Company details for:

Elite Thermal Systems Ltd

Elite Court,

6 Stuart Road,

Market Harborough,

Leicestershire,

LE16 9PQ,

United Kingdom

Quick Links:

Products / Services

750 °C - Air Recirculating Chamber Furnace

Applications include annealing, stress relieving, tempering and normalising.

> Max operating temperature 750°C

> Available in 15, 31 & 45 litres capacities as standard, with larger units being made to customer specifications.

> Stainless steel liner.

> MI heating elements which are isolated from the liner.

1200°C - Laboratory Chamber Furnaces

The BSF design is ideal for treating heavy loads, and the processing of materials that could contaminate bottom heating elements through spillage.

> Vertical lifting door protects operator from heat when the door is opened.

> Positive break door safety switch isolates chamber from power supply when door is open.

> Double skin case construction ensures external case surfaces meet safety standards.

> Replaceable ceramic hearth tile.

Options:-

> 4 side heating for heavy loads or where a metal retort is fitted.

Note: This option increases the furnace power rating.

> Metal gas tight retorts.

Note: This option reduces furnaces temperature rating to 1050° C

> Ashing conversion kit to provide good combustion conditions in the chamber and improved fume extraction.

1300°C - Rapid Heating Chamber Furnaces

> Vertical lifting door protects operator from heat when the door is opened.

> Positive break door safety switch isolates chamber from power supply when door is open.

> Fast heating rates.

> Double skin case construction ensures external case surfaces meet safety standards.

Options

> Ceramic liners to help protect against chemical attack; to minimise dusting and to facilitate the use of inert gases.

1700°C & 1800°C - Elevator Hearth Furnace

> Choice of electric or pneumatic elevator drive mechanism.

> 4 side heating provides good temperature uniformity.

> Heated by Molybdenum disilicide/Molybdenum tungsten disilicide elements.

Options

> Ceramic liner for use where corrosive fumes are generated, or for use under protective atmospheres.

> Flowmeters - for air or inert gases.

1200°C, 1500°C & 1700°C - General Purpose Chamber Furnace

The BIF range offers temperature processing capability from 700°C through to 1700°C. Applications covered include sintering of Engineering Ceramics, Metal Heat Treatments and Glass Melting and Processing.

Options:-

> Retorts (ceramic/metal)

> Gas control systems

> Independent monitoring probes

> Loading/unloading systems

> Calibration/furnace surveys

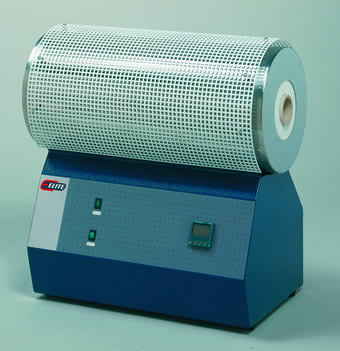

1200°C Single Zone - Horizontal / Vertical Tube Furnaces

The furnace design incorporates an integral elemental-worktube.

For aggressive processes we recommend the use of a separate worktube to minimise the risk of contaminating the elemental-worktube.

The TSH12 furnace range is ideal for most general laboratory thermal processing applications.

Options:-

> Worktubes with end seals allow processing under vacuum or gas atmospheres

> Supplied in horizontal and/or vertical format

1850°C Single Zone Horizontal Tube Furnace

1100°C 1700°C − Single Zone − Split Horizontal / Vertical Tube Furnaces

The THH furnaces can be supplied in both horizontal and vertical format, however the THV is only available in a vertical format.

The worktube is not supplied as standard equipment.

THH11:-

> Heated by high grade resistance wire spirals

> A wide range of worktubes available

THV17:-

> Heated by Molybdenum disilicide elements

> Capable of fast heating rates

Note: High heating rates may thermally shock ceramic worktubes. If you have specific rapid heating/cooling rates please consult our technical staff for guidance

> Overtemperature protection fitted as standard

250°C to 300°C General Purpose, High Performance & Moisture Extraction Ovens

400°C to 600°C High Temperature Ovens

General Purpose Drying Cabinets

They are available in 4 capacities 113, 226, 540 and 1000 litre, with optional fan assistance, variable rate extraction and updated temperature (amb +65°C) features being available on the 540 and 1000 litre models.

Heavy Duty Ovens & Incubators

We also offer a Custom Design & Build service for specific applications.

Custom Design Furnaces & Ovens

By drawing on this experience and knowledge base, Elite is able to offer cost effective design solutions tailored to suit specific customer requirements.

The designs offered vary from lightly modified standard equipment to heavily customised systems for innovative processing applications and materials. The examples give an indication of the variety of systems that Elite have supplied.

1200°C - Ashing Furnaces

Features:-

> Pre-heated airflow system for good temperature uniformity.

> Double skin construction ensures external case surfaces meet safety standards.

> Good airflow to optimise combustion.

> Positive break door safety switch isolates chamber from power supply when door is open.

1100°C - Economy Chamber Furnaces

> The BCF is suitable for light-duty general laboratory work and provides satisfactory performance for many firing applications.

> The BMF is designed for ashing applications and features a pre-heated airflow system and large chimney to ensure good combustion conditions within the chamber

1700°C & 1800°C - Laboratory Chamber Furnaces

The 4 litre and 5 litre models are bench mounted with all other models being floor standing. A choice of either manual (M) or electric (E) door operation is offered on all models.

> Heated by Molybdenum disilicide/Molybdenum tungsten disilicide elements.

> Overtemperature protection system included.

> Choice of electric (E) or manual (M) door operation.

> Lockable electric door mechanism.

> Vertical lifting door protects operator from heat when the door is opened.

> Double skin case construction ensures external case surfaces meet safety standards.

1200°C - Top Loading Furnaces

Features

> Robust construction.

> 4 side heating for good temperature uniformity.

> Exhaust port to remove fumes.

> Swing aside door keeps hot door surface away from operator.

Options:-

> Tinted sight glass.

> Monitoring probes.

2000°C - Vacuum Chamber Furnace

> Choice of high or low vacuum

> Heating by high grade graphite elements.

> Fully automatic "fail safe" system is fitted as standard.

> The top loading swing door is fully interlocked for safety.

> Temperature control is by thermocouple up to 1800°C and by optical pyrometer above 1800°C.

1200°C, 1500°C & 1700°C - Elevator Hearth Chamber Furnaces

The BEB range offers temperature processing capability from 700°C through to 1700°C. Applications covered include sintering of Engineering Ceramics, Metals Heat Treatments and Glass Melting and Processing.

Options:-

> Retorts (ceramic/metal)

> Gas control systems

> Independent monitoring probes

> Loading/unloading systems

> Calibration/furnace surveys

1500°C & 1600°C Single Zone Horizontal / Vertical Tube Furnaces

This furnace design requires the use of a separate worktube of a grade suitable for the maximum temperature rating of the respective furnace model.

This family of furnaces is ideal for most laboratory high temperature processing applications.

Options:-

> Various style end seals to allow processing under vacuum or gas atmospheres

> Radiation screens

> A wide range of furnace worktubes available

1700°C & 1800°C Single Zone Horizontal Tube Furnaces

The furnaces use Molybdenum disilicide and Molybdenum Tungsten disilicide heating elements which are capable of producing very fast heating rates. [nb. Care should be taken to match the furnace heating rates to the type of worktube being used].

In their standard format both models offer a choice of 4 heated zone lengths and a single worktube size of up to 75mm I/D. [ Non standard sizes are available on request ].

The TSV18 model, which is supplied in vertical format only, provides an economically viable alternative to the TSH18, where the process requires only occasional use at 1800°C.

The TSV18 model is heated by vertically suspended Lanthanum Chromite elements. Both furnace types require the use of a separate worktube suitable for the maximum temperature rating of the respective furnace model.

Options:-

> A wide range of furnace worktubes is available.

> Various style end seals to allow processing under vacuum or gas atmospheres.

1500°C, 1600°C, 1700°C & 1800°C - Three Zone Horizontal / Vertical Tube Furnaces

The furnace zone control is by setpoint retransmission. This control method operates by the main temperature programmer retransmitting its setpoint to each of the end zone temperature controllers so ensuring that all zones follow the installed temperature profile with only one programmer.

A facility is included for the local "trimming" of the end zone setpoints in order to optimise the temperature along the worktube.

The TMH15 & TMH16 models are available in both horizontal and vertical format. The TMH17 & TMH18 models are only available in horizontal format.

The TMH furnace design requires the use of a separate worktube of a grade suitable for the maximum temperature rating of the respective furnace model.

Options:-

> Worktubes with end seals allow processing under vacuum or gas atmospheres

> A wide range of furnace worktubes is available

1700°C Single Zone Split Vertical Tube Furnace

Options:-

> Worktubes with end seals allow processing under vacuum or gas atmospheres

> A wide range of furnace worktubes is available

1200°C Three Zone Horizontal / Vertical Tube Furnaces

Alternative control systems having different interzone communication methods are available depending on the application and degree of accuracy required.

Options:-

> Worktubes with end seals allow processing under vacuum or gas atmospheres.

> Supplied in horizontal and/or vertical format.

Cermaics

> Boats - with Tail and Hole

> Boats - Plain without Tail

Crucibles

> Cylindrical

> Circular - with Tappered Walls

> Circular - with Rounded Base

Dishes

> Round - Shallow

> Rectangular

Discs & Plates

> A wide ranfe of sizes available on request

About us

As leading manufacturers of furnaces and ovens, we offer clients a varying collection of electric furnaces and ovens as well creating bespoke units for the laboratory and industrial environment.

Elite Ovens and Incubators are designed to last for many years to come and are available with either gravity convection or forced air circulation. Many other features are available and can be tailored to meet your specific requirements such simple drying/curing processes or long term stability testing of advanced materials.

Elite Thermal Systems works closely with each client as well as the technician and managers in research, labs and process plants thorough the world enabling us to offer the best solution for your requirements.

With many years in the furnace industry, Elite Thermal Systems dates back to the 1990’s where many of our engineers have spent their whole working career in the furnace and oven industry.

Elite Thermal Systems are continually looking for ways to improve through researching new and innovative design techniques and working closely with technicians and managers across the world.

All Services, Maintenance and Repair work is carried out by our professional, factory-trained engineers. On site work is fully insured.

Our furnaces and ovens are currently used in varied market sectors including

- Aerospace

- Automotive

- Ceramics

- Coal & Coke

- Construction

- Dental

- Education

- Electronics

- Finishing Industry

- Glass

- Lighting

- Materials Testing

- Medical

- Metals Industry

- Nuclear

- Petrochemical

- Pharmaceutical

- Plastics/Rubber

- Quality Assurance

- Research

- Superconductivity