Company details for:

Focus Packaging Ltd

PO Box 1374,

Sun Street,

Wolverhampton,

West Midlands,

WV10 0YE,

United Kingdom

Quick Links:

Products

Alpha 104 EcoPlat Base

Top only wrapping cycle

Bottom only wrapping cycle

Manual cycle

Variable film carriage speed

2 only top wraps, 2 only bottom wraps

Manual spool carriage and reinforcing wraps

Variable turntable speed

Acoustic warning. Start & stop of cycle

Alpha 204 EcoPlat Plus FRD

Spool carriage;- adjustable up and down speed

Top wrap counter

Bottom wrap counter

Manual homing position

Variable wrapping cycles

Operates in manual mode

Eco wrap;- copy store & learning program

Spool carriage, manual lifting, lowering and home position

Spool carriage halt for reinforcing wraps

Variable turntable speed

Variable film carriage speed

Acoustic warning. Start & stop of cycle

Alpha 205 − Versatile

Reinforcing operation& manual.

3 working cycles;-ascent/decent;- topsheet;- ascent only

6 saveable programs. Security locked

2 working methods;- semi manual & semi automatic

Acoustic warning. Start &stop of cycle

Fork liftable, front or back

24 months parts warranty. 12 months labour

The Walk A Bout − Manual Wrapper

There are no electrical mechanical parts on the machine.

It is all manually controlled.

The weak point in manually wrapping a pallet is securing the load to the pallet. This is the hardest part for an operator to achieve because of the low level of work, back bending and walking backwards involved.

The walkabout guarantees well wrapped and tightly secured loads to the pallet with an efficient, comfortable and safe working position for the operator.

Alpha 508

Both water proof and dust proof wrapping cycles

Bottom & top wraps − Turn table rotation and film carriage speed up & down wraps are all independent.

Electronically adjustable, film lay on tension to the pallet.

Reinforcing wrap, that’s programmable

5 working cycles;-ascent/decent;- topsheet;- ascent only

32savable programs Security locked

3 working methods;-

semi manual & semi-automatic and fixed height

Acoustic warning. Start &stop of cycle

Alpha 701

Both water proof and dust proof wrapping cycles

Bottom & top wraps − Turn table rotation and film carriage speed up & down wraps are all independent.

Electronically adjustable, film lay on tension to the pallet.

Reinforcing wrap, that’s programmable

5 working cycles;-ascent/decent;- topsheet;- ascent only

32savable programs Security locked

3 working methods;-

semi manual & semi-automatic and fixed height

Acoustic warning. Start &stop of cycle

Alpha 407

Both water proof and dust proof wrapping cycles

Bottom & top wraps − Turn table rotation and film carriage speed up & down wraps are all independent.

Electronically adjustable, film lay on tension to the pallet.

Reinforcing wrap,(applied manually).

3 working cycles;-ascent/decent;- top sheet;- ascent only

6 saveable programs Security locked

2 working methods;- semi manual &semi automatic

Acoustic warning. Start & stop of cycle

Alpha 601RD

Both water proof and dust proof wrapping cycles

Bottom & top wraps − Turn table rotation and film carriage speed up & down wraps are all independent.

Electronically adjustable, film lay on tension to the pallet.

Reinforcing wrap 9 levels, that’s programmable

5 working cycles;-ascent/decent;- top sheet;- ascent only

32 saveable programs Security locked

3 working methods;-

Semi manual & semi-automatic and automatic.

Alpha Robot

Rotation speed setting

Upward & downward speed carriage setting

Upward& downward cycle setting

Reinforce cycle setting

Upward & downward film tensioning

Upward & downward pre stretch setting

Manual upward-downward setting

Upward & downward cycle

Only upward or downward cycle

Top sheet cycle

F1 program extra pallet

F2 program cylindrical products

Adjustable parameters by the control panel without password cycle

Both water proof and dust proof wrapping cycles

Bottom & top wraps − Turn table rotation and film carriage speed up & down wraps are all independent.

Electronically adjustable, film lay on tension to the pallet.

Reinforcing wrap, that’s programmable

Semi manual & semi-automatic and fixed height

Artimus

Such as:

Square unglazed window frames

Rubber tyres

Coils of flexible tubing or wire products etc.

Atis

The Atis orbital is a semi automatic wrapper, designed for low to meduim output. It saves time in wrapping such difficult products and is far faster and better than hand wrapping.

The working table with its roller systems allows for the product to be quickly easily positioned for stretch wrapping.

These are strong robust and easy to operate machines. They are fully CE and H&S compliant Guarantee. All parts for 12 months. Not covered, accidental damage or misuse

If you have a requirement that does not fit the above, then a special machine can be designed and built for you.

Neleo

The Neleo Orbital is a semi-automatic wrapper designed for low volume output. Semi-automatic machines generally have simple infeed and out feed rollers that are operator controlled, with the product being fed manually through the rotating spools of film.

The width and height of the product will dictate what size wrapping diameter is required, then the machine can be sized accordingly. The smallest stock sizes start from 50cm going up to 200 cm.

Alpha 800 Turntable Inline Pallet Wrapper

There are 3 versions of this machine allowing for light medium or heavy duty usage. Production rates will vary from 40 to 60 pallets per hour.

The stretch ratio can be chosen according to need so will vary from zero to 300%

Alpha Inline Overarm Pallet Wrapper

As the arm rotates around the load it is ideal for unstable loads or products such as heavy loads and liquids that take a lot of energy to start and stop rotating as with a conventional turn table pallet wrapper.

There are several versions of this rotary arm pallet wrapper enabling the concept to accommodate most of the challenging types of pallet wrapping situations. The top end model (above) with twin film dispensers is capable of wrapping 150 pallets per hour.

It can accommodate a very advanced and exclusive form of stretching the film that will allow, as an example, a 200% stretch film to be stretched to over 300%. It has facilities to that allow the purchaser to test the film before purchasing. It can test the breaking and stretch levels of different films.

Alpha G Ring Wrapper

The film dispensers are fixed to a ring that allows them to rotate around the pallet, therefore it is ideal for unstable loads or products such as heavy loads and liquids that take a lot of energy to start and stop rotating as experienced with a convential turn table pallet wrapper. Ie the load remains static while being wrapped.

Power Stretch Rotary Arm

Both water proof and dust proof wrapping cycles

Bottom & top wraps − Turn table rotation and film carriage speed up & down wraps are all independent.

Electronically adjustable, film lay on tension to the pallet.

Reinforcing wrap, that’s programmable

5 working cycles;-ascent/decent;- topsheet;- ascent only

32savable programs Security locked

3 working methods;-

semi manual & semi-automatic and fixed height

Acoustic warning. Start &stop of cycle

Overhead Mechanical Break Wrapper

Reinforcing operation& manual.

3 working cycles;-ascent/decent;- topsheet;- ascent only

6 saveable programs. Security locked

2 working methods;- semi manual & semi automatic

Acoustic warning. Start &stop of cycle

Fork liftable, front or back

24 months parts warranty. 12 months labour

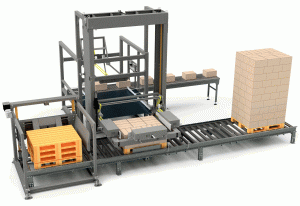

Stacking & Palletising Systems

It has a capacity of 4 layers per minute. Available as a “high loading ” version at 7 layers per minute.

Variable pallet dispenser unit, operating with either Euro and UK standard pallet, change size at press of a button.

In-built Scanner to detect unsealed cartons. ie. loose flaps. Stops machine stacking an unstable load.

Extra item;- Automatic application of inter-layer sheet if required.

It is a highly reliable, extremely fast and an environmentally friendly production system. Driven by servo motors instead of using compressed air. It is far cheaper than compressed air to operate. Savings up to £750.00 per month on running costs.

Collaborative Robots

Easy to program and competitively priced

Robust and high quality construction.

The compact and highly flexible arm makes it ideal for applications where access is restricted i.e. machine tending. It has +/- 360 degrees rotation on all axes.

Protective Packaging Applicator

This applicator is designed to apply either or both (foam or bubble wrap) at the same time. Its positioned infront of the Orbital wrapper with the product to be wrapped being pushed through it. The protecting materials then cover the product and it is held into position by the stretch wrap as it travels through the Orbital wrapper.

It can be made for a manual operation or part of an automated wrapping line.

Pallet Wrapping Film | Stretch & Shrink Wrap

The 4 Pallet Wrap Groups

Group 1/ mechanical brake machines;- no stretch

Group 2/ power stretch machines with 100/200% stretch, mainly the older machines.

Group 3/ super power stretch 200% to 300% stretch, today’s machines

Group 4/ Ultra high stretch 300% to 500% coming now, and for the future

It’s important that the stretch ratio of machine be identified before buying the film. We can assist you here, (free of charge).

Pallet Wrapping Machine Rental

Demand for these machines can be higher than the supply side.

So if you have a future need, please register your requirement and the dates, then we shall keep you informed of availability as it occurs.

We can also (lease out), pallet wrapping machines over a long term.

National On-Site Repair Service

Pallet wrapping machines do require regular servicing (most manufacturers recommend every 1000 hours), dependant on working environment.

1/ We attend site and can repair most broken down pallet wrappers.

2/ We offer a maintenance program for pallet wrapping machines throughout the UK mainland

Used Pallet Wrapping Machines

Nano High Technology Stretch Film

How to avoid the single use plastic tax

How to reduce your wrapping cost per pallet

How to use up to 40-50% less stretch wrap

The solution is BETA Nano Machine Stretch Films

About us

Customer satisfaction is our top priority in all our endeavours. Our goal is to assist you in ensuring that your products are packaged and palletised securely, efficiently, and affordably. We offer an excellent selection of products and resources to accomplish this. Ultimately, the wrapped pallets containing your customer merchandise represent your company's first impression, making it crucial to get it right.

Since we specialise in both the equipment and the stretch film, we offer a comprehensive service. Instead of just selling you equipment, we ensure you have the best stretch film for both the machine and the pallet load, minimising your wrapping costs. Additionally, we provide pallet wrap machine maintenance to keep your equipment in optimal condition for years to come. Our finance, rental, and pre-used options make it easier for you to afford the equipment necessary to enhance your business's effectiveness and efficiency.

Our Products & Services Include:

Power Stretch Pallet Wrappers

We offer a wide selection of Power Stretch Pallet Wrappers catering to varying usage levels, from light to high volume users. These wrappers can significantly reduce stretch film usage compared to mechanical brake pallet wrappers, with potential savings of 60/70%. The Alpha 508 pallet stretch wrapper, ideal for medium to high volume users and heavier loads, boasts high stretch potential (up to 300%) to achieve cost-efficient pallet wrapping. For automated wrapping, the Alpha 701 stretch film machine features a low-profile turntable with a 300mm ramp, conserving ramp space and facilitating easy loading with a pump truck. Each automatic stretch wrap machine includes an extended parts guarantee.

Orbital Stretch Wrapper Semi-Automatic Machine

Orbital pallet wrappers are engineered to wrap pallets, bubble wrap, and even foam wrap elongated items like doors, wooden mouldings, metal, and plastic tubing. They can utilize a combination of any two materials simultaneously. There are two versions available: the Neleo, a semi-automatic machine that requires labour to aid in wrapping products. Depending on the items being wrapped, it's possible to operate these machines with no conveyor or just one. On the other hand, the Atis is the fully automatic version capable of bundling and securing multiple items simultaneously. The Neleo Orbital stretch wrapper is semi-automatic, needing an operator to assist in wrapping. Due to low volume use, an after conveyor might not be necessary, depending on the products being wrapped. The wrapping ring on this orbital stretch wrap machine ranges in size from 50 cm up to 2 meters.

Nano Pallet Wrapping Films

Nano stretch film is produced using 55 layers of diverse polymers, resulting in exceptional strength and puncture resistance despite its lightweight and thin composition.

Pallet Wrapping Film

We provide an extensive selection of premium machine stretch films, including a top-tier 12-micron film with 300% stretch capability. All our products are readily available in stock for immediate delivery. Moreover, every purchase comes with comprehensive technical support for all your pallet wrapping needs. We offer a money-back guarantee if the quality doesn't meet your expectations. Contact us today to learn more about our offerings.

Pallet Wrapping Machine Rental

We offer pallet wrapping machine rentals on short or long-term terms tailored to market needs. Demand for these machines may exceed supply. If you anticipate a future need, kindly register your requirements and dates, and we'll keep you updated on availability. Additionally, we provide long-term leasing options for pallet wrapping machines.

… And more.

We provide consultancy services for general packaging design and sampling, assisting you in developing secure and stable packaging solutions for your products. Our goal is to ensure your products remain safe during transit while also maintaining cost-effectiveness.

We'll assist you in minimising waste and enhancing your environmental impact by offering eco-friendly and efficient pallet wrap materials and machinery.

Based in Wolverhampton, our central location enables us to efficiently cater to businesses across the UK mainland. With a vast product range, we offer next-day delivery services for most orders.

Images