Company details for:

Energy Chemical & Equipment Company

Southwell Business Park,

Crew Lane,

Off Upton Road,

Southwell,

Nottinghamshire,

NG25 0TX,

United Kingdom

Quick Links:

Products / Services

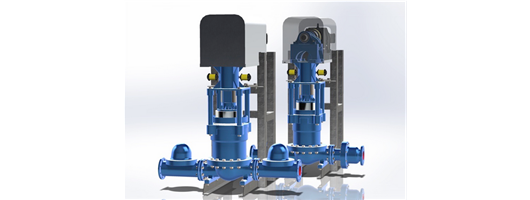

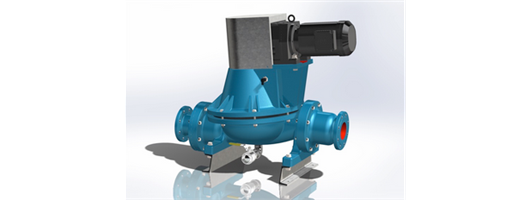

Diaphragm Pumps

Our pumps are self-priming and are generally fixed speed although variable speed options are available. Flows ranging from 0.2l/s up to 14l/s (≤1m3/hr. up to 50m3/hr.) across the three sizes of diaphragm pump and a maximum working pressure of 2.5 Bar makes them suitable for use across a wide range of applications.

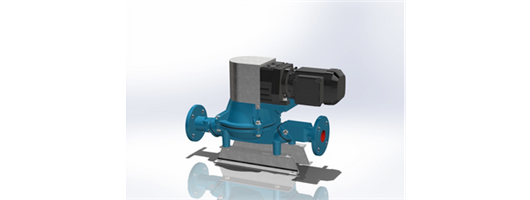

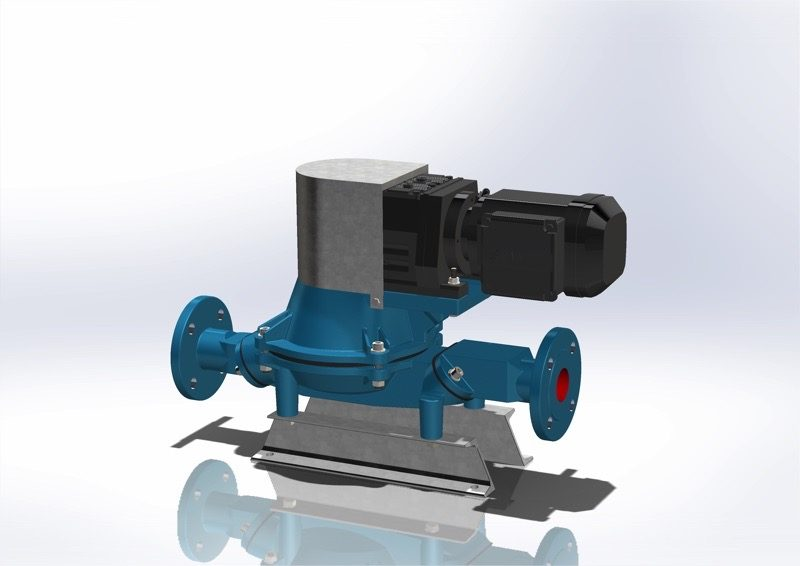

Maxi Diaphragm Pump

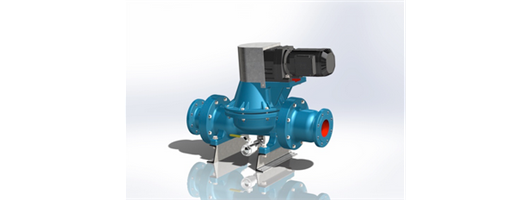

Major Diaphragm Pump

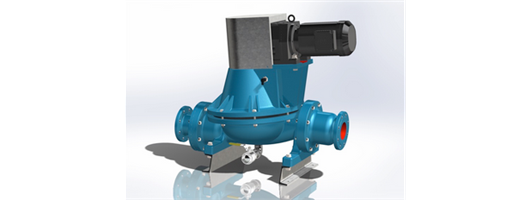

Mastiff Diaphragm Pump

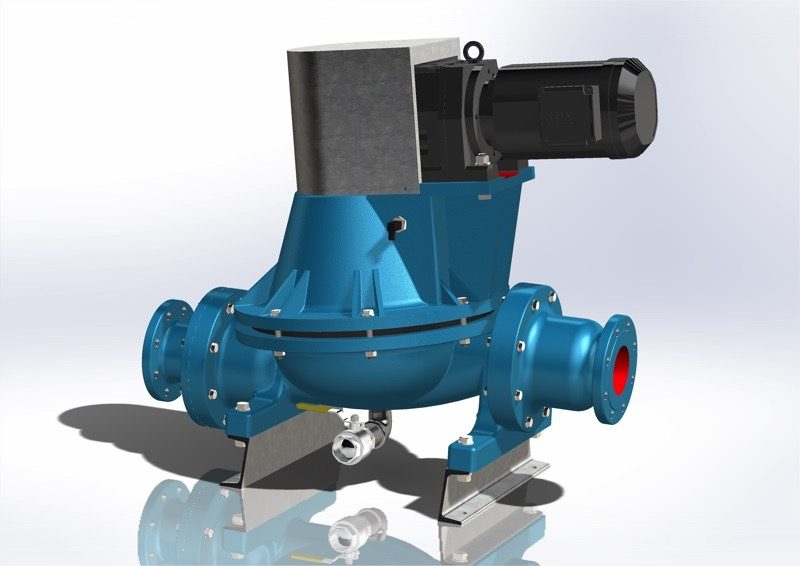

Ram Pumps

Our pumps are self-priming and are generally fixed speed although variable speed options can be specified. Both mechanically driven and hydraulically driven variants are available. With flow rates up to 30l/s (≥100m3/hr.) and a maximum working pressure of 16 Bar, these pumps are an alternative to our diaphragm Pumps for more demanding applications.

Mallard Valved 240 & 270mm Ram Pumps

Pressures of up to 4 Bar

Flows of up to 6l/s @ 40RPM (240mm)

Flows of up to 7.5l/s @ 40RPM (270mm)

Camel Ball Valved 240 & 270mm Ram Pumps

Pressures of up to 6 Bar

Flows of up to 6l/s @ 40RPM (240mm)

Flows of up to 7.5l/s @ 40RPM (270mm)

Mallet Ram Pumps

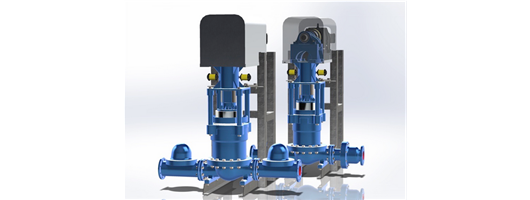

Our hydraulic ram pumps are controlled by our own software, developed “in-house”, so we can tailor it to your exact needs, and to ensure maximum performance for the job in hand. Our hydraulic pumps are also available in a duplex configuration which allows for higher flow rates, with pressures reaching up to 16 Bar.

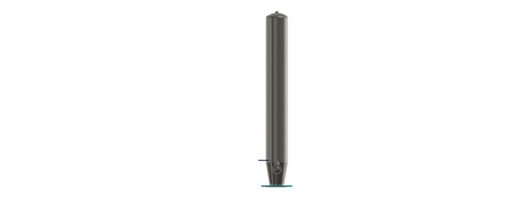

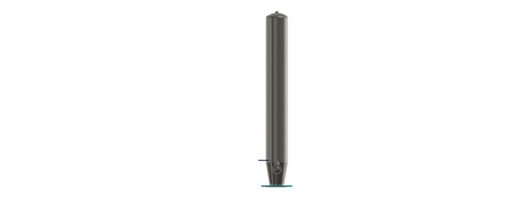

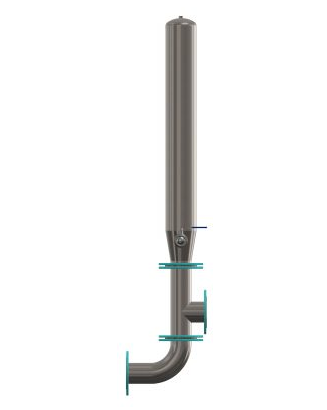

Surge Arrestors

Energy surge arrestors are no more than a piece of upright pipe capped off at the top, they contain no bladders, diaphragms or anything else. Our surge arrestors operate on the theory that a column of air at the top of the surge arrestors acts as a cushion to counteract the pulsed flow characteristics of this type of pump, as the pump draws in and discharges the medium the surge arrestors store some of the fluid and then release it again giving a smoother flow down the pipe (reducing hammer).

Our surge arrestors can also be supplied with pressure gauges, switches or sensors to show the current pressure in the pipework.

Upright Surge Arrestors

Inline Surge Arrestors

Swan-Neck Surge Arrestors

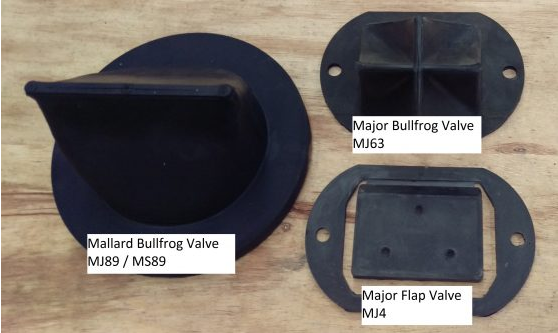

Energy Valves

Pump Types

Diaphragm and ram pumps are almost identical in operation, differing only in the type of actuator used. The diaphragm or ram is moved backwards and forwards in a reciprocal motion to draw fluid into, and push fluid out of the pumping chamber. Valves are used to constrain the flow into one direction. The flow volume is driven by the displacement of the diaphragm or ram and the frequency of the reciprocating motion. In our pumps, as they are mainly driven by a geared motor, we refer to the RPM of the geared motor as the ‘speed’ of the pump. As our pumps are driven by a reciprocating motion, we often recommend fitting surge arrestors (pulsation dampers) to our pumps. These help smooth out the flow, protecting the pump and pipework.

Flow & Pressure Calculation

Pump Selector

About us

We are one of the last manufacturers of industrial pumps in the UK that continues to develop traditional engineering skills and provide an outlet for quality British products.

We design and manufacture an extensive range of Ram and Diaphragm pumps primarily for the Waste Water Treatment industry in Southwell, Nottinghamshire. Over the years, we have developed a good relationship with our customers, and the key to our success is their satisfaction with our products and services.

Our Range of Pumps include;

Diaphragm Pumps

Our range of diaphragm pumps has a long established heritage within the Wastewater and Waste Process industries because of their simple design, ease of maintenance, and robust construction.

There are variable speed options available for our pumps, although they are generally self-priming. Diaphragm pumps are available with flow rates ranging from 0.2 to 14 litres per second (from 1 to 50 litres per second) with a working pressure maximum of 2.5 bar to suit a huge range of applications.

Maxi Diaphragm Pump

With its easy maintenance, robust construction, and favourable whole life costs, our Maxi diaphragm pump has a long history of being used in wastewater and waste process applications.

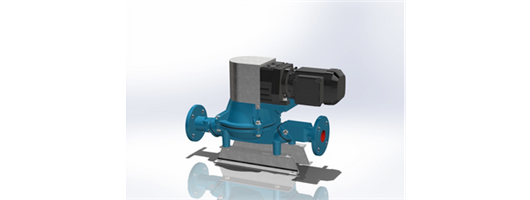

Major Diaphragm Pump

Self-priming Major pumps are generally fixed speed, although variable speed options are available. This pump is suitable for use across a variety of applications, with a flow range of 0.6L/s up to 4L/s (2.2M3/hr. up to 14.5M3/hr.) and a maximum working pressure of 2 Bar.

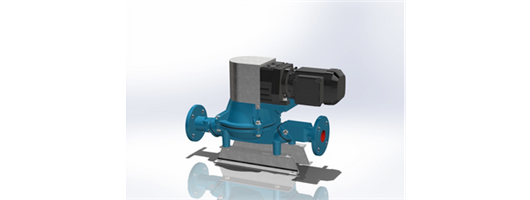

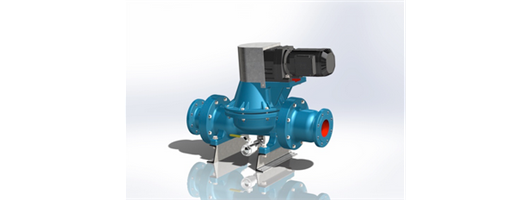

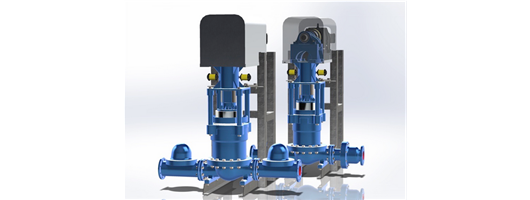

Ram Pumps

Similarly to our diaphragm pumps, our Ram Pumps are designed and manufactured with quality and reliability in mind. In the wastewater and waste process industries, their reputation for easy maintenance, robust construction, and favourable whole life costs has long been established.

We offer self-priming and variable speed pumps, although we also offer self-priming pumps with fixed speeds. Mechanically driven and hydraulically driven variants are available. Pumps with flow rates up to 30 liters per second (100 m3/hr.) and a maximum working pressure of 16 bars are an alternative to our diaphragm pumps.

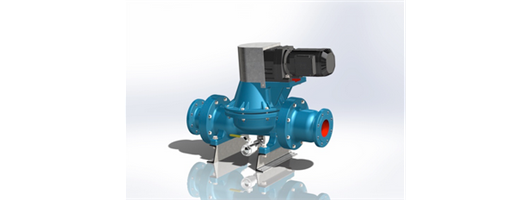

Mallard Ram Pumps

Mallard ram pumps are mechanically driven, and have a flow rate of up to 7.5 liters per second (26 m3/hr). Mallard Bullfrog valves can achieve pressures up to 4 Bar. Our Camel ball valves can, however, handle up to 6 Bar of pressure if you need a greater pressure handling capability.

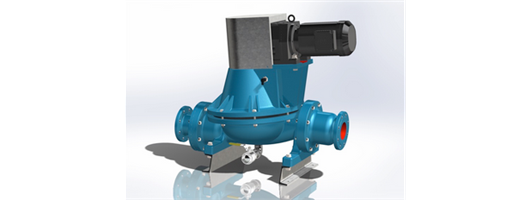

Mallet Ram Pumps

In the same way that our diaphragm pumps are made with quality and reliability in mind, Ram Pumps are made with the same commitment. In our range of ram pumps, we have mechanical 240mm pumps and hydraulic 480mm pumps. There is a pump for almost every application because there are so many sizes available.

We control our hydraulic ram pumps by our own software, developed "in-house", so we can tailor it to your exact needs, ensuring max performance. Additionally, we offer hydraulic pumps in a duplex configuration, which allows for higher flow rates and pressures up to 16 Bar.

Images