Company details for:

Flo-Dyne Controls UK Ltd

Unit 4,

Summerleys Business Centre,

Summerleys Road,

Princes Risborough,

Buckinghamshire,

HP27 9EQ,

United Kingdom

Quick Links:

Products / Services

Surge Tank Options

Bladder Tanks

Compressor Tanks

Control Systems for Surge Tanks

The control system will be constructed in such a way that it will manage and correct for absorption of the air/gas cushion by the liquid in the tank, which will tend to cause the liquid level to rise, and out gassing from the liquid in the tank which will tend to cause the liquid level in the tank to fall.

Simple Diffuser Silencers

Steam Vent Silencers

The steam may be released from either low pressure (LP steam vent silencer) of high pressure (HP steam vent silencer) as part of boiler start up system, a bypass vent or a safety relief valve vent system.

In each case Flo-Dyne offer the most economical approach by optimizing silencer design to produce a guaranteed solution through selection of silencer pressure drop and flow velocities appropriate to the duty.

Atmospheric Vent Silencers

Atmospheric vent silencers are used to control the noise created when steam, air, natural gas, nitorgen, oxygen or other process gases are vented (blown off) from a high pressure to atmosphere. At such times high noise levels which are dangerous to plant personnel and may be environmentally unacceptable are generated.

Safety Relief Valve Vent Silencers

The gas or steam released from either low pressure (LP steam vent silencer) or high pressure (HP steam vent silencer) safety relief valve will normally result in very high noise levels, often more than 150 dB(A) at 1 metre, which, as well as being dangerous to personnel, can result in acoustic fatigue in the pipework or equipment that is immediately downstream of the valve.

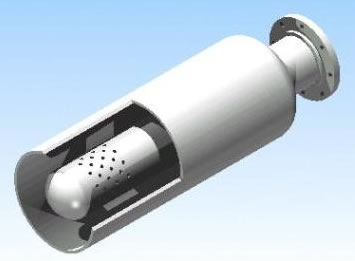

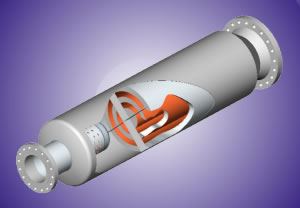

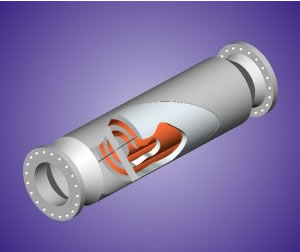

In-Line Diffusers

To accomplish this pressure reduction the diffuser is designed to pass the flow through many small holes. Correct hole size and spacing are critical to diffuser performance. It is also important to match the diffuser flow capabilities to the individual system requirements. Flo-Dyne Controls custom design each diffuser for the particular valve and piping system it is to be used with.

Control Valve Silencers

Typical measures to combat this pipework radiated noise include acoustic insulation and quiet trims for valves. Both of these options can be expensive and in the case of acoustic insulation introduce an ongoing maintenance cost as the integrity of the insulation may deteriorate with time.

Compressor Silencers

Blower Silencers

Exhauster Silencers

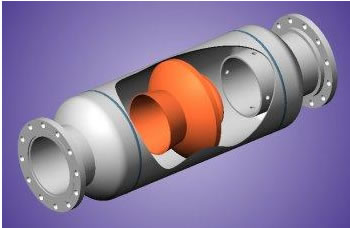

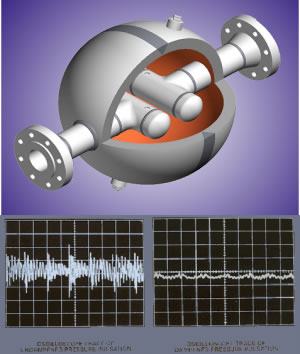

Discharge Dampeners

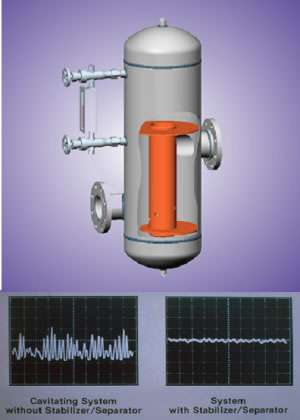

Pulsation dampeners are often necessary for multi-plunger high pressure reciprocating pumps which produce damaging levels of pulsation and vibration. These forces can be significantly reduced by the Flo-Dyne non-charged maintenance-free pulsation dampener which is completely filled with the pumped liquid. Our unique spherical in-line design results in optimized low weight and cost and is ideal where rubber bladder or metallic diaphragm types cannot be applied.

Suction Dampeners

Surge Analysis

Acoustic Filters

Typical applications include multi-plunger hydraulic pumps, gear pumps and refrigeration compressors.

Pulsation Analysis to API674

Gas Pulsation Analysis to AP1618

Gas Pulsation Dampeners

Guidance on the allowable pressure pulsation levels is given in API618 together with the requirements for theoretical analysis.

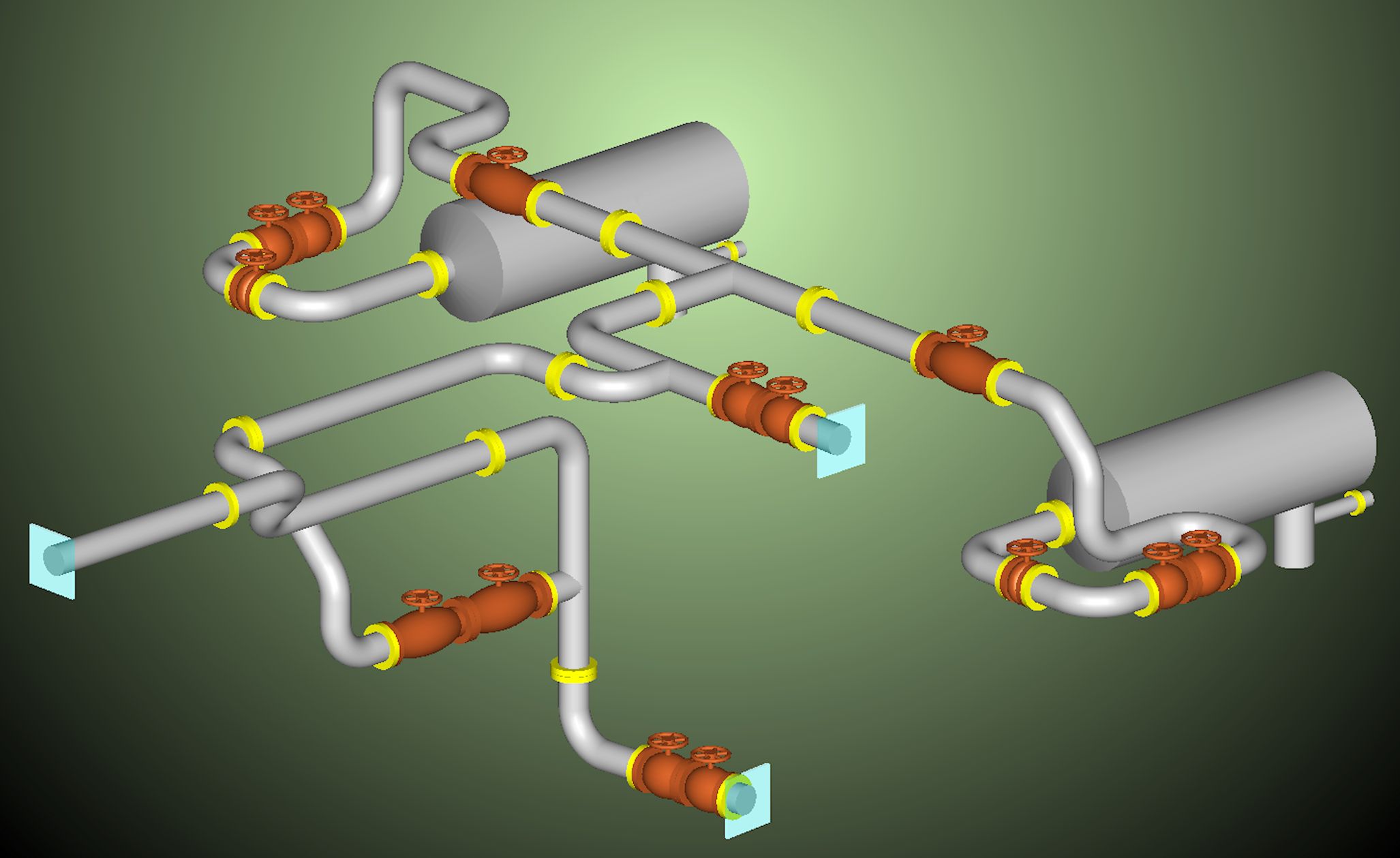

About us

Flo-Dyne also have a subsidiary in India offering the same services and products as our UK parent company. We specialise in the design and supply of customised solutions for steam vent silencers, atmospheric vent silencers, liquid pulsation dampeners & surge tanks and their controls.

Flo-Dyne Design & Manufacture:

Vent & In-Line Silencers

Atmospheric vent silencers to reduce noise from the release of air, steam, and other high-pressure gases.

Pulsation Dampeners

Maintenance-free liquid-filled pulsation dampeners for positive displacement liquid power pumps.

Surge Tanks, Expansion Tanks & Bladder Tanks

Bladder tanks for managing surges and pressure spikes in pipelines.

Noise & Vibration Measurement

On-site measurement of noise and vibration levels for exhausts, atmospheric vents, compressors, and pump lines/pipework.

API674 Pulsation Analysis & Pulsation Measurement

On-site measurement of pressure pulsation and vibration, along with API674 pressure pulsation analysis for reciprocating pumps.

Pipeline Surge Analysis & Surge Pressure Measurement

Transient pressure analysis and measurement for all types of liquid pipelines, ranging from drinking water to hydrocarbons.

Our solutions will reduce the noise, vibration and pulsations generated by the movement of gases and liquids caused by changes in pressure.

Flo-Dyne serve Europe, India, Asia, Australia & North & South America. All products fully comply with ISO 9001 standards and a CE mark will be applied when required.

Uncoded equipment is manufactured to high standards here in the UK. Products can be made in a wide variety of materials including ordinary carbon steels and duplex stainless steels.

We have a cost effective solution for guaranteed results in the gas, water, power, chemical and process industries.

Flo-Dyne use sophisticated computer programmes enabling us to design an individual piece of equipment for every customer.

Images