Company details for:

Euroby Ltd

New Dawn House,

Gorse Lane,

High Salvington,

Worthing,

West Sussex,

BN13 3HD,

United Kingdom

Quick Links:

Products

Edible Fats / Oils

Centrifuges are often the focal point of process engineering systems used in oil and fat extraction as well as for manufacturing biofuels. They are used in various applications:

> Extracting of olive oil

> Manufacturing and refining of palm oil

> Refining of seed oil

> Refining of press oil

> Manufacturing bioethanol with the Flottweg decanter: Dewatering of stillage for lower energy consumption

> Manufacturing biodiesel: Biodiesel glycerol separation, biodiesel washing, biodiesel fine clarification, removal of sterol glucosides, glycerol processing and salt washing

> Recycling of animal carcasses

> Processing of slaughterhouse waste / byproducts

> Manufacture of surimi

> Processing of fish and fish byproducts

> Processing of limed fleshings for recovering animal fats: Processing of limed fleshings, recovery of animal fats, processing of wastewater in tanneries, processing of tannery waste

> Enalgy − highly efficient algae harvest and oil extraction

Municipal Waste

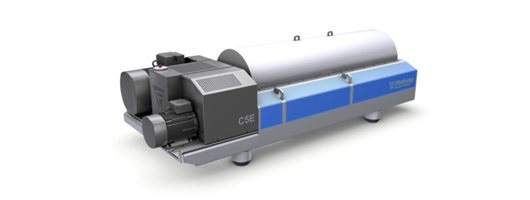

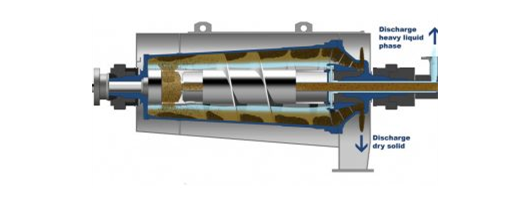

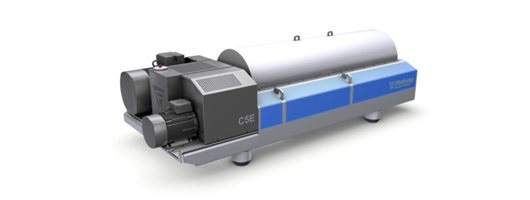

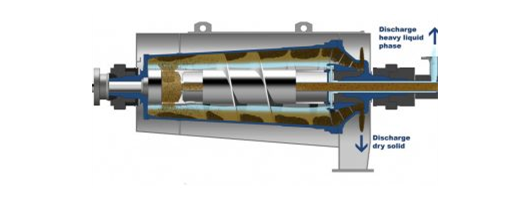

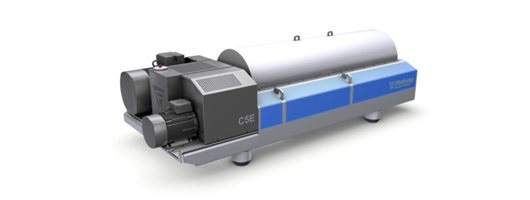

Euroby and Flottweg combined have more than 70 years of experience in dewatering and thickening sewage slurry. We understand the special requirements of sewage treatment plants and the water industry. As a result our suppliers Flottweg have developed a special decanter series especially for sewage treatment plants: the Flottweg C series.

For dewatering and thickening sewage slurry, it is necessary for special properties of the bowl, gear unit and control system to be guaranteed. This is the only way to achieve maximum dewatering and thickening of the sewage slurry. The Flottweg C series is the new generation of environmental centrifuges which is characterised by familiar quality and reliability as well as an optimum price/performance ratio.

Beverage Production

Mechanical separation technology in the manufacture of beverages optimises yield while guaranteeing consistent quality. Flottweg decanters, separators, Tricanter® machines and belt presses are used for various applications in beverage manufacture:

Manufacturing fruit juice, direct juice and vegetable juice

Economical production of fruit juice, direct juice and vegetable juice is characterised by more than just outstanding juice quality. It is just as important to achieve a high raw material yield with the lowest possible complexity for operation, maintenance and servicing of the centrifuges, belt presses and lines used.

Manufacture of beer

Mechanical separation technology in the manufacture of beer optimises yield while guaranteeing consistent beer quality. Flottweg decanters, separators and belt presses are used for various applications in beer manufacture:

> Dewatering brewer’s grains

> Beer recovery from surplus yeast

> Wort recovery from hot trub

> Green beer separation

> Clarification of beer before filtration

> Defined turbidity adjustment

> Reduction in brewery wastewater

Chemicals, Pharmaceuticals & Food

In the areas of chemicals, pharmaceuticals and foodstuffs, Manufacturing lactose and casein in the dairy industry

> Separating plastics − plastics recycling

> Algae harvest

> Manufacturing soya milk and soya proteins

> Drying okara

> Manufacturing wheat starch

> Dewatering PVC

> Dewatering suspension polymers

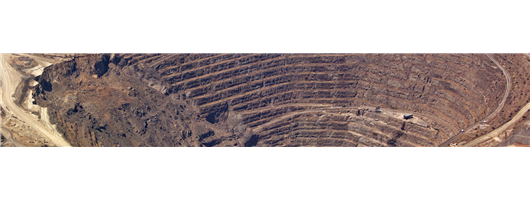

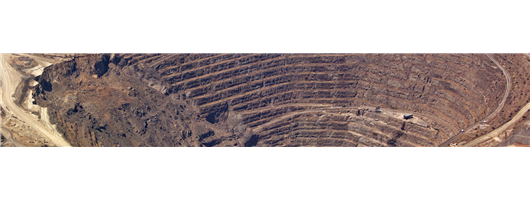

Industrial Water & Minerals

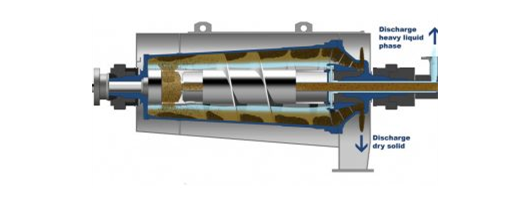

Residues containing oil are created wherever oil is extracted or processed. Flottweg decanters, Tricanter®, separators and systems offer an environmentally friendly solution to the following applications in the processing industry:

> Processing of sand washing water and gravel wash water

> Cleaning wastewater and exhaust gases in steelworks

> Cleaning and processing of tar in coking plants

> Processing of wastewater containing oil

> Processing of oil sludge from ponds and lagoons

> Processing of residues containing oil from the cleaning of crude oil tanks

> Processing of drilling slurry, drilling emulsion and drilling muds

> Processing of ore and minerals

The Flottweg decanter guarantees optimum treatment of the gravel wash water and sand washing water. For example, a treatment system with a Flottweg Z92 machine can process up to 2200 tonnes of sludge daily.

Flottweg decanters are used worldwide in the steel industry and are an important constituent in cleaning of various exhaust gases and wastewater in steelworks:

> Furnace gas cleaning

> Converter gas dedusting

> Scale slurry processing

> Pickling slurry processing

> Sewage slurry processing

> Water circuit cleaning

During processing of tar in coking plants, decanters separate the solid impurities out of the raw tar. The cleaned tar contains less than 0.3% quinolin. The separated solid has a total dry solids of approx. 33 − 40% and its consistency is between clumpy and almost solid.

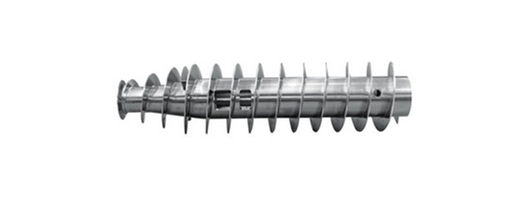

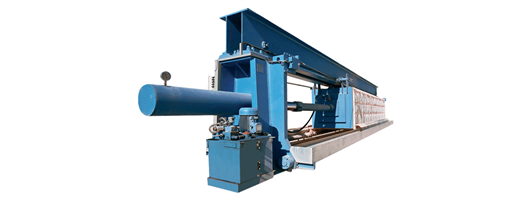

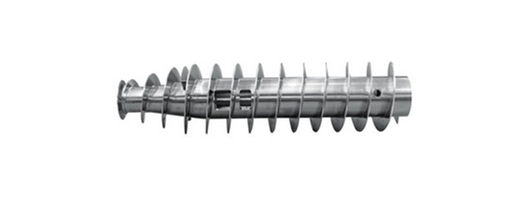

Centrifuges

Filter Presses

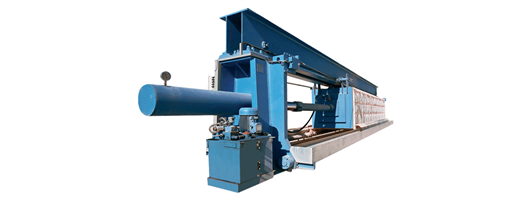

Our filter press units are manufactured by TEFSA and are available in a range of sizes to suit customer’s specific requirement from small manually operated 500mm units to large fully automated 2mtr x 2mtr systems.

Filter press units are available in side bar and overhead designs with a range of plate types and materials to suit all applications.

Filter Press Plates & Membranes

A range of plate types are available with standard recessed or membrane inflation and can be supplied with cloth wash and cake discharge systems. These plates are supplied to all of the leading filter press manufacturers for inclusion in their presses and can be retrofitted into all makes of press, including those currently fitted with rubber steel plates.

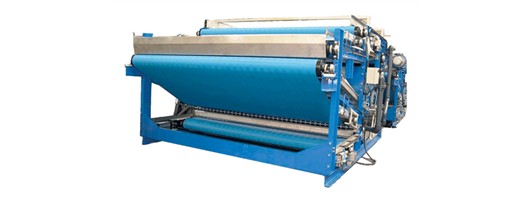

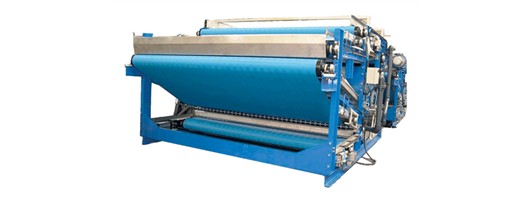

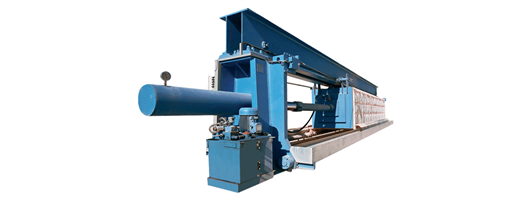

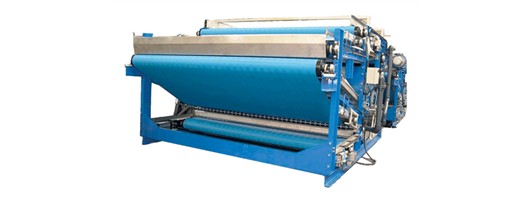

Belt Filter Presses

The low energy bills and frugal polymer consumption of belt dewatering systems appeals to the cost conscious, without compromising on performance or reliability. This, combined with very low operator input requirements make belt filter presses ideal for today’s streamlined processes.

Polymer Preparation Systems

The INDAG polymer dissolving station type FlowMix® MD is a single-stage, continuously operating dissolving and dosing station for liquid polymers. The heart of the system is the INDAG mixing pump, which dynamically introduces the mixing energy required for the dissolving process during the pumping process.

Submerged Aerated Filter Systems

The I-SAF and SAF cover applications for PE’s of between 50 and 3000 and Euroby can also supply turnkey hire equipment for applications up to 1000PE.

Belt Conveyors

In the past, whilst working in the Water Industry we found it very difficult to link our high quality products with good quality, robust, reliable and purpose designed sludge cake belt conveyor systems. This caused our engineers much anguish until we found the right product, which suited our own needs and that of our customers.

Therefore we offer a belt conveyor system which although particularly suitable for the Water Industry will also convey most granular materials and types of cake.

Lime Stabilisation Systems

The equipment is supplied either as compact, self-contained units with integrated silo and mixer, or as individual components, depending on site constraints.

Each system utilises weighing facilities to accurately measure the amount of burnt lime to be mixed with the incoming sludge cake.

Lime dosing is controlled automatically, enabling the correct dosing levels to be maintained despite fluctuating levels of sludge cake.

The systems are sufficiently adaptable to allow them to be retrofitted into areas with limited space, or where planning restrictions prevent the installation of full height silos.

Used & Reconditioned Machinery

UK Mobile Dewatering Equipment

The range enables the company’s experienced operators to successfully process the most difficult of materials and solid/liquid wastes from a variety of sources including but not restricted to the water, municipal (sewage), food, soil, dairy, pharmaceutical, petrochemical, brewing, animal feeds, tannery, biofuels and quarrying industries.

Filter Press Maintenance & Repair

We have filter press maintenance engineers who are qualified for any kind of installation, commissioning, repair, service, refurbishment and process optimisation involving filter press products and processes.

Mobile Lime Stabilisation Services

Lime stabilisation units are supplied with operational personnel and comply with HACCP requirements to ensure an efficient safe kill of pathogens.

Units available for purchase are designed for specific applications but generally consist of lime storage silo complete with aeration, silo filling and lime discharge ancillieries, chutes, lime and cake conveyors, lime dosing system, twin screw paddle mixer or plough share mixer.

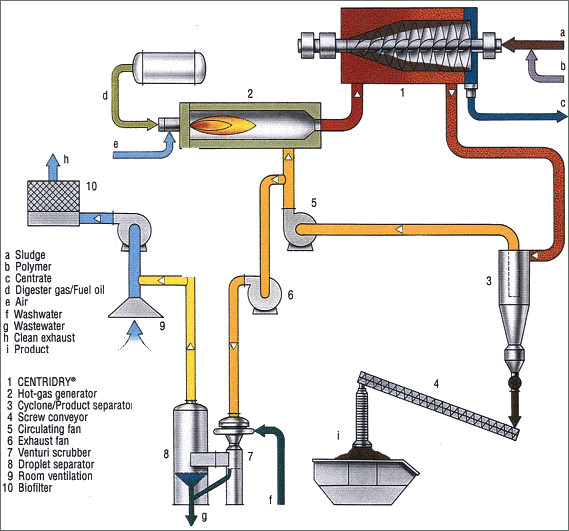

Sludge Drying

Technical Support

About us

We are a leading supplier of centrifuges, decanters, belt presses, filter presses and separators providing a comprehensive service to the chemical, pharmaceutical, industrial and food industry.

Originally formed in 1996 as a consultancy service to the power industry, Euroby Ltd swiftly diversified into the water market with the focus on improving efficiency, reducing costs and increasing the effectiveness in all waste management programmes and food and beverage production.

Whether you require equipment to separate sand and aggregates or produce fruit and hop based beverages including juices, beer and wine or even purifying fish oil for omega 3 from algae then here at Euroby we can help.

Equipment Includes:

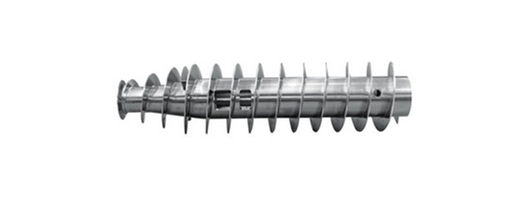

- Centrifuges − Decanter, Sedicanter®, Separators, Sorticanter®, Tricanter®

- Filter Presses

- Filter Press Plates & Membranes

- Belt Filter Presses

- Submerged Aerated Filters − Anoxic SAF, I-SAF, SAF

- Belt Conveyors

- Lime Stabilisation Systems

- Sludge Drying

With a passion to help improve the environment and fulfil the needs and expectations of our customers we strive to provide solutions that reduce operational costs and increase the sustainability of procedures whilst seeking opportunities for further growth.

Images

Reviews

Trade Associations