Company details for:

Fereday Cylinder Company

Quick Links:

Products / Services

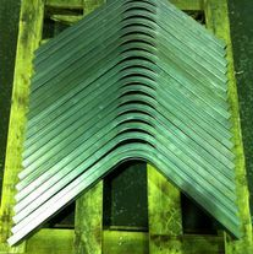

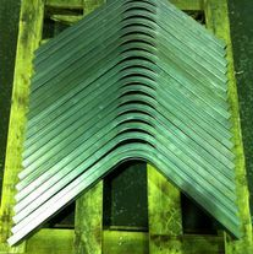

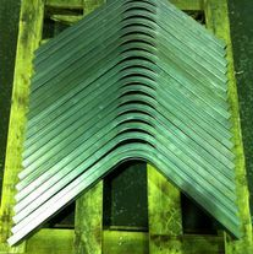

Premier Plate Rolling Facilities

If you’re looking for plate rolling service in the West Midlands area, then look no further. At Fereday Cylinder Company, we have one of the biggest plate rolling facilities, consisting of 16 sets of plate rolling machines. We have the capacity to roll metal of various widths and thicknesses, with typical values measuring as little as 50mm in diameter. We’re capable of working with metals that are up to 75mm thick. We work with clients across a wide range of industries due to our versatility and our ability to offer a plate rolling service catering to numerous applications. We have a team of skilled manufacturers who can roll tanks, cylinders, spiral stringers, hoppers, silos, drums, conical frustums and so on.

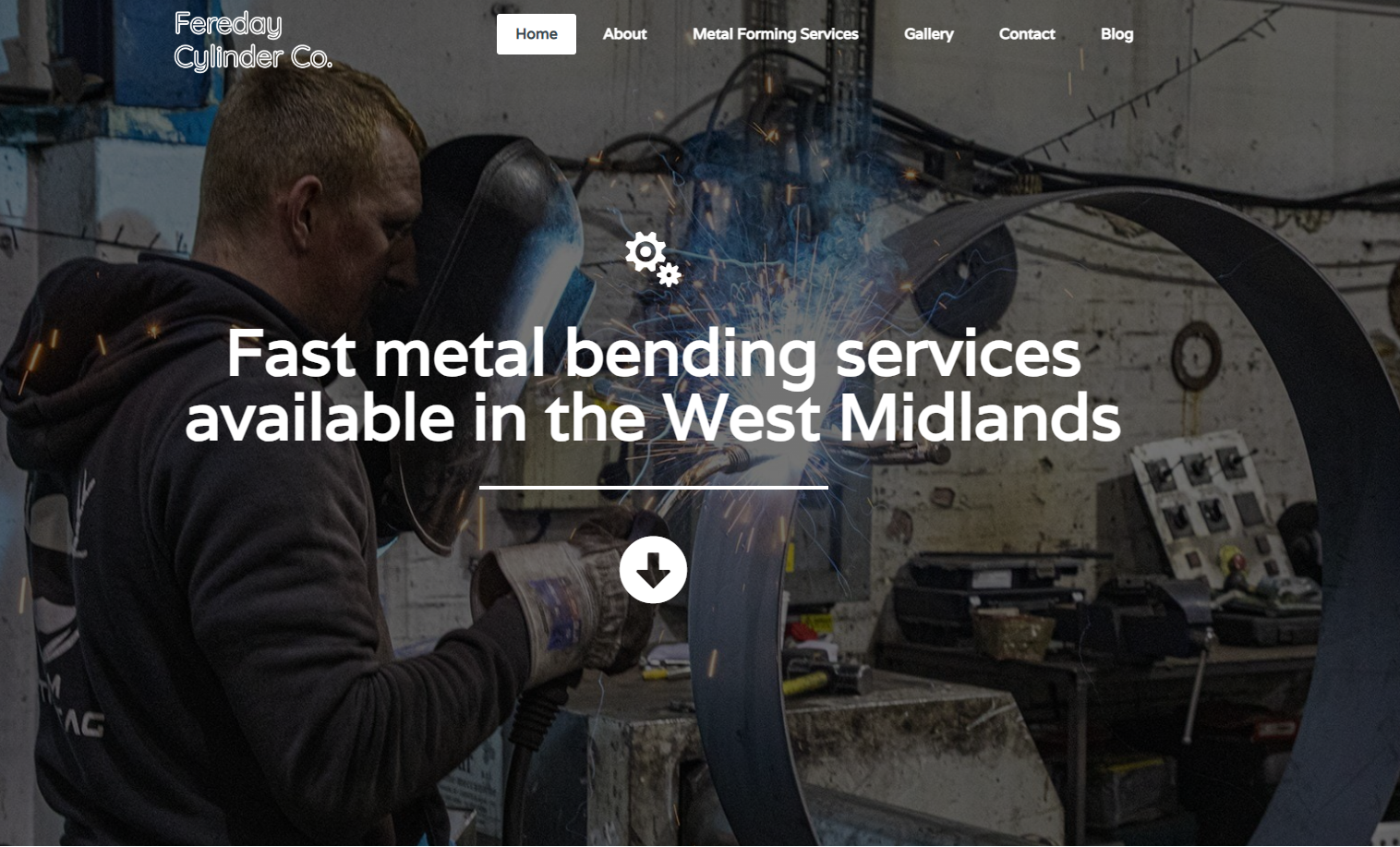

High-Quality Metal Bending Services with Rapid Turnaround

At Fereday Cylinder Company, we prioritise swift turnaround times for our plate rolling services. Depending on your specifications and the scale of the job, we aim to complete your order within as little as two weeks or even on the same day of placement. For added convenience, you’re welcome to visit our Dudley site, where we can fulfill your requirements while you wait. Whether you require a one-off job or a large batch of products, we’re committed to providing a flexible and personalised service to each client. We offer a range of high-quality materials tailored to your project’s needs, or we can work with sheet metal provided by you. For further details or a quotation tailored to your requirements, please don’t hesitate to contact our team. We serve clients across the UK.

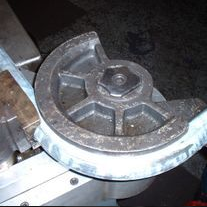

Press Braking

When it comes to shaping metal to your exact specifications, rely on a trusted press braking service for optimal results. At Fereday Cylinder Company in the West Midlands, we take pride in delivering exceptional metal products and services tailored to our customers’ needs. Our personalised approach ensures that you receive metal units precisely crafted to your measurements. Rest assured, your metal shaping needs are in capable hands with our fully trained team, dedicated to continuous professional development. With expertise in press forming metal sheets, we confidently tackle even the most challenging bending projects. Equipped with both 250 and 125-tonne press brake machines capable of forming metal units up to four meters wide, we prioritise ultimate accuracy to meet your requirements. Our goal is to ensure your complete satisfaction with the end result. We understand the importance of affordability and offer competitive pricing without compromising on quality. Whatever your press braking project entails, we’re prepared to exceed expectations. Explore our gallery to view some of our past projects, and for more information or a personalized quote, please reach out by completing our contact form. We cover the entire UK and look forward to the opportunity to work with you.

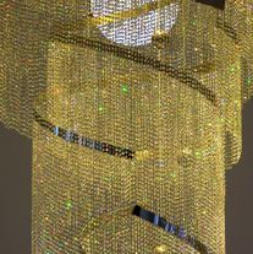

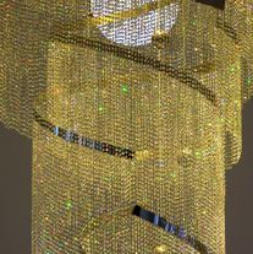

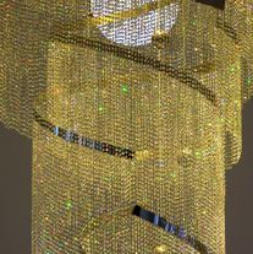

Section Rolling Service in the West Midlands

In metalworking, section rolling is an essential process for shaping various metal parts. Whether reducing width or achieving a smoother section, this specialised manufacturing technique is widely utilised. From creating rings and tubes to decorative items like spiral handrails for staircases, section rolling plays a crucial role in metal fabrication. During section rolling, metal passes through pairs of rolls to ensure a uniformly even surface. There are two options: cold section rolling, where the metal is below its recrystallisation temperature, and hot section rolling, where it’s rolled at a higher temperature. Cold rolling increases metal strength, enhancing the final finish, while hot rolling offers greater malleability for easier shaping. At Fereday Cylinder Company, our section rolling service stands out for its versatility. We offer tailored solutions to meet your specific needs, ensuring the desired end product. With a passion for excellence, we’re dedicated to providing bespoke solutions for every project. Explore our gallery for insights into our past projects, and to discuss how we can assist with your project, reach out to us today. We proudly serve clients across the entire UK.

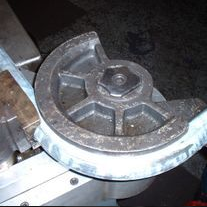

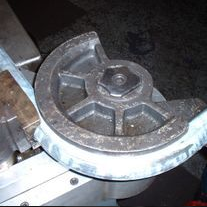

Metal Cones & Transition Pieces

The beauty of commissioning bespoke metal cones and metal transition pieces is that whatever your project is, you can have them made to exact specifications, so you don’t have to adjust or make do with a part that doesn’t allow for the efficiency and smoothness you require for your finished product or project. For example, you can purchase any number of tubing and metal cones from most DIY or hardware stores. You may spend hours perusing the choice, trying to find a size and shape that will do what you need. Our team in the West Midlands are professional metal cone manufacturers and we specialise in making exact pieces that are perfect for the job and that are made with materials suited to the task. The uses for our metal cones and transition pieces are not limited only to industrial or mechanical uses. Here at Fereday Cylinder Company, we have enjoyed using our skill for a number of challenging and unique requests. We welcome any enquiries and specifications you may have for our metal manufacturing service. We can provide our own high-quality materials, or we can work with yours. Our gallery provides some excellent examples of metal cone manipulation and the creation of transition pieces needed to connect one part to another. The latter group is especially valuable when the dimensions of the property or placement of your product or machinery require transition pieces to be bent or moulded to an exact shape and size. This process allows for the best use of the space you have available. At Fereday Cylinder Company, we’re sure you will be happy with the end result. We ensure exact metal cones and transition pieces that match your specifications. Please don’t hesitate to ask for more details. We cover the whole of the UK.

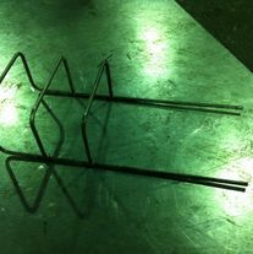

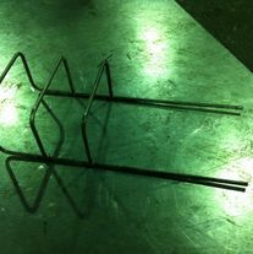

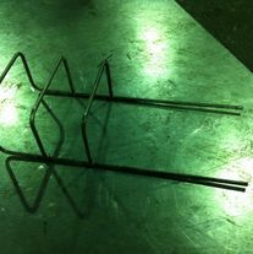

Tube Manipulation

When you need to form pipes or tubing, at Fereday Cylinder Company in the West Midlands we offer our tube bending services as part of our range of metal-making processes. This enables pipes to be made at a range of different angles and directions. We make use of mechanical force whereby a metal pipe or tube is pushed against a die. The result of this tube manipulation is that the metal pipe or tube conforms to the die’s shape. Precise bends can be achieved with great success, particularly within larger pipe or tube systems, depending on the shape and dimensions of individual sections. We are able to offer a bespoke service for tube manipulation, focusing on your individual requirements. We make use of a CNC bender, which is known to be one of the best tools in this industry. Tubes that measure up to 76mm in diameter can be bent and shaped to your specifications. We are sure to have a solution, however big or complex your project may be. We cater to your needs exactly, understanding you may also be working within a small time frame. We always aim to offer our clients a fast and effective service, communicating with you to ensure we can offer the best tube manipulation solution, with results that adhere to your requirements.

Weld Preparation

We can cut weld preps onto plates up to the size of 40mm, using our state of the art Trumpf nibbling machines. Contact us today for more information. We’re based in the West Midlands and cover the whole of the UK.

About us

Founded in 1985, the Fereday Cylinder Company began in a small unit in Old Hill and has since grown, relocating twice and now operating from a modern facility in Dudley, West Midlands.

Our growth goes beyond physical expansion, as we continually improve our expertise to handle more complex projects.

Through regular training for our metal fabricators and ongoing machinery upgrades, we ensure high standards and deliver cutting-edge products.

Our Services Include:

Plate Rolling

For plate rolling services in the West Midlands, Fereday Cylinder Company is your go-to provider. With one of the largest plate rolling facilities and 16 machines, we can roll metal of various widths and thicknesses, up to 75mm thick. Our skilled team handles a wide range of applications, including tanks, cylinders, silos, and more.

Press Braking

At Fereday Cylinder Company, we offer reliable press braking services tailored to your exact specifications. Using 250 and 125-tonne press brake machines, we shape metal with precision, tackling even the most complex projects. Our fully trained team ensures accuracy and quality, offering competitive pricing without compromising on standards. Serving the entire UK, we’re committed to exceeding your expectations with every project.

Section Rolling

Section rolling is a key metalworking process for shaping metal parts, from rings and tubes to decorative items like spiral handrails. At Fereday Cylinder Company, we offer both cold and hot section rolling to meet specific needs, ensuring the desired finish. Our versatile, bespoke solutions deliver high-quality results for clients across the UK.

Metal Cones & Transition Pieces

Commissioning bespoke metal cones and transition pieces ensures your project receives parts made to precise specifications, eliminating the need to compromise on size or fit. At Fereday Cylinder Company, we specialise in creating custom pieces using high-quality materials suited to your needs. Serving a variety of industries, we offer tailored solutions and can work with your materials or provide our own. Explore our gallery for examples of our work, and contact us for more details—we proudly serve clients across the UK.

Tube Manipulation

At Fereday Cylinder Company, we offer expert tube bending services to form pipes at various angles and directions. Using a CNC bender, we precisely shape pipes up to 76mm in diameter, ensuring they meet your specific requirements. Whether your project is large or complex, we deliver fast, effective solutions with clear communication to meet your needs.

Weld Preparation

We offer precise weld prep cutting on plates up to 40mm using advanced Trumpf nibbling machines. Based in the West Midlands, we serve clients across the UK. Contact us for more details.

Our customers are our top priority, followed closely by our dedicated employees, many of whom have over 20 years of experience. This long tenure reflects the supportive work environment we cultivate.

Our skilled team of metal fabricators is carefully selected for their passion and proficiency, bringing diverse skills to every project. They approach each task with enthusiasm and precision, ensuring the same level of dedication for every order.

Renowned across the West Midlands for our high-quality fabricated metal products, we pride ourselves on providing efficient, professional service tailored to our customers’ needs. Many returning clients appreciate our consistent standards and continue to recommend our services to family and friends.

Images