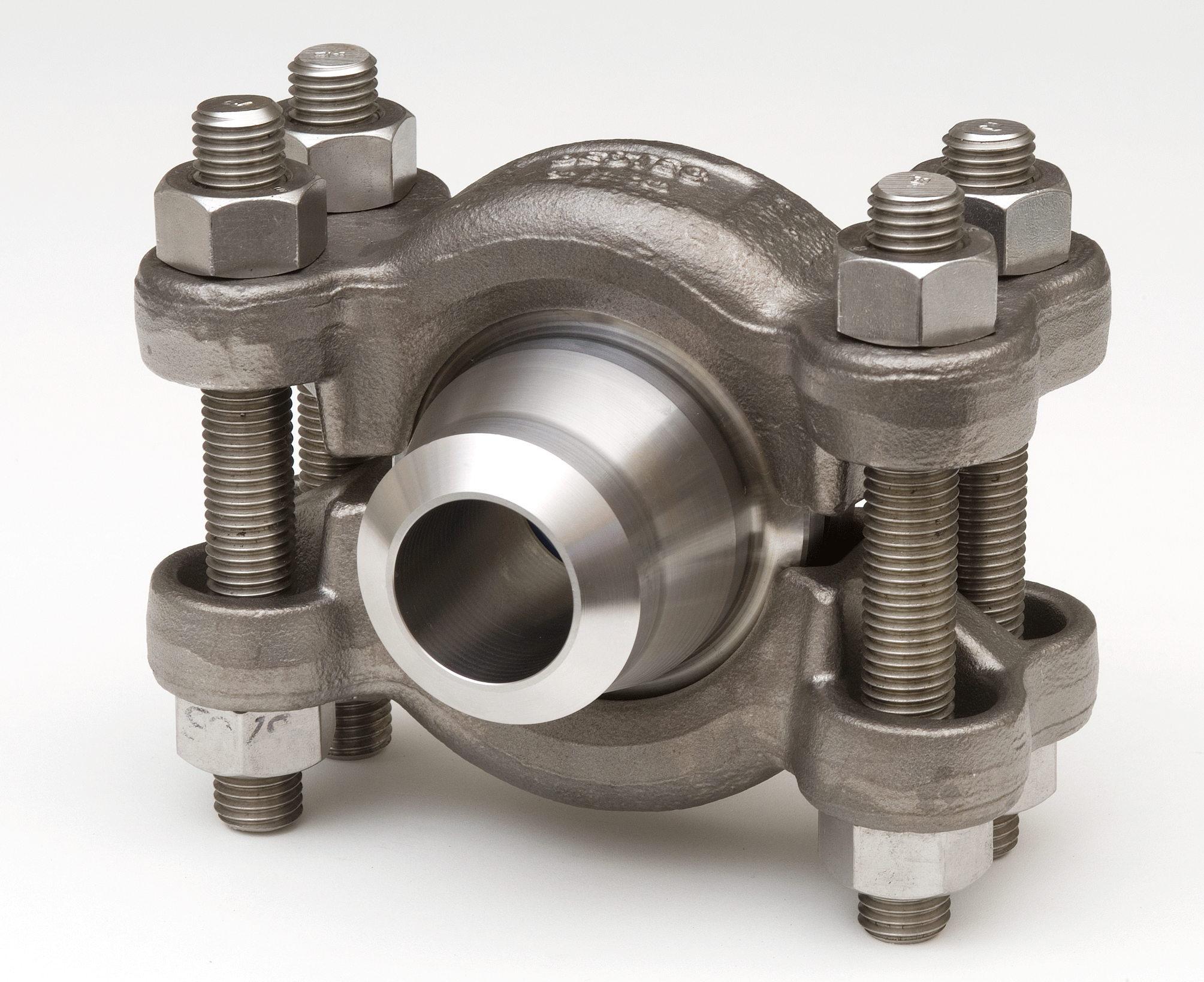

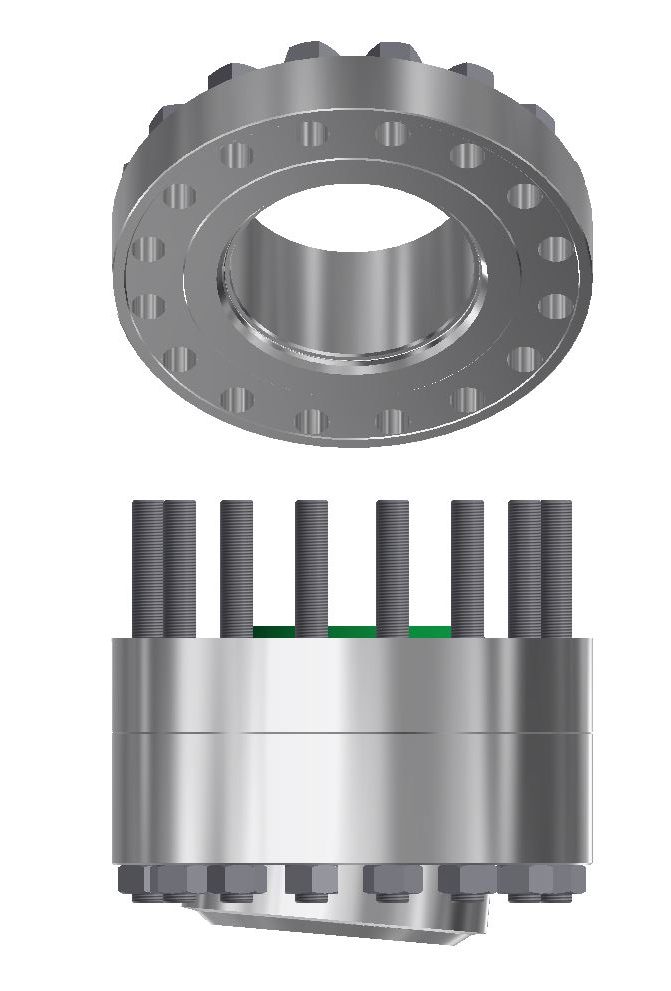

G-Range Clamp Connectors

Due to their efficiency, lightness and reliability, together with extreme qualities of leak tightness, the G-Range pipe connection offers significant benefits for use in industrial plant in a wide variety of applications. Although designed primarily for adverse pressure and temperature conditions, more modest applications can be considered due to ease-of-installation and assembly, particularly when compared with the alignment and tightening of standard flanges.

The G-Range pipe connection comprises: a pair of hubs for welding to the pipe (similar to a flange); a clamp set, which can be rotated around the hubs to suit the most practical positions; and a seal ring.

The seal ring is a modified cone ring giving excellent leak tightness properties under the most severe conditions of pressure and/or thermal shock.

On assembly the taper joint faces compress the seal ring radially. The sealing force is provided by the stored energy in the stressed seal ring, any internal pressure intensifies the sealing action.

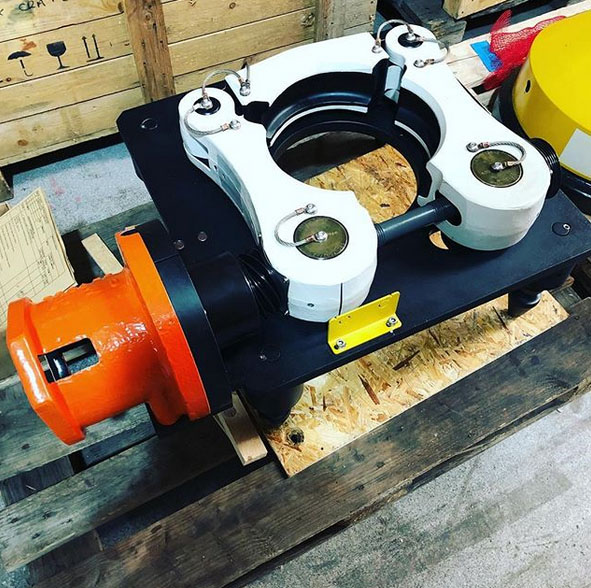

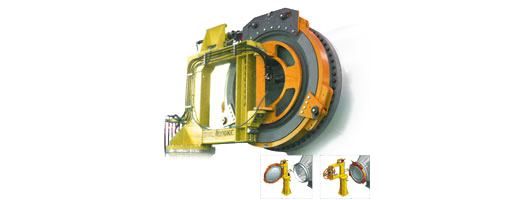

Door Closure

Applications include Industrial Waste Treatment closures, Pig traps, Separator vessels, Subsea Access Hatches and Medical Waste treatment vessels.

Sizes ranging from 0.5m to 2m diameter.

Please consult Destec Engineering Ltd for sizes outside this range.

Designed to meet ASME and other pressure vessel requirements for quick release connectors.

Destec Engineering offer front end design studies to determine cost effective solutions and provide manufacture and project management with our own in-house technical expertise.

A range of doors has been developed for domestic waste treatment plants designed for continuous and remote operation.

Compact Flanges

Offering weight savings of up to 88% when compared to the equivalent ANSI Flange. Quick and easy make-up with superior mechanical strength and fatigue performance.

The Desflex Compact Flange is ideal for both topsides and sub-sea applications where minimum weight is essential and reduced maintenance.

Both standard and swivel type weld neck flanges are available in Carbon, Stainless, Alloy and Duplex steels.

Desflex Flanges are Type Approved and have successfully passed API Fire tests.

Available to meet NORSOK standards

The patented design includes several unique features including spherical nuts on the bolting to reduce bolt stresses and a toe at the outside diameter to limit Flange rotation and to prevent overstressing of the flange.

Reusable metal-to-metal Seal

The Destec D and RD range of all metal Seal Rings are used.

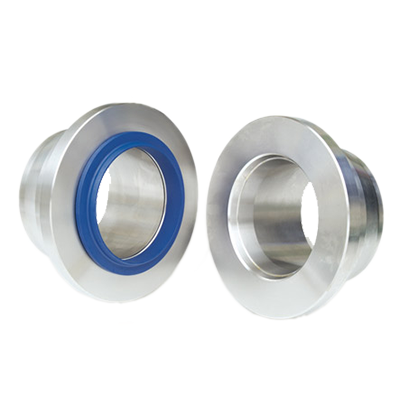

Seal Rings

Destec have developed a sealing system which uses a modified cone ring giving excellent leak tightness properties under the most severe conditions of pressure, temperature, thermal cycling and shock.

Destec seal rings are being used as original equipment in client’s products and are also in service as replacement for original troublesome joints.

With conversions of old joints to Destec seals our engineers carry out the design modifications in accordance with established codes and standards, whilst the practical site work is handled by Destec’s on-site machining service using portable machines to carry out the modification and re-build on site.

Boiler Inspection Caps

Available in 3 sizes:- 40mm, 100mm & 150mm full through bore at maximum pressure and temperature rating.

Ease of Access

Extreme Leak Tightness

Re-Useable Seal Rings

Standard Fittings

Long Service Life

“For the price of Destec Inspection Caps, how much longer can you afford to use standard welded caps with all the welding, N.D.T and heat treatment involved”.

Inspection Services

These are now available as a service at either our Washingborough site or, if applicable, at your location.

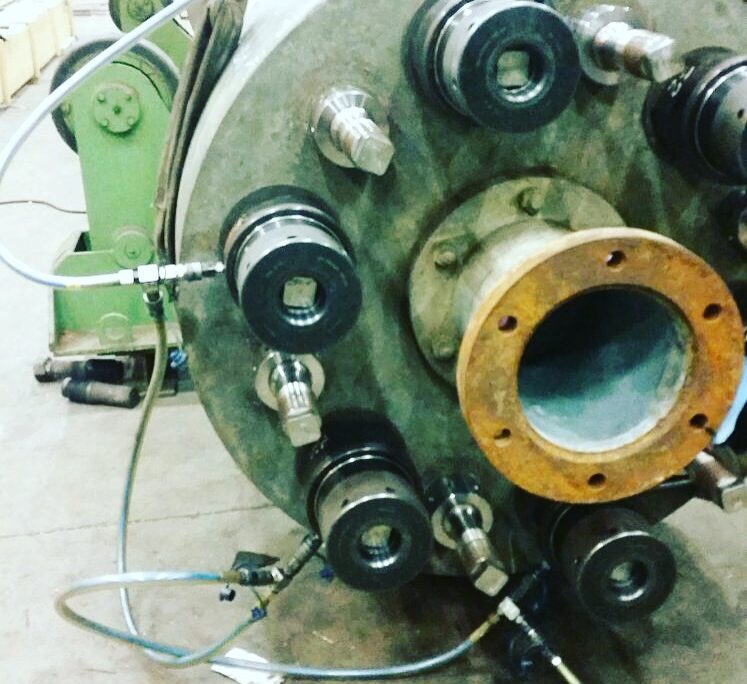

Bolt Tensioning

Hydraulic tensioners can be used with extended bolts. This method gives very controlled bolt stress levels as required when using conventional flat-faced joints.

The Ratchet Torque tensioner uses standard sockets and is one of the fastest methods of tightening heavy bolting.

Low Height Torque tensioners are used where access is limited and can be used only with one bolt diameter clearance at the end of a bolt. High pressure power packs, with reverse flow facilities, drive the double-acting cylinders of the torque tensioners for rapid bolt tightening.

On-line Leak Sealing

1. The pipeline can be shut down for conventional repair.

2. The leak can be left to blow, usually only for a limited time.

3. The leak can be cured while the line remains at full PRESSURE and TEMPERATURE from sub-zero to 600degC and from vacuum to 6,000psi.

Applications include:

Nuclear Power Plants and Fossil Fuel Plants Refineries and Petrochemical Plants Steelworks Marine Offshore Paper Industry Food Industries Transmission Pipelines

The service is available 24 hours a day, 7 days a week.

The Destec on-line leak sealing service can prevent loss of energy without loss of production.

By the use of specialised techniques, perfected over many years of practical experience, many millions of pounds of wasted energy are saved each year. This is achieved without plant or system shutdown while operations continue at full pressure and temperature.

On-site Machining

Destec’s on-site machining services can make significant savings on heavy plant construction, modifications and maintenance.

Our engineers co-operate with clients on new plant and modifications, to give the most viable solutions for on-site machining.

The service division offers a rapid response for maintenance and breakdown situations.

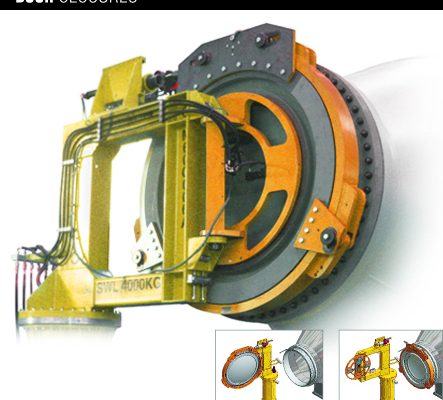

Regenerator & Vessel Head Removal

Cutting of both the vessel shell and internal refractory was carried out dry, from the outside. and included all necessary weld preparation ready for reinstatement of the head.

The dry cutting operation is carried out using portable milling or grinding equipment running on two circumferential, parallel rails, fixed either side of the cut line. The method is relatively quick, with very little post operative cleaning − unlike water jet cutting, which can take as long as 10 days to 'mop-up'. Thus, the method effectively reduces overall plant down time and is very environmentally friendly.

Destec, has continued with development of the technique and equipment, and in 2006, with the number of projects carried out well into double figures. the company carried out a Regenerator Head removal at Fawley Refinery, UK. At 17m diameter, 22mm wall thickness and 125mm refractory lining thickness, this is the largest Destec has undertaken so far, and one of the largest undertaken anywhere in the world.

The dry cutting method developed by Destec is now readily available to use anywhere in the world and the growing number of satisfied customers who have benefited from this unique system extends from the UK and Europe through the Middle East.

Special Purpose Machine Tools

This was a natural progression from the in-house designed and built on-site portable machines that have been used by our own technicians over the last 25 years.

Destec was awarded a design and build contract for Mobil for a machine to remove the regenerator head at Mobil, Coryton, the vessel was 9.4M diameter by 26mm thick with a 100mm think refractory lining. The work involved dry cutting both the vessel shell and internal refractory and also reforming of the weld prep. The machine design and operation were instrumental to the fastest turnaround for a unit of that size achieved by Mobil.

About us

Our products span from GSB single bolt subsea clamp connectors; compact flanges that meet ASME 8 Div 1 & 2, are type approved and are fire tested; colour coded seal rings; door closures ranging in size; easy to use and reliable boiler inspection caps; type approved and fire tested G-range clamp connectors, and so on. These items are manufactured with quality and effectiveness in mind.

Destec owns a comprehensive machine workshop including CNC turning facilities, various machine tools and other machines providing the highest level of services.

Destec has marvelous services available including on-site machining services, necessary ultrasonic testing services, special purpose machine tools, on-line leak sealing services, bolt tensioning services, regenerator and vessel head removal services, polymer coating and repair services and CNC machining.

Clients know to put trust in our products as we have a team who know all there is to know about design and development. They undertake extensive analysis for each product using state of the art computer programs.

As if you couldn’t trust us enough, we can assure you we have a quality system approved by Lloyds Register of Quality Assurance and BS EN ISO 9001:2000.

We can be contacted through telephone, email or fax and can help on any information and advice you may require. Our website also has plenty of information on our products, services and more about Destec Engineering itself.

Images

Videos

Articles / Press Releases

Brochures

Reviews

Trade Associations