Company details for:

DW Plastics Ltd

Chandler Road,

Terminus Road Ind Estate,

Chichester,

West Sussex,

PO19 8UE,

United Kingdom

Quick Links:

Products / Services

Plastic Extrusion Products

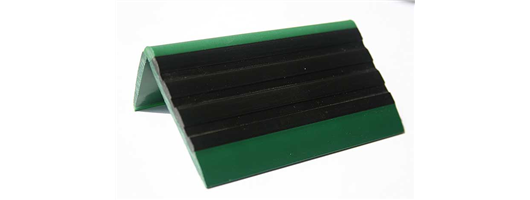

PVC Safety Products

Horticultural & Gardening Products

Profiles for Retail Display

Standard Plastic Extrusions

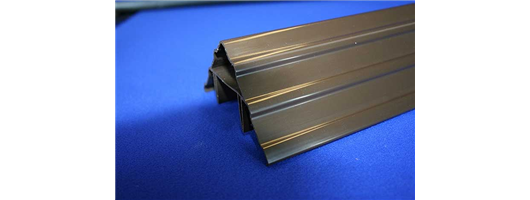

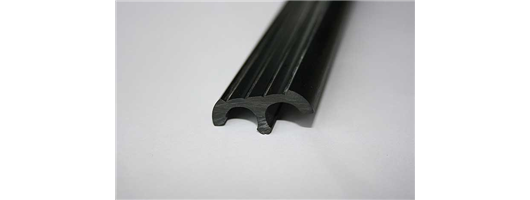

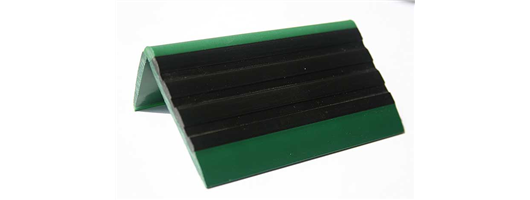

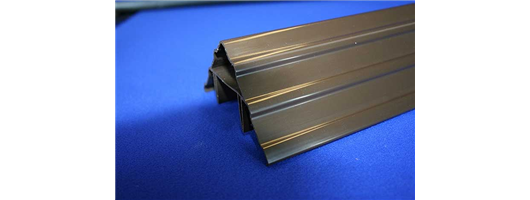

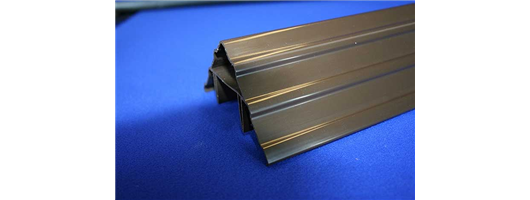

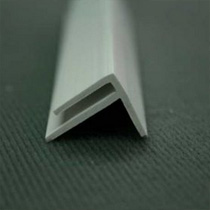

White plastic profiles made from rigid PVC, such as self-adhesive mini-trunking, partition joints and division bars, angle profiles used for beading, corner covers, guards and protectors, capping and edging trims (J and C joints), H and T-sections, U-channels and plastic strapping are available in different sizes. Please see the photos below to view some of the standard extrusion products.

Rigid Plastic Extrusion Profiles

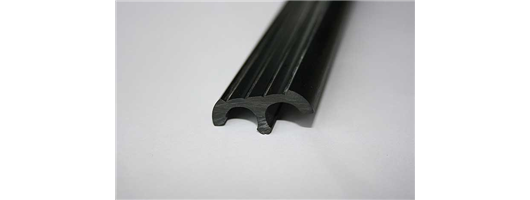

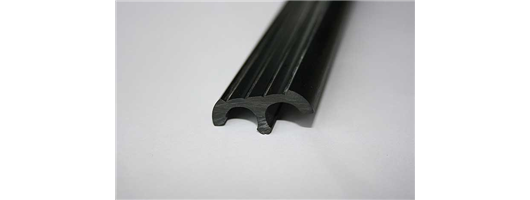

Flexible Plastic Extrusion Profiles

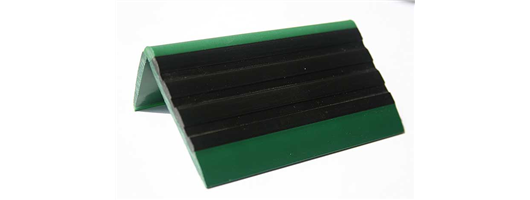

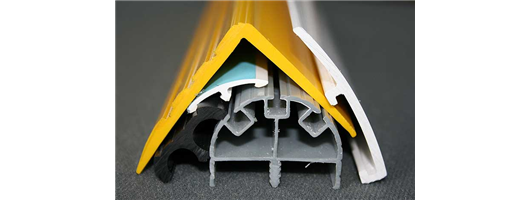

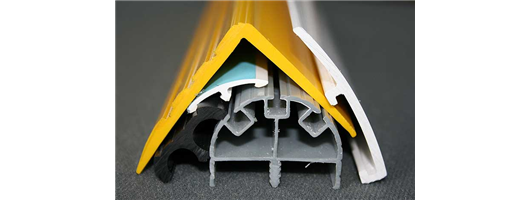

Co-Extruded Plastic Extrusion Profiles

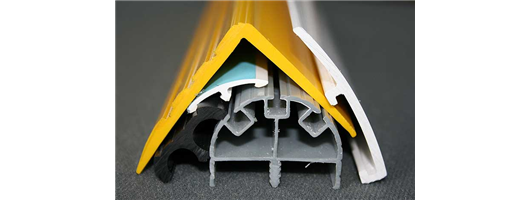

The co-extrusion process allows two or more materials to be joined together using two or more extruders and one tool. A co-extrusion requires compatible PVC materials that will bond together to form a strong finished part.

Cross Head Plastic Extrusion Profiles

The cross-head process can also allow two or more materials to be joined together using two or more extruders through the same die. It allows compatible materials to bond together to form a finished part.

Colours for Plastic Extrusion

The colour can be matched to a sample supplied by the customer, or alternatively to a recognized standard or architectural colour references.

Recycled Material

Reprocessed material can be extruded to make extrusion profiles where a specific colour and excellent finish are not required.

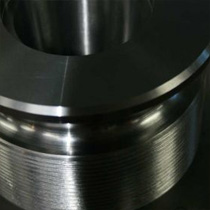

Plastic Extrusion Tooling

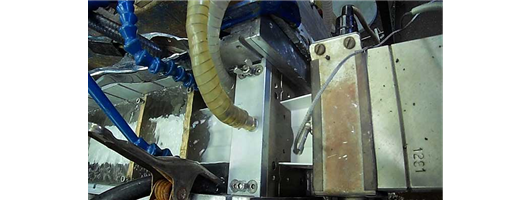

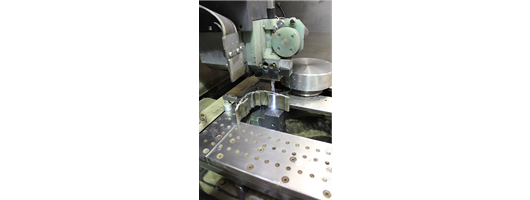

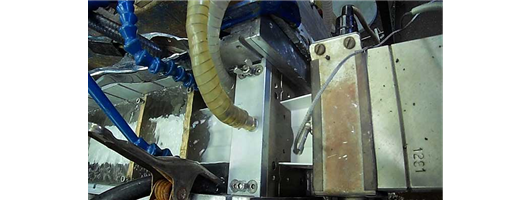

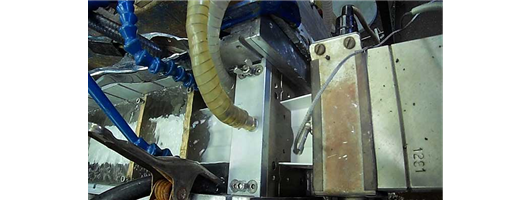

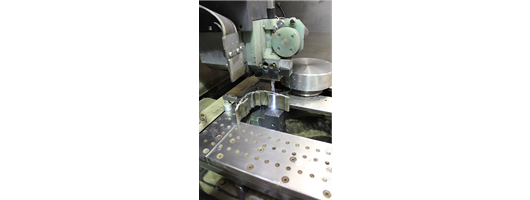

D W Plastics has a fully equipped tool room that has made tooling for a wide range of thermoplastic extrusion profiles and compounds.

The in-house tool making facilities and our skilled engineers allow us to provide comprehensive tool production and maintenance services. Dies are designed, engineered and optimized on site for the manufacture of accurate, high-quality, bespoke PVC extrusions in our factory.

Quality Control

PVC Plastic & Extrusion Manufacturing

D W Plastics’ well-equipped factory has a wide range of extrusion equipment which allows the manufacture of a great variety of plastic extrusions for many industry sectors.

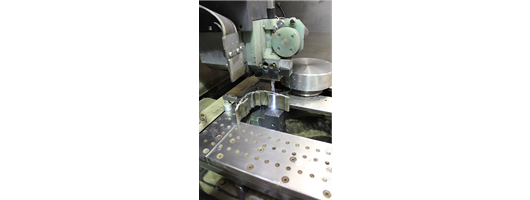

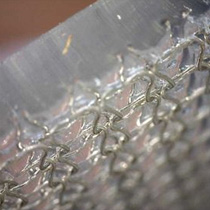

Wire Erosion of Tooling for Plastic Extrusions

In addition to its fully equipped tool room that makes tooling for a wide range of thermo plastic extrusions, D W Plastics has wire eroding facilities which enables the development team to keep a tighter control on the manufacture of the dies and formers for our customers’ plastic extrusion tooling requirements.

Bespoke Plastic Products for Healthcare And Hygiene

Profiles for hygienic ceiling cladding systems, bathroom and washroom trims, shower rails, coving and skirting, and bump rails for wall protection can be manufactured in various plastics materials and colours. To ensure the highest levels of hygiene anti-bacterial or anti-fungal additives can be added to help control and prevent cross-contamination and virus spread. The advantages of plastic are durability, easy cleaning and maintenance, versatility and cost-efficiency.

About us

DW Plastics Ltd are experts in the manufacture of high quality bespoke extrusion profiles. We supply competitively priced plastic extrusions in big bulk to a diverse range of trade sectors. Based in West Sussex, DW Plastics are highly regarded for our quality custom plastic extrusions, PVC design and technical support.

Our dedicated team work closely with each customer to ensure all their extrusion profile requirements are being met, from design through to finalisation.

DW Plastics welcome even the most challenging & complex of designs. We design and manufacture products at our fully equipped in-house design and tool making facility in West Sussex. DW Plastics have the best range of extrusion equipment, allowing for a variety of plastic extrusion profiles.

Our extrusion products are deported to locations all over the world.

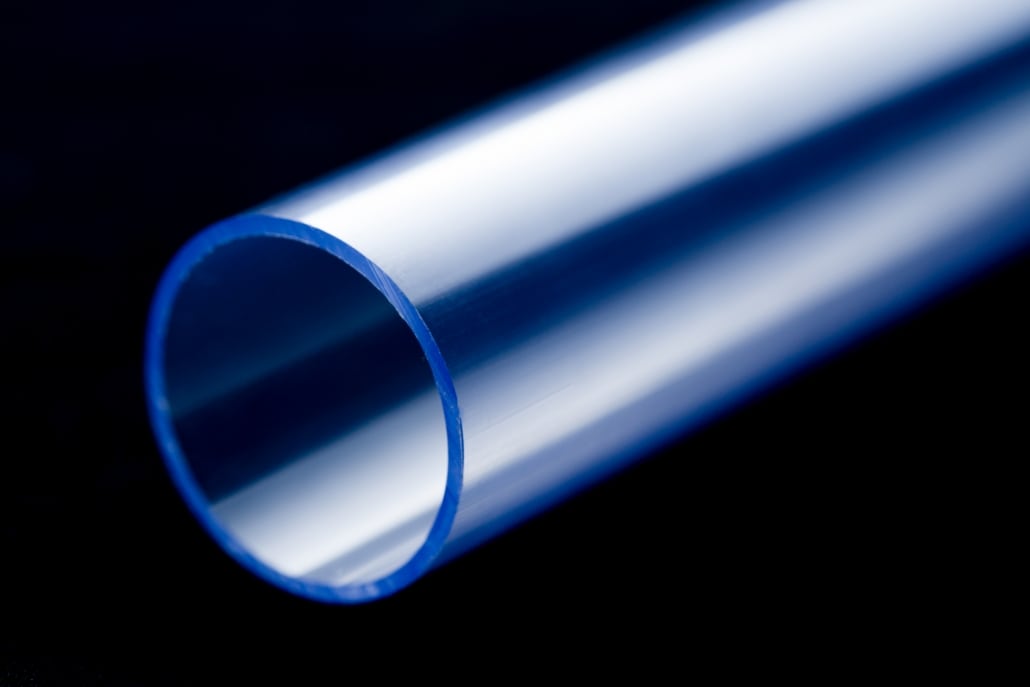

DW Plastics offer a wide selection of plastic extrusion materials including UPVC, ABS, HIP, WPC, Polyethylene, PVC & TPE. These can be used for many types of applications from windows, glazing & trims to pipes, cladding & seals.

Our Services

> Plastic Extrusion Design Services - Using our fully integrated computer-aided design system, we are able to optimize existing extrusion products as well as develop new ones.

> Plastic Extrusions Tooling - Our team of skilled engineers are able to provide comprehensive tool production and maintenance services.

> Quality Control - Developing internal systems to ensure that all products meet the standards and requirements set by our loyal customers.

> Manufacturing - We are able to design a vast array of plastic profiles for a variety of industry sectors, each specifically designed in various materials, shapes, sizes and colours

> Wire Erosion - Our development team have enough experience and skill to keep a tighter control on the manufacture of the dies and formers.

Our Products

> Plastic Tube & Pipe Extrusions - Standard Plastic PVC Tubes, Rigid and Flexible Plastic Rods, UPVC Angles & Plastic Pipes.

> Standard Plastic Extrusions - Self-Adhesive Mini-Trunking, Partition Joints & Division Bars.

> Plastic Extrusions for Construction & Building - Windows & Conservatories, Cladding & Panelling, & Jointing Strips.

> Plastic Synthetic Marine Decking - Durable, Strong & Resistant to Water.

> PVC Extrusions for Transport sector - Glazing Seals, Plastic Sheaths for Signalling, Power and Earthing Cables.

> Plastic Extrusions for Safety Products - Protective Edge & Corner Strips, Hygienic Cladding Profiles, Fire Blanket Holders, & Sealing Strips.

> Plastic Extrusions for Gardening & Horticulture - Composters, Plastic Posts & Synthetic Decking Products.

> Plastic Extrusions for Retail & Display - Label Holders, Ticket & Shelf Strips, Price Holders,

Please get in touch to discuss your requirements.

Images