Company details for:

GEW (EC) Ltd

Crompton Way,

Crawley,

West Sussex,

RH10 9QR,

United Kingdom

Quick Links:

Products / Services

UV LED Curing Systems

GEW’s UV LED curing systems use ultraviolet light-emitting diodes (UV LEDs) as the primary light source. Tens or even hundreds of UV LEDs are built onto GEW’s highly specialised circuit boards − named LED modules. Multiple LED modules are mounted together to create a light array which can vary from 15cm to 250cm in length. GEW offers different UV LED product form factors, power levels and wavelength ranges to satisfy many different application requirements.

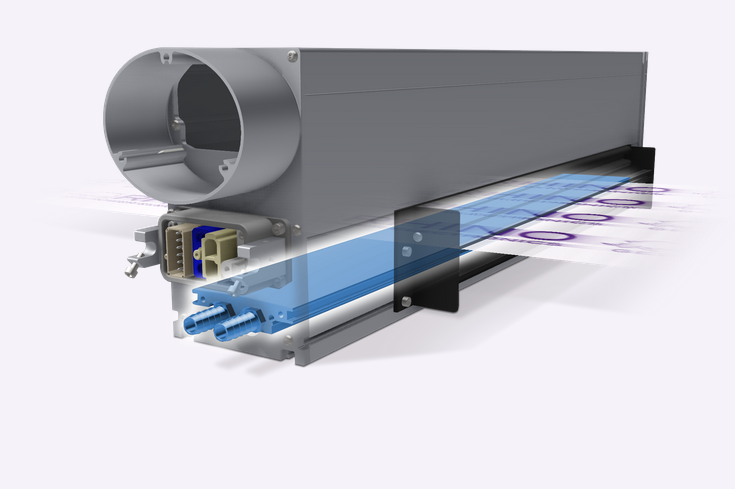

AeroLED

AeroLED is a high power system for full cure, printing, coating and converting applications up to 60cm wide; it is also compatible with GEW’s renowned ArcLED system. Using the same fan and ducting arrangement as the industry standard E2C, customers have total flexibility to switch between arc and LED curing on any station. No filters are required due to the high redundancy, making maintenance a breeze and an AeroLED retrofit more cost effective than ever before. Moreover any customers with GEW’s RHINO/RLT power supply platform can upgrade to LED within a matter of hours, by simply changing the cassettes and running a software upgrade.

LeoLED Cassette

GEW’s LeoLED Cassette has a unique concept: deliver more UV dose for your money than any other product available. Over 5 years of product development and the latest LED technology combine to transform the economics of UV LED curing. Fully water-cooled, LeoLED provides over 35% more dose and 40% higher irradiance than GEW’s previous LED models.

No other product on the market enables you to print faster, whilst the cassette is designed to interchange with every current arc lamp model in GEW’s range. This ArcLED concept gives ultimate flexibility on press, and is also the cheapest route to upgrade any existing GEW UV system to LED − only the LED cassette and the chiller are required.

LeoLED Standard

GEW’s LeoLED Standard has a unique concept: deliver more UV dose for your money than any other product available. Over 5 years of product development & the latest LED technology combine to transform the economics of UV LED curing. Fully water-cooled, LeoLED provides over 35% more dose and 40% higher irradiance than GEW’s previous LED models.

LeoLED Standard is water-cooled with a compact 40x100mm profile while extensive customisation integration is available to ensure our system fits your press. Furthermore, the system has a large window which allows for maximum light extraction from the lamp and delivers maximum UV dosage to your substrate.

UV Lamp Curing Systems

GEW’s UV lamp curing systems use medium pressure mercury vapour lamps as the UV light source. Depending on power level, length of lamp and form factor required, GEW have various lamp systems with different cooling methods to meet a vast array of UV irradiation applications.

E2C

E2C is GEW’s most popular UV dryer with over 30,000 units installed worldwide. Fully air cooled, it delivers unparalleled curing performance up to 140W/cm due to patented ultra-efficient reflector designs. No similar product delivers more curing performance at this energy level.

Perfect for use on any machine up to 60cm in width, E2C supports printing on the widest range of heat-sensitive materials because our actively air-cooled reflectors reduce heat transfer to the substrate. It also boasts GEW’s renowned quick-change cassette design enabling a new lamp to be fitted in under 2 minutes with only one hex key tool required.

E2C HP

E2C HP comprises a standard E2C UV lamp cassette housed in a larger casing to enable more air cooling and thus higher running power, up to 180W/cm. Perfect for low migration or high speed print applications up to 80cm wide, it boasts the same reliability and patented reflector designs contained in GEW’s most popular E2C product.

E2C HP still supports printing on the widest range of heat-sensitive materials because our actively air-cooled reflectors reduce heat transfer to the substrate. It also boasts GEW’s famous quick-change cassette design enabling a new lamp to be fitted in under 2 minutes with only 1 hex key tool required.

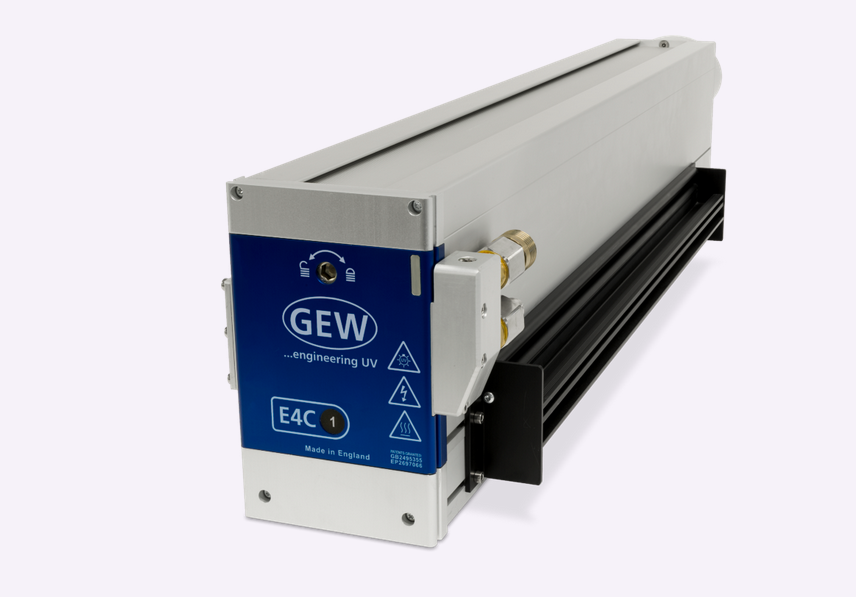

E4C

E4C offers the highest power available from the GEW range, to support the most demanding UV curing applications and the fastest printing speeds on web or sheetfed machines. It performs to the harshest cure test procedures and is suitable for low migration applications.

E4C has optically tuned reflectors to maximise curing power and operates quietly, with minimal air requirements. Water flow monitoring technology ensures water flow at all times, and the E4C’s water-cooled reflectors support the highest UV power whilst limiting heat transfer to the substrate, making it safe for a broad range of heat-sensitive materials.

NUVA2

NUVA2 is the most effective UV curing system for wide web coating and specialist industrial applications. Fully air cooled up to 250cm and available up to 27kW total lamp power, NUVA2 is available with a wide range of customisation and integration options.

GEW’s patented reflectors are actively cooled to ensure that heat transfer to the substrate is minimised, whilst delivering the highest UV intensity and dose available. The quick-change cassette design ensures fast lamp changes with only 1 hex key tool required and the innovative spherical lamp ends prevent breakages on long lamp changes.

NUVA2 HP

NUVA2 HP is the same NUVA2 cassette in a narrower format − the extra cooling available allows running up to 240W/cm, with maximum power decreasing as lamp length increases. Fully air-cooled, NUVA2 HP is available with a wide range of customisation options and is perfect for final cure inkjet applications (with iron-doped lamps) or high-speed web machines.

GEW’s patented reflectors are actively cooled to ensure that heat transfer to the substrate is minimised, whilst delivering the highest UV intensity and dose available. The quick-change cassette design ensures fast lamp changes with only 1 hex key tool required and all replaceable components are plug and play for easiest maintenance.

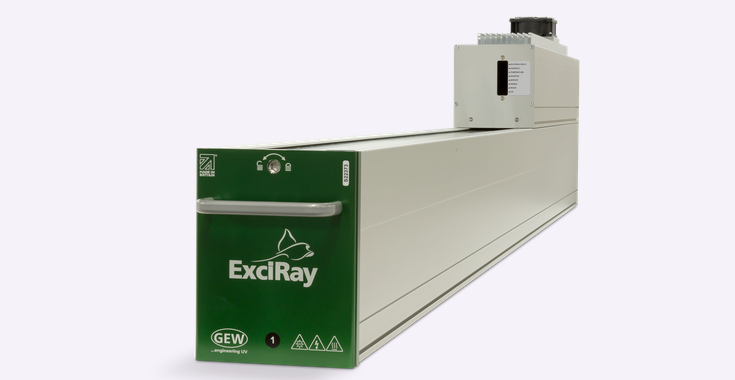

Excimer Systems

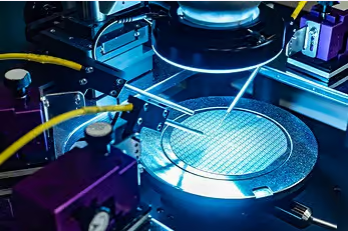

GEW’s ExciRay lamp systems utilise dielectric barrier discharge (DBD) lamps to produce quasi-monochromatic vacuum ultraviolet radiation, typically at 172nm. This radiation is commonly used for mattification of surface coatings, modification of surface tension for improved adhesion or surface cleaning for semiconductor and medical industries.

ExciRay Lamps

GEW’s ExciRay lamp systems utilise dielectric barrier discharge (DBD) lamps to produce quasi-monochromatic vacuum ultraviolet radiation, typically at 172nm. This radiation is commonly used for mattification of surface coatings, modification of surface tension for improved adhesion or surface cleaning for semiconductor and medical industries.

GEW ExciRay lamps, which are incorporated into the familiar NUVA2 cassette design, can be produced up to 255cm in length and can be custom integrated for your specific application, including provision for all required nitrogen inerting and control.

UV Lab Units

GEW designs and manufactures UV laboratory equipment, or UV lab units, for use in research & development and press room facilities. LED and mercury arc lamp variants are available immediately from stock while custom laboratory units can be manufactured to meet a wide range of requirements using any combination of GEW’s production UV systems.

UV LED Lab Unit

GEW’s LED lab unit utilises a high precision linear drive to pass a sample tray under the UV LED array.

Variable speed control ensures highly repeatable testing up to 100m/min with UV power adjustable in set increments and LED array height adjustable up to 25mm.

A simple magnetic hinged tray carries print samples or can accommodate an EIT radiometer for precise UV power measurement.

UV Custom Lab Unit

Multiple lamps can be arranged in series and with RHINO ArcLED control; LED and arc lamp curing can then be rapidly interchanged as required. Appropriate cooling systems are specified according to customer requirements and the floor standing units can be set on wheels or permanently located.

Whatever your laboratory requirements, GEW can custom design a solution to accurately reflect the production environment you serve.

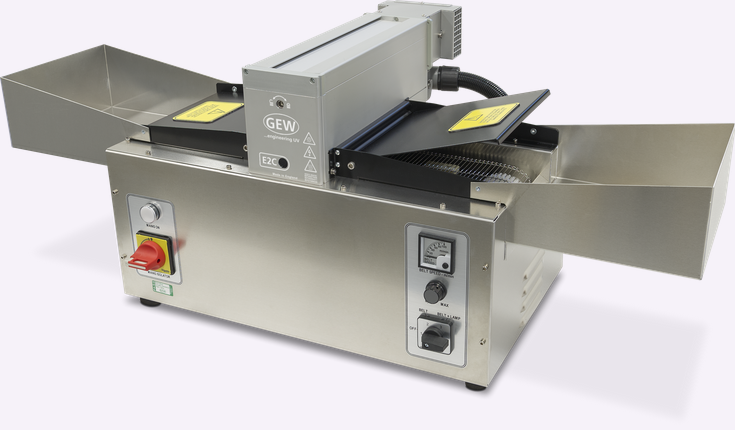

UV Lamp Lab Unit

The UV lamp lab unit utilises a 150mm wide stainless steel conveyor belt to drive samples under the UV lamp at variable speeds up to 70m/min.

The E2C UV lamp contains an ozone-free bulb to prevent the need for duct extraction and an integrated fan controls the lamp at a constant 80W/cm.

A robust, bench-top curing unit incorporating simple feeder/catcher trays, it is a perfect, cost-effective tool for laboratory, press proofing and even low volume production.

Compact Cassette Laboratory

The Compact Cassette Laboratory offers a fast, simple and accurate method to measure the total UV output of any GEW UV arc or LED cassette across its entire width under standard conditions.

Interchangeable casings allow rapid analysis of UV cassettes from any GEW UV system (c. year 2000 onwards). The perfect quality control tool for any pressroom with multiple GEW UV equipped machines.

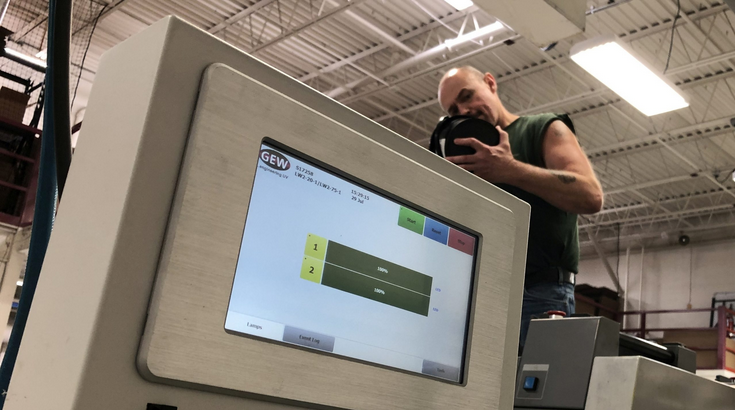

UV LED Control Systems

GEW UV systems are controlled by a combination of user commands and settings (entered on a modern industrial touchscreen), as well as machine signals which are either hardwired or electronically communicated to the GEW RHINO power units. GEW’s proprietary RHINO software is able to handle a vast array of common industrial control interfaces from simple relay logic to web-based APIs.

The HMI itself has a simple user interface for operating all key parameters on up to 16 lamps simultaneously, customised for each specific machine configuration. Optional accessories such as GEW’s UV monitoring or inert gas chambers are also controlled through the same user interface. It can be mounted freestanding in any location on or around the press or bevel mounted for seamless integration in machine panels.

UV LED Cooling Systems

All UV systems produce excess heat which must be efficiently removed to ensure uniform, stable & long-term output of the ultraviolet radiation. GEW utilises air, water and/or nitrogen cooling across the wide variety of products produced. All cooling systems are rigorously designed and tested internally by GEW to ensure perfect compatibility with your UV system.

Air cooling systems typically consist of a central fan connected to a rigid steel ducting manifold which runs the length of the press. Outlets at regular spacing are connected to the lamps via flexible ducting and an automatic damper valve controls the volume of air passing through the lamphead ensuring it remains at constant temperature. The central fan is ducted to atmosphere outside the factory.

UV LED Power Systems

GEW UV arc and LED systems are powered by the proprietary RHINO and RLT power supplies. Available in a range of sizes up to 27kW, they are custom designed and manufactured by GEW, exclusively to power our UV systems. They meet the highest international safety standards (including ETL listing for all RHINO units), are monitored over the internet 24/7 and can be purchased with up to a 5-year warranty − unparalleled in the industry.

Every power supply is equipped with GEW’s ArcLED technology, enabling both UV arc and LED to be powered interchangeably by the same unit. Every RHINO & RLT system in the field is ready to run LED − only the LED lamp and chiller are required to make this change.

UV LED Customisation Options

UV LED Modules

The UV spectral output of an LED is relatively monochromatic compared to broadband mercury sources. The material structure of the LED semiconductor determines the exact UV output wavelength, which is fixed and unchanging for each individual diode. Typically, a UV LED module will contain many LEDs with very similar UV spectra and will be specified at a nominal peak wavelength (e.g. 395 ± 5nm).

All GEW LED modules are available with peak wavelengths of 365, 385, 395 or 405nm, with a range of market leading irradiancies to suit many different applications.

Contact us to discuss which option is right for you.

Substrate Cooling

The UV curing process is energy-intensive and causes both direct and indirect heating of the target substrate, which in the majority of cases needs to be controlled. For safety reasons, some form of barrier behind the target substrate to shield off and dissipate stray radiation from the lamp is essential for protecting the machine and its operators. The three most common methods of substrate cooling that meet both of these requirements are:

Air cooled heatsinks

Water cooled heatsinks

Water cooled chill rollers

Where roll material is being processed, the most common solution for this is an extruded aluminium heatsink plate. GEW have a very neat solution for this which is integral to the UV lamphead and can be either air or water cooled, depending on the application. For the majority of processes this method is very effective, unless very heat sensitive materials are being used.

Inert Gas Curing

Under normal atmospheric conditions, oxygen reacts with photoinitiators in the ink after they are exposed to UV light. This renders some of them inactive and limits the extent of polymerisation that can occur. The coating is then poorly cured or the process is forced to run much slower. This is where inert gas curing comes into play.

Curing under an inert atmosphere eliminates oxygen and significantly increases the rate and extent of cross-linking. Curing speeds are greatly improved, migration of harmful materials is reduced and the finished product odour is better.

Quartz Window

In the majority of cases it is best to have a direct path of radiation from the UV lamp to the target area to maximise the curing effect. However, in some cases, the application necessitates a quartz glass filter to be installed in the lamp’s emitting window.

About us

We are recognised as the primary manufacturer of UV systems specifically designed for label and narrow web printing. Moreover, GEW is rapidly expanding its presence on a global scale in the sheetfed and web offset sectors, catering to the needs of commercial printing and packaging industries. GEW's UV systems are not only available for new machinery but can also be retrofitted onto existing active presses, providing an opportunity for printers to rejuvenate their older printing equipment. The company operates a top-notch production facility at our headquarters in the UK and has subsidiaries located in the USA and Germany. Additionally, GEW has established an extensive network of distributors worldwide.

GEW is an expert in the field of UV LED systems, focusing on their design and installation. In early 2022, the company launched its latest UV LED product called AeroLED, which represents a significant advancement in UV LED curing technology. What sets AeroLED apart is its innovative air-cooling system, eliminating the need for a chiller. By utilising a single remote fan, AeroLED makes UV LED technology more affordable and accessible for a wider range of applications. GEW's water-cooled LED offering, LeoLED, was introduced in 2019 and is designed to deliver maximum power and UV dose, specifically for demanding applications. Both AeroLED and LeoLED are fully compatible with GEW's renowned ArcLED hybrid system, providing customers with flexibility and options for their specific curing requirements.

GEW UV Curing Systems & Products

GEW offers a diverse range of UV lamp and LED products that cater to nearly every printing or converting requirement. These products can be seamlessly integrated by GEW to perfectly suit your specific machine.

UV LED Systems

UV LED systems are widely recognised as the future of UV curing, and GEW's products stand out as unparalleled in terms of performance and value within the industry. The company's UV LED systems offer cutting-edge technology and exceptional capabilities that set them apart from competitors. GEW's commitment to delivering high-quality and cost-effective solutions has positioned them as a leader in the field, earning them a reputation for excellence.

UV Lamp Systems

Mercury lamp systems have long been established as an efficient UV light source for various industrial processes, and their popularity continues to grow even today. These systems have proven their effectiveness and reliability over time, making them a trusted choice in the industry. Despite the advancements in UV LED technology, mercury lamp systems still hold a significant place and find increasing applications in various industrial sectors. Their continued use is a testament to their efficiency and continued relevance in UV curing processes.

Excimer Systems

Excimer lamps are capable of generating vacuum ultraviolet (VUV) radiation, which finds applications in a wide range of industries. These lamps can be seamlessly integrated onto machinery with a maximum width of 2.55 meters, providing flexibility and adaptability to different setups. The ability to harness VUV radiation makes excimer lamps suitable for diverse processes that require this specific wavelength, such as surface treatment, photochemical reactions, and precision manufacturing. Their integration onto machinery allows for efficient utilisation of the VUV radiation in various industrial applications.

Laboratory Units

GEW specialises in the design and construction of stand-alone UV laboratory units, which are ideal for research and development facilities or press room ink proofing. These units are specifically tailored to meet the needs of such environments, providing a controlled and reliable UV curing solution. Whether it's conducting experiments, testing ink formulations, or proofing press room materials, GEW's UV laboratory units offer a dedicated and efficient platform for these activities. The company's expertise in UV technology ensures that these units are designed with precision and attention to detail, allowing for accurate and reproducible results in laboratory settings.

GEW places a strong emphasis on providing long-term support and excellent customer care, ensuring that their UV systems maintain optimal efficiency throughout the entire lifespan of the machines they are installed on. The company's commitment to ongoing assistance and maintenance services guarantees that the UV systems continue to operate smoothly and effectively. By prioritising customer satisfaction and offering comprehensive support, GEW ensures that our UV systems deliver consistent performance and reliability, providing customers with peace of mind.

Our commitment lies in providing effective UV curing solutions that enable our customers to achieve faster and continuous printing operations, minimising energy consumption and eliminating downtime.

Images