Company details for:

GF Lift Hydraulics Ltd

7 Griffin Industrial Mall,

Griffin Lane,

Aylesbury,

Buckinghamshire,

HP19 8BP,

United Kingdom

Quick Links:

Products / Services

Minor Repair Works

Prices for the works listed below are included in our Repairs Price Guide 2020.

Any hydraulic related repair works not listed below please do not hesitate to contact us.

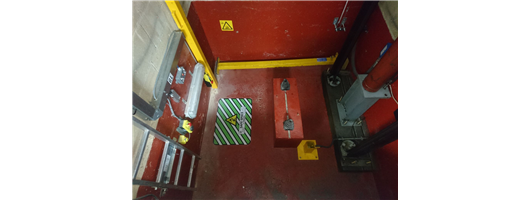

Site Attendance

Investigation - To attend site and carry out an investigation on a pre-determined fault. Where possible we will look to rectify the issue, subject to parts availability. If we are unable to cure the fault whilst on site a report will be issued on our findings along with a quotation for any remedial work.

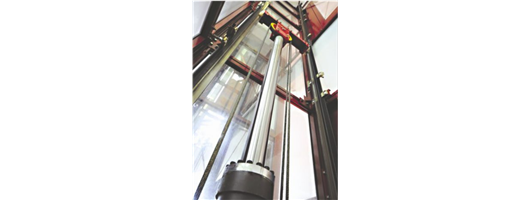

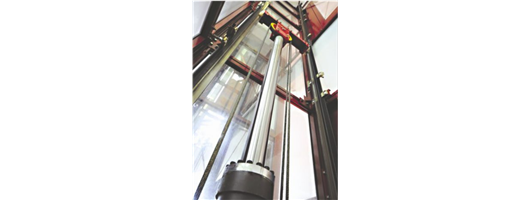

Ram Seal Replacement

In order to add value to our customers we offer the option of supporting the lift car using guide grabbers rather than incurring the cost of a lifting beam test. On applications where no lifting beam is present, this guide grabber solution provides a vital safe method of working. Alongside this GF Lift Hydraulics have developed a bespoke designed guide grabber for the safe removal of the ram diverter and ropes, eliminating the risk associated with lifting heavier items mid shaft.

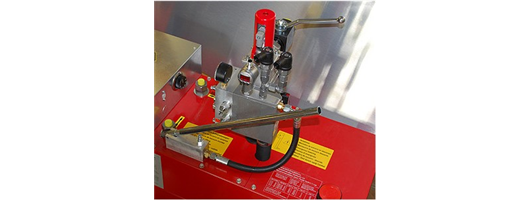

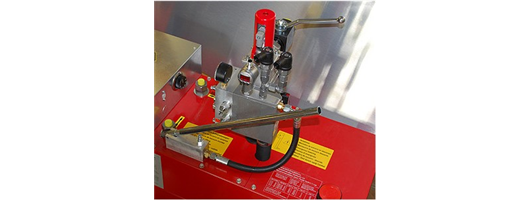

Valve Overhaul

Valve Changes/Upgrades

Hydraulic Oil Changes

In addition to the above we also offer the option of a system flush to remove contaminates such as water or debris from within the hydraulic system.

Pump & Motor Replacement

Motor Rewinds

Hose Replacement

Oil Coolers

Pipe Rupture Valves

Chains/Roping

In the addition to the above, we offer a re-rope service for hydraulic installation including new ropes, clips and ends depending on requirements. Upon completion, rope certificates will be issued.

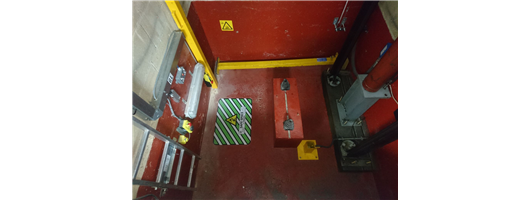

Borehole Camera Inspections

Supplementary / SaFed Testing

Power Unit Accessories

Diverter Re-bush

Modernisation

Each Modernisation project is carefully assessed by our specialist team to ensure not only is the correct equipment installed but the best suited and value for money solution is found. Our extensive knowledge allows our project team to carefully manage each installation from its conception to completion, ensuring the minimum down time and disruption to your customer.

Cylinder Replacement

For borehole cylinders we can also offer a jacket liner as an alternative to denso tape which can used to protect your borehole cylinder from water ingress and debris resulting in prolonging the life of your cylinder.

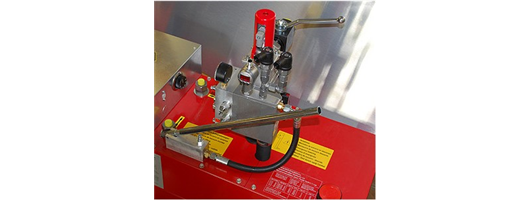

Power Units / VF Units

For high use applications, we would recommend a VVVF power unit which will not only substantially reduce the heat generated it will also save energy and reduce noise. It is also possible to upgrade your existing power unit to VVVF without the need to replace your control panel with a specially engineered interface providing a more cost effective solution for your customer.

Hydroelite Systems

The heart of the Hydroelite drive and control system is the unique Dynahyd valve. It is equipped with a servo valve which allows the lift to travel directly into the floor, without creeping. The valve also runs without bypassing oil at full speed upwards. This combination of direct floor approach and maximum oil use in the up direction not only reduces the travel time but also the energy consumption compared to traditional lift systems.

Hydroelite is quick and easy to install because the complete drive and control system is pre-assembled and system tested in the factory. In addition, almost all the wiring is pre-commissioned with plugs and as a result the installation time is reduced by up to 50% compared to traditional hard-wired lifts. The package is entirely self-learning and self-adjusting with no manual adjustments required for the slowing or stopping set up. The lift floor accuracy increases with each trip due to the innovative servo valve, encoder and lift processor combination. Each Hydroelite system is 100% pre-tested in Hydroware's factory on real lifts before dispatch, reducing the possibility of component issues on site.

In addition to the above Hydroware offer a plug and play range of pushes and indicators along with Safeline auto dial and LED shaft lighting kits.

Control Panels

Each control panel package comes complete with all shaft information, flexes, wiring and car top control units. As part of the modernisation package we can include new landing pushes, indicators, car operating panels with an array of auto dials and buttons to suit your specification.

In additon to the above we can upgrade door operators, car doors and landing entrances along with infared safety edges.

Sundry Items

Please request a copy of our 2020 Modernisation Product Guide for a comprehensive list of sundry items.

Supply Only

If we do not stock the items you require, our internal purchasing department will endeavour to source these for you using one of our many valued suppliers, guaranteeing you the best lead time possible.

About us

Founded in 1985, our company has quickly become a market leader in offering a friendly and responsive service to the entire industry, priding ourselves on our team of professional, highly-skilled engineers who have enough experience to carry out projects effectively.

Over the years, we at GF Hydraulics have provided numerous excellent quality services that have been highly praised by our loyal customer base. Some of these services include minor repair works, site attendance, ram seal replacement, valve overhaul, valve changes and upgrades, hydraulic oil changes, pump and motor replacement, motor rewinds, hose replacement, lift modernisations, cylinder replacement, hydroelite systems, control panels, sundry items and more.

Our specialist team here at GF Lift are fully dedicated to ensuring that clients are 100% satisfied with their service, carefully assessing each project and providing the perfect solution for their needs. From initial concept through to final completion, our team will work closely with customers to ensure that the correct equipment is installed as quickly and efficiently as possible. Some of our partners and suppliers within the industry include ALGI, Hydroware and Omar Lift.

Images

Articles / Press Releases

Reviews

Trade Associations